Understanding the benefits, challenges, and future of recycled polyester in modern textiles

Nearly half of all clothing produced today contains synthetic fabrics, with production expected to keep growing. But there’s a better way forward: turning plastic waste into durable textiles. Five discarded water bottles can create enough fiber for a single shirt, giving new life to materials that would otherwise end up in landfills or oceans.

Table of Contents

- What is Recycled Polyester (rPET)?

- Environmental Benefits of rPET

- How rPET is Made

- The Microplastics Problem

- The Bottle-to-Fiber Supply Battle

- Next-Generation Recycling

- GRS Certification Explained

- The 2025 Recycled Polyester Challenge

- Leading Brands Using rPET

- rPET vs Other Fabrics

- How to Care for rPET Garments

- Frequently Asked Questions

Key Takeaways

- Synthetic fabrics dominate nearly 50% of global clothing production

- Converting plastic bottles into textiles reduces energy use by 59% compared to virgin polyester

- The global rPET market is projected to reach $36.39 billion by 2034

- Microplastics from synthetic fabrics are a growing concern that needs addressing

- Textile-to-textile recycling is the future, with major brands investing $600+ million

What is Recycled Polyester (rPET)?

Recycled polyester, commonly called rPET (recycled polyethylene terephthalate), is a sustainable material made from post-consumer plastic waste. The technology dates back to 1993, when a breakthrough in Japan transformed soda bottles into sportswear fibers. Today, over 60% of global apparel brands use these fibers.

rPET shares identical chemical properties with conventional polyester fabric, but comes from discarded plastics instead of new petroleum. Manufacturers collect items like bottles and industrial scraps, clean them, and shred them into flakes. These flakes melt into pellets, which are then spun into yarn.

Is Recycled Polyester a Good Material?

Yes, rPET performs just as well as virgin polyester in most applications. Lab tests show near-identical durability between both materials. Stretch recovery and moisture-wicking capabilities remain consistent across athletic wear and outerwear. Recent chemical recycling improvements now produce fibers matching virgin-grade tensile strength.

The main advantage? Environmental impact. Reprocessing existing plastics uses 59% less energy than oil extraction and refinement. Water consumption drops by 90%, which matters in drought-affected manufacturing regions. One ton of rPET saves three barrels of crude oil.

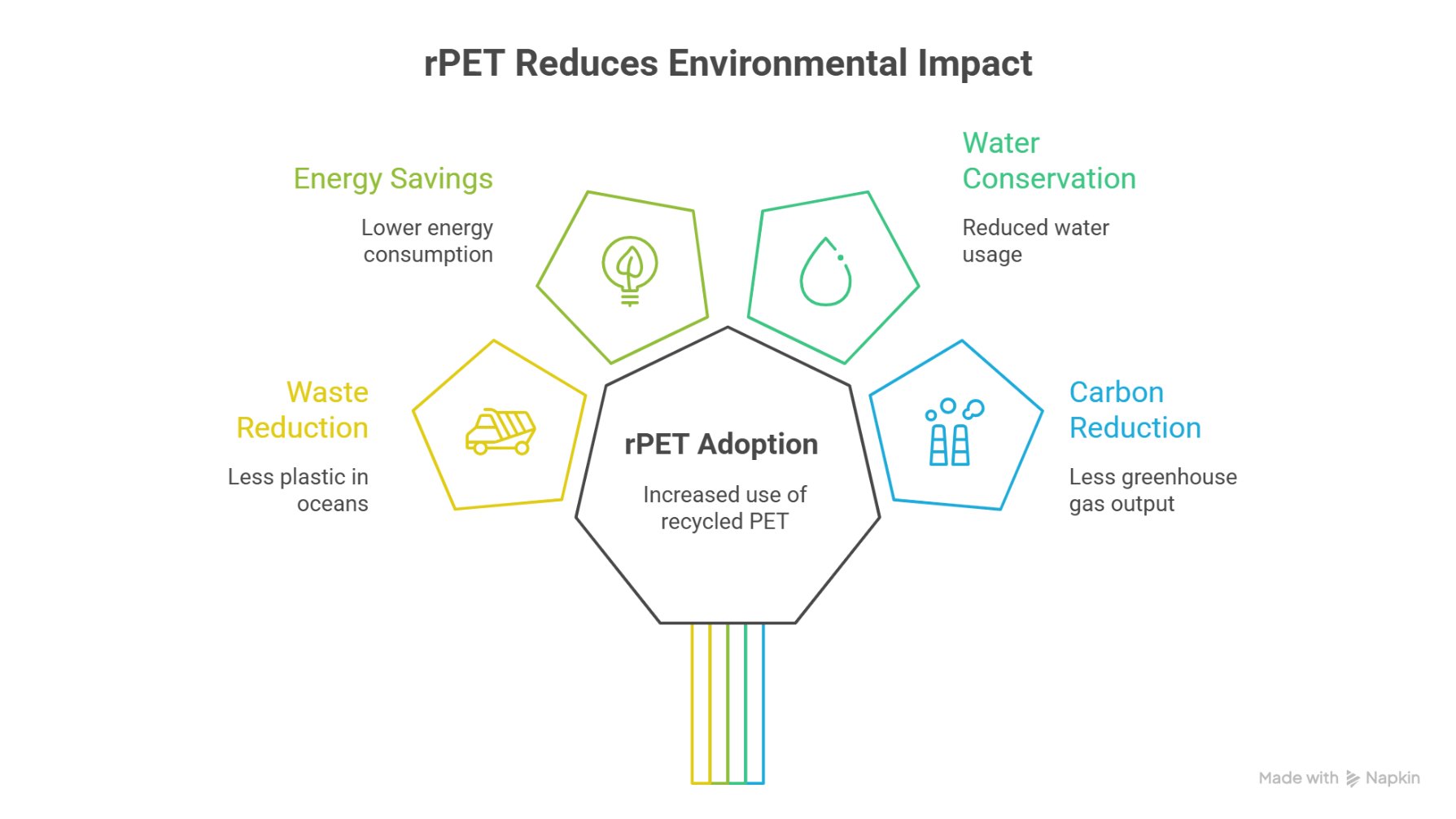

Environmental Benefits of rPET

Every minute, a garbage truck’s worth of plastic enters our oceans. rPET tackles two problems at once: diverting waste streams while creating durable fabrics. Over 150 million metric tons of plastics currently pollute marine ecosystems. rPET production intercepts bottles and packaging before they reach waterways or burial sites.

Reducing Plastic Waste

One ton of rPET prevents three cubic meters of landfill space from being consumed. Since 2020, apparel brands using this approach have diverted 4 billion containers from dumps. That’s real impact you can measure.

Lower Energy and Water Use

Creating fibers from existing materials skips oil-intensive processes. Manufacturers report 59-63% less energy use compared to conventional methods. That’s enough to power 700,000 homes annually. Water needs drop by 90%, which matters when textile plants operate in drought-prone regions.

The numbers get more impressive at scale. Every 10% increase in rPET adoption could prevent 50 million tons of CO₂ emissions by 2035. That equals removing 11 million cars from roads. Brands achieving full conversion see supply chain emissions halved within five years.

Carbon Footprint Reduction

Greenhouse gas output shrinks by 32% in reprocessed fiber production. A 2023 Textile Exchange study found brands switching entirely to rPET halve supply chain emissions within five years. The circular system amplifies benefits since post-consumer waste becomes raw material, reducing landfill overflow.

How rPET is Made: Manufacturing Process

Converting discarded plastics into wearable fabrics requires precision. Two methods dominate: mechanical and chemical recycling. Each offers different advantages in resource recovery and material quality.

Watch how an Indian company transforms 1.5 million plastic bottles daily into clothing through sorting, melting, and spinning techniques

Mechanical Recycling: The Standard Method

Over 80% of rPET production uses mechanical processing. Here’s how it works:

- Workers sort collected plastic bottles by type and color

- Thorough washing removes labels and contaminants

- Machines shred clean containers into uniform flakes

- Flakes melt into pellets for fiber extrusion

This method faces challenges. Repeated melting weakens molecular bonds, requiring 15-30% virgin material blending. Color consistency fluctuates between batches, limiting dye options. Think of it like photocopying a document multiple times – quality degrades each cycle.

Chemical Recycling: The Advanced Approach

Advanced depolymerization breaks materials into base components. Catalysts separate plastic waste into pure monomers through controlled reactions. These building blocks reconstruct into high-grade fibers matching virgin quality.

The technique handles mixed plastics and colored items mechanical systems reject. Laboratory tests show chemically processed textiles withstand 40% more stress than mechanically recycled ones. Though currently more expensive, scaling could reduce costs by 60% by 2030.

| Factor | Mechanical Method | Chemical Method |

|---|---|---|

| Energy Use | 59% less than virgin | 72% less than virgin |

| Output Quality | Grade B (limited reuse) | Grade A (virgin equivalent) |

| Input Flexibility | Clear bottles only | Mixed plastics/carpets |

| Cost | Lower (current) | Higher (current) |

| Scalability | Widely available | Limited (growing) |

Emerging Technologies

Enzymatic breakdown promises faster processing times. Pilot plants now convert ocean plastics into premium yarns, expanding material sources while cleaning ecosystems. These biological processes can handle fiber blends that stump other methods.

The Microplastics Problem: What You Need to Know

Critical Issue: rPET Sheds More Microplastics Than Virgin Polyester

Recent research shows rPET releases approximately 31% more microplastic fibers during washing compared to virgin polyester (1,193 microfibers vs. 908 under identical conditions). This is a serious environmental concern that deserves attention.

Let’s address the elephant in the room. While rPET offers clear benefits in reducing plastic waste and energy use, it comes with a significant downside: microplastic pollution. These tiny plastic fragments shed from synthetic clothes during wear and washing, entering water systems and oceans.

Why rPET Sheds More Microplastics

The recycling process creates shorter, more fragile fibers. When you wash fleece jackets or other rPET garments, these weaker fibers break off more easily. Each wash cycle can release thousands of microfibers into wastewater.

The science backs this up. Studies show synthetic apparel production and washing are primary sources of microplastic pollution, along with car tires. These specs of plastic now appear everywhere – in the deepest ocean depths, on mountain peaks, and even inside our bodies.

The Health and Environmental Impact

Microplastics are now so widespread that the average person consumes about 5 grams weekly – roughly the weight of a credit card. They’ve been found in seafood, sea salt, and drinking water. Research even detected microplastics in human placentas, raising concerns about health effects.

The ocean impacts are clear. An estimated 35% of ocean microplastics come from synthetic clothing. Marine life consumes these particles, which work their way up the food chain back to us.

Solutions and What You Can Do

Don’t panic – there are practical steps to reduce microplastic shedding:

- Use a Guppyfriend bag: These special laundry bags capture up to 90% of microfibers during washing

- Install washing machine filters: Modern filters can catch microplastics before they reach water systems

- Wash less frequently: Full loads and gentler cycles release fewer fibers

- Choose knitted over woven: Knitted fabrics release fewer microfibers than woven ones

- Skip pre-wash cycles: Pre-washing releases significantly more fibers than regular washing

- Design matters: Buy garments that require fewer washes, like jackets and backpacks

New Regulations Coming Soon

Governments are taking action. France now requires all new washing machines to include microfiber filters as of January 2025. Oregon will require them by 2030, and California is working on similar legislation for 2029. The EU is developing broader mandates.

These regulations show the issue is serious. Modern filters can catch up to 90% of microfibers before they reach water supplies, making a real difference.

The Bottom Line on Microplastics

Yes, rPET has a microplastics problem. But this doesn’t mean we should abandon it completely. Instead, we need to:

• Use rPET strategically for items that need less washing

• Support development of biodegradable alternatives

• Invest in filtering technology

• Push for textile-to-textile recycling that creates stronger fibers

The Bottle-to-Fiber Supply Battle

Here’s a problem most people don’t know about: the beverage industry and textile manufacturers are fighting over the same plastic bottles. Both want to use recycled PET, but there isn’t enough supply to meet everyone’s targets.

The Supply Crunch

The Textile Exchange and UN Fashion Industry Charter set ambitious goals: 45% recycled polyester by 2025, reaching 90% by 2030. That requires roughly 17.1 million metric tons of rPET.

Meanwhile, beverage companies target 25% rPET content in their bottles by 2025. The problem? According to Alasdair Carmichael, program director for the National Association for PET Container Resources (NAPCOR), there isn’t enough rPET from bottles to meet both targets.

Why This Matters

Bottles can be recycled endlessly in their own loop – bottle to bottle to bottle. But once PET becomes textile fiber, current technology can’t recycle it back into food-grade bottles. The material drops out of the circular system.

This creates a one-way street. Textile manufacturers rely on bottle feedstock, but bottle companies want their bottles back. As regulations tighten and bottle companies secure their supply chains, textile manufacturers face a crunch.

The Solution: Textile-to-Textile Recycling

Industry experts agree: textiles need their own recycling loop. The EU already legislated separate collection of waste textiles beginning in 2025. This pushes the industry toward textile-to-textile systems instead of competing for bottles.

Next-Generation Recycling: Beyond Bottles

Less than 1% of sustainable fabrics come from old clothes. That’s the real problem. The industry heavily depends on plastic bottles, creating the bottleneck we just discussed. But cutting-edge companies are changing this with textile-to-textile recycling.

Syre: H&M’s $600 Million Bet

Syre represents one of the biggest investments in textile recycling. Backed by H&M Group, Vargas, Volvo, and TPG Rise Climate, the company uses depolymerization to break down polyester textiles into BHET (the building block of PET), then reconstructs it into new polyester.

What makes Syre different? They can handle polyester blends and reduce CO₂ emissions by up to 85% compared to oil-based virgin polyester. Their Blueprint Plant in Cedar Creek, North Carolina, opens mid-2025 with capacity for 10,000 metric tons annually. H&M committed to a $600 million offtake agreement over seven years.

Samsara Eco: Enzymatic Innovation

Australian company Samsara Eco uses plastic-eating enzymes called EosEco™ to create infinitely recyclable nylon 6,6 and polyester from textile waste. Think of it as nature’s way of breaking down plastic.

The enzymatic process works at lower temperatures and pressures than chemical methods, reducing energy use. Samsara’s Commercial Innovation Hub opens in Jerrabomberra, New South Wales in mid-2025, with a full-scale Southeast Asian facility planned for late 2026.

They’ve already produced a sold-out clothing line with Lululemon, proving the technology works at commercial scale.

Reju: The Regeneration Company

Reju, owned by engineering giant Technip Energies, opened its Regeneration Hub Zero in Frankfurt, Germany with deliveries starting in 2025. They use VolCat, an organic catalytic process developed jointly by Technip, IBM, and Under Armour.

The process extracts clean monomers while creating 50% less CO₂ emissions than virgin polyester. Reju focuses on creating an infinite loop where textile waste continuously becomes new textiles.

Other Game-Changers

Several other companies are pushing boundaries:

- Unifi (REPREVE): Transformed 35 billion bottles into textiles, now expanding their Textile Takeback™ program for closed-loop recycling

- Ambercycle: Testing processes near Los Angeles that separate polyester from mixed waste, using 80% less energy than standard recycling

- Eastman: Operating facilities in Tennessee producing 110,000 metric tons annually, targeting 250 million pounds by 2025

Technical Breakthroughs

Recent innovations are solving long-standing problems:

- Microwave-assisted glycolysis: University of Delaware developed a process that depolymerizes polyester and spandex blends in just 15 minutes

- Enzymatic processes for mixed textiles: New enzymes can handle unsorted, contaminated fabrics that mechanical systems reject

- Vitrimerization: Adding epoxy cross-linking agents allows recycling of hard-to-process polyesters

GRS Certification: Verifying Sustainability Claims

Anyone can claim their product uses recycled materials. How do you know it’s true? That’s where Global Recycled Standard (GRS) certification comes in.

What is GRS Certification?

The Global Recycled Standard is an international certification managed by Textile Exchange. It verifies recycled content in products and ensures responsible social, environmental, and chemical practices throughout production.

GRS covers the full supply chain – from the company collecting waste plastic to the final garment you buy. Every step gets audited by independent third-party certification bodies.

Key Requirements

Products need at least 50% recycled content to display GRS labeling. But certification requires more than just recycled materials:

- Chain of custody: Tracking materials from source to final product

- Social requirements: Fair labor practices based on International Labour Organization standards

- Environmental criteria: Water use, energy recovery, waste management, emissions

- Chemical restrictions: Banned substances with harmful potential

Why GRS Matters

Greenwashing is real. Companies sometimes exaggerate sustainability claims. GRS provides third-party verification you can trust. When you see a GRS logo, you know:

- The recycled content percentage is accurate

- Materials are tracked through the entire supply chain

- Workers are treated fairly

- Environmental standards are met

- Harmful chemicals aren’t used

Major retailers like Zalando require GRS certification from suppliers. As consumer awareness grows, GRS is becoming a minimum requirement for serious brands.

The Upcoming Standards Transition

Textile Exchange is launching a new Materials Matter Standard in December 2025, harmonizing their current suite of standards. This will replace GRS with a more comprehensive framework. Organizations currently certified to GRS should watch for transition timelines, with mandatory compliance expected in 2027.

How to Identify Genuine rPET Products

When shopping for recycled polyester items, look for these indicators of authenticity:

- GRS certification logo: The most reliable indicator. Look for the official GRS label on tags

- Specific percentage claims: Legitimate products state exact recycled content (e.g., “50% recycled polyester”)

- Supply chain transparency: Reputable brands list their suppliers and provide traceability information

- Third-party verification: Look for other certifications like RCS (Recycled Claim Standard) for products with 5-50% recycled content

- Brand reputation: Research whether the brand has made public commitments to the 2025 Recycled Polyester Challenge

Red Flags for Greenwashing

- Vague claims like “eco-friendly” without specific percentages

- No certification logos or third-party verification

- Impossibly low prices (genuine rPET costs more than virgin polyester)

- Missing supply chain information

- Generic sustainability claims without proof

The 2025 Recycled Polyester Challenge

In April 2021, Textile Exchange teamed up with the UN Fashion Industry Charter for Climate Action to launch an ambitious initiative: get the industry to increase recycled polyester from 14% to 45% by 2025.

The Goals and Why They Matter

The challenge calls for 17.1 million metric tons of rPET by 2025 (assuming 3% industry growth). This isn’t about substituting other materials or justifying growth – it’s about replacing virgin synthetic feedstocks with recycled alternatives.

Why these numbers? To stay within the 1.5-degree climate pathway recommended by the Intergovernmental Panel on Climate Change, the industry needs to reach 90% mechanically recycled polyester by 2030. The 2025 target of 45% is a necessary stepping stone.

Progress So Far

Several brands have already hit their targets or made substantial progress:

- Adidas: Committed to using only recycled polyester from 2024, with 90% of articles sustainable by 2025

- Patagonia: 87% of product lines incorporate recycled materials

- H&M: Major investor in Syre with $600 million commitment over seven years

The challenge concludes at the end of 2025, with final reporting in 2026. Textile Exchange is developing new “Commitments” to launch in 2026, building on lessons learned.

The Reality Check

Despite progress, less than 1% of recycled fibers come from textile-to-textile recycling. Most rPET still comes from bottles. This highlights why textile-to-textile innovations are so important – and why the “bottle wars” supply issue needs solving.

Leading Brands Using rPET

Global fashion leaders are turning sustainability commitments into real products. Here’s how major brands are using rPET.

Adidas: Eliminating Virgin Plastics

Adidas aims to eliminate virgin plastics from footwear and clothing by 2024. Over 90% of their current sportswear line contains reprocessed materials. Each pair of Ultraboost sneakers repurposes 12 plastic bottles without sacrificing performance.

The brand also launched the first running shoe “made to be remade” – designed for easy disassembly and recycling at end of life.

Patagonia: The Original Pioneer

Patagonia set the standard decades ago. Their 1993 fleece jacket collaboration with Polartec marked the first commercial use of reprocessed fibers in outdoor gear. Today, 87% of their product lines incorporate this approach, proving long-term viability in technical apparel.

The company continues pushing boundaries with repair programs and take-back initiatives, working toward true circularity.

H&M Group: Betting Big on Circularity

H&M Group’s partnership with Syre represents one of the largest investments in textile-to-textile recycling. Their $600 million commitment will help scale circular production, targeting 3 billion recycled garments annually by 2030.

Early prototypes show 98% material recovery rates from worn clothing, demonstrating the technology’s potential.

Other Notable Brands

- Lululemon: Partnering with Samsara Eco on enzymatically recycled nylon

- Reformation: Strong stance against conventional synthetics, committed to rPET challenge

- Helly Hansen: Part of founding cohort, focusing on reducing fossil fuel dependency

Consumer Impact

A 2023 Nielsen study found 68% of U.S. shoppers prefer brands using sustainable materials, even at premium prices. As industry giants prove ecological responsibility aligns with profitability, smaller competitors face mounting pressure to follow.

rPET vs Other Fabrics: Complete Comparisons

How Does Recycled Polyester Compare to Cotton?

This comparison isn’t straightforward because each fabric serves different purposes. Cotton versus polyester debates often miss the point – they’re fundamentally different materials.

| Characteristic | rPET | Cotton |

|---|---|---|

| Breathability | Moderate (moisture-wicking) | Excellent (natural airflow) |

| Durability | Very high (resists abrasion) | Good (weakens when wet) |

| Water Resistance | Naturally water-resistant | Absorbs water readily |

| Drying Time | Fast (hydrophobic) | Slow (holds moisture) |

| Wrinkle Resistance | Excellent | Poor (needs ironing) |

| Microplastic Shedding | Yes (environmental concern) | No (biodegradable fibers) |

| Static Electricity | Builds static | No static buildup |

Best uses for rPET: Athletic wear, outdoor gear, swimwear, bags, anything needing water resistance or quick drying.

Best uses for organic cotton: Everyday wear, underwear, baby clothes, anything touching sensitive skin for extended periods.

Is Recycled Polyester Better Than Cotton?

Neither is universally “better” – it depends on the application. rPET wins for performance sportswear and durability. Cotton wins for comfort, breathability, and biodegradability. Choose based on what you’re making and what matters most to you.

Recycled Polyester vs Virgin Polyester

Performance-wise, they’re nearly identical. The differences lie in environmental impact:

- Energy use: rPET requires 59% less energy

- Water consumption: 90% reduction

- CO₂ emissions: 32% lower

- Oil savings: 3 barrels per ton

- Quality: Chemical recycling matches virgin quality; mechanical recycling slightly lower

Chemical recycling produces virgin-equivalent fibers, while mechanical recycling may require 15-30% virgin material blending for optimal strength.

Is Nylon Better Than Recycled Polyester?

Both are synthetic fabrics with similar properties, but differences matter:

- Strength: Nylon is stronger and more elastic

- Abrasion resistance: Nylon wins (better for high-wear items)

- UV resistance: rPET handles sunlight better

- Cost: rPET typically costs less

- Microplastic shedding: Nylon sheds at one-sixth the rate of polyester

Choose nylon for items needing extreme durability (backpacks, outdoor gear). Choose rPET for general athletic wear and cost-effective performance fabrics.

Is Recycled Polyester Warmer Than Down?

No, down insulation provides better warmth-to-weight ratio. However, rPET insulation works better when wet. Down clumps and loses insulating properties when moisture gets in. Synthetic insulation maintains warmth even damp, making it better for wet climates or high-output activities where you’ll sweat.

How to Care for rPET Garments

How Do You Wash Recycled Polyester?

Proper care extends garment life and reduces microplastic shedding. Follow these washing guidelines:

- Use cold water: Wash in cold water (30°C/86°F or less) to prevent fiber degradation

- Skip pre-wash: Pre-wash cycles release significantly more microfibers

- Wash full loads: Fuller loads create less agitation and reduce shedding

- Use a Guppyfriend bag: Captures up to 90% of microfibers before they enter water systems

- Gentle cycle: Reduces mechanical stress on fibers

- Liquid detergent: Dissolves better than powder, reducing residue

Should I Use Fabric Softener on Polyester?

No. Fabric softener coats synthetic fibers, reducing their moisture-wicking properties. It can also leave residue that attracts dirt and reduces breathability. If your rPET clothes feel stiff, the issue is usually detergent buildup – try an extra rinse cycle instead.

Can You Wash 100% Polyester If It Says Dry Clean Only?

Usually yes, despite the label. Manufacturers often put “dry clean only” as a safe recommendation. Most rPET items can handle gentle machine washing in cold water. Test on an inconspicuous area first, or hand wash the first time to check colorfastness.

What Happens When You Tumble Dry Recycled Polyester?

rPET handles dryers better than natural fibers, but heat still causes problems:

- Low heat is fine: Most rPET tolerates low dryer settings

- High heat damages fibers: Can cause melting, shrinkage, or permanent wrinkles

- Air drying is best: Preserves fabric integrity and saves energy

- Permanent press setting: Good compromise if you must use a dryer

Will Recycled Polyester Shrink in the Dryer?

Minimal shrinkage if you follow care instructions. Unlike cotton, polyester rarely shrinks significantly. Heat can cause slight dimensional changes, but nowhere near cotton’s 5-10% potential shrinkage. Use low heat or air dry to maintain original size.

Does Recycled Polyester Shrink or Stretch?

rPET is dimensionally stable. It won’t shrink like cotton or stretch out like wool. That’s why it works well for athletic wear – garments maintain their shape through repeated wear and washing.

However, garments can stretch if they’re poorly constructed or subjected to excessive pulling when wet. Always wash inside out and avoid twisting or wringing.

Can You Unshrink Polyester?

If your polyester garment somehow shrunk (usually from very high heat), you can sometimes recover it. Soak in lukewarm water with hair conditioner for 30 minutes, then gently stretch while wet. Lay flat to dry. This works about 50% of the time.

Does Recycled Polyester Wrinkle?

One of rPET’s best features: excellent wrinkle resistance. Unlike natural fibers, polyester maintains shape without ironing. If wrinkles do form:

- Hang immediately after washing: Prevents most wrinkles

- Low heat iron: Use lowest setting if needed

- Steam: Hang in bathroom during hot shower to release wrinkles

- Dryer with damp towel: 10 minutes on low with a damp towel smooths wrinkles

What is the Most Wrinkle Free Fabric?

Polyester (including rPET) tops the list for wrinkle resistance, followed by nylon and acrylic. Natural fibers like cotton and linen wrinkle easily. Blends like cotton-polyester offer a compromise between breathability and wrinkle resistance.

Does Recycled Polyester Make You Warm?

It depends on construction, not the material itself. rPET can be made into lightweight, breathable fabrics or thick insulating layers. The fiber is neither inherently warm nor cool – fabric weight and weave determine thermal properties.

Hollow-fiber rPET provides insulation (used in jackets). Lightweight knit rPET breathes well (used in athletic wear). The versatility is why you see rPET in both winter coats and summer sportswear.

Does Recycled Polyester Make You Hot?

Not necessarily. Modern athletic wear uses engineered rPET fabrics with excellent moisture-wicking properties. These actually help keep you cooler during exercise by moving sweat away from skin.

However, non-breathable rPET (like in rain jackets) can trap heat. The fabric construction matters more than the rPET material itself.

What Are the Coolest Fabrics to Wear?

For hot weather, natural breathable fabrics typically win:

- Linen: Best airflow and moisture absorption

- Cotton: Breathable and comfortable

- Bamboo: Moisture-wicking and soft

- Lightweight rPET: Moisture-wicking (but less breathable than natural fibers)

For athletic activities, modern moisture-wicking rPET performs better than cotton because it dries faster, preventing that clammy feeling.

Does Polyester Make You Sweat at Night?

Some people find polyester bedding uncomfortable because it doesn’t breathe as well as cotton or linen. The fabric can trap heat and moisture against skin. For sleepwear and sheets, natural fibers usually feel more comfortable.

That said, high-quality performance rPET with moisture-wicking technology can work for hot sleepers, especially in pajamas.

Can Recycled Polyester Get Wet?

Absolutely. rPET’s hydrophobic nature is actually an advantage. Water beads up on the surface rather than soaking in. This makes rPET perfect for:

- Swimwear

- Rain jackets (with DWR coating)

- Athletic wear

- Outdoor gear

- Bags and backpacks

rPET dries much faster than cotton or wool, maintaining performance even when wet.

Frequently Asked Questions

Is Recycled Polyester Safe to Wear?

Yes, rPET is safe to wear. The recycling process involves high heat that sterilizes materials and removes contaminants. Finished fabrics undergo testing to ensure they meet safety standards. Any concerns about chemicals apply equally to virgin polyester.

The main health consideration is skin sensitivity. Some people find synthetic fabrics less comfortable than natural fibers, particularly for prolonged skin contact. This isn’t a safety issue – just a comfort preference.

Is Recycled Polyester Good for the Body?

rPET performs well for athletic wear due to moisture-wicking properties. It moves sweat away from skin, helping regulate body temperature during exercise. For everyday wear, natural fibers like cotton often feel more comfortable against skin, especially for people with sensitivities.

Does Recycled Polyester Have Microplastics?

Yes. All synthetic fabrics shed microplastics during washing. Research shows rPET sheds approximately 31% more microfibers than virgin polyester due to shorter fiber lengths from the recycling process. This is a legitimate environmental concern that needs addressing through filtering technology, washing practices, and development of biodegradable alternatives.

Is Polyester Good for Skin?

Polyester is generally safe but not ideal for sensitive skin. It doesn’t breathe as well as natural fibers, which can cause irritation for some people. The fabric can trap heat and moisture, potentially leading to rashes or discomfort during prolonged wear.

For people without sensitivities, modern performance polyester works well, especially for athletic activities. Always wash new garments before wearing to remove any processing chemicals.

Why Do People Not Like Polyester Fabric?

Common complaints include:

- Less breathable than natural fibers

- Can feel plasticky or synthetic

- Static electricity buildup

- Holds odors more than natural fibers

- Environmental concerns (microplastics, petroleum-based)

- Doesn’t feel as “natural” against skin

However, modern polyester has improved significantly. High-quality performance fabrics address many of these issues.

Is 100% Polyester Bad for You?

No, 100% polyester isn’t inherently harmful to health. It’s been used safely in clothing for decades. The “bad” reputation comes from comfort and environmental concerns rather than health risks.

People with sensitive skin might prefer natural fibers, but most people can wear 100% polyester without issues.

What Are the Disadvantages of Polyester?

Main drawbacks include:

- Microplastic pollution: Sheds plastic fibers during washing

- Not biodegradable: Takes hundreds of years to break down

- Less breathable: Can feel clammy in hot weather

- Holds odors: Bacteria thrives on synthetic fibers

- Static prone: Clings to body and other fabrics

- Heat sensitive: Can melt or damage from high heat

- Petroleum-based: Virgin polyester relies on fossil fuels

What Are the Disadvantages of Recycled Polyester?

Specific concerns with rPET:

- Higher microplastic shedding: Releases about 31% more microfibers than virgin polyester

- Quality variability: Mechanically recycled rPET may be slightly lower quality

- Color consistency issues: Harder to achieve uniform colors

- Still non-biodegradable: Recycling doesn’t solve end-of-life issues

- Limited recyclability: Currently difficult to recycle textiles back into textiles

- Bottle competition: Creates supply issues with beverage industry

What Are the Benefits of Recycled Polyester?

Advantages include:

- 59% less energy use compared to virgin polyester

- 90% reduction in water consumption

- 32% lower carbon emissions

- Diverts plastic waste from landfills and oceans

- Performance equal to virgin polyester

- Durability and water resistance

- Wrinkle resistance and easy care

- Cost-effective sustainable option

Is Recycled Polyester Better Than 100% Polyester?

From an environmental standpoint, yes – rPET uses significantly less energy, water, and produces fewer emissions. Performance-wise, chemically recycled rPET matches virgin quality. Mechanically recycled rPET may be slightly lower quality but works fine for most applications.

The microplastics issue affects both equally (actually worse for rPET), so neither wins there.

Is Cotton or Polyester Better?

This depends entirely on the application:

Choose cotton for: Everyday comfort, breathability, natural feel, sensitive skin, items worn close to body

Choose polyester for: Athletic performance, durability, water resistance, quick drying, wrinkle-free travel clothing, outdoor gear

Many garments use blends to get benefits of both.

Is Recycled Polyester Similar to Cotton?

No, they’re fundamentally different. Cotton is a natural plant fiber that breathes well and biodegrades. rPET is a synthetic plastic fiber that wicks moisture and dries quickly. They feel different, perform differently, and serve different purposes.

Cotton feels soft and natural. Polyester feels smooth and slightly synthetic. Neither is universally better – just different tools for different jobs.

What is the Warmest Natural Fabric?

Wool, particularly merino wool, provides the best warmth-to-weight ratio among natural fibers. Other warm natural options include:

- Down (technically natural, from birds)

- Cashmere

- Alpaca

- Mohair

These all outperform plant-based fibers like cotton for insulation.

Will Recycled Polyester Stretch?

Pure rPET has minimal stretch – typically 2-5% give from the weave structure. For garments needing stretch, manufacturers blend rPET with elastane (spandex). Common blends include:

- 95% rPET / 5% elastane: Light stretch for activewear

- 88% rPET / 12% elastane: Moderate stretch for fitted clothing

The rPET itself doesn’t stretch much, but the fabric construction and blending can create stretch properties.

How Does Using Recycled Materials in Clothing Reduce Environmental Harm?

Repurposing post-consumer plastics like water bottles diverts waste from landfills and oceans. This lowers greenhouse gas emissions by 32% and reduces reliance on virgin petroleum extraction. One ton of rPET saves three barrels of crude oil while using 59% less energy and 90% less water than virgin production.

Can Recycled Fabrics Match the Performance of New Synthetics?

Yes. Modern mechanical and chemical recycling processes preserve fiber strength. Chemical recycling produces virgin-equivalent quality. Rigorous testing ensures moisture-wicking and durability standards meet consumer expectations. Brands like Adidas and Patagonia prove rPET performs just as well as virgin polyester in demanding applications.

What Obstacles Hinder Large-Scale Adoption of Recycled Textiles?

Key barriers include:

- Contamination during waste collection

- Limited textile-to-textile recycling infrastructure

- Color consistency challenges

- Higher initial costs for chemical recycling

- Supply competition with beverage industry

- Need for improved sorting technologies

Brands collaborate with suppliers to improve sorting technologies and scale chemical recycling methods that restore polymers to virgin-like quality.

How Does Recycling Plastics Into Apparel Support Sustainability Goals?

Converting single-use items into long-lasting garments extends material lifecycles. This approach reduces ocean pollution and aligns with global frameworks like the UN’s Sustainable Development Goals, encouraging responsible production across supply chains. The circular economy model keeps materials in use instead of becoming waste.

Conclusion

Recycled polyester represents both promise and complexity in sustainable fashion. The numbers look compelling: 59% less energy, 90% less water, and 32% fewer carbon emissions compared to virgin polyester. With the market projected to reach $36.39 billion by 2034, rPET clearly has momentum.

But this isn’t a simple good-versus-bad story. While rPET reduces plastic waste and resource extraction, it comes with real challenges. The microplastics issue matters – rPET sheds about 31% more plastic fibers than virgin polyester during washing. These particles end up in oceans, drinking water, and even our bodies. That’s not a problem we can ignore.

The supply battle between textile manufacturers and the beverage industry highlights another issue. Both industries competing for the same plastic bottles isn’t sustainable long-term. The solution lies in textile-to-textile recycling, and companies like Syre, Samsara Eco, and Reju are showing the way forward with billion-dollar investments.

Here’s what matters going forward:

For Consumers

- Look for GRS certification to verify sustainability claims

- Use Guppyfriend bags or washing machine filters to catch microplastics

- Choose rPET for items that need less frequent washing (jackets, bags, outdoor gear)

- Wash in cold water, skip pre-wash cycles, and air dry when possible

- Support brands investing in textile-to-textile recycling

For the Industry

- Prioritize textile-to-textile recycling over bottle-to-fiber systems

- Invest in chemical and enzymatic recycling technologies that produce virgin-quality fibers

- Design for recyclability from the start

- Develop stronger collection and sorting infrastructure

- Research biodegradable alternatives to synthetic fibers

- Address microplastics through better fiber engineering

The Bigger Picture

rPET is better than virgin polyester, but it’s not the final answer. The real goal is creating truly circular systems where textiles continuously become new textiles without quality loss or environmental harm. We’re seeing the foundations of this system with companies achieving 98% material recovery rates.

The 2025 Recycled Polyester Challenge pushes the industry toward 45% recycled content, with 90% targeted by 2030. These goals drive innovation, but success requires solving the textile-to-textile puzzle and addressing microplastics.

Think of rPET as a transition technology. It’s significantly better than virgin polyester and helps reduce plastic waste now. But the industry needs to keep pushing toward biodegradable alternatives, closed-loop systems, and materials that don’t shed microplastics.

Making Smart Choices

Don’t let perfect be the enemy of good. rPET isn’t flawless, but it’s a step forward. When shopping, consider the full lifecycle:

- What will the garment be used for? (Athletic wear, everyday clothing, outdoor gear)

- How often will it need washing? (Less washing = less microplastic shedding)

- Does the brand use GRS-certified materials?

- Are they investing in closed-loop systems?

- What happens to the garment at end of life?

The future of sustainable textiles involves multiple solutions: rPET for performance applications, organic cotton for comfort items, innovative materials like plant-based polyester, and continued development of genuinely circular systems.

We’re not there yet, but the combination of consumer demand, regulatory pressure, and technological innovation is pushing the industry in the right direction. The $600 million investments in textile recycling, new microfiber filter regulations, and growing adoption of GRS certification all point toward meaningful change.

The question isn’t whether recycled polyester is perfect – it’s not. The question is whether it moves us closer to a sustainable textile industry. The answer is yes, as long as we keep pushing for better solutions and remain honest about the challenges that still need solving.

Interactive Tools

Plan your sustainable wardrobe with our free calculators:

- Fabric Cost Comparison Calculator – Compare cotton vs polyester total ownership costs

- Fabric Durability Calculator – Calculate clothing lifespan and value

- Fabric Care Calculator – Get personalized washing instructions