Everything you need to know about choosing, using, and maintaining spun polyester fabric for your projects

Table of Contents

- What is Spun Polyester Fabric?

- Spun vs. Regular Polyester: Key Differences

- Properties and Technical Specifications

- How Spun Polyester is Made

- Applications and Uses

- Care and Maintenance Guide

- Certifications and Sustainability

- Flame Retardancy Standards

- Common Problems and Solutions

- Buyer’s Guide and Selection Criteria

- Frequently Asked Questions

- Conclusion

Modern textile manufacturing combines strength with comfort, and spun polyester stands as one of the industry’s most practical solutions. This synthetic fabric serves businesses and consumers across multiple sectors, from hospitality table linens to outdoor furniture and professional uniforms.

With a breaking strength of 15,775 pounds and weighing just 0.22 pounds per unit, this material delivers performance where you need it. The fabric resists UV exposure for over 1,000 hours while maintaining 98% color retention. These metrics matter when you’re selecting materials for projects that need to last.

You’ll find this guide covers everything from technical specifications to daily care, helping you make smart decisions about fabric selection. Whether you’re outfitting a restaurant, updating outdoor cushions, or choosing materials for a sewing project, understanding spun polyester’s capabilities saves time and money.

What is Spun Polyester Fabric?

Spun polyester is a synthetic textile made by cutting polyester filaments into short fibers (called staple fibers), then twisting them together into yarn. Unlike regular polyester, which uses continuous filament strands, this manufacturing process creates a fabric with a softer, more natural texture similar to cotton.

Material Composition and Fiber Structure

The base material is polyethylene terephthalate (PET), the same type of plastic used in water bottles and food packaging. When manufacturers create spun polyester, they:

- Extrude polyester into long filaments

- Cut these filaments into 1-3 inch lengths

- Align and twist the short fibers together

- Create yarn that can be woven or knitted into fabric

Some spun polyester features a dual-layer construction where polypropylene cores are wrapped in polyester strands. This hybrid design adds structural strength while keeping the soft surface texture that makes the fabric comfortable against skin.

Quick Answer: Is polyester spun plastic? Yes. Polyester is a petroleum-based plastic polymer that’s transformed into fiber through heat and extrusion. While it’s technically plastic, the manufacturing process creates soft, fabric-like fibers that work well in textiles.

Core Characteristics

The fabric stands out for three main reasons:

Consistency: Each production run delivers uniform thickness and quality. Unlike cotton’s organic structure, manufacturing controls eliminate natural variations.

Moisture resistance: The fabric repels water rather than absorbing it. This hydrophobic property prevents mildew growth in humid settings and speeds drying time after washing.

Chemical stability: You can expose spun polyester to industrial solvents and cleaning agents without material degradation. This makes it practical for commercial kitchens and medical facilities where strong cleaners are standard.

Spun vs. Filament Structure

Think of it this way: regular filament polyester works like fishing line – one continuous, smooth strand. Spun polyester is more like cotton thread – many short fibers twisted together. This structural difference creates the softer hand feel people prefer in clothing and home textiles.

Spun vs. Regular Polyester: Key Differences

Understanding what separates spun polyester from regular (filament) polyester helps you choose the right material for your needs. The two fabrics start from the same base material but take different manufacturing paths that affect their performance. Use our fabric identification quiz to test your knowledge of different fabric types.

Texture and Feel

Spun polyester feels softer and more natural, similar to cotton poplin or muslin. The twisted short fibers create a slightly rougher surface that many find more comfortable. Regular filament polyester has a smooth, almost slippery feel that can seem artificial or plastic-like against skin.

When you run your hand across both fabrics, spun polyester has more texture and drape, while filament polyester stays crisp and sleek.

Strength and Durability

Filament polyester wins on pure tensile strength. Those continuous fibers can handle more stress before breaking. But here’s the trade-off: spun polyester resists abrasion better in everyday use. The twisted fiber structure holds up well to rubbing and friction, making it better for furniture upholstery or uniforms that see constant wear.

For applications needing maximum strength (like industrial straps or technical gear), filament works best. For comfort and daily durability, spun delivers.

| Feature | Spun Polyester | Regular/Filament Polyester |

|---|---|---|

| Fiber Type | Short staple fibers (1-3 inches) | Continuous filament strands |

| Texture | Soft, cotton-like, matte finish | Smooth, slippery, shiny |

| Tensile Strength | Good | Excellent |

| Abrasion Resistance | Excellent | Good |

| Breathability | Better (more air pockets) | Less breathable |

| Cost | Lower production cost | Higher production cost |

| Best For | Apparel, home textiles, table linens | Technical gear, outdoor equipment |

| Pilling Risk | Higher (short fibers can work loose) | Lower |

Appearance and Finish

Spun polyester has a matte, natural-looking finish that blends well in home decor and clothing. Filament polyester tends to have more shine and looks distinctly synthetic. If you want fabric that looks and feels less “plastic,” spun is your choice.

Cost Considerations

Spun polyester typically costs less to produce than filament polyester. The manufacturing process is simpler, which translates to lower prices for buyers. You’ll see this reflected in the SKU 3351 pricing flexibility mentioned earlier, ranging from $2.25 to $1,348.20 depending on order volume and specifications.

When to Choose Each Type: Pick spun polyester for clothing, restaurant linens, curtains, and furniture where comfort matters. Choose filament polyester for outdoor gear, industrial applications, and technical products where maximum strength is needed.

What About Core Spun Polyester?

Core spun polyester combines both types. It features a filament polyester core wrapped in spun polyester fibers. This gives you the strength of continuous filaments with the soft feel of spun fibers. It’s popular for sewing thread where you need both durability and a matte finish.

Is spun polyester better than core spun polyester? Not necessarily – they serve different purposes. Core spun offers superior strength for high-stress seams, while 100% spun polyester provides better drape and softness for fabrics.

Properties and Technical Specifications

When you’re selecting materials for commercial or personal projects, specific performance data helps you make the right choice. Here’s what spun polyester delivers in measurable terms.

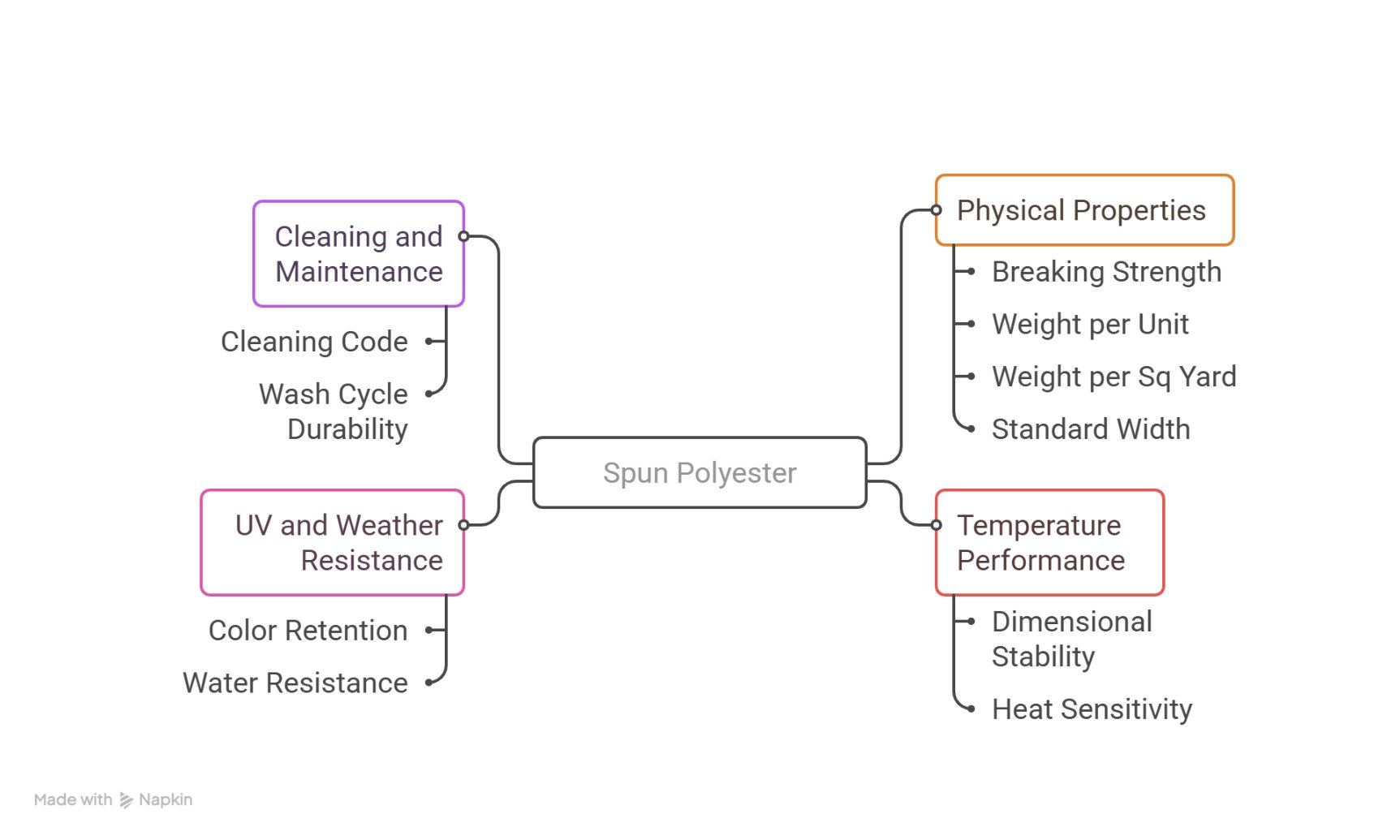

Physical Properties

Temperature Performance

The fabric maintains dimensional stability across a wide range: -40°F to 190°F (-40°C to 88°C). This means you won’t see warping or shrinking through normal seasonal temperature changes. Contractors report 94% less shrinkage compared to untreated natural alternatives during seasonal transitions.

Heat Sensitivity: While spun polyester resists everyday temperatures, it will melt if exposed to direct heat above 300°F (149°C). Keep irons on low settings and avoid placing the fabric near open flames or extremely hot surfaces.

UV and Weather Resistance

Lab tests show spun polyester retains 98% of its color after 1,000 hours of direct sunlight exposure. In real-world conditions, this translates to five years or more of outdoor use with less than 2% fading. The UV-resistant formula prevents the brittleness and fiber breakdown that damages untreated fabrics.

Is spun polyester waterproof? No, but it’s water-resistant. The fabric repels moisture due to its hydrophobic nature, but it’s not completely waterproof like treated water-resistant fabrics or vinyl-coated materials. Water beads up on the surface rather than soaking through immediately, giving you time to wipe spills.

Cleaning and Maintenance Specs

The fabric carries a WB cleaning code, meaning you can clean it with water-based solutions or professional dry cleaning. This versatility makes maintenance easier compared to S-coded fabrics that require solvent-only cleaning.

After 200+ wash cycles, spun polyester maintains its structural integrity, texture, and color vibrancy. This durability keeps the fabric looking new far longer than natural alternatives that fade and weaken with repeated washing.

Performance Ratings

| Property | Spun Polyester | Industry Standard |

|---|---|---|

| Color Retention (5 years) | 98% | 75% (untreated cotton) |

| Shrinkage Rate | 6% or less | 15-20% (cotton) |

| Static Buildup | Low-moderate | Variable |

| Pilling Resistance | Moderate | Good to Excellent |

Is Spun Polyester Strong?

Yes. With a 15,775-pound breaking strength, spun polyester handles heavy-duty applications effectively. While it’s not quite as strong as filament polyester or materials like nylon (which averages 12,400 lbs), it exceeds the strength requirements for most commercial and residential uses.

Stretch and Elasticity

Does polyester stretch? Pure spun polyester has minimal stretch – typically less than 5% elasticity. If you need stretch, look for polyester spandex blends (also called polyester-elastane). These combine spun polyester with 2-10% spandex fibers to create fabrics that move with your body, popular in athletic wear and comfortable clothing.

How Spun Polyester is Made

Understanding the manufacturing process helps explain why spun polyester performs differently than other synthetics. The journey from raw material to finished fabric involves several precise steps.

Step 1: Fiber Preparation

Polyester chips or pellets (made from petroleum) are melted at high temperatures (around 280°C). This molten polyester is forced through a spinneret – imagine a showerhead with tiny holes. As the liquid polyester streams through these holes, it cools and solidifies into long filaments.

These continuous filaments are then cut into short lengths, typically 1-3 inches. These short pieces are called staple fibers. The length of these fibers affects the final fabric’s texture and performance.

Step 2: Carding

The staple fibers go through a carding machine, which separates and aligns them. Think of it like brushing tangled hair – the fibers come out parallel and ready for the next step. This process creates a thin web of aligned fibers.

Step 3: Spinning

This is where the magic happens. The carded fibers are twisted together to form continuous yarn. The amount of twist determines the yarn’s strength and texture. More twist creates stronger, tighter yarn. Less twist produces softer, more flexible yarn.

The spinning creates the fabric’s characteristic matte finish and cotton-like feel. Unlike filament polyester where smooth strands simply lie next to each other, spun polyester’s twisted structure creates texture and air pockets.

Step 4: Weaving or Knitting

The spun yarn moves to weaving or knitting machines that create the final fabric structure. Weaving produces stable, structured fabrics good for table linens and upholstery. Knitting creates more flexible fabrics better for clothing and drapery.

Manufacturers can adjust spinning parameters to create different fabric weights and textures. Lightweight meshes work well for summer clothing, while heavy-duty textiles suit industrial applications.

What is Spunbond Polyester?

Don’t confuse spun polyester with spunbond (also called spunbonded) polyester. Spunbond is a nonwoven fabric where fibers are bonded directly after extrusion, without the spinning step. It’s used for disposable medical garments, filters, and insulation – different applications than traditional spun polyester textiles.

What is Ring Spun Polyester?

Ring spun polyester uses a specific spinning method where fibers pass through a ring that adds extra twist. This creates stronger, smoother yarn than standard spinning methods. The process costs more but produces higher-quality fabric with better durability and a softer hand.

Manufacturing Efficiency: Spun polyester production is relatively quick and cost-effective. A single spinning line can produce 50-300 tonnes per day, making it one of the more economical synthetic fabrics to manufacture.

Applications and Uses

Spun polyester’s combination of durability, comfort, and low maintenance makes it practical across numerous settings. Here’s where you’ll find it and why it works in each application.

Commercial and Hospitality

Hotels, restaurants, and event venues rely on spun polyester for good reasons. The fabric withstands frequent washing (critical in food service) while maintaining its appearance through hundreds of cycles.

Table Linens: Restaurants use spun polyester tablecloths because they resist staining better than linen and need less ironing than cotton. The 54-inch width reduces cutting waste by 18% compared to narrower fabrics, saving money on large orders.

Uniforms: Healthcare facilities and hospitality staff benefit from uniforms that survive daily washing with strong detergents. The fabric keeps its color and shape after repeated cleaning, reducing replacement costs.

Drapery and Curtains: Hotels choose spun polyester curtains for their room-darkening properties and shape retention. Unlike natural fibers that sag over time, this fabric maintains crisp lines for years.

Home and Interior Use

For residential settings, spun polyester offers practical benefits without the “plastic” feel of some synthetics.

Upholstery: Furniture covered in spun polyester holds up to daily use, pet wear, and occasional spills. The fabric resists fading from sunlight streaming through windows, keeping your sofa looking newer longer.

Bedding: While not as breathable as cotton, polyester-blend bedding offers wrinkle resistance and easy care. The fabric dries quickly after washing, meaning you can strip and remake beds in hours, not days.

Throw Pillows: The fabric’s resistance to dust mites and mildew makes it better for people with allergies compared to down or cotton fills that harbor allergens.

Outdoor Applications

The fabric’s weather resistance extends its usefulness outdoors.

Patio Furniture: Outdoor cushions face sun, rain, and temperature swings. Spun polyester handles these conditions while remaining comfortable to sit on. The quick-dry properties mean cushions are ready to use shortly after rain.

Awnings and Shade Structures: The UV-resistant formula maintains integrity through years of sun exposure. Commercial buildings use it for entrance awnings and outdoor dining areas where durability matters.

Protective Covers: Boat covers, grill covers, and equipment tarps made from spun polyester protect against weather while being lighter and easier to handle than canvas alternatives.

Apparel

The soft texture makes spun polyester work well in clothing, especially when blended with other fibers.

Workwear: Uniforms for manufacturing, construction, and service industries use spun polyester or poly-cotton blends. The fabric resists abrasion and maintains professional appearance through tough conditions. Learn more about polyester in children’s clothing for additional insights on fabric applications.

Activewear: While pure polyester isn’t as breathable as cotton, its moisture-wicking properties pull sweat away from skin. Many athletic shirts use spun polyester because it dries faster than cotton during workouts.

Casual Wear: T-shirts, polo shirts, and casual pants often blend spun polyester with cotton. A 65% polyester/35% cotton mix gives you wrinkle resistance with better breathability than 100% synthetic.

Industrial Uses

Beyond consumer applications, spun polyester serves technical purposes.

Filters: Industrial air and liquid filters use spun polyester for its consistent fiber structure and chemical resistance. The material captures particles effectively while withstanding harsh cleaning processes.

Banners and Signage: Outdoor advertising banners need to survive wind and weather. Spun polyester provides the durability while accepting printed graphics well.

Medical Textiles: Some medical applications use spun polyester for its cleanability and resistance to bacterial growth. Hospital privacy curtains and patient gowns benefit from easy sterilization.

Seasonal Considerations

Is spun fabric good for summer? It’s decent but not ideal. The moisture-wicking properties help, but spun polyester isn’t as breathable as natural fibers like cotton lawn or linen. For hot weather, look for lightweight spun polyester blends with natural fibers that improve air circulation. Check our seasonal fabric quiz to find the best materials for your climate.

Is spun fabric good for winter? Better than for summer. The fabric provides some insulation while resisting moisture. Layered with other materials, it works well in cold weather clothing.

Care and Maintenance Guide

Proper care keeps spun polyester looking good and extends its lifespan. The good news: this fabric is easier to maintain than most natural alternatives. Use our fabric care calculator for personalized washing instructions based on your specific items.

Washing Instructions

- Check the care label first. While these are general guidelines, always follow manufacturer recommendations on your specific item.

- Sort by color. Wash dark colors separately from lights to prevent any color transfer, though spun polyester is more colorfast than cotton.

- Turn garments inside out. This protects the outer surface from friction and reduces pilling.

- Use cool or warm water (30-40°C/86-104°F). Hot water isn’t necessary and can weaken synthetic fibers over time.

- Select gentle cycle. Standard cycle works fine for most items, but gentle cycle reduces wear on delicate pieces.

- Use mild detergent. You don’t need special detergent – standard laundry soap works well. Avoid bleach and harsh stain removers that can damage fibers.

- Skip fabric softener. It leaves residue on synthetic fabrics that reduces their moisture-wicking abilities and can make them feel greasy.

Does spun polyester shrink? Minimal shrinkage occurs – typically 6% or less. Pre-washing fabric before cutting for sewing projects eliminates most shrinkage risk.

Pro Tip: To reduce microplastic pollution, wash polyester items in a Guppyfriend bag or similar filter product. These capture tiny plastic fibers before they enter waterways. Also, wash full loads less frequently rather than many small loads.

Drying Methods

Air Drying (Recommended): Hang items to dry naturally. Spun polyester dries quickly – usually in a few hours. This method saves energy and prevents heat damage.

Machine Drying: If using a dryer, select low or medium heat. High heat can melt synthetic fibers or cause permanent wrinkles. Remove items while slightly damp to prevent over-drying.

Never leave polyester fabrics in a hot dryer or exposed to direct heat sources for extended periods. The synthetic fibers will melt at high temperatures.

Ironing and Pressing

Can you iron spun polyester? Yes, but carefully:

- Set iron to low or synthetic setting (110°C/230°F maximum)

- Place a thin cloth between iron and fabric

- Avoid steam, which can cause water spots

- Iron on the reverse side when possible

The good news: spun polyester resists wrinkling better than natural fibers. Many items come out of the washer nearly wrinkle-free and need no ironing if hung immediately.

Stain Treatment

Spun polyester’s hydrophobic nature makes many stains easier to remove than on absorbent natural fibers.

- Blot (don’t rub) fresh stains immediately. The water-resistant surface gives you time before stains set.

- Apply mild detergent directly to the stain. Work it gently with your fingers.

- Let sit for 5-10 minutes.

- Rinse with cool water.

- Wash normally. Most stains release during regular washing.

For oil-based stains, use a small amount of dish soap before washing. For stubborn stains, pre-treat with a commercial stain remover safe for synthetics.

Storage Tips

- Store in a cool, dry place away from direct sunlight

- Fold rather than hanging heavy items to prevent stretching

- Keep away from heat sources (radiators, heating vents)

- Ensure items are completely dry before storage to prevent mildew

Professional Cleaning

For large items like curtains or upholstered furniture, professional cleaning works well. The WB cleaning code means professionals can use water-based or dry-cleaning methods. Discuss the best approach with your cleaner based on the item’s construction and any staining.

Commercial Laundry Settings

For hospitality and healthcare facilities washing large quantities:

- Alkalinity in wash cycle should be 650-1,500 ppm Na2O

- Avoid fluorescent whitening agents (FWAs) which can cause yellowing

- Adjust starch levels based on desired stiffness (8-12 oz typical)

- Maintain pH between 5.5-6.5 in final rinse

For detailed guidance on caring for synthetic fabrics, check our complete care guide.

Certifications and Sustainability

When you’re sourcing spun polyester for projects, certifications tell you what you’re really getting. These third-party verifications confirm quality, safety, and environmental claims.

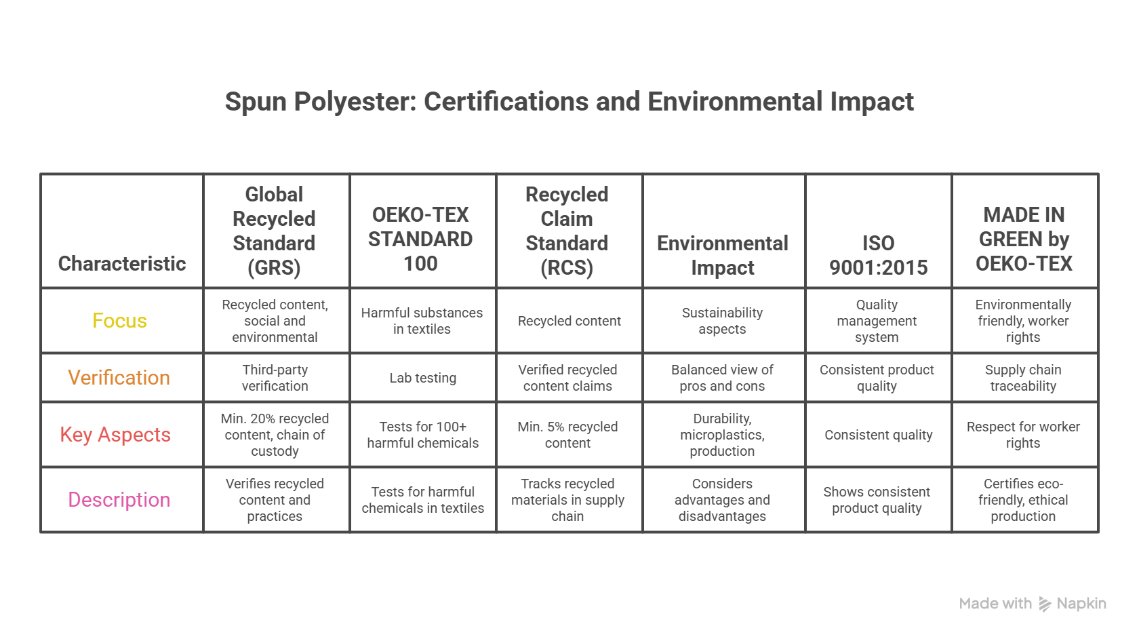

Global Recycled Standard (GRS)

GRS certification verifies recycled content in products while tracking environmental and social practices throughout production. The standard requires:

- Minimum 20% recycled material content (50% for consumer-facing labels)

- Third-party verification of recycled content claims

- Chain of custody documentation from source to final product

- Social and environmental compliance at all production stages

- Chemical restrictions to minimize environmental harm

When you see GRS-certified spun polyester, you know the material contains verified recycled content, often from post-consumer plastic bottles. This reduces petroleum demand and diverts plastic from landfills. Learn more about sustainable polyester alternatives.

OEKO-TEX STANDARD 100

This certification tests textiles for harmful substances. OEKO-TEX labs check for over 100 regulated and unregulated chemicals that could affect human health, including:

- Formaldehyde

- Heavy metals (lead, cadmium, nickel)

- Pesticides and herbicides

- Chlorinated phenols

- Phthalates

- Allergenic dyes

The certification divides products into classes based on skin contact level. Class I covers baby products, Class II covers direct skin contact items, and Classes III and IV cover other textiles. When buying spun polyester for baby clothing or bedding, look for OEKO-TEX certification.

Recycled Claim Standard (RCS)

RCS tracks recycled materials through the supply chain but doesn’t include the social and environmental requirements of GRS. Products need minimum 5% recycled content for RCS certification. It’s less strict than GRS but still provides verified recycled content claims.

Environmental Considerations

Is spun polyester sustainable? It depends on your definition. Here’s the balanced view:

Advantages:

- Durable material lasts years, reducing replacement frequency

- Recycled versions divert plastic from landfills

- Requires less water to produce than cotton

- Low maintenance means less water and energy for washing

- Resistant to mildew and pests without chemical treatments

Concerns:

- Made from petroleum, a non-renewable resource

- Not biodegradable (takes hundreds of years to break down)

- Releases microplastics when washed

- Energy-intensive production process

- Can’t be composted at end of life

Making Better Choices: Look for GRS-certified recycled spun polyester when possible. Wash less frequently and use microfiber-catching products. Buy quality items that will last rather than cheap products you’ll replace quickly. At end of life, see if textile recycling programs in your area accept polyester.

Other Relevant Certifications

ISO 9001:2015: Quality management system certification showing consistent product quality.

MADE IN GREEN by OEKO-TEX: Certifies products made in environmentally friendly facilities that respect worker rights, with full supply chain traceability.

When sourcing spun polyester for commercial use, ask suppliers about their certifications. Legitimate certificates include numbers you can verify online through the certifying organization’s database.

Flame Retardancy Standards

For commercial spaces, flame retardancy isn’t optional. Many state and local fire codes require flame-resistant fabrics in public buildings. Here’s what you need to know about fire-resistant fabric standards for spun polyester.

NFPA 701 Certification

NFPA 701 is the national standard developed by the National Fire Protection Association for flame propagation testing of textiles and films. Most states and cities accept this certification for curtains, draperies, and hanging textiles in public spaces including:

- Schools and universities

- Theaters and auditoriums

- Churches and places of worship

- Hotels and restaurants

- Healthcare facilities

- Office buildings

The test exposes fabric to a 12-second flame and measures after-flame time, char length, and flaming residue. Fabrics pass when they self-extinguish within 2 seconds after flame removal and meet char length limits.

Types of Flame Retardancy

FR (Flame Retardant): Topically treated after weaving with chemical fire retardants. This treatment wears off over time with washing and exposure. FR certification typically lasts one year and requires periodic retesting and retreatment.

IFR/PFR (Inherently/Permanently Flame Retardant): The flame-resistant properties are built into the fiber itself during manufacturing. These properties last for the life of the fabric and don’t diminish with washing. More expensive but better for long-term installations.

Some spun polyester is inherently flame retardant because polyester fibers are self-extinguishing. However, not all spun polyester automatically passes NFPA 701. The fabric construction, weave density, and finishing affect fire performance.

Common Misconception: Many assume all polyester fabrics pass fire safety tests because polyester yarns are self-extinguishing. This isn’t true. The fabric construction matters. Always verify certification rather than assuming polyester equals fire-safe.

Other Fire Safety Standards

NFPA 260: Required for commercial upholstery fabrics. Tests resistance to cigarette ignition.

California Technical Bulletin 117 (CAL 117): Standard for upholstered furniture flammability in California, but widely adopted elsewhere.

CPAI-84: Specifically for tents and camping fabric flammability.

British Standards (BS 5867, BS 7175): UK and European fire safety standards for curtains and upholstery.

Certificate of Flame Retardancy

When ordering flame-retardant spun polyester for commercial installation:

- Request a Certificate of Flame Retardancy with your order

- Verify the certificate shows the specific standard met (NFPA 701, etc.)

- Check that the fabric type matches what you’re receiving

- Keep certificates on file for fire marshal inspections

Some venues require you to present fire certificates before installation. Restaurant and theater owners should confirm local requirements with their fire marshal before ordering materials.

Maintenance of Fire Retardancy

For FR-treated (not IFR) fabrics:

- Follow care instructions precisely to preserve treatment

- Avoid harsh detergents and bleach that dissolve FR chemicals

- Retest fabric every 1-3 years depending on use and local codes

- Retreat as needed to maintain certification

IFR fabrics require no special maintenance beyond normal cleaning. The fire resistance is permanent.

Common Problems and Solutions

Even durable fabrics like spun polyester encounter issues. Here’s how to address the most common problems you’ll face.

Pilling

The Problem: Small balls of fiber form on the surface, making fabric look worn and fuzzy. Pilling happens when short fibers work loose and tangle together during wear and washing.

Prevention:

- Turn garments inside out before washing

- Use gentle cycle and avoid overcrowding the washer

- Wash with similar fabrics (don’t mix with rough textures like denim)

- Avoid excessive rubbing or friction during wear

Treatment:

- Use a fabric shaver or pill remover to gently cut away pills

- A sweater stone can remove pills from upholstery

- Never pull pills by hand – this creates more loose fibers

Static Buildup

The Problem: Synthetic fabrics generate static electricity, causing clothes to cling and attract lint.

Solutions:

- Add 1/4 cup white vinegar to the rinse cycle (natural fabric softener alternative)

- Use dryer balls instead of dryer sheets

- Hang dry when possible – tumble drying increases static

- Lightly mist with water or anti-static spray before wearing

- Run a metal hanger over the fabric surface

Odor Retention

The Problem: Polyester can trap body odors more than natural fibers, especially in activewear.

Solutions:

- Pre-soak items in a mixture of water and baking soda (1/4 cup per gallon) for 30 minutes

- Add 1/2 cup white vinegar to the wash cycle

- Wash items promptly after wearing – don’t let them sit

- Ensure items are completely dry before storage

- Avoid fabric softener, which can trap odors

Color Fading (Rare but Possible)

The Problem: While spun polyester resists fading better than natural fibers, extended sun exposure or harsh washing can dull colors.

Prevention:

- Wash dark colors inside out in cold water

- Use detergents designed for dark or bright fabrics

- Avoid chlorine bleach, which yellows polyester

- Limit direct sunlight exposure for stored items

- Remove from dryer promptly to prevent heat damage

Wrinkles from Heat

The Problem: Polyester can develop permanent wrinkles if exposed to high heat while wet or compressed.

Solutions:

- For fresh wrinkles: Hang in steamy bathroom or use handheld steamer

- For set wrinkles: Iron on low heat with pressing cloth

- Prevention: Remove from dryer while slightly damp and hang immediately

Melting or Heat Damage

The Problem: Contact with high heat (hot irons, hair straighteners, cigarettes) melts synthetic fibers, creating permanent damage.

Prevention:

- Always use low heat settings on irons and dryers

- Keep fabric away from open flames, heaters, and hot surfaces

- Use pressing cloths when ironing

- Be careful with hair styling tools when wearing polyester clothing

No Fix: Melted polyester cannot be repaired. Prevention is the only solution.

Stiffness After Washing

The Problem: Fabric feels stiff or scratchy after washing, especially commercial linens.

Solutions:

- Add 1/2 cup white vinegar to rinse cycle

- Reduce detergent amount (buildup causes stiffness)

- Ensure thorough rinsing – run extra rinse cycle if needed

- Tumble dry with dryer balls for softer finish

Buyer’s Guide and Selection Criteria

Choosing the right spun polyester for your project requires understanding several key factors. This guide helps you make informed decisions whether you’re buying for commercial installations or personal projects.

Weight Selection

Fabric weight determines durability, drape, and appropriate applications. Use a fabric weight calculator to determine the best GSM or oz/sq yard for your needs.

| Weight Category | Oz per Sq Yard | Best Applications |

|---|---|---|

| Lightweight | 3-6 oz | Summer clothing, sheer curtains, linings, lightweight scarves |

| Medium Weight | 6-8 oz | Table linens, casual clothing, general upholstery, indoor curtains |

| Heavy Weight | 8-12+ oz | Outdoor furniture, commercial upholstery, heavy-duty curtains, awnings |

When to Choose IFR vs. FR Treatment

Choose IFR (Inherently Flame Retardant) when:

- Installing in permanent commercial locations

- Long-term use is expected (5+ years)

- Frequent washing is required

- Budget allows for higher upfront cost

Choose FR (topically treated) when:

- Budget is tight and upfront costs matter

- Installation is temporary (events, short-term rentals)

- You can commit to periodic retreatment

- Washing will be infrequent

Certification Checklist

Before purchasing, verify these certifications based on your needs:

- For baby/children’s items: OEKO-TEX STANDARD 100 Class I certification (verify here)

- For eco-conscious buyers: GRS certification showing 50%+ recycled content (learn more)

- For public spaces: NFPA 701 Certificate of Flame Retardancy (check requirements)

- For direct skin contact items: OEKO-TEX Class II minimum

Questions to Ask Suppliers

When sourcing spun polyester, get clear answers to these questions:

- What’s the exact fiber composition? (100% polyester vs. polyester-polypropylene blend)

- Is this spun or filament polyester? (Don’t assume based on appearance)

- What certifications do you hold? (Request certificate numbers to verify)

- What’s the expected shrinkage rate? (Should be 6% or less)

- Is the fabric pre-shrunk? (Important for sewing projects)

- What’s the colorfastness rating? (Should maintain 95%+ after specified wash cycles)

- Do you provide samples? (Always test before large orders)

- What’s the minimum order quantity? (MOQ varies widely by supplier)

Cost Considerations

Calculate total ownership cost, not just purchase price. A fabric cost calculator helps you compare options:

- Initial cost per yard/meter

- Expected lifespan (spun polyester typically 5-7 years in commercial use)

- Maintenance costs (cleaning frequency, replacement cycles)

- Installation labor (especially for large commercial projects)

- Certification costs (if periodic retesting required for FR fabrics)

Pro Tip: For commercial projects, request at least 3 samples from different suppliers. Test each for hand feel, color accuracy, and how they perform with your intended cleaning methods before committing to large orders.

Comparing Polyester vs. Cotton

Still deciding between spun polyester and cotton? Here’s a direct comparison:

| Factor | Spun Polyester | Cotton |

|---|---|---|

| Durability | Excellent (5-7+ years commercial use) | Good (3-5 years, degrades faster) |

| Breathability | Moderate (less breathable) | Excellent (natural air circulation) |

| Moisture Handling | Wicks away, dries fast | Absorbs, slower drying |

| Wrinkle Resistance | Excellent | Poor (needs frequent ironing) |

| Shrinkage | Minimal (6% or less) | High (15-20% without treatment) |

| Cost | Lower to moderate | Moderate to high (especially organic) |

| Environmental Impact | Non-biodegradable, microplastics | Biodegradable, high water use in growing |

| Best For | Durability, easy care, outdoor use | Comfort, breathability, natural feel |

For a deeper comparison, see our guide on cotton vs. polyester fabric.

Special Fabric Types

What is spun polyester pique? Pique is a textured weave pattern creating small geometric patterns (often diamond or square shapes) with raised surfaces. Spun polyester pique combines the soft texture of spun fibers with pique’s distinctive pattern. It’s popular for polo shirts and sportswear because it adds visual interest while maintaining breathability through the textured weave.

Is polyester staple spun? The terms overlap but aren’t identical. “Staple” refers to short fiber lengths (1-3 inches). “Spun” describes the process of twisting these staples into yarn. So yes, spun polyester uses polyester staple fibers. However, you can have polyester staples that aren’t yet spun into yarn. The term “spun” specifically indicates the fibers have been twisted into usable yarn.

Frequently Asked Questions

Conclusion

Spun polyester delivers practical benefits across residential and commercial applications. The fabric’s 15,775-pound breaking strength, combined with its lightweight 0.22-pound-per-unit construction, provides durability without bulk. You get materials that maintain 98% color retention through five years of outdoor exposure while surviving 200+ wash cycles.

The manufacturing process – cutting polyester filaments into short fibers and twisting them into yarn – creates the soft, cotton-like texture that sets spun polyester apart from regular filament polyester. This structure gives you comfort without sacrificing the synthetic fabric’s inherent benefits: moisture resistance, chemical stability, and dimensional stability across temperature ranges from -40°F to 190°F.

Smart material selection requires understanding trade-offs. Spun polyester excels in durability, stain resistance, and low maintenance but falls short in breathability compared to natural fibers like cotton or linen. The fabric works best in applications where longevity and easy care outweigh the need for maximum air circulation. Restaurant table linens, outdoor furniture cushions, and commercial drapery benefit most from these properties.

Care requirements remain straightforward: wash in cool water (30-40°C), skip the fabric softener, air dry when possible, and use low heat if ironing becomes necessary. These simple steps preserve the fabric’s performance through years of use. For commercial applications requiring flame retardancy, verify NFPA 701 certification rather than assuming all polyester meets fire safety codes.

Sustainability concerns warrant attention. While polyester originates from petroleum and releases microplastics during washing, GRS-certified recycled options divert plastic bottles from landfills. The fabric’s durability means less frequent replacement, potentially offsetting some environmental impact through extended use cycles. Use microfiber-catching wash bags to reduce plastic particle pollution in waterways.

When comparing costs, factor in the total ownership picture. Initial prices range from $2.25 to $1,348.20 depending on specifications and volume, but the fabric’s longevity and minimal maintenance requirements often result in lower lifetime costs than cheaper natural alternatives requiring frequent replacement.

Key Takeaways

- Spun polyester offers cotton-like softness with synthetic durability, making it practical for both comfort and longevity

- The fabric maintains performance through extreme conditions: -40°F to 190°F temperature range, 1,000+ hours UV exposure, and 200+ wash cycles

- Choose spun over filament polyester when texture and comfort matter more than maximum tensile strength

- Proper care is simple: cool water, gentle cycle, air dry, low heat for ironing – avoid fabric softener and high heat

- Look for GRS certification for recycled content and OEKO-TEX for chemical safety, especially in items with direct skin contact

- NFPA 701 certification is required for commercial installations in public spaces – verify rather than assume compliance

- Prevent common issues (pilling, static, odor) through proper washing techniques: turn items inside out, use vinegar instead of softener, wash promptly after wearing

- Weight selection matters: lightweight (under 6 oz/sq yd) for summer wear and sheer applications, heavy (8-12 oz/sq yd) for outdoor furniture and high-traffic commercial use

- For stretch applications, look for polyester-spandex blends; pure polyester has less than 5% elasticity

- Use fabric calculators and selection tools to determine exact yardage needs and appropriate weight for your specific project

Your next steps depend on your application. For home projects, start by determining the weight and finish you need using a fabric weight calculator. Commercial buyers should request certification documentation and fabric samples before placing large orders. Always verify fire safety requirements with local authorities before installing fabrics in public spaces.

If you’re planning a sewing project, calculate exact fabric needs with our fabric yardage calculator. For help determining which synthetic fabric works best for your needs, try our interactive fabric selector tool.

Whether you’re sourcing materials for restaurant renovations, updating outdoor living spaces, or selecting fabrics for apparel production, spun polyester’s combination of performance, affordability, and ease of maintenance makes it worth consideration. The key lies in matching the fabric’s strengths to your specific requirements rather than expecting it to excel in every application.

For additional guidance on fabric selection, care techniques, and project planning, explore our related resources on natural versus synthetic fabrics and comprehensive fabric care methods.