Everything you need to know about choosing, using, and caring for coated cotton fabrics in 2025

Table of Contents

- What is Coated Cotton Fabric?

- Understanding Coated Cotton Construction

- Types of Coated Cotton Fabrics

- Key Features and Benefits

- Coated Cotton vs. Other Waterproof Materials

- Sustainability and Environmental Certifications

- Industry Trends and Market Data

- Commercial and Residential Applications

- How to Identify Quality Coated Cotton

- Care and Maintenance Guide

- Buyer’s Guide

- Technical Specifications

- Frequently Asked Questions

What is Coated Cotton Fabric?

Coated cotton fabric is a hybrid textile that brings together the best of both worlds. Think of it as regular cotton that’s been given a protective shield. One side maintains the soft, breathable texture you love about cotton, while the reverse side features a smooth, water-resistant coating.

This isn’t your grandmother’s oilcloth (though that was an early version of coated fabric). Today’s coated cotton uses advanced polymer technology to create a durable, flexible material that won’t crack, peel, or become stiff over time.

What is Coated Cotton Called?

You’ll find coated cotton sold under several names depending on the coating type and manufacturer:

- Laminated cotton – when a plastic film is bonded to the fabric

- PU coated cotton – uses polyurethane coating (most common)

- Oilcloth – traditional term, now refers to PVC-coated cotton

- Vinyl-coated cotton – heavy-duty PVC coating

- Acrylic-coated cotton – uses acrylic polymer coating

- Glazed cotton – light coating that adds sheen and water resistance

Understanding Coated Cotton Construction

The magic of coated cotton happens at the molecular level. Here’s how manufacturers create this performance fabric:

Dual-Layer Design

Coated cotton features two distinct layers working together:

- Base fabric layer – This is your 100% cotton foundation. The quality of this cotton determines the fabric’s overall feel, breathability, and durability.

- Protective coating layer – A thin polymer film (typically 0.2mm thick) applied to one side using heat-activated fusion or chemical bonding.

Advanced Bonding Techniques

Modern coated cotton uses three main production methods:

Manufacturing Process Overview

- Surface preparation – The cotton is cleaned and treated with eco-friendly primers to help the coating stick

- Precision application – The coating is applied using roller systems or spray technology at exactly 0.2mm thickness

- Curing – The fabric passes through controlled temperature chambers (usually 150-180°C) to bond the layers permanently

This three-stage process creates molecular bonds between the cotton fibers and the coating. Unlike older methods where coatings would separate after a few washes, modern bonding techniques keep the layers together for 500+ wash cycles without degradation.

Types of Coated Cotton Fabrics

PU Coated Cotton (Polyurethane)

Most popular choice – PU coating offers the best balance of waterproofing, flexibility, and breathability. It’s the go-to for apparel, bags, and lightweight outdoor gear.

Characteristics:

- Lightweight and flexible

- Better breathability than PVC

- Softer hand feel

- Environmentally friendlier than vinyl

- Good for temperatures from -20°C to 70°C

PVC Coated Cotton (Vinyl)

Heavy-duty option – PVC creates the most waterproof barrier. You’ll find this in outdoor furniture, tarps, and commercial applications where maximum protection matters more than flexibility.

Characteristics:

- Completely waterproof

- Excellent UV resistance

- Fire-resistant properties

- Thicker and stiffer than PU

- Longer lifespan in harsh conditions

Acrylic Coated Cotton

Balance option – Acrylic coating sits between PU and PVC in terms of performance. It’s popular for event textiles and hospitality applications.

Characteristics:

- Good water repellency (not fully waterproof)

- Maintains fabric drape

- Better color retention than PVC

- More affordable than PU

Wax-Coated Cotton

Traditional option – Uses natural or synthetic wax for water resistance. Common in heritage outdoor gear and canvas products.

Characteristics:

- Natural appearance and feel

- Requires reapplication over time

- Breathable

- Develops unique patina with age

| Coating Type | Waterproof Rating | Flexibility | Breathability | Best For |

|---|---|---|---|---|

| PU (Polyurethane) | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ | Apparel, bags, light outdoor use |

| PVC (Vinyl) | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐ | Outdoor furniture, tarps, marine |

| Acrylic | ⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐ | Table linens, event decor |

| Wax | ⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | Jackets, heritage gear |

Key Features and Benefits

For Commercial Applications

Coated cotton delivers measurable value for businesses:

Durability That Saves Money

Restaurant and hotel managers report replacing coated cotton linens 60% less often than standard materials. The reinforced construction extends product life from 2-3 years to 5-7 years in high-traffic settings.

Abrasion resistance: Laboratory tests show coated cotton withstands 5,000+ abrasion cycles with only 28% wear compared to standard cotton’s 72% wear rate.

UV Resistance

The protective coating blocks 98% of UV rays, preventing:

- Color fading even after 2,000+ hours of direct sunlight

- Fiber degradation from sun exposure

- Heat transfer (stays cooler than uncoated fabric)

Outdoor cafes and event companies see their patio furniture maintaining vibrant colors through three summers instead of needing replacement after one season.

Easy Maintenance

The stain-resistant surface means:

- No need for special detergents

- Machine washable at standard temperatures

- Air dries quickly (no commercial dryers needed)

- No ironing required (stays smooth)

For Home Use

You’ll appreciate coated cotton for everyday family living:

- Kid-friendly – Art projects, snacks, and juice spills wipe away without panic

- Pet-proof – Muddy paws and water bowls won’t damage your furniture

- Outdoor ready – Use the same cushions on your patio and sunroom without weather worries

- Easy cleaning – Damp cloth handles most messes in seconds

Performance Features

✓ Advantages

- Waterproof or highly water-resistant

- Stain-resistant surface

- UV protection (prevents fading)

- Maintains cotton’s soft feel

- Flexible and drapable

- Temperature resistant (-20°C to 70°C)

- Easy to clean and maintain

- Longer lifespan than uncoated fabrics

✗ Limitations

- Less breathable than pure cotton

- Cannot be ironed on coated side

- More expensive than standard cotton

- Coating may wear in high-friction areas

- PVC options are less eco-friendly

- Requires specific care instructions

Coated Cotton vs. Other Waterproof Materials

How does coated cotton stack up against alternatives? Here’s what you need to know:

| Material | Water Resistance | Breathability | Eco-Friendly | Cost | Lifespan |

|---|---|---|---|---|---|

| Coated Cotton | Excellent | Moderate | Good (PU) / Fair (PVC) | $$ | 5-7 years |

| Waxed Canvas | Good | Excellent | Excellent | $$$ | 10+ years |

| DWR-Treated Fabric | Moderate | Excellent | Good | $$ | 2-3 years |

| Pure PVC | Excellent | Poor | Poor | $ | 3-5 years |

| Polyester + Coating | Excellent | Poor | Fair | $ | 3-5 years |

When to Choose Coated Cotton Over Alternatives

Choose coated cotton when you need:

- Balance between protection and comfort

- Natural fabric feel with waterproof benefits

- Indoor/outdoor versatility

- Easy care without sacrificing performance

- Aesthetic appeal (looks like fabric, not plastic)

Choose alternatives when you need:

- Waxed canvas – Maximum durability and traditional appearance for bags, outerwear

- DWR treatment – Breathability is top priority (activewear, light rain gear)

- Pure synthetic – Lowest cost and maximum waterproofing (tarps, industrial covers)

Sustainability and Environmental Certifications

The textile industry is moving toward greener production methods, and coated cotton is following this trend. Here’s what you should look for:

Key Certifications

GOTS (Global Organic Textile Standard)

The gold standard for organic cotton products. GOTS certification means:

- Cotton grown without synthetic pesticides or fertilizers

- Coating materials meet strict chemical safety standards

- Fair labor practices throughout production

- Wastewater treatment requirements met

OEKO-TEX Standard 100

Tests for harmful substances in the finished fabric. This certification guarantees:

- No harmful chemicals that could affect your health

- Safe for direct skin contact (even baby products)

- Independent lab testing of every production batch

bluesign® Approved

Focuses on the entire manufacturing process:

- Minimizes water and energy use during production

- Eliminates hazardous chemicals before they enter the factory

- Reduces carbon footprint of manufacturing

Environmental Impact

Positive aspects:

- Longer lifespan – Using one coated cotton item for 7 years beats replacing standard cotton items every 2 years

- Less water waste – Requires fewer washes than stain-prone alternatives

- Reduced chemical cleaning – No need for harsh stain removers

- Cotton base is biodegradable – Unlike pure synthetic waterproof fabrics

Concerns to consider:

- PVC coatings contain plastics that don’t biodegrade

- Recycling coated fabrics is challenging (coating must be separated)

- Some coating processes use solvent-based chemicals

Eco-Friendly Alternatives in Coated Cotton

Look for these newer options if sustainability matters to you:

- Bio-based PU coatings – Made from plant oils instead of petroleum

- Water-based coating processes – Eliminate solvent emissions

- Organic cotton base – Reduces agricultural chemical use

- Recycled polyester coatings – Uses post-consumer plastic bottles

Smart Sustainability Tip

The most sustainable coated cotton is the one you’ll use for years. A durable PVC-coated fabric lasting 10 years has less environmental impact than replacing an “eco-friendly” but short-lived alternative three times.

Industry Trends and Market Data

2025 Coated Textiles Market Overview

Market Size: The global coated textiles market reached $27.36 billion in 2024 and is projected to grow to $42.98 billion by 2034, representing a 4.2% annual growth rate.

Leading Applications:

- Automotive – 31.8% market share (interior components, seat covers)

- Construction – Tents, tarps, building facades

- Healthcare – Antimicrobial covers, medical textiles

- Protective Clothing – Fastest-growing segment

Geographic Leaders:

- Asia Pacific dominates with 47.3% market share

- China leads global coated textile output

- North America shows fastest growth (expected through 2034)

What’s Driving Growth?

Rising demand for durability: Consumers and businesses want products that last longer, reducing replacement frequency and overall costs.

Sustainability push: Manufacturers are developing eco-friendly coatings using bio-based polymers and water-based processes. Companies like BASF expanded production facilities in 2025 to meet growing demand for sustainable coated fabrics.

Electric vehicle boom: The automotive industry’s shift to EVs requires new interior materials. Coated cotton offers functionality with reduced environmental impact compared to traditional vinyl.

Smart textile integration: Researchers are developing coated cotton with embedded sensors for temperature regulation and moisture management.

Recent Innovations

- Trelleborg’s Dartex Zoned Coatings (2023 Patent) – Different coating zones on single fabric for multi-functional medical surfaces

- Toray’s Chemical Recycling (2025) – New technology for recycling nylon-based coatings

- AI Quality Control – Machine learning systems now detect coating defects and inconsistencies in real-time during production

Commercial and Residential Applications

Hospitality and Food Service

Restaurants, hotels, and catering companies use coated cotton for:

- Table linens – Wipes clean between guests, maintains upscale appearance

- Chair covers and cushions – Protects furniture from spills and wear

- Outdoor dining setups – Weather-resistant patio furniture

- Buffet and display tables – Professional presentation with easy cleanup

Event Planning and Decor

The event industry relies on coated cotton for its versatility:

- Modular display systems – Create tiered buffet presentations with structured fabric risers

- Weather-proof outdoor events – Functions continue rain or shine

- Reusable decorations – Same materials work for corporate galas and outdoor weddings

- Easy transport – Folds compactly, resists wrinkles

Outdoor Recreation and Marine

Boaters, campers, and outdoor enthusiasts choose coated cotton for:

- Boat covers and cushions – Resists saltwater and UV damage

- Camping gear – Groundsheets, equipment bags, storage covers

- Patio furniture – All-season cushions and umbrellas

- Beach bags and gear – Sand shakes off easily, water doesn’t penetrate

Healthcare Settings

Medical facilities use specialized coated cotton for:

- Examination table covers – Easy to sanitize between patients

- Wheelchair and bed protectors – Waterproof yet comfortable

- Medical equipment covers – Dust and moisture protection

- Antimicrobial options – Coatings infused with silver or copper particles

Children’s Products

Parents appreciate coated cotton for:

- High chair cushions – Food spills wipe away instantly

- Play mats and craft surfaces – Paint, markers, and glue won’t stain

- Diaper bags – Leaks stay contained

- Bibs and mealtime accessories – Machine washable protection

Check out these helpful tools: Baby Fabric Selection Quiz

Fashion and Accessories

Designers use coated cotton in:

- Weather-resistant outerwear – Jackets and raincoats

- Handbags and totes – Structured shape with easy care

- Shoes and accessories – Wipeable, durable finish

- Aprons and work wear – Professional appearance with stain protection

How to Identify Quality Coated Cotton

Visual Inspection

What to look for:

- Even coating – No thin spots, bubbles, or inconsistencies when held to light

- Clean edges – Coating shouldn’t extend beyond fabric edge or peel away

- Smooth surface – No wrinkles or texture variations in the coating

- Color consistency – Uniform color across entire piece

Touch Test

Quality coated cotton should feel:

- Flexible – Bends easily without cracking or stiffness

- Smooth on coated side – Not tacky or sticky to touch

- Soft on cotton side – Maintains natural cotton texture

- Substantial weight – Not flimsy or paper-thin

Performance Checks

Simple Water Test

Place a few drops of water on the coated surface. Quality coating should:

- Create beading (water forms round droplets)

- Not absorb after 5 minutes

- Wipe away completely with no stain

How to Tell if Fabric is 100% Cotton Base

Check the uncoated side:

- Burn test (safe area only) – Pure cotton burns steadily with gray smoke and leaves soft gray ash. Synthetic blends melt and smell like plastic

- Feel test – 100% cotton feels soft and natural, not slippery or synthetic

- Label check – Look for fiber content labels. Quality products specify “100% cotton base” or similar

- Wrinkle test – Crumple in your hand. Cotton wrinkles naturally; synthetic blends bounce back

Red Flags to Avoid

- Chemical smell – Quality coated cotton shouldn’t have strong odors

- Coating peeling at edges – Sign of poor bonding

- Stiff or plastic-like feel – Over-coating or low-quality materials

- No care instructions – Reputable manufacturers always provide care labels

- Extremely low price – Quality coated cotton costs more than basic fabric due to production process

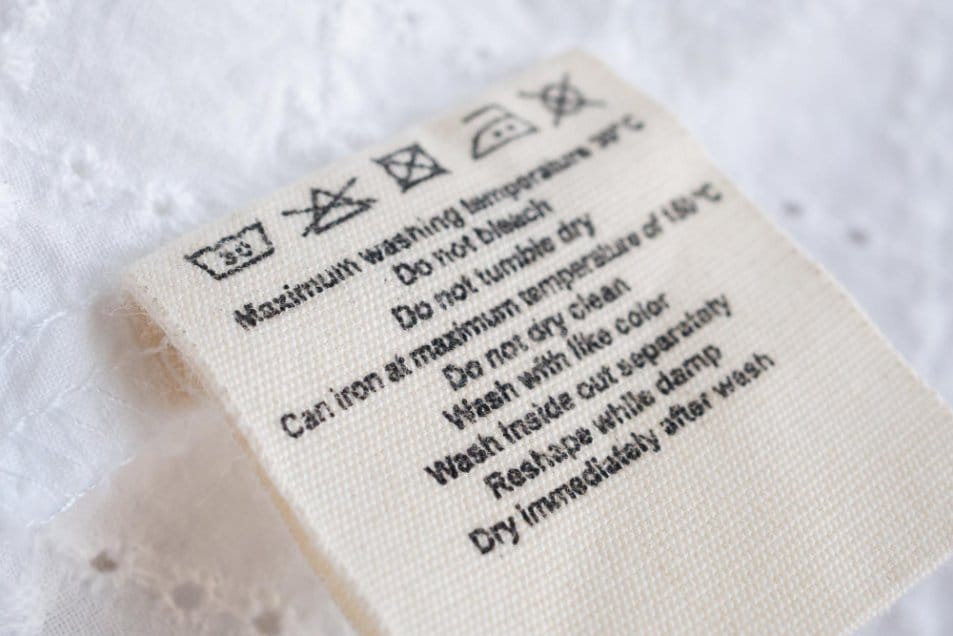

Care and Maintenance Guide

Can You Wash Coated Cotton?

How to Wash Coated Cotton

Machine Washing (Recommended Method)

- Remove loose dirt – Shake or wipe off debris before washing

- Use cold to warm water – Maximum 40°C (104°F). Hot water can damage coating

- Mild detergent only – Avoid bleach, fabric softeners, or harsh chemicals

- Gentle cycle – Reduces stress on coating bonds

- Don’t overload – Give items room to move freely

- Remove promptly – Don’t let items sit in washer after cycle ends

Hand Washing (Safest Option)

- Fill basin with lukewarm water and mild soap

- Submerge fabric and gently agitate

- Let soak 10-15 minutes for stubborn stains

- Rinse thoroughly with clean water

- Squeeze gently (don’t wring or twist)

Spot Cleaning (Daily Maintenance)

For minor spills and daily cleaning:

- Wipe immediately with damp cloth

- Use mild soap solution if needed

- Rinse with clean damp cloth

- Pat dry with towel

Drying Coated Cotton

Best practice: Air dry only

- Hang over shower rod or clothesline

- Avoid direct sunlight during drying (prolonged UV exposure)

- Don’t use clothes dryer – heat damages coating

- Never tumble dry – friction can cause peeling

- Ensure complete drying before storage to prevent mildew

Ironing Guidelines

⚠️ Important Warning

Never iron the coated side! Heat will melt or damage the coating irreversibly.

If you must iron (usually unnecessary):

- Iron only the cotton side

- Use lowest heat setting

- Place pressing cloth between iron and fabric

- Test small hidden area first

Storage Tips

- Store flat or loosely rolled – Avoid sharp creases that stress coating

- Keep in cool, dry place – Heat and humidity degrade coating over time

- Avoid plastic bags – Use breathable cotton storage bags instead

- Don’t stack heavy items on top – Can cause permanent creases

- Check periodically – Ensure no mold or mildew development

Stain Removal Guide

| Stain Type | Treatment Method | What to Avoid |

|---|---|---|

| Food & Grease | Wipe immediately, use mild dish soap | Don’t scrub hard – damages coating |

| Ink & Markers | Rubbing alcohol on cloth, dab gently | Avoid acetone/nail polish remover |

| Wine & Beverages | Blot immediately, soap and water | Don’t let dry before cleaning |

| Mud & Dirt | Let dry, brush off, then wipe | Don’t rub wet mud deeper |

| Mold/Mildew | White vinegar solution, air dry in sun | Prevent by ensuring thorough drying |

Try our helpful tool: Fabric Care Calculator

Extending Product Life

- Clean spills immediately – Prevents staining and reduces deep cleaning needs

- Rotate items regularly – Distributes wear evenly

- Avoid sharp objects – Punctures and cuts can’t be repaired

- Keep away from extreme heat – Radiators, heaters, hot car interiors

- Regular maintenance – Wipe down weekly even without visible dirt

When to Replace

Consider replacement when you notice:

- Coating peeling or flaking

- Loss of water resistance

- Cracks appearing in the coating

- Fading that affects appearance

- Tears or punctures in high-stress areas

Buyer’s Guide

Choosing the Right Coated Cotton

Step 1: Identify Your Needs

Ask yourself:

- Indoor or outdoor use? Outdoor needs UV-resistant PVC coating

- Heavy use or light? Commercial settings need heavier-duty options

- Contact with food? Ensure food-safe certifications

- Skin contact? Choose OEKO-TEX certified for safety

- Budget? Higher quality costs more but lasts longer

Step 2: Select Coating Type

| Use Case | Recommended Coating | Why |

|---|---|---|

| Bags & Apparel | PU Polyurethane | Flexible, lightweight, comfortable |

| Outdoor Furniture | PVC Vinyl | Maximum UV and weather protection |

| Table Linens | Acrylic | Good drape, stain resistance, elegant |

| Children’s Items | PU (OEKO-TEX) | Safe, wipeable, soft feel |

| Marine/Boat | PVC Vinyl | Saltwater resistant, mold-resistant |

Step 3: Check Specifications

Look for these details:

- Weight – Measured in GSM (grams per square meter). Heavier = more durable

- 150-200 GSM: Light use (linings, light bags)

- 200-300 GSM: Medium use (table linens, cushion covers)

- 300+ GSM: Heavy use (outdoor furniture, commercial)

- Width – Common widths 54″ or 60″. Wider reduces seams in projects

- Coating thickness – Usually 0.15-0.3mm. Thicker = more protection

- Thread count – Higher count in base cotton = better quality

Use our tool: Fabric Weight Calculator

Step 4: Questions to Ask Suppliers

- What type of coating is used? (PU, PVC, acrylic, wax)

- Is the cotton base 100% cotton?

- What certifications does it have? (OEKO-TEX, GOTS, etc.)

- How many wash cycles will it withstand?

- What is the waterproof rating? (hydrostatic pressure)

- Is it suitable for my specific use? (food-safe, UV-resistant, etc.)

- What’s the return policy?

- Can I get a sample? (Always test before bulk purchase)

Price Considerations

Typical price ranges (per yard):

- Budget ($8-12) – Basic PU coating, lighter weight, fewer certifications

- Mid-range ($12-20) – Quality PU or acrylic, good durability, some certifications

- Premium ($20-35) – Heavy-duty PVC or certified organic, maximum durability

- Luxury ($35+) – Designer patterns, multiple certifications, exceptional quality

ROI Calculator

Cost Comparison Example: Restaurant Table Linens

Standard Cotton Tablecloths:

- Cost: $15 each

- Replacement every 6 months due to stains

- Annual cost for 20 tables: $600

- 5-year cost: $3,000

Coated Cotton Tablecloths:

- Cost: $35 each

- Replacement every 3 years

- Initial cost for 20 tables: $700

- 5-year cost: $1,167

Savings: $1,833 over 5 years (61% reduction)

Where to Buy

Online retailers:

- Fabric specialty stores (Fabric.com, Mood Fabrics)

- Industrial suppliers for bulk orders

- Direct from manufacturers for best prices

Local options:

- Fabric stores with outdoor/marine sections

- Upholstery supply shops

- Commercial restaurant supply stores

Red Flags When Shopping

- No sample available – Reputable sellers offer swatches

- Vague descriptions – Should specify coating type, weight, certifications

- No care instructions – Quality products include care details

- Too cheap – If price seems too good, quality likely suffers

- No return policy – Should allow returns for defects

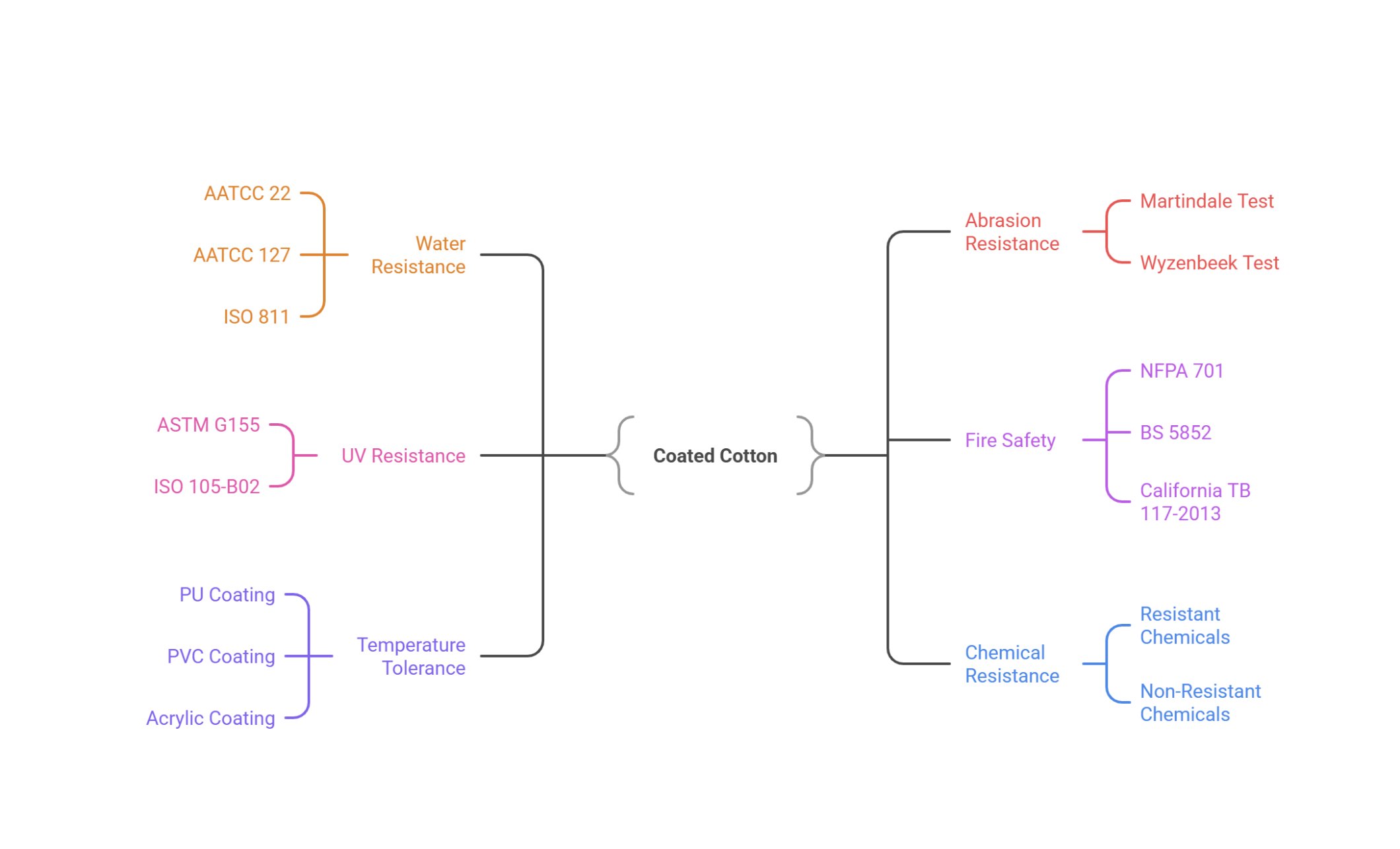

Technical Specifications and Testing Standards

International Testing Standards

Quality coated cotton undergoes rigorous testing:

Water Resistance Standards

- AATCC 22 – Water repellency spray test (rates 0-100)

- AATCC 127 – Hydrostatic pressure test (measures mm of water column)

- ISO 811 – International water penetration standard

Abrasion Resistance

- Martindale Test – Measures fabric wear after repeated rubbing cycles

- Light use: 15,000+ cycles

- Medium use: 25,000+ cycles

- Heavy commercial: 40,000+ cycles

- Wyzenbeek Test – Alternative abrasion measurement (double rubs)

- Light duty: 15,000 double rubs

- Heavy duty: 30,000 double rubs

UV Resistance Testing

- ASTM G155 – Xenon arc weathering test

- ISO 105-B02 – Color fastness to artificial light

- Rating scale – 1-8, with 8 being best (most coated cotton rates 6-8)

Fire Safety Standards

Important for commercial applications:

- NFPA 701 – Fire tests for flame-resistant textiles

- BS 5852 – UK furniture fire resistance

- California TB 117-2013 – Flammability standard

Performance Metrics

| Property | Test Method | Quality Standard |

|---|---|---|

| Waterproofness | AATCC 127 | 2,000-5,000mm hydrostatic |

| Abrasion | Martindale | 25,000+ cycles |

| UV Resistance | ISO 105-B02 | Grade 6-8 |

| Tear Strength | ASTM D1424 | 15+ lbs force |

| Coating Adhesion | ASTM D3359 | 4B or 5B rating |

Temperature Tolerance

- PU coating – Functions -20°C to 70°C (-4°F to 158°F)

- PVC coating – Functions -30°C to 80°C (-22°F to 176°F)

- Acrylic coating – Functions -10°C to 60°C (14°F to 140°F)

Chemical Resistance

Coated cotton resists:

- Mild acids and alkalis

- Salt water

- Most household cleaners

- Alcohol-based solutions

Not resistant to:

- Strong solvents (acetone, paint thinner)

- Bleach (will damage coating)

- Strong acids

Frequently Asked Questions

What is coated cotton fabric?

Coated cotton is natural cotton fabric with a protective polymer layer applied to one side. The coating (usually polyurethane, PVC, or acrylic) makes the fabric waterproof, stain-resistant, and more durable while keeping the cotton’s soft feel on the uncoated side.

Is coated cotton waterproof?

Yes, most coated cotton is waterproof or highly water-resistant. PVC-coated cotton provides complete waterproofing, while PU and acrylic coatings offer excellent water resistance suitable for rain protection and spill resistance. The level of waterproofing depends on the coating type and thickness.

Can you wash coated cotton?

Yes, you can wash coated cotton. Use cold to warm water (maximum 40°C), mild detergent, and gentle cycle in your washing machine. Never use bleach, fabric softener, or hot water. Air dry only – never put coated cotton in the dryer as heat damages the coating. For daily maintenance, simply wipe clean with a damp cloth.

Is coated cotton good?

Yes, coated cotton is excellent for applications needing water resistance and durability. It lasts 2-3 times longer than uncoated cotton, resists stains and UV damage, and requires less maintenance. It’s ideal for outdoor furniture, table linens, bags, and children’s items. The main trade-off is reduced breathability compared to pure cotton.

Is coated cotton durable?

Coated cotton is highly durable, typically lasting 5-7 years in commercial settings compared to 2-3 years for standard cotton. It withstands 500+ wash cycles without coating degradation and shows 72% less wear after 5,000 abrasion cycles. The protective coating prevents staining, fading, and moisture damage that typically shortens fabric lifespan.

What is PU coated cotton?

PU coated cotton uses polyurethane as the protective layer. It’s the most popular coating type because it’s lightweight, flexible, breathable, and environmentally friendlier than PVC. PU coating provides excellent waterproofing while maintaining a soft feel, making it perfect for bags, apparel, and items requiring flexibility.

What is acrylic coated cotton fabric?

Acrylic coated cotton uses acrylic polymer for water repellency. It sits between PU and PVC in terms of performance – offers good water resistance (though not completely waterproof), maintains fabric drape better than PVC, and provides excellent color retention. It’s popular for table linens and event textiles where appearance and moderate protection matter.

What’s the difference between cotton and 100% cotton?

100% cotton means the fabric contains only cotton fibers with no synthetic blends. “Cotton” without the 100% qualifier might be a cotton blend (like 80% cotton, 20% polyester). For coated cotton, check if the base fabric is 100% cotton or a blend – pure cotton generally provides better quality, breathability, and comfort.

Are there different types of 100% cotton?

Yes, several types exist even when all are 100% cotton. The main varieties include: Pima cotton (extra-long fibers for softness), Egyptian cotton (premium long-staple), Supima (American Pima), organic cotton (grown without pesticides), and regular upland cotton. The coating can be applied to any cotton type, but higher quality cotton bases produce better coated fabrics.

What is the highest quality cotton fabric?

Egyptian cotton with high thread count (400+) is generally considered the highest quality due to its extra-long staple fibers, producing exceptionally soft and durable fabric. For coated cotton specifically, look for products using Egyptian or Pima cotton as the base layer combined with high-grade PU coating and certifications like OEKO-TEX or GOTS.

What is the most luxurious type of cotton called?

Sea Island cotton is the most luxurious and rare cotton variety, followed closely by Egyptian Giza 45 and Supima cotton. These varieties feature extra-long staple fibers (1.5-2 inches) that create silky-smooth, strong fabric. While rarely used for coated cotton due to cost, some premium manufacturers offer coated versions of Pima or Egyptian cotton for luxury applications.

What is an example of a popular coated fabric?

Oilcloth (PVC-coated cotton) is probably the most recognized coated fabric, traditionally used for tablecloths. Modern examples include laminated cotton for quilting and crafts, PU-coated canvas for bags and outdoor gear, and vinyl-coated fabrics for commercial upholstery. Brands like Sunbrella and Gore-Tex use similar coating technologies on different base fabrics.

What is glazed cotton fabric called?

Glazed cotton is called “chintz” or “polished cotton.” This fabric has a shiny, smooth finish created by applying a resin coating and then polishing. Chintz originated as a printed, glazed cotton used for draperies and upholstery. The glaze provides moderate water resistance and a decorative sheen, though it’s less durable than modern polymer coatings.

What are the different types of coated fabrics?

Beyond coated cotton, other coated fabrics include: polyester with PU/PVC coating (outdoor gear), nylon with waterproof coating (rainwear), silicone-coated fiberglass (extreme heat resistance), rubber-coated canvas (industrial uses), and TPU-coated technical fabrics (performance wear). Each base fabric and coating combination serves different purposes.

What’s the difference between pure cotton and 100% cotton?

There’s no practical difference – both terms mean the fabric contains only cotton fibers with no synthetic additions. “Pure cotton” and “100% cotton” are interchangeable marketing terms. Both indicate you’re getting natural cotton without polyester, rayon, or other fiber blends. For coated cotton, ensure the base fabric (not the coating) is 100% or pure cotton.

What’s the difference between 100% cotton and polycotton?

100% cotton contains only cotton fibers, while polycotton (also called cotton-poly blend) mixes cotton with polyester, typically 50/50 or 65/35 ratios. Polycotton wrinkles less and dries faster but feels less natural and breathable. Some coated fabrics use polycotton bases for added strength, but 100% cotton bases generally provide better quality and comfort.

How can you tell if fabric is 100% cotton?

Check the fabric label first – it must state fiber content. For unlabeled fabric: (1) Feel it – cotton feels soft and natural, not slippery like synthetics. (2) Burn test (carefully) – cotton burns steadily with gray smoke and leaves soft ash; synthetics melt and smell like plastic. (3) Wrinkle test – cotton wrinkles easily when crumpled; blends resist wrinkling. (4) Water absorption – cotton absorbs water quickly; synthetics repel it.

What is plastic coated fabric called?

Plastic-coated fabric is commonly called “vinyl fabric” or “PVC-coated fabric.” It can also be referred to as oilcloth (when cotton-based), laminated fabric, or simply coated fabric. The plastic coating is usually polyvinyl chloride (PVC) or polyurethane (PU), both of which are polymer-based plastics that create waterproof barriers.

What is vinyl coated fabric used for?

Vinyl-coated fabric is used where maximum waterproofing and durability are needed: outdoor furniture cushions, boat covers and marine upholstery, restaurant booth seating, medical examination tables, gym equipment covers, protective tarps, awnings and canopies, and commercial vehicle interiors. Its resistance to water, UV rays, and heavy use makes it ideal for demanding applications.

What is coated Oxford fabric?

Coated Oxford fabric is Oxford weave cotton (basket-weave pattern creating a textured surface) with a waterproof coating applied. Oxford fabric is naturally strong and durable, making it popular for bags, luggage, and outdoor gear. When coated with PU or PVC, it becomes even more durable and weather-resistant while maintaining its distinctive texture.

What is a shiny cotton fabric called?

Shiny cotton fabrics include: sateen (satin weave creating natural luster), chintz (glazed/polished finish), mercerized cotton (chemically treated for permanent shine), and laminated or coated cotton (polymer coating creates glossy surface). The shiniest option is PVC-coated cotton, which has a plastic-like gloss on the coated side.

What is a cotton fabric with a shiny finish?

Sateen is the most common shiny cotton fabric, created by floating weft yarns over multiple warp yarns in the weave. Other options include mercerized cotton (treated with caustic soda for luster), polished cotton/chintz (resin-glazed), and coated cotton with glossy polymer finish. Each achieves shine differently – sateen through weaving, others through surface treatments.

Is cotton material shiny or dull?

Natural cotton is typically matte or slightly dull in appearance. The shine depends on the weave and finish: plain weave cotton (like calico) is matte, satin/sateen weaves have natural luster, and treatments like mercerization, glazing, or coating can add shine. Pure cotton without special processing will always have a soft, non-shiny appearance.

Does 100% cotton fabric pill?

Yes, 100% cotton can pill, though less than synthetic blends. Pilling happens when short fibers work loose and tangle on the surface. Lower-quality cotton with shorter fibers pills more. Higher-quality long-staple cotton (Egyptian, Pima) pills minimally. Coated cotton rarely pills on the coated side since the coating prevents fiber movement, though the uncoated cotton side may show some pilling with heavy use.

What type of cotton is good for lining?

Cotton lawn, batiste, or lightweight voile work well for garment linings – they’re thin, smooth, and breathable. Broadcloth is another popular choice. For bags and accessories, cotton twill or poplin provides structure. Coated cotton isn’t typically used for linings since the coating reduces breathability and drape.

What is wrinkle-resistant cotton?

Wrinkle-resistant cotton is treated with chemicals (typically formaldehyde-based resins) that create cross-links between cotton fibers, preventing them from wrinkling. It’s also called “easy-care” or “no-iron” cotton. While convenient, the treatment reduces fabric breathability and softness. Coated cotton naturally resists wrinkles due to the coating’s smooth, firm surface – no chemical treatment needed.

Why wear cotton over polyester?

Cotton offers several advantages: better breathability (absorbs moisture from skin), more comfortable in hot weather, hypoallergenic (less likely to irritate skin), biodegradable, and feels more natural. Polyester is more durable and wrinkle-resistant but traps heat and moisture. Coated cotton gives you cotton’s comfort on one side with polyester-like waterproofing on the other – best of both worlds.

What are the 4 types of cotton?

The four main cotton species are: (1) Gossypium hirsutum (Upland cotton) – 90% of world production, medium-length fibers; (2) Gossypium barbadense (Extra-long staple) – includes Egyptian, Pima, and Sea Island, premium quality; (3) Gossypium arboreum (Tree cotton) – short fibers, mainly India/Pakistan; (4) Gossypium herbaceum (Levant cotton) – short fibers, limited production. Most coated cotton uses Upland or Pima as the base.

What is the difference between cotton and better cotton?

Better Cotton refers to the Better Cotton Initiative (BCI), a sustainability program promoting responsible cotton farming. Better Cotton is grown using less water, fewer pesticides, and better labor practices compared to conventional cotton, but it’s not certified organic. It represents a middle ground between regular and organic cotton. BCI cotton can be used as the base for coated cotton products.

What is 100% cotton fabric good for?

100% cotton excels in: breathable clothing (t-shirts, underwear, summer wear), bedding and towels (absorbent and soft), baby products (gentle on sensitive skin), home textiles (curtains, upholstery), and sewing projects. When coated, it becomes ideal for bags, outdoor cushions, tablecloths, aprons, and rain gear – keeping cotton’s comfort while adding protection.

Why is 100% cotton the best type of cloth to use with fiber reactive dyes?

Fiber reactive dyes form permanent chemical bonds with cotton’s cellulose structure, creating vibrant, wash-fast colors. Cotton’s molecular structure has hydroxyl groups that react directly with the dye molecules. Synthetic fibers like polyester lack these reactive sites, so dyes don’t bond properly. This is why 100% cotton base fabric is preferred for coated cotton – it accepts dye better before coating is applied.

Is coated cotton leather?

No, coated cotton is not leather. It’s a textile (woven cotton fabric) with a synthetic coating, while leather is animal hide. However, some high-quality PU-coated cotton can look and feel similar to leather – often called “vegan leather” or “faux leather.” True leather is more expensive, requires different care, and has unique characteristics like natural grain patterns that coated cotton doesn’t have.

Conclusion

Coated cotton represents a smart textile solution for 2025 and beyond. By combining natural cotton’s comfort with polymer technology’s protective benefits, you get a fabric that performs well in demanding situations while maintaining an appealing look and feel.

Key Takeaways

- Performance that pays off – Coated cotton lasts 2-3x longer than standard fabric, reducing replacement costs by 60% in commercial settings

- Versatility matters – Works equally well indoors and outdoors, from restaurant tables to boat cushions

- Maintenance is simple – Most spills wipe clean; machine washable with basic care

- Choose the right coating – PU for flexibility and comfort, PVC for maximum protection, acrylic for elegant drape

- Quality indicators – Look for certifications (OEKO-TEX, GOTS), even coating, and 100% cotton base

Making Your Purchase Decision

Start by honestly evaluating your needs:

- For families with kids and pets – Choose PU-coated cotton with OEKO-TEX certification. It’s safe, wipeable, and comfortable

- For commercial businesses – Invest in heavier-weight PVC-coated options. The higher upfront cost pays back through extended lifespan

- For outdoor furniture – Select UV-resistant coatings rated for 2,000+ hours sun exposure

- For fashion and accessories – Lightweight PU-coated cotton offers flexibility without sacrificing protection

- For eco-conscious buyers – Look for organic cotton base with bio-based PU coating and multiple certifications

The Investment Perspective

Yes, coated cotton costs more than basic fabric – typically $12-35 per yard compared to $5-10 for standard cotton. But consider the full picture:

- Lasts 5-7 years instead of 2-3 years

- Requires no special cleaning products

- No dry cleaning needed

- Reduced replacement frequency

- Better appearance retention over time

The total cost of ownership actually favors coated cotton in most applications. Businesses report ROI within 6-18 months, and home users appreciate not replacing cushions every season.

Looking Ahead

The coated cotton industry continues evolving toward sustainability and performance. With the market growing at 4.2% annually and reaching $42.98 billion by 2034, manufacturers are investing in:

- Bio-based coating materials that biodegrade

- Improved recycling methods for end-of-life fabrics

- Smart textiles with temperature regulation

- Enhanced antimicrobial properties for healthcare

- More durable coatings lasting 10+ years

Your Next Steps

- Request samples – Always test before buying bulk quantities. Feel the texture, try the water test, check flexibility

- Verify certifications – Don’t just trust marketing claims. Ask for certification documents

- Calculate your ROI – Use the formulas in our buying guide to see real savings over time

- Start small – Try coated cotton for one application before converting everything

- Proper care from day one – Follow care instructions to maximize your investment

Whether you’re outfitting a restaurant, updating your patio furniture, or creating handmade bags, coated cotton offers a practical solution that balances protection, aesthetics, and longevity. The technology has matured to the point where you don’t have to sacrifice comfort for durability or style for function.

Final Recommendation

For most applications, start with mid-range PU-coated cotton from a certified manufacturer. It provides the best balance of performance, cost, and environmental responsibility. As you gain experience with the material, you can fine-tune your choices based on specific needs.

The bottom line: Coated cotton works. It’s proven technology, backed by decades of use and continuous improvement. When you choose quality products and care for them properly, you’ll enjoy years of reliable performance that justifies every dollar spent.

Helpful Resources

External References:

- OEKO-TEX Certification Standards

- Global Organic Textile Standard (GOTS)

- Cotton Incorporated – Research and Technical Resources

Related Articles on Clothing Digest:

- Water-Resistant vs Waterproof Fabrics: Complete Guide

- DWR Coating: What You Need to Know

- How to Wash and Care for Different Fabrics

- Most Durable Fabrics for Everyday Wear

Interactive Tools:

Fabric Weight Calculator Fabric Care Calculator Fabric Selector Tool Cotton Type Selector Quiz