From Thread Breaks to Tension Troubles: Your Complete Step-by-Step Solution Guide

Ever wondered why your thread keeps breaking right in the middle of your favorite project? You’re definitely not alone. Almost every sewist faces these hiccups, but here’s the good news: most sewing machine problems have simple fixes you can handle at home.

Your machine works like a precise team where every part needs to do its job perfectly. When one thing goes wrong, it affects everything else. But don’t worry – this guide will walk you through the most common issues and show you exactly how to fix them.

Table of Contents

What is the Common Problem in Sewing?

Thread-related issues top the list of sewing frustrations. Whether it’s breaking, bunching, or creating loops, thread problems affect nearly 80% of all sewing sessions. The second most common issue? Tension troubles that create uneven stitches.

These problems usually happen because of:

- Incorrect threading

- Wrong needle for your fabric

- Dirty or damaged machine parts

- Poor quality thread

Let’s dive into each problem and get your machine running smoothly again.

Understanding Your Sewing Machine’s Basics

Before jumping into fixes, you need to understand how your machine creates stitches. Your sewing machine works by having the top thread meet the bobbin thread inside your fabric. When this meeting doesn’t happen correctly, you get skipped stitches, loops, or breaks.

The main players in this process are:

- Thread tension discs (control how tightly thread flows)

- Take-up lever (pulls thread through the stitch)

- Feed dogs (move fabric forward)

- Bobbin case (holds bottom thread)

Thread Problems and Solutions

Why Does My Thread Keep Breaking When I’m Sewing?

Thread breakage happens for several reasons, and finding the right cause saves you tons of frustration.

Most Common Causes:

- Dull or bent needle – Replace every 6-8 hours of sewing

- Wrong needle size – Use larger needles for thicker fabrics

- Old or cheap thread – Quality thread makes a huge difference

- Incorrect tension – Usually too tight on top thread

- Rough needle eye – Even tiny burrs can snap thread

Quick Fix Steps:

- Change your needle first (this fixes 60% of thread breaks)

- Rethread your machine completely with the presser foot up

- Test with quality thread like Gutermann or Coats & Clark

- Lower your top tension by one number and test

Why is the Thread Not Going Through Fabric?

When your needle penetrates fabric but doesn’t create stitches, you’ve got a timing or threading issue.

Check These Areas:

- Needle position – Make sure the flat side faces the correct direction

- Threading path – Follow your manual exactly, missing even one guide causes problems

- Bobbin insertion – Wrong direction prevents proper thread catch

- Take-up lever position – Should be at highest point when you start sewing

Thread Bunching and Bird’s Nests

Thread bunching (also called “bird nesting”) creates messy tangles under your fabric. This happens when your threads don’t balance properly.

For Bunching on Top:

- Bobbin tension too loose

- Top thread not in tension discs

- Bobbin incorrectly inserted

For Bunching Underneath:

- Top tension too loose

- Incorrect upper threading

- Starting too close to fabric edge

Professional Fix: Always rethread both top and bobbin threads after any jam. Clean out all thread bits first, then thread with your presser foot raised so tension discs can open properly.

How to Fix Thread Nesting Under Fabric

Thread nesting creates those frustrating tangles that jam your machine. Here’s the step-by-step fix:

- Stop immediately – Don’t pull fabric or force anything

- Cut threads – Snip tangled threads carefully with small scissors

- Remove fabric – Lift presser foot and remove work gently

- Clean thoroughly – Remove needle plate and clear all thread bits

- Rethread completely – Both top and bobbin threads

- Test on scraps – Always test before returning to your project

Tension Troubles: Getting It Just Right

How Do I Know if My Thread Tension is Too High?

High tension creates several telltale signs:

- Thread breaks frequently

- Fabric puckers along seam lines

- Tight, rope-like stitches

- Difficulty pulling fabric through machine

Visual Check: Proper tension hides the knot between fabric layers. If you see bobbin thread on top or top thread on bottom, your tension needs adjustment.

What Tension Should My Sewing Machine Be On?

Most machines work best with tension set between 3-5, but this varies by fabric and thread combination.

Tension Guidelines by Fabric:

| Fabric Type | Tension Setting | Notes |

|---|---|---|

| Cotton | 4-5 | Standard setting for most projects |

| Silk/Delicate | 2-3 | Lower tension prevents damage |

| Denim/Heavy | 5-6 | Higher tension handles thick layers |

| Stretch/Knit | 3-4 | Moderate tension with ballpoint needle |

| Lace fabrics | 2-3 | Very light tension to prevent pulls |

What Tension Should I Use for Cotton?

Cotton fabrics typically sew best with tension set to 4 or 5. Start at 4 and test on fabric scraps. If stitches look loose, increase to 5. For heavy cotton like denim, you might need 6.

What Should the Tension Be Set at on a Singer Sewing Machine?

Singer machines usually come preset to 4, which works for most common fabric types. Singer’s official tension troubleshooting documentation confirms that tension settings between 3-5 work optimally for most medium-weight fabrics, with adjustments needed based on thread weight and fabric density. Start with 4 and adjust from there.

How to Tell if Tension is Too Loose or Tight

Too Loose Signs:

- Loops on fabric surface

- Stitches pull apart easily

- Bobbin thread visible on top

Too Tight Signs:

- Fabric puckers

- Thread breaks often

- Hard to turn hand wheel

Perfect Tension:

- Stitches lock between fabric layers

- Even appearance on both sides

- Fabric lays flat without puckering

Needle and Bobbin Issues

Choosing the Right Needle

Your needle choice affects everything from stitch quality to thread breaks. Match your needle to both fabric weight and thread type.

Needle Guide:

| Fabric Weight | Needle Size | Best For |

|---|---|---|

| Lightweight | 60/8 – 70/10 | Silk, chiffon, organza |

| Medium Weight | 80/12 – 90/14 | Cotton, linen, wool |

| Heavy Weight | 100/16 – 110/18 | Denim, canvas, leather |

| Stretch Fabrics | 75/11 – 90/14 | Jersey, knits, spandex |

Pro Tip: When working with delicate lace fabrics, use a 60/8 or 70/10 needle to prevent snags and pulls.

According to Brother International’s official troubleshooting guidelines, proper needle insertion prevents up to 70% of stitch formation problems. Always ensure the flat side of your needle faces the correct direction as specified in your machine manual.

Correct Bobbin Insertion and Tension

Bobbin problems cause more frustration than almost any other issue. Here’s how to get it right:

Bobbin Insertion Check:

- Thread should unwind in the direction shown in your manual

- Thread must click into the tension spring

- Bobbin should sit flat in the case

- Case should drop in smoothly without forcing

Bobbin Tension Test: Hold the bobbin case by the thread. It should drop slowly and stop when you jerk slightly. If it drops fast, tension is too loose. If it won’t drop, tension is too tight.

Machine Mechanics and Maintenance

Why Isn’t My Sewing Machine Stitching Properly?

Poor stitching usually comes down to four main areas:

- Threading errors – Most common cause

- Needle problems – Wrong type, dull, or bent

- Timing issues – Needs professional adjustment

- Dirt buildup – Regular cleaning prevents this

Why Isn’t My Sewing Machine Pulling the Fabric Through?

When fabric won’t feed properly, check these components:

Feed Dog Problems:

- Lowered for free-motion sewing

- Clogged with lint and thread bits

- Worn teeth can’t grip fabric

Presser Foot Issues:

- Wrong pressure for fabric type

- Foot not lowered properly

- Using wrong foot for your project

Quick Fix: Clean feed dogs weekly with a stiff brush. For different presser feet options, match the foot to your sewing technique.

How to Lubricate a Sewing Machine

Regular lubrication keeps your machine running smoothly and prevents costly repairs.

Lubrication Steps:

- Clean first – Remove lint and debris before oiling

- Use proper oil – Only sewing machine oil, never household oils

- Apply sparingly – One drop per point marked in manual

- Run machine – Sew without fabric for 2-3 minutes to distribute oil

- Wipe excess – Clean any oil residue to prevent dust attraction

Frequency: Oil every 8-10 hours of sewing time, or monthly for regular users.

For complete maintenance guidance, check our detailed sewing machine maintenance guide.

Advanced Troubleshooting

Skipped Stitches Solutions

Skipped stitches happen when your needle doesn’t catch the bobbin thread properly.

Common Causes:

- Wrong needle type for fabric

- Needle inserted incorrectly

- Machine timing off (needs professional service)

- Thread too heavy for needle size

Fabric-Specific Solutions:

For Stretch Fabrics: Use ballpoint needles that slip between fibers instead of piercing them. Regular needles can cause runs in knit fabrics.

For Heavy Fabrics: Switch to a leather or denim needle. These have stronger shafts and sharper points to penetrate thick materials.

Why is My Fabric Puckering When Sewing?

Fabric puckering ruins the look of your finished project. Here’s how to prevent it:

Main Causes:

- Tension too tight

- Wrong needle size

- Poor quality thread

- Sewing too fast on delicate fabrics

Prevention Tips:

- Test stitch on fabric scraps first

- Use appropriate sewing machine stitches for your fabric

- Support fabric weight while sewing

- Consider using stabilizer for very light fabrics

How to Fix a Pulled Thread in Fabric

Pulled threads happen especially with delicate fabrics like silk or fine knits.

For Minor Pulls:

- Gently work thread back into fabric with a needle

- Steam lightly to relax fibers

- Press with appropriate heat setting

For Major Pulls:

- Assess if fabric is still usable

- Consider creative solutions like decorative patches

- In severe cases, you may need to replace the fabric piece

Computerized and Smart Sewing Machine Issues

Modern sewing machines bring new challenges alongside their convenience features.

Software and Connectivity Problems

Common Smart Machine Issues:

- App connectivity failures

- Touch screen calibration problems

- Software update glitches

- Design transfer errors

Basic Troubleshooting:

- Restart machine completely

- Check Wi-Fi connection strength

- Update app and machine firmware

- Reset to factory settings if problems persist

Automatic Feature Malfunctions

When Automatic Features Fail:

- Switch to manual mode temporarily

- Check user manual for reset procedures

- Ensure proper threading for automatic functions

- Contact manufacturer if under warranty

Seasonal Maintenance Calendar

Keeping your machine in top shape requires regular attention throughout the year.

Monthly Tasks

- Clean lint from bobbin area and feed dogs

- Oil according to manual specifications

- Check needle condition and replace if needed

- Test tension on different fabric scraps

Quarterly Tasks

- Deep clean entire machine interior

- Replace any worn presser feet

- Check all moving parts for smooth operation

- Update software on computerized machines

Annual Tasks

- Professional tune-up and timing check

- Replace worn parts like belts or gears

- Calibrate computerized features

- Replace all needles regardless of use

Emergency Mid-Project Fixes

Sometimes problems happen right in the middle of important projects. Here are quick fixes to get you back on track:

Temporary Solutions

For Thread Breaks:

- Switch to slightly looser tension temporarily

- Use higher quality thread for remainder of project

- Take more frequent breaks to check needle condition

For Tension Problems:

- Mark your current settings before adjusting

- Make small changes (quarter turns) and test

- Keep fabric scraps nearby for testing

For Feed Problems:

- Reduce stitch length temporarily

- Help guide fabric gently (don’t pull)

- Clean feed dogs quickly with brush

When to Call a Professional

Some problems require expert attention to prevent further damage.

Professional Service Indicators

Immediate Professional Help Needed:

- Grinding or unusual mechanical noises

- Needle bar doesn’t move smoothly

- Timing problems (needle hits bobbin case)

- Electrical issues or smoke

Can Wait for Scheduled Service:

- Minor tension inconsistencies

- Worn feed dog teeth

- Belt replacement needs

- Routine maintenance overdue

Choosing a Repair Service

What to Look For:

- Certified technicians for your machine brand

- Written estimates before work begins

- Warranty on repair work

- Quick turnaround times

The American Sewing Guild recommends professional servicing every 12-18 months for regular users, or after every 100 hours of operation for heavy use, to maintain optimal performance and prevent costly repairs. This professional maintenance schedule helps catch small issues before they become expensive problems.

Brand-Specific Tips

Different sewing machine brands have unique quirks and solutions.

Singer Troubleshooting

Singer machines typically need tension around 4 for most projects. Common Singer issues include:

- Bobbin case placement sensitivity

- Needle threading sequence importance

- Model-specific oil points

Brother Machine Tips

Brother machines often feature:

- Automatic threading that can jam

- Touch screen calibration needs

- Specific needle orientation requirements

Janome Considerations

Janome machines are known for:

- Precise tension requirements

- High-quality internal components

- Longer service intervals

Understanding Different Fabric Challenges

Different fabrics present unique sewing challenges that require specific solutions.

Working with Delicate Fabrics

For Silk and Chiffon:

- Use size 60/8 or 70/10 needles

- Reduce presser foot pressure

- Lower tension settings

- Sew slowly for control

For Lace Materials:

- Use sharp microtex needles

- Minimal tension to prevent pulls

- Consider using tissue paper underneath

- Test on scraps first

Heavy Fabric Solutions

For Denim and Canvas:

- Use size 100/16 or 110/18 needles

- Increase tension slightly

- Slow down stitching speed

- Use heavy-duty thread

For Multiple Layers:

- Switch to longer stitch length

- Use appropriate seam allowances

- Consider grading seams to reduce bulk

Quality Thread Matters

Your thread choice affects every aspect of sewing performance.

How to Tell if Threads are Bad

Signs of Poor Quality Thread:

- Frequent breaks during sewing

- Fuzzy or hairy appearance

- Inconsistent thickness

- Fading or color bleeding

- Brittle feel when bent

Thread Storage Tips:

- Keep spools in cool, dry places

- Avoid direct sunlight exposure

- Use thread within 2-3 years of purchase

- Store upright to prevent unwinding

Thread Weight and Fabric Matching

Thread Weight Guide:

- 30-40 weight: Heavy fabrics, topstitching

- 40-50 weight: General sewing, most cottons

- 60-80 weight: Delicate fabrics, quilting

- 100+ weight: Very fine work, heirloom sewing

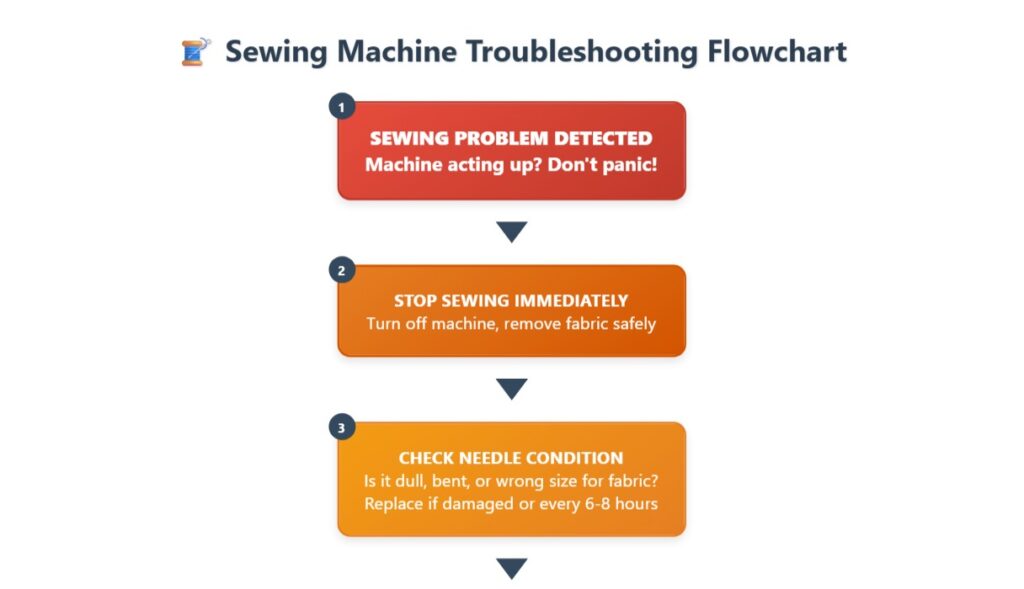

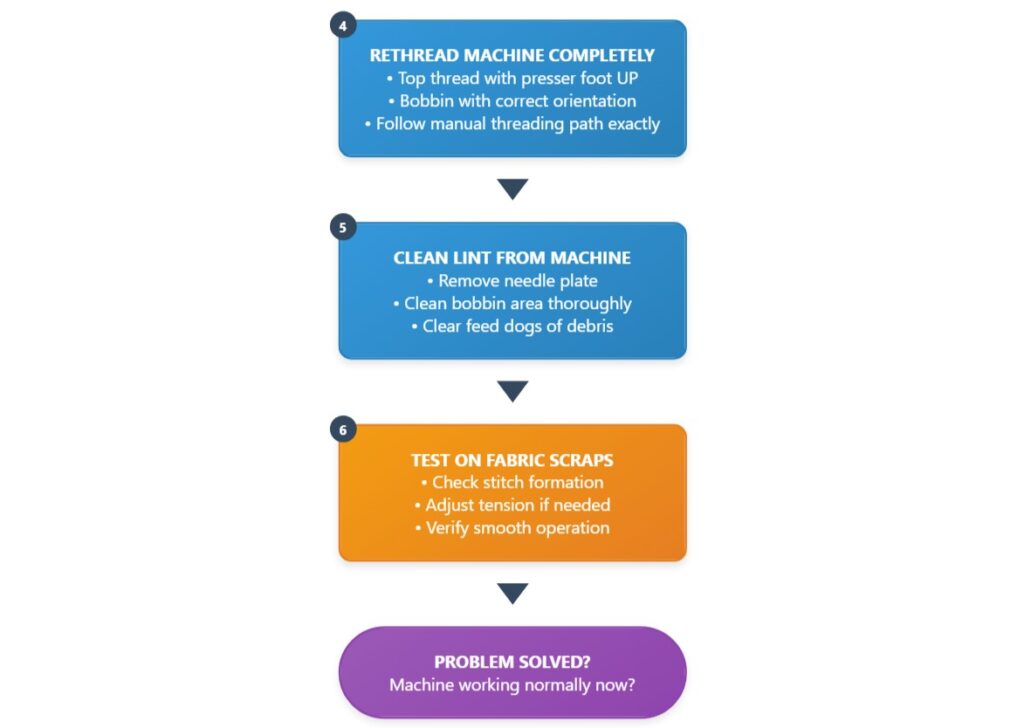

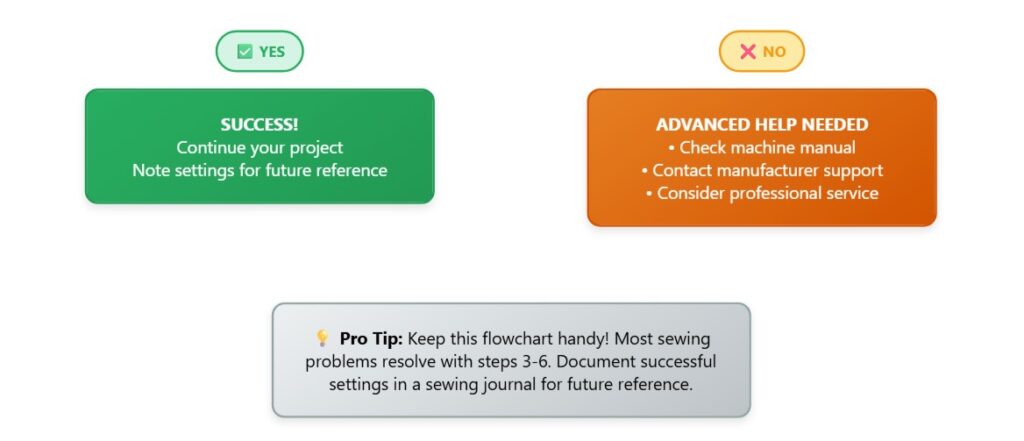

Troubleshooting Flowchart: Your Step-by-Step Problem Solver

When sewing problems hit, don’t guess at solutions. This systematic approach will guide you through the most effective troubleshooting sequence that professional repair technicians use. Follow these steps in order for the best chance of quick resolution.

Most sewing issues resolve within the first four steps, but having a clear process prevents you from missing obvious fixes or making problems worse. Print this flowchart and keep it near your sewing station for quick reference during projects.

This flowchart covers about 85% of common sewing machine problems. The key is following the sequence exactly – skipping steps often leads to missed solutions. For example, many sewists jump straight to tension adjustments when a simple needle change would have solved the problem immediately.

Important Notes:

- Always complete steps 1-5 before testing, even if you think you know the problem

- Keep fabric scraps near your machine for testing adjustments

- Document successful settings in a sewing journal for future reference

- If problems persist after following this flowchart, the issue likely requires professional attention

Remember: patience during troubleshooting saves time in the long run. Taking five minutes to work through this process systematically often prevents hours of frustration later.

Prevention Strategies

The best troubleshooting is prevention. Build these habits into your sewing routine:

Daily Sewing Habits

- Start each session with needle check

- Keep quality thread at your machine

- Clean lint after every project

- Test tension on scraps before starting

Weekly Maintenance

- Deep clean bobbin area

- Check all threading paths

- Inspect presser feet for damage

- Organize and check supply quality

Project Planning

- Choose appropriate needles for each fabric

- Plan seam finishing methods in advance

- Have backup supplies ready

- Keep detailed notes of successful settings

Troubleshooting by Symptom Quick Reference

Thread Issues

- Breaks frequently: Change needle, check tension, verify thread quality

- Forms loops: Check bobbin insertion, adjust top tension

- Won’t go through needle: Use needle threader, check needle eye for damage

- Bunches under fabric: Rethread top thread, check bobbin orientation

Stitch Problems

- Skips stitches: Replace needle, check threading path, verify fabric/needle match

- Loose stitches: Increase tension gradually, check bobbin thread path

- Uneven stitches: Clean machine, check needle condition, verify proper threading

Fabric Issues

- Won’t feed through: Clean feed dogs, adjust presser foot pressure, check for lint

- Puckers while sewing: Reduce tension, use appropriate needle, slow down speed

- Pulls or snags: Change to ballpoint needle for knits, reduce presser foot pressure

Building Your Troubleshooting Skills

Becoming proficient at machine troubleshooting takes practice and patience.

Keep a Sewing Journal

Track successful settings for different fabric combinations:

- Fabric type and weight

- Needle size and type used

- Thread brand and weight

- Tension settings that worked

- Any special techniques used

Build Your Skills Gradually

Start with basic sewing techniques and gradually work up to more challenging projects. This builds your troubleshooting instincts naturally.

Join Sewing Communities

Online and local sewing groups offer valuable troubleshooting support and shared experiences from fellow sewists.

Conclusion

Sewing machine troubleshooting doesn’t have to be overwhelming or mysterious. Most problems you’ll encounter have straightforward solutions that you can handle yourself with the right knowledge and approach.

The key takeaways for successful troubleshooting are:

- Start with the basics every time. A fresh needle and complete rethreading solve the majority of sewing problems. These simple steps should be your first response to any issue, regardless of how complex it might seem.

- Quality supplies make a real difference. Investing in good needles, thread, and regular maintenance prevents most problems before they start. Cheap supplies often cost more in frustration and time than quality materials cost upfront.

- Develop systematic habits. Clean your machine regularly, test settings on scraps, and maintain a troubleshooting journal. These practices build your skills and confidence while preventing many common issues.

- Know when to seek help. While you can handle most problems yourself, don’t hesitate to consult professionals for timing issues, unusual noises, or problems that persist despite following proper troubleshooting steps. Professional service protects your investment and ensures your machine continues performing well.

- Practice patience with yourself and your machine. Troubleshooting is a skill that improves with experience. Each problem you solve successfully builds your confidence and makes future issues easier to handle.

Remember that even experienced sewists encounter these challenges regularly. The difference lies in approaching problems systematically rather than randomly trying different solutions. With the techniques and knowledge in this guide, you’re well-equipped to handle whatever sewing challenges come your way.

Keep this guide handy during your sewing sessions, and don’t forget to check our essential sewing supplies and common sewing mistakes articles for additional support in your sewing journey.

Happy sewing, and may your projects flow smoothly from start to finish!

Frequently Asked Questions

What is the most common sewing machine problem?

Thread-related issues are the most common, affecting about 80% of sewing sessions. This includes thread breaking, bunching, or creating loops under fabric.

How often should I replace my sewing machine needle?

Replace your needle every 6-8 hours of sewing time, or immediately if it becomes bent, dull, or starts causing problems like skipped stitches or pulls in fabric.

Why does my thread keep bunching underneath my fabric?

Thread bunching usually indicates incorrect upper threading or that your bobbin isn’t inserted properly. Always rethread your machine with the presser foot raised to ensure proper tension disc engagement.

What tension setting should I use for most fabrics?

Most sewing machines work best with tension set between 4-5 for medium-weight fabrics like cotton. Start at 4 and adjust up or down based on your test stitches.

How can I tell if my sewing machine needs professional service?

Seek professional help if you hear grinding noises, the needle hits the bobbin case, timing seems off, or problems persist despite proper troubleshooting. Annual professional maintenance is also recommended.

Why won’t my sewing machine feed fabric through properly?

Check that your feed dogs are raised and clean, presser foot pressure is appropriate for your fabric, and there’s no lint buildup preventing proper fabric movement.

How do I know if my thread tension is correct?

Perfect tension creates stitches that lock between fabric layers, with the knot invisible from both sides. If you see bobbin thread on top or top thread on bottom, adjust tension accordingly.

Can I use any type of oil on my sewing machine?

Only use oil specifically designed for sewing machines. Household oils can gum up mechanisms and attract dust, causing more problems than they solve.