Understanding bio-based fabrics, their benefits, limitations, and what they mean for the future of fashion

Table of Contents

- What Is Plant-Based Polyester?

- From Laboratory Discovery to Modern Innovation

- How Bio-Based Polyester Is Made

- The 30% Reality: Understanding Bio-Content

- Certifications and Standards

- Major Brands Using Bio-Based Materials

- The Microplastics Challenge

- Bio-Based vs Traditional vs Alternatives

- Performance and Durability

- Market Growth and Future Outlook

- Cost and Scalability

- End-of-Life and Recycling

- Common Questions About Polyester

- What to Look For When Shopping

- Frequently Asked Questions

The fashion industry stands at a turning point. With traditional polyester dominating over half the global textile market, the environmental cost has become impossible to ignore. Every year, 70 million barrels of oil go into polyester production alone. But what if there was a better way?

Bio-based polyester promises to break the petroleum cycle while maintaining the performance people expect from synthetic fabrics. This guide explores what plant-based polyester really is, how it’s made, which brands are using it, and most importantly, what it doesn’t solve.

What Is Plant-Based Polyester?

Plant-based polyester, also called bio-based PET (polyethylene terephthalate), is a synthetic fiber where at least one component comes from renewable plant sources instead of petroleum. The most common production method uses sugarcane waste to create monoethylene glycol (MEG), which then combines with terephthalic acid to form the final polymer.

Companies like Toray Industries pioneered this technology by converting molasses, a sticky byproduct from sugar refining, into functional textile fibers. Instead of sending agricultural waste to landfills, it gets transformed into clothing, activewear, and outdoor gear.

Key Point: Bio-based polyester is still polyester. It has the same molecular structure as conventional PET, which means it behaves identically in terms of durability, washability, and performance. The difference lies in where the raw materials come from, not what the final product is.

Does Polyester Come From a Plant?

Traditional polyester does not come from plants. It’s made from petroleum, specifically from crude oil derivatives like ethylene and p-xylene. However, bio-based polyester uses plant materials like sugarcane, corn, or other agricultural waste for part of its production.

What Fabric Is Plant-Based?

Several fabrics can be considered plant-based or bio-based:

- Natural plant fibers: Cotton, linen, hemp, bamboo

- Semi-synthetic plant fibers: Rayon, viscose, Tencel (lyocell), modal

- Bio-based synthetics: Bio-based polyester (partially), PLA (polylactic acid), PBS (polybutylene succinate)

Is There Such a Thing as Natural Polyester?

No, there is no such thing as “natural” polyester. All polyester is synthetic, meaning it’s manufactured through chemical processes. The term “natural” refers to fibers that grow in nature without chemical processing, like cotton or wool. Even bio-based polyester, while using plant materials as feedstock, requires extensive chemical processing to create the final polymer.

From Laboratory Discovery to Modern Innovation

The polyester story began in the 1930s when DuPont chemist W.H. Carothers discovered that mixing alcohol with carboxyl acids could form synthetic fibers. His early polymer lacked stability, but it sparked decades of research.

British scientists W.K. Birtwistle and C.G. Ritchie built on this work, creating Terylene, the first practical polyester fiber. DuPont marketed it as a “wrinkle-free miracle” in 1951, though early consumers rejected its stiff texture and artificial shine. Over time, manufacturers refined weaving techniques, transforming it into the soft, breathable fabric found in stores today.

Breaking Free From Fossil Fuels

Traditional polyester manufacturing starts with crude oil. Refineries break it into ethylene and p-xylene, which combine to form PET pellets. These pellets melt into fibers through high-heat extrusion. While effective, this process ties textile manufacturing directly to non-renewable resources.

Recent progress uses agricultural waste and recycled materials to create similar polymers. These methods copy PET’s durability while cutting reliance on petroleum. Brands now blend synthetic and natural fibers like cotton, balancing performance with environmental goals.

How Bio-Based Polyester Is Made

From Sugarcane Waste to Wearable Fiber

The production process starts at sugar refineries. After extracting sugar from sugarcane, what remains is molasses, a thick, dark syrup. Through fermentation (similar to making alcohol), this molasses becomes monoethylene glycol (MEG). This bio-based MEG replaces the petroleum-derived version used in traditional polyester.

Next, manufacturers combine the bio-MEG with terephthalic acid under intense heat and pressure. High-pressure reactors fuse these components into polyethylene terephthalate. The resulting polymer matches conventional PET’s molecular structure exactly, which ensures compatibility with existing manufacturing equipment.

Fiber Extrusion Process

Granulated bio-PET enters extrusion machines as marble-sized pellets. Heating transforms them into a thick liquid. Precision pumps force this molten material through spinnerets, which are metal plates with thousands of microscopic holes.

Modern spinnerets contain up to 10,000 openings. The hole diameter controls fiber thickness, while the shape affects texture. Some manufacturers use hexagonal nozzles to create hollow fibers that trap warmth for insulation.

The extruded threads cool rapidly before stretching. This drawing process aligns molecules, increasing strength. Factories then twist strands into yarn using about 40% less water than traditional methods. Energy recovery systems capture excess heat, reducing power demands.

The 30% Reality: Understanding Bio-Content

Important Limitation: Most commercial “bio-based” polyester is only about 30% bio-based. Only the MEG (monoethylene glycol) component typically comes from sugarcane or other plants, while terephthalic acid (which makes up roughly 70% of the polymer) still comes from petroleum.

This is one of the most misunderstood aspects of bio-based polyester. When brands advertise “plant-based polyester,” they’re usually referring to partially bio-based material, not 100% renewable content.

Researchers are working on bio-based terephthalic acid from agricultural waste like wheat straw and corn stover, but commercial production remains limited. Early trials use pine resin and corn starch as potential sources. Until bio-based terephthalic acid becomes widely available and cost-effective, the “70% petroleum problem” continues.

Why This Matters

The carbon footprint reduction from bio-based polyester is real but limited. Studies show bio-derived PET emits about 52% fewer greenhouse gases during production compared to fully petroleum-based versions. However, this benefit comes primarily from the 30% bio-based component, not from eliminating fossil fuels entirely.

| Factor | Bio-Based PET (Typical) | Traditional PET |

|---|---|---|

| Bio-Based Content | ~30% (MEG only) | 0% |

| Petroleum Content | ~70% (terephthalic acid) | 100% |

| CO2 Emissions | 2.1 kg per kg | 4.4 kg per kg |

| Recyclability | Same as traditional | Recyclable (degrades) |

| Microplastic Shedding | Identical to traditional | Yes, significant |

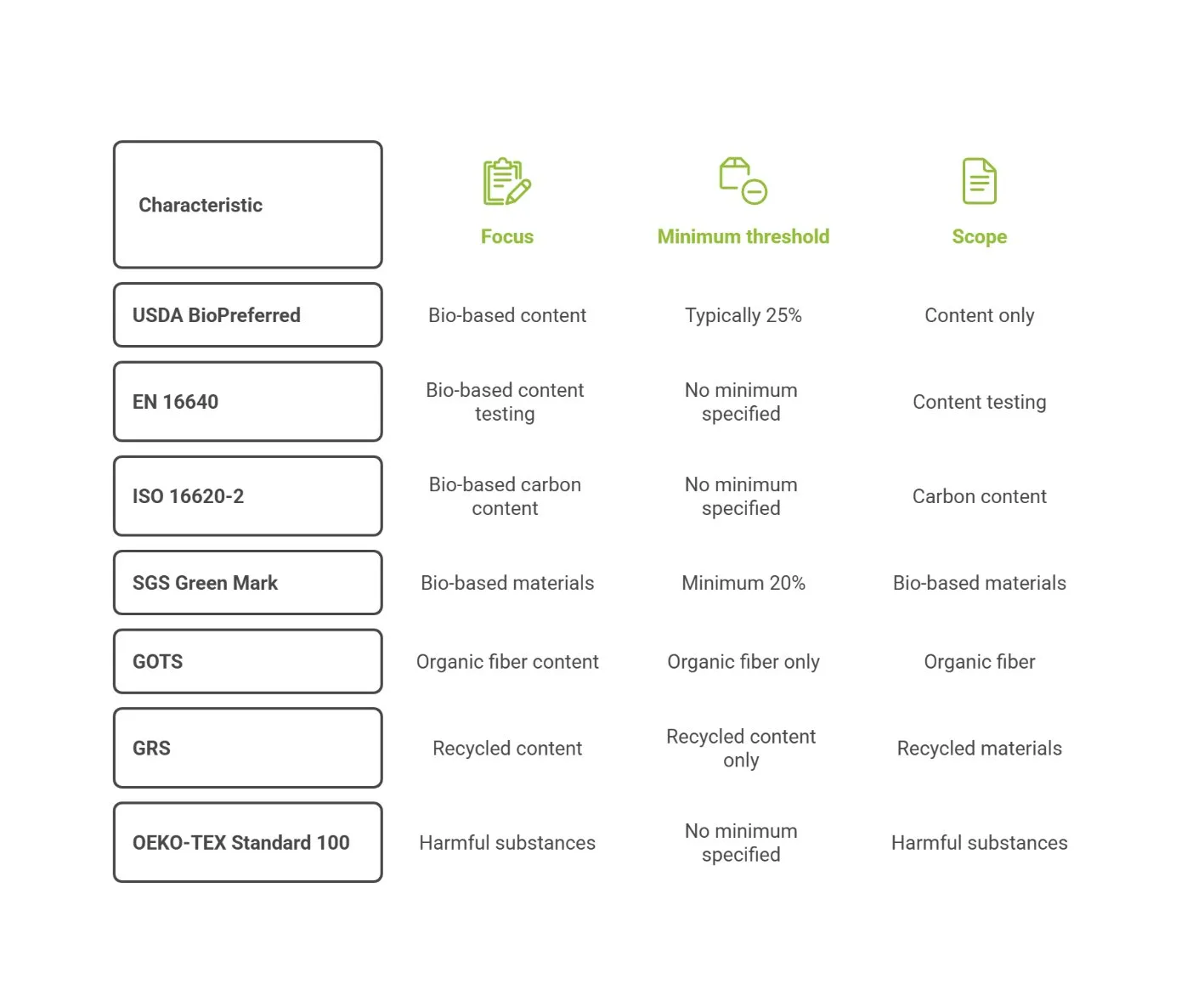

Certifications and Standards You Should Know

With so many brands making sustainability claims, third-party certifications help separate genuine efforts from greenwashing. Here are the main standards for bio-based textiles:

USDA BioPreferred Certification

The USDA Certified Biobased Product label shows verified bio-based content. Products must meet minimum thresholds (typically 25% bio-based content for general products, or category-specific minimums). Testing uses ASTM D6866 standards at independent laboratories.

What it means: When you see “USDA Certified Biobased Product 30%,” it confirms that 30% of the carbon in that product comes from renewable biological sources, verified through radiocarbon dating analysis.

What it doesn’t mean: This certification measures bio-based content only. It doesn’t evaluate environmental impact, sustainability practices, working conditions, or whether the product is biodegradable.

International Standards

- EN 16640 (Europe): European standard for bio-based content testing

- ISO 16620-2: International standard for determining bio-based carbon content

- SGS Green Mark: Verification program for bio-based materials, requires minimum 20% bio-based content

Other Relevant Certifications

- Global Organic Textile Standard (GOTS): For organic fiber content (doesn’t apply to synthetic bio-based materials)

- Global Recycled Standard (GRS): Verifies recycled content in products

- OEKO-TEX Standard 100: Tests for harmful substances in textiles

Major Brands Using Bio-Based Materials

Several fashion and outdoor brands have started using bio-based polyester or alternative materials. Here’s what major companies are doing:

Patagonia

Uses bio-based polyester alongside recycled content, organic cotton, and hemp. Known for transparency about material sources and environmental impact.

H&M Group

Invested in Kintra Fibers, which makes PBS (polybutylene succinate) that biodegrades in industrial composting facilities.

Bestseller

Testing Kintra’s bio-based and biodegradable polyester alternatives in product lines as part of long-term sustainability strategy.

Inditex (Zara, Massimo Dutti)

Prototyping bio-based materials and partnering with Fashion for Good on sustainable textile innovation.

Reformation

Road-testing sustainable alternatives including bio-based polyester in garments designed for their customer base.

Adidas & Nike

Both brands use significant amounts of polyester, including recycled versions. Exploring bio-based options as technology scales.

The 2025 Recycled Polyester Challenge

Created by Textile Exchange and the United Nations Framework Convention on Climate Change, this initiative challenged fashion brands to increase recycled polyester content from 14% (2019) to 45% by 2025. While focused on recycled rather than bio-based content, it shows industry commitment to reducing virgin petroleum use.

The Microplastics Challenge: What Bio-Based Doesn’t Solve

Here’s the uncomfortable truth: bio-based polyester releases the exact same microplastics as conventional polyester. This is the elephant in the room that many sustainability advocates would prefer to avoid.

The Hard Facts

- One laundry load of polyester clothes can release up to 700,000 microplastic fibers

- Washing one polyester shirt every two weeks releases approximately 52,000 microfibers annually

- Synthetic textiles account for 35% of ocean microplastics

- Scientists estimate there are 51 trillion microplastic particles in our oceans (2024)

Why Bio-Based Doesn’t Change This

The source of the carbon (plant vs. petroleum) and the fate of the carbon are two separate issues. Bio-based PET has the same molecular structure as petroleum-based PET. When the fabric rubs against itself during washing or wearing, tiny fibers break off. These microfibers behave identically whether they came from sugarcane or crude oil.

The only difference is that bio-based microplastics contain “younger” carbon (recently captured from the atmosphere through photosynthesis) rather than “ancient” carbon (stored underground for millions of years). From a microplastic pollution standpoint, this distinction doesn’t help marine life or human health.

What Actually Helps Reduce Microplastic Shedding

- Washing machine filters: Devices like the Filtrol 160 or Lint LUV-R capture fibers before they reach wastewater

- Guppyfriend washing bags: Mesh bags that trap shed fibers during washing

- Lower wash temperatures: Cold water washing reduces fiber breakage

- Front-loading washers: Gentler on fabrics than top-loaders with agitators

- Less frequent washing: Spot cleaning between full washes

- Fabric design improvements: Tighter weaves and low-shed textile engineering

The Real Alternative: Truly Biodegradable Materials

Companies like Kintra Fibers are developing PBS (polybutylene succinate), which is 100% bio-based AND biodegrades in industrial composting environments. Unlike bio-based PET, PBS actually breaks down completely under the right conditions.

However, PBS doesn’t yet match polyester’s performance in all applications, and it requires industrial composting facilities (not backyard compost piles or ocean environments). It’s a step forward, but not a complete solution either.

Bio-Based vs Traditional Polyester vs Alternatives

Understanding your options helps make informed choices. Here’s how different materials compare. Use our Interactive Fabric Comparison Tool to see how these materials stack up for your specific needs.

| Material | Bio-Content | Biodegradable? | Performance | Main Limitation |

|---|---|---|---|---|

| Bio-Based PET | ~30% (MEG only) | No | Identical to conventional | Still 70% petroleum; sheds microplastics |

| Recycled PET | 0% (petroleum origin) | No | Slightly lower than virgin | Competes with bottle recycling; degrades with each cycle |

| PLA (Polylactic Acid) | 100% | Industrial compost only | Lower than polyester | Doesn’t match polyester durability; requires specific conditions |

| PBS (Polybutylene Succinate) | 100% | Industrial compost | Close to polyester | Early stage; limited availability; higher cost |

| PEF (Polyethylene Furanoate) | 100% | No | Superior to PET | New technology; scaling up production |

| Organic Cotton | 100% natural | Yes | Different properties | Water-intensive; wrinkles easily; not stretchy |

Is Cotton Better Than Polyester?

“Better” depends on your priorities. Cotton and polyester each have advantages:

Cotton advantages:

- Natural, biodegradable fiber

- Breathable and comfortable

- No microplastic shedding

- Absorbs moisture well

Polyester advantages:

- More durable and resistant to wear

- Dries quickly

- Resists wrinkles and shrinking

- Less expensive to produce

- Requires less water during cultivation

For detailed comparisons, check out our guides on natural vs synthetic fabrics and types of fabrics. You can also use our Fabric Cost Calculator to compare the total ownership costs of cotton versus polyester over time.

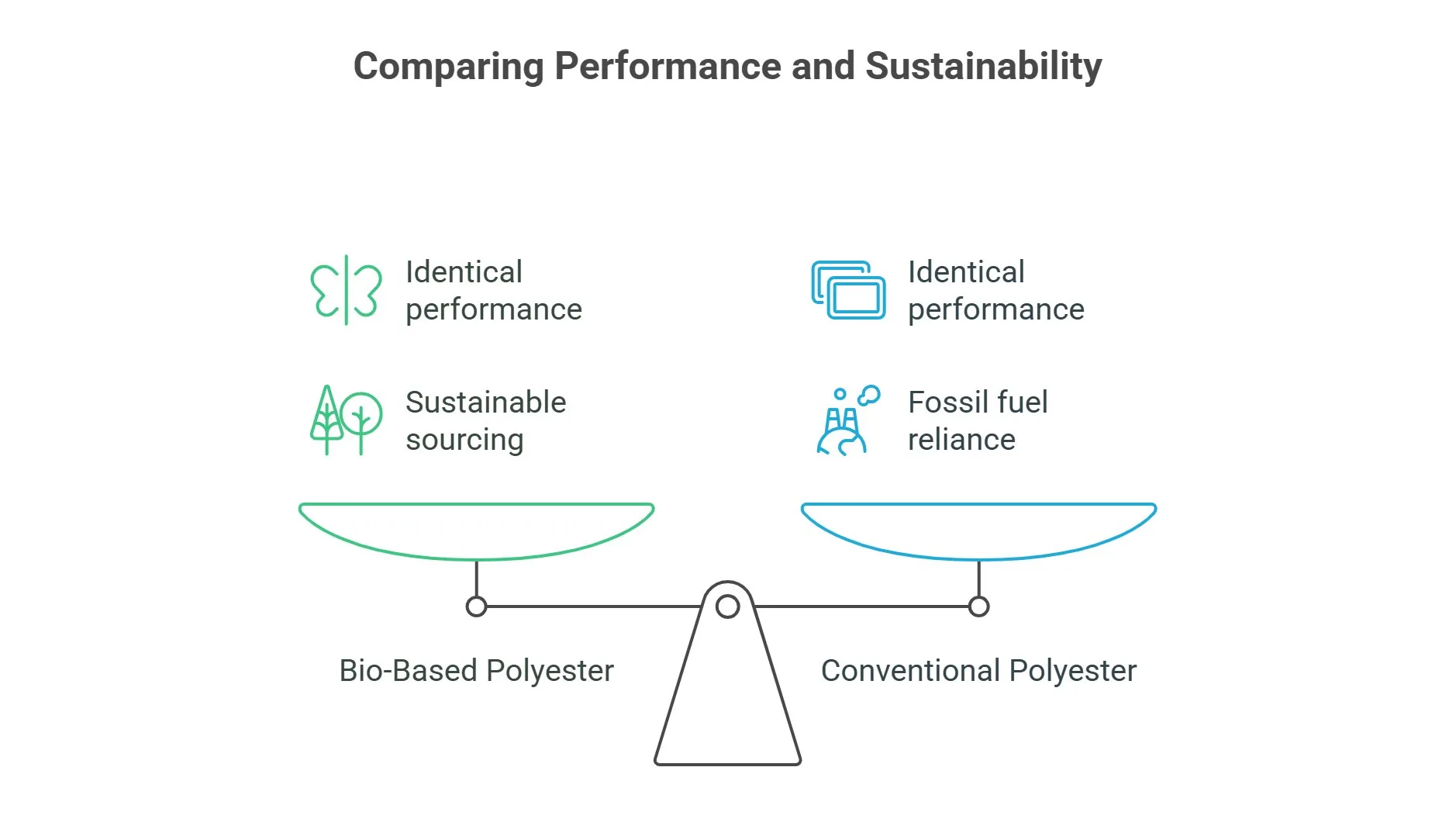

Performance and Durability

One major advantage of bio-based polyester is that it performs identically to conventional polyester. Since the molecular structure is the same, you get:

Strength and Longevity

Bio-based PET maintains excellent tensile strength. Independent studies show plant-sourced options can withstand similar stress levels as traditional fabrics. The fibers resist tearing and maintain structure through repeated washes, addressing common wear concerns.

Moisture Management

Polyester naturally wicks moisture away from skin, making it popular for activewear and athletic clothing. Bio-based versions maintain these same properties. The fabric dries quickly, preventing odor buildup during extended wear.

Weather Resistance

When treated with durable water repellent (DWR) coatings, bio-based polyester sheds water effectively. Some manufacturers embed water-repellent properties at the molecular level for longer-lasting protection. UV-blocking capabilities have also improved, with some fabrics blocking up to 98% of harmful rays without additional chemical coatings.

Care and Maintenance

Bio-based polyester follows the same care instructions as conventional polyester. Machine wash in cold water, tumble dry on low, and avoid high heat that could damage fibers. The fabric resists wrinkles naturally, making it convenient for travel and everyday wear. Use our Fabric Care Calculator to get personalized washing instructions based on your specific garment type.

Market Growth and Future Outlook

The bio-based polyester market is experiencing rapid growth driven by consumer demand, regulatory pressure, and technological advancement.

Current Market Size

- Global bio-based polyester market: $3.28 billion in 2025

- Projected to reach $14.47 billion by 2035

- Compound annual growth rate (CAGR): 16%

- Currently, only 1% of polyester in textiles is bio-based

Regional Growth Leaders

South Korea: Expected to expand at 16.5% CAGR between 2025 and 2035, driven by electronics and automobile industries alongside packaging.

Germany: Projected 18% CAGR with heavy investment in renewable resources and green technologies as part of circular economy operations.

United Kingdom: Anticipated 16% CAGR as the country focuses on reducing carbon emissions and moving toward renewable sources.

Industry Challenges and Opportunities

Textile Exchange estimates that fiber production must cut greenhouse gas emissions by 45% by 2030 to align with the 1.5°C global warming target. This creates both pressure and opportunity for bio-based alternatives.

The EU Strategy for Sustainable and Circular Textiles (introduced March 2022) aims to transform the textile industry by 2030, focusing on durability, repairability, and recycling. These regulations create market pull for alternatives to virgin fossil-fuel-based polyester.

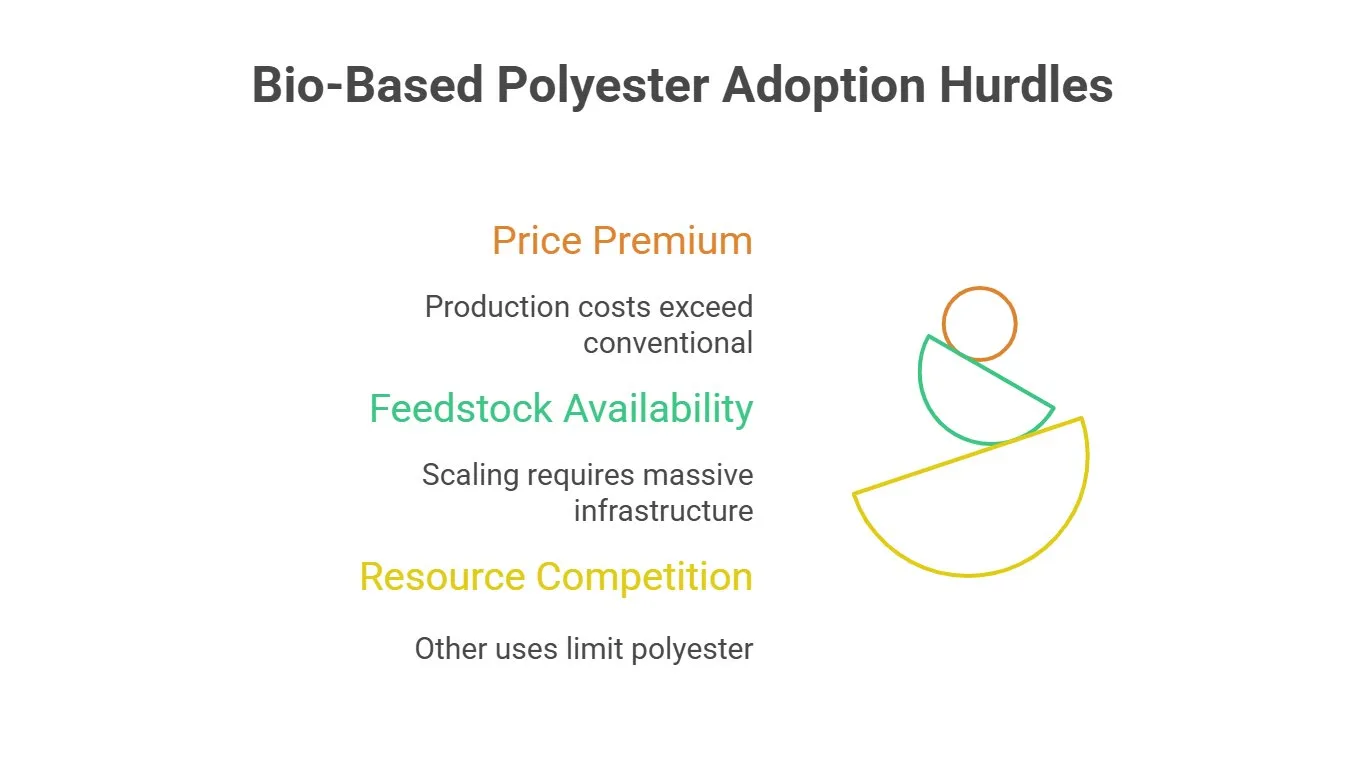

Cost and Scalability Challenges

While technology exists to produce bio-based polyester, economic and practical challenges remain.

Price Premium

Bio-based alternatives typically cost 15-30% more than conventional polyester. This premium comes from:

- Smaller production scale compared to established petroleum infrastructure

- Agricultural feedstock processing costs

- Investment in new production facilities

- Research and development expenses

Feedstock Availability

Scaling bio-based polyester to meet global textile demand raises questions about agricultural waste streams. Can sugarcane byproducts and corn stover supply enough feedstock without competing with food production or requiring additional land use?

Current estimates suggest agricultural waste could support significant growth, but reaching the scale needed to replace petroleum-based polyester entirely would require massive infrastructure development.

Competition for Resources

Bio-based materials don’t just compete with petroleum products. They also compete with other uses for agricultural waste, including:

- Animal feed

- Biofuel production

- Soil amendment and composting

- Paper and packaging materials

End-of-Life and Recycling Challenges

What happens to bio-based polyester after you’re done wearing it? This question reveals another area where bio-based doesn’t differ much from conventional.

The Recycling Reality

Bio-based PET can be recycled the same way as petroleum-based PET. Chemically, they’re identical, so recycling facilities can’t tell them apart and don’t need to process them differently.

However, the claim of “infinite recyclability” often seen in marketing materials is misleading. PET degrades slightly with each recycling cycle. After multiple cycles, the polymer chains break down, reducing quality.

The Bottle Wars

Here’s a complication: recycled polyester (rPET) for textiles traditionally comes from post-consumer PET beverage bottles. But beverage companies now target 25% recycled content in their own bottles by 2025, creating competition for the same feedstock.

As one industry expert noted, “Bottle companies will demand their bottles back. These bottle wars will not end well for fiber companies.”

Textile-to-Textile Recycling

The EU has legislated separate collection of textile waste beginning in 2025. This creates opportunity for closed-loop textile recycling. Companies like Unifi have expanded Textile Takeback programs that collect polyester-based fabric waste, turning it back into fiber.

However, textile-to-textile recycling faces technical challenges:

- Mixed fiber content (cotton-polyester blends are hard to separate)

- Dyes and finishes that contaminate recycling streams

- Lower quality output compared to virgin fiber

Digital Product Passports

Starting in 2026, the EU will introduce digital product passports for textiles. These will allow consumers to scan a QR code and see the complete journey of a garment, from raw material sourcing through manufacturing to end-of-life options. This technology aims to improve transparency and enable better recycling. Organizations like the Ellen MacArthur Foundation are working with industry leaders to accelerate the transition to a circular economy for fashion.

Common Questions About Polyester

What Is the Downside of 100% Polyester?

The main downsides of polyester include:

- Microplastic pollution: Sheds thousands of plastic fibers with each wash

- Not biodegradable: Persists in the environment for hundreds of years

- Less breathable: Doesn’t allow air circulation like natural fibers

- Can trap odors: Synthetic fibers hold onto sweat smells more than natural materials

- Petroleum-based: Traditional versions rely on non-renewable fossil fuels

- Static cling: Tends to create static electricity

- Can feel less comfortable: Some people find it less pleasant against skin compared to natural fibers

Does Polyester Mean It’s Cheap?

No, polyester doesn’t automatically mean cheap or low-quality. While polyester costs less to produce than silk or wool, quality varies widely. High-end polyester can be engineered for specific performance characteristics that exceed natural fibers in certain applications.

Luxury brands use polyester because of its technical properties, not to cut costs. Athletic wear, outdoor gear, and performance clothing often use premium polyester that costs more than basic cotton.

Why Do High-End Brands Use Polyester?

High-end and luxury brands choose polyester for several reasons:

- Performance properties: Superior moisture-wicking, quick-drying, and durability

- Shape retention: Maintains structure better than many natural fibers

- Wrinkle resistance: Keeps garments looking crisp without ironing

- Versatility: Can be engineered for specific textures and properties

- Consistency: More predictable performance than natural fibers

- Technical innovation: Allows for advanced features like stretch, compression, or temperature regulation

Brands like Patagonia, Nike, and Adidas use polyester because it performs better for their products’ intended use, not to save money.

Why Are People Getting Rid of Polyester Clothing?

Some consumers are reducing polyester in their wardrobes due to:

- Growing awareness of microplastic pollution

- Preference for natural, biodegradable materials

- Concerns about petroleum dependency

- Desire for more breathable, comfortable fabrics

- General shift toward slow fashion and sustainable choices

However, many people continue wearing polyester because it’s practical, durable, and often necessary for athletic and outdoor activities. The key is making informed choices about when polyester makes sense and when alternatives work better.

Is Polyester Safe?

Yes, polyester fabric is generally safe to wear. It’s been used in clothing for over 70 years without causing widespread health issues. However, some considerations include:

- People with sensitive skin may experience irritation from synthetic fibers

- Chemical treatments and dyes (not the polyester itself) can sometimes cause reactions

- Polyester doesn’t breathe as well, potentially causing discomfort in hot weather

- Some studies suggest synthetic fabrics may harbor more bacteria than natural fibers

For babies and young children, many parents prefer natural fibers for comfort and breathability. Our guide on best fabrics for newborn clothing covers safe options for infants.

Is Polyester Just Plastic?

Yes, polyester is a type of plastic. Specifically, it’s a polymer made from petrochemicals (or partially from plant materials in bio-based versions). The term “polyester” refers to the chemical structure, which includes ester linkages between repeating units.

The polyester used in textiles is the same basic material (PET) used in plastic bottles. The difference is in the form: fibers for clothing versus solid sheets or bottles for containers.

Is Polyester Fake Cotton?

No, polyester is not fake cotton. It’s a completely different material with a different chemical structure. Cotton is a natural fiber that grows on plants, while polyester is a synthetic fiber manufactured from petroleum or plant-based chemicals.

Some polyester fabrics are designed to mimic the feel or appearance of cotton, but they remain fundamentally different materials with different properties.

Is Polyester OK for Vegans?

Yes, polyester is vegan. It contains no animal products or byproducts. Unlike wool, silk, or leather, polyester is made from petrochemicals or plant materials, making it suitable for people following a vegan lifestyle.

However, some vegans avoid polyester due to environmental concerns rather than animal welfare issues, preferring plant-based natural fibers like cotton or hemp instead.

Is Polyester Real or Fake?

Polyester is real fabric, but it’s synthetic (manufactured) rather than natural. “Real” and “fake” aren’t the best terms here. Better distinctions are:

- Natural fibers: Cotton, wool, silk, linen (come from plants or animals)

- Synthetic fibers: Polyester, nylon, acrylic (manufactured through chemical processes)

- Semi-synthetic fibers: Rayon, viscose (made from natural materials through chemical processing)

Does Polyester Have Microplastics?

Yes, polyester releases microplastics. Every time you wash polyester clothing, tiny plastic fibers break off and enter wastewater systems. These microfibers are a form of microplastic pollution.

As discussed earlier, one polyester garment can release hundreds of thousands of microfibers per wash. These eventually reach oceans and other waterways, where they harm marine life and enter the food chain.

This is true for both conventional and bio-based polyester, as both have the same physical structure that breaks into microplastics.

What Natural Material Is Like Polyester?

No natural material perfectly mimics polyester’s properties, but some come close for specific applications:

- For moisture-wicking: Merino wool naturally wicks moisture and regulates temperature

- For quick-drying: Linen dries relatively quickly for a natural fiber

- For durability: Hemp is extremely strong and durable

- For wrinkle resistance: Some wools naturally resist wrinkles

However, none match polyester’s combination of all these properties simultaneously, which is why polyester dominates performance apparel.

How Does Polyester Compare to Cotton?

We’ve covered this extensively in our cotton vs polyester guide, but here’s a quick summary:

Polyester wins for: Durability, wrinkle resistance, quick drying, moisture-wicking, shape retention, lower cost

Cotton wins for: Breathability, natural biodegradability, comfort against skin, absorbency, no microplastic shedding

Many garments use cotton-polyester blends to get benefits from both, though these mixed-fiber fabrics are harder to recycle.

Which Is Better, Bamboo or Polyester?

Bamboo fabric (usually bamboo viscose or rayon) and polyester serve different purposes:

Bamboo fabric advantages:

- Softer and more breathable

- Naturally moisture-wicking

- Biodegradable (the cellulose breaks down)

- Antibacterial properties

- Doesn’t release microplastics

Polyester advantages:

- More durable and longer-lasting

- Better shape retention

- Dries even faster

- Less expensive

- More wrinkle-resistant

Note that bamboo fabric production involves chemical processing (similar to rayon), so it’s not as “natural” as the bamboo plant itself.

Does Lyocell Create Microplastics?

No, lyocell (brand name Tencel) does not create microplastics because it’s not plastic. Lyocell is a cellulosic fiber made from wood pulp (usually eucalyptus) through a closed-loop process. When fibers break off during washing, they’re cellulose, not plastic, and will biodegrade naturally.

This makes lyocell a better choice than polyester from a microplastic pollution perspective, though it has other environmental considerations like land use for tree farming.

What Are the Disadvantages of Lyocell?

While lyocell is more sustainable than conventional polyester, it has drawbacks:

- Higher cost: More expensive than polyester or conventional cotton

- Can wrinkle: Requires more care than synthetic fabrics

- Shrinkage potential: May shrink if not cared for properly

- Less durable when wet: Fibers weaken when soaked

- Limited stretch: Not as elastic as polyester blends

- Special care needed: Often requires gentle washing or dry cleaning

Is Rayon a Microplastic?

No, rayon is not a microplastic. Like lyocell, rayon is made from cellulose (wood pulp) through chemical processing. When rayon fibers break off during washing, they’re cellulose-based and will biodegrade, unlike polyester microfibers that persist as plastic pollution.

However, rayon is still a semi-synthetic fiber produced through industrial processes, so it’s not the same as wearing 100% natural, unprocessed plant fibers.

Does Spandex Have Microplastics?

Yes, spandex (also called elastane or Lycra) is a synthetic polymer that releases microplastics. It’s made from polyurethane, which is a type of plastic. Any garment containing spandex will shed microplastic fibers during washing and wearing.

This includes many athletic wear, yoga pants, and stretchy jeans that contain even small percentages of spandex for flexibility.

Is Polyester a Plastic or Rubber?

Polyester is a plastic, not rubber. Specifically, it’s a thermoplastic polymer, meaning it can be melted and reshaped with heat. Rubber is a different type of polymer (elastomer) with different properties, primarily its ability to stretch and return to its original shape.

Some confusion arises because both are polymers (large molecules made of repeating units), but they have different chemical structures and different properties.

Is Polyester Artificial Cotton?

No, polyester is not artificial cotton. It’s a completely different material. Cotton is cellulose from plant fibers, while polyester is a synthetic polymer. They have different chemical structures, different properties, and behave differently.

Some polyester fabrics are designed to look or feel similar to cotton, but calling it “artificial cotton” would be misleading. It’s more accurate to call polyester a “synthetic alternative to cotton.”

Is Nike Clothing Polyester?

Yes, much of Nike’s athletic wear contains polyester. Nike uses polyester (including recycled versions) extensively because it provides the performance properties needed for sportswear: moisture-wicking, durability, quick-drying, and stretch when blended with spandex.

Nike has also committed to sustainability initiatives, including using recycled polyester in many products and developing more sustainable material alternatives.

Are Adidas Made of Polyester?

Yes, Adidas uses significant amounts of polyester in their products, particularly in athletic and sportswear lines. Like Nike, Adidas uses polyester for its performance benefits and has programs to incorporate recycled polyester.

Adidas has also partnered with Parley for the Oceans to create shoes and apparel from recycled ocean plastic, turning environmental pollution into functional products. For more details about polyester in children’s clothing, including major brand choices, check out this detailed breakdown.

Is Polyester Good for Hot Weather?

Polyester can be good for hot weather, but it depends on the fabric construction and treatment. Modern performance polyester is designed to wick moisture away from skin and dry quickly, which helps with cooling during physical activity.

However, polyester is less breathable than natural fibers like cotton or linen. For hot, humid weather without much activity, natural fibers often feel more comfortable because they allow better air circulation.

For hot weather fabric choices, see our guides on summer fabrics and the softest fabrics for sensitive skin.

Is Polyester the Same as Silk?

No, polyester and silk are completely different. Silk is a natural protein fiber produced by silkworms, while polyester is a synthetic plastic fiber. They have different chemical structures, different textures, and different properties.

Some polyester fabrics are designed to mimic silk’s appearance and drape (often called “charmeuse” or “satin”), but they don’t have silk’s natural temperature-regulating properties or luxurious feel.

Is Hemp Polyester?

No, hemp is not polyester. Hemp is a natural plant fiber from the Cannabis sativa plant, while polyester is a synthetic plastic fiber. They’re completely different materials.

However, hemp can be blended with polyester in some fabrics to combine hemp’s natural properties with polyester’s durability and wrinkle resistance.

Is Nylon Better Than Polyester?

Neither is universally “better” – they serve different purposes:

Nylon advantages:

- Stronger and more abrasion-resistant

- More elastic and flexible

- Softer feel against skin

- Better for high-stress applications

Polyester advantages:

- Better UV resistance

- More resistant to stretching

- Retains color better

- Less expensive

- Better moisture-wicking in some constructions

Both are synthetic fibers that release microplastics and rely on petroleum (though bio-based versions of both are being developed).

What Is High-Quality Polyester?

High-quality polyester typically features:

- Higher thread count: More densely woven fibers

- Finer denier: Thinner individual fibers create softer fabric

- Advanced finishes: Special treatments for moisture-wicking, antimicrobial properties, or softness

- Better dye quality: Colors that don’t fade quickly

- Specialized construction: Engineered for specific performance needs

Brands like Patagonia, Arc’teryx, and high-end athletic wear companies use premium polyester that costs significantly more than cheap polyester used in fast fashion.

Why Are So Many Clothes Made of Polyester?

Polyester dominates the textile market (over 50% of all fiber production) because:

- Cost-effective: Cheaper to produce than natural fibers at scale

- Versatile: Can be engineered for many different applications

- Durable: Lasts longer than many natural alternatives

- Low-maintenance: Easy to care for, resists wrinkles and shrinking

- Consistent quality: More predictable than natural fibers that vary by growing conditions

- Performance properties: Moisture-wicking and quick-drying for active wear

- Manufacturing efficiency: Established global production infrastructure

Are There Different Types of Polyester?

Yes, several types of polyester exist:

- PET (Polyethylene Terephthalate): Most common type, used in clothing and bottles

- PCDT (Poly-1,4-cyclohexylene-dimethylene terephthalate): More elastic, used in heavier applications

- PBT (Polybutylene Terephthalate): More flexible, used in some technical applications

- Plant-based PET: Uses bio-based MEG from sugarcane

Within these categories, polyester can be manufactured in different forms:

- Filament polyester (long continuous fibers)

- Staple polyester (short fibers spun into yarn)

- Microfiber polyester (extremely fine fibers)

What Fabric Is Made From Plant Fibers?

Many fabrics come from plant fibers:

Natural plant-based fabrics:

- Cotton (from cotton plant seed pods)

- Linen (from flax plant stems)

- Hemp (from Cannabis sativa plant stalks)

- Jute (from jute plant stems)

- Ramie (from ramie plant stems)

Semi-synthetic plant-based fabrics:

- Rayon/Viscose (from wood pulp)

- Lyocell/Tencel (from eucalyptus wood pulp)

- Modal (from beech tree pulp)

- Bamboo rayon (from bamboo pulp)

For more information on different fabric types, check our guide on common fabric types and their uses.

What Is Plant-Based Cloth?

Plant-based cloth refers to any fabric made from plant materials. This includes both natural plant fibers (cotton, linen, hemp) and semi-synthetic materials where plants provide the cellulose that’s then chemically processed (rayon, lyocell).

It can also refer to bio-based synthetics like bio-based polyester, where plants provide part of the raw materials for synthetic fiber production.

Is Polyester a Natural or Plastic?

Polyester is a plastic, not a natural fiber. Even bio-based polyester, which uses plant materials as part of its feedstock, is still a synthetic plastic. The plant materials are chemically transformed into synthetic polymers, not used in their natural form like cotton or linen.

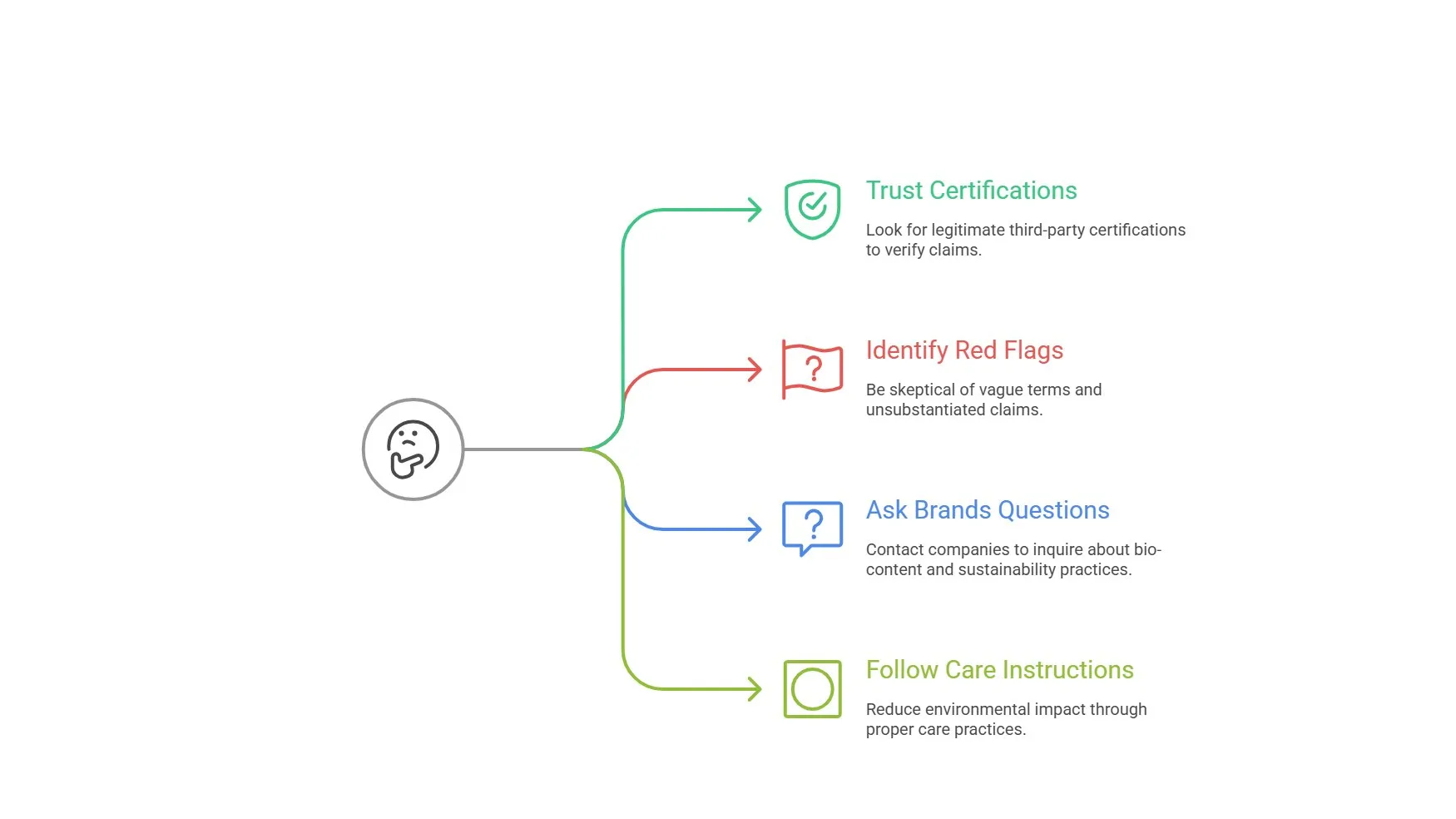

What to Look For When Shopping

Making informed choices about bio-based polyester requires knowing what to look for and what questions to ask.

Certifications to Trust

Look for these legitimate third-party certifications:

- USDA Certified Biobased Product label: Shows verified percentage of bio-based content

- Global Recycled Standard (GRS): Verifies recycled content in products

- OEKO-TEX Standard 100: Tests for harmful substances

- Bluesign: Ensures sustainable chemical use in production

Greenwashing Red Flags

Be skeptical of:

- Vague terms like “eco-friendly” or “sustainable” without specifics

- No percentage listed for bio-based content

- Claims of “biodegradable polyester” (standard PET is not biodegradable)

- Marketing that emphasizes plants without explaining the actual bio-content

- No third-party certifications to verify claims

Questions to Ask Brands

Don’t hesitate to contact companies and ask:

- What percentage of the polyester is bio-based?

- Which component is bio-based (MEG, terephthalic acid, or both)?

- What are the original plant sources?

- Do you have third-party certification?

- What happens to this product at end-of-life?

- How do you address microplastic shedding?

Care Instructions to Reduce Impact

Regardless of whether polyester is bio-based or conventional, you can reduce environmental impact through proper care:

- Wash in cold water (saves energy and reduces fiber breakage)

- Use a Guppyfriend bag or similar filter to capture microfibers

- Wash full loads (reduces total water and energy use)

- Air dry when possible (saves energy and extends garment life)

- Spot clean between washes (reduces washing frequency)

- Repair rather than replace when possible

Frequently Asked Questions

Conclusion

Bio-based polyester represents progress, but it’s not a silver bullet for fashion’s environmental challenges. Understanding what it truly offers helps separate marketing hype from reality.

What We’ve Learned

Plant-based polyester reduces reliance on petroleum and cuts carbon emissions by roughly half compared to conventional production. Major brands from Patagonia to H&M are testing and adopting these materials. The technology works, and the market is growing at 16% annually, projected to reach $14.5 billion by 2035.

However, the “30% reality” matters. Most bio-based polyester is only partially plant-derived, with 70% still coming from petroleum. The microplastics problem remains unchanged. Whether fibers come from sugarcane or crude oil, they shed the same plastic pollution into waterways with every wash.

Key Takeaways

Bio-based polyester is better than conventional polyester for:

- Reducing carbon footprint (52% fewer emissions)

- Decreasing petroleum dependency

- Creating value from agricultural waste

- Maintaining performance while improving sustainability

Bio-based polyester does NOT solve:

- Microplastic pollution (identical shedding to conventional)

- Biodegradability (still persists for hundreds of years)

- Complete fossil fuel elimination (70% still petroleum-based)

- Recycling challenges (same limitations as traditional PET)

Practical Recommendations

When buying bio-based polyester:

- Look for USDA Certified Biobased Product labels showing actual percentages

- Ask brands which components are bio-based and what the total bio-content is

- Consider cost per wear, not just upfront price

- Check for other certifications like GRS for recycled content or OEKO-TEX for safety

To reduce environmental impact:

- Use washing machine filters or Guppyfriend bags to capture microfibers

- Wash clothes less frequently and in cold water

- Choose truly biodegradable alternatives like PBS or PLA when performance requirements allow

- Consider natural fibers (cotton, linen, wool) for applications where synthetics aren’t necessary

- Buy quality items that last longer rather than cheap fast fashion

- Support brands with comprehensive sustainability programs, not just material swaps

The Bigger Picture

The textile industry needs multiple solutions, not a single magic material. Bio-based polyester plays a role alongside recycled fibers, natural materials, and emerging innovations like PBS and PEF. The EU’s push for circular textiles, digital product passports, and separate textile waste collection creates infrastructure for better end-of-life solutions. The United Nations Environment Programme (UNEP) provides strategic leadership through its Textile Initiative to accelerate the transition toward sustainable and circular textile value chains.

Consumer awareness matters. The more people understand what “bio-based” really means, what it solves, and what it doesn’t, the better choices they can make. Brands respond to informed consumers who ask tough questions about sustainability claims.

Looking Forward

Technology continues advancing. Researchers are working on 100% bio-based terephthalic acid, which would eliminate petroleum from polyester production entirely. Companies are developing lower-shed fabric constructions and better microfiber filtration. The market for truly biodegradable alternatives is growing.

But solutions take time to scale. In the meantime, bio-based polyester offers a stepping stone: not perfect, but better than what came before. Paired with responsible consumption, proper care, and support for continued innovation, it can be part of moving fashion in a more sustainable direction.

The key is staying informed, asking questions, and making choices that align with your values while understanding the trade-offs. Whether you choose bio-based polyester, recycled synthetics, or natural fibers depends on your specific needs, budget, and priorities. There’s no single right answer for everyone, but armed with accurate information, you can make decisions that work for you and the planet.

For more information on fabric choices and sustainable fashion, explore our guides on understanding textiles, caring for synthetic fabrics, and washing and care for different fabrics.