Everything you need to know about choosing, using, and caring for denim cotton fabric in 2025

Table of Contents

- What is Denim Cotton Fabric?

- The History and Evolution of Denim

- Fabric Composition and Construction

- Types of Denim: Stretch vs. Non-Stretch

- Properties and Benefits

- Sustainability and Environmental Impact

- Apparel Applications

- Home Decor and Other Uses

- Buying Guide: How to Choose Quality Denim

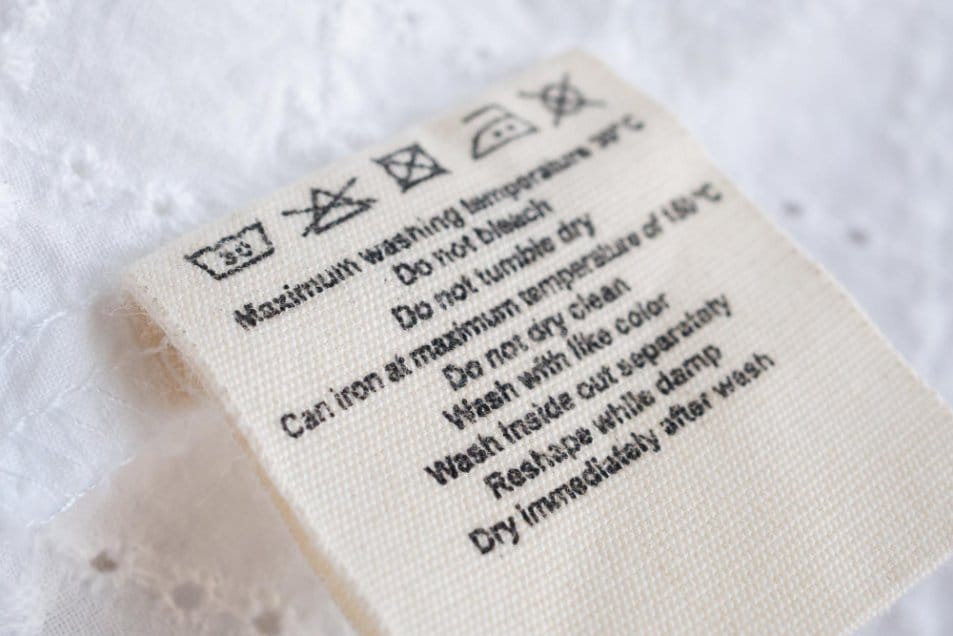

- Care and Maintenance Guide

- Current Trends for 2025

- Frequently Asked Questions

What is Denim Cotton Fabric?

Denim cotton fabric is a sturdy twill-woven textile traditionally made from 100% cotton fibers. The name comes from “serge de Nîmes,” referring to a fabric style that originated in Nîmes, France. What sets denim apart from other cotton fabrics is its distinctive diagonal ribbing pattern, created through a specific weaving technique where the weft passes under two or more warp threads.

The fabric gets its characteristic appearance from the way it’s dyed. Typically, only the warp threads (the lengthwise yarns) are dyed with indigo, while the weft threads (crosswise yarns) remain white or natural. This creates the iconic blue-on-white look that becomes more pronounced as the fabric wears and fades over time.

Is Denim Cotton Real?

Yes, traditional denim is made from real cotton fibers. However, the term “denim” refers to the weaving technique and construction method rather than the fiber content alone. While classic denim uses 100% cotton fabric, modern variations may include blends with synthetic fibers like polyester, elastane, or spandex to achieve specific properties like stretch or water resistance.

What Makes Denim Different from Other Cotton Fabrics?

Unlike fabrics such as chambray cotton, which uses a plain weave where warp and weft threads are the same color, denim uses a twill weave with dyed warp and undyed weft. This construction creates several unique characteristics:

- Diagonal ribbing that increases durability and strength

- One-sided dyeing that creates depth and fading potential

- Heavier weight compared to plain-weave cotton fabrics

- Greater resistance to tearing due to the twill construction

The History and Evolution of Denim

The story of denim begins in 17th-century France, where weavers in Nîmes created a durable twill fabric called “serge de Nîmes.” This name eventually shortened to “denim” as the fabric gained popularity. Meanwhile, in Genoa, Italy, sailors wore similar sturdy cotton pants. The French word for Genoa is “Gênes,” which is where we get the word “jeans.”

From Workwear to Worldwide Icon

American innovation transformed denim during the Industrial Revolution. In 1873, Levi Strauss and tailor Jacob Davis patented the process of riveting denim pants, creating what we now know as blue jeans. This innovation was designed specifically for miners during the California Gold Rush who needed tough, tear-resistant clothing.

The Cone Mills White Oak plant in North Carolina became one of the most famous denim producers in American history. Operating from 1905 until its closure in 2017, the mill supplied premium selvage denim to brands worldwide and set quality standards that many manufacturers still follow today.

Today, most denim production has shifted to countries like China, India, Bangladesh, Turkey, and Pakistan. However, specialty mills in the United States, Japan, and Italy continue to produce premium denim for high-end fashion brands.

Japanese Denim: A Modern Revival

Japanese denim has earned a reputation as some of the highest quality in the world. Japanese mills use vintage shuttle looms that create selvage denim with clean, self-finished edges. These mills focus on traditional techniques combined with meticulous attention to detail, producing fabrics that many denim enthusiasts consider superior to mass-produced alternatives.

Fabric Composition and Construction

Is There 100% Cotton Denim?

Yes, 100% cotton denim is widely available and remains popular among denim purists. Pure cotton denim offers several advantages including breathability, natural feel, and the ability to develop authentic vintage-looking fades. Brands like Levi’s still produce many styles in 100% cotton, particularly their classic 501 line.

However, you’ll also find many blended options on the market. Understanding the difference helps you choose the right fabric for your needs.

Is Denim Cotton or Polyester?

Traditional denim is made from cotton, but modern denim often includes polyester or other synthetic fibers. The fiber content affects the fabric’s performance and characteristics. Here’s what different blends offer:

| Fiber Blend | Typical Ratio | Benefits | Best For |

|---|---|---|---|

| 100% Cotton | 100% cotton | Breathable, natural fading, authentic feel | Classic jeans, raw denim, vintage looks |

| Cotton + Elastane | 97-99% cotton, 1-3% elastane | Comfort stretch, shape retention, movement | Skinny jeans, activewear, fitted styles |

| Cotton + Polyester | 60-80% cotton, 20-40% polyester | Wrinkle resistance, durability, quick-dry | Workwear, travel clothing, easy care |

| Cotton + Lyocell | 60-80% cotton, 20-40% lyocell | Softness, drape, eco-friendly, luxurious feel | Premium fashion denim, sustainable lines |

Understanding Denim Weave Construction

Denim uses a 3×1 twill weave, meaning the weft thread passes under one warp thread and over three. This creates the diagonal lines you can see on the fabric surface. The tight weave construction provides several benefits:

- Absorbs significant friction before breaking apart

- Distributes stress across multiple threads

- Creates a smooth surface that’s comfortable against skin

- Allows the fabric to drape better than plain weaves

Is Denim Cotton Woven or Knit?

Denim cotton is a woven fabric, not knit. This distinction is important because woven fabrics are generally more durable and hold their shape better than knits. However, you may encounter “knit denim,” which is a knitted fabric designed to look like denim. Knit denim offers more stretch and a softer feel but doesn’t have the same durability or authentic texture as woven denim.

What About Cotton Twill Denim?

This term can be confusing because all denim is technically a twill fabric. When people refer to “cotton twill denim,” they’re usually emphasizing the traditional twill weave construction. The term distinguishes it from other types of cotton fabrics that might use plain weave or satin weave patterns.

Types of Denim: Stretch vs. Non-Stretch

Is Cotton Denim Stretchy?

Pure 100% cotton denim has minimal stretch. It may give slightly with wear but won’t bounce back to its original shape. This is why vintage jeans sometimes become baggy at the knees or seat after extended wear. However, modern stretch denim incorporates elastane (also called spandex or Lycra) to provide flexibility while maintaining the denim look.

| Type | Composition | Stretch Level | Best Applications |

|---|---|---|---|

| Rigid/Raw Denim | 100% cotton | None to minimal | Classic jeans, workwear, structured jackets |

| Comfort Stretch | 98-99% cotton, 1-2% elastane | 15-20% stretch | Everyday jeans, casual wear |

| High Stretch | 92-97% cotton, 3-8% elastane | 30-50% stretch | Skinny jeans, leggings, activewear |

| Dual-Core Stretch | Cotton + elastane + PBT | 20-30% with recovery | Premium jeans with shape retention |

Raw Denim vs. Washed Denim

Raw denim (also called dry or unwashed denim) comes straight from the loom without any washing or treatments. It’s stiffer, darker, and will shrink on first wash. Raw denim enthusiasts value it because it develops personalized fade patterns based on how you wear it.

Washed or treated denim has been processed to achieve specific looks and feel softer right off the shelf. Common finishes include:

- Stone wash: Tumbled with pumice stones for a worn look

- Enzyme wash: Treated with enzymes to soften and fade

- Acid wash: Bleached for a distinctive mottled appearance

- Sanforized: Pre-shrunk to prevent size changes

Selvage Denim: What Makes It Special?

Selvage (or selvedge) denim is woven on traditional shuttle looms that create a self-finished edge, preventing fraying and unraveling. You can spot selvage denim by the clean edge with a colored thread running through it, typically visible when jeans are cuffed. This construction method is more time-consuming and expensive but produces fabric many consider superior in quality.

Properties and Benefits of Cotton Denim

What Are the Benefits of Cotton Denim?

Cotton denim offers a unique combination of properties that explain its enduring popularity across generations. Understanding these characteristics helps you make informed decisions about when and how to use this versatile fabric.

Exceptional Durability

The twill weave construction allows denim to withstand three times more abrasion than plain-weave fabrics before breaking down. This makes it ideal for applications where the fabric experiences constant friction, like knees and elbows in clothing or seat cushions in furniture.

Natural Breathability

Is cotton denim breathable? Yes, cotton denim allows air circulation through its fibers, helping regulate body temperature. While heavier weights (12-16 oz) provide less airflow than lighter options, even heavy denim breathes better than synthetic alternatives. This natural ventilation prevents the clammy feeling you get with non-breathable fabrics.

Comfortable Weight Options

Is cotton denim heavy? It depends on the weight you choose. Denim weight is measured in ounces per square yard:

- Lightweight (4-7 oz): Soft, drapey, suitable for shirts and summer clothing

- Midweight (8-12 oz): Versatile for most jeans and jackets

- Heavyweight (13-16+ oz): Extremely durable for workwear and raw denim

Temperature Regulation

Is denim fabric good for summer? Lightweight denim (under 10 oz) works well in warm weather because cotton fibers naturally wick moisture away from your skin and allow heat to escape. However, heavy raw denim is better suited for cooler seasons. The fabric’s temperature performance depends largely on weight and weave density.

Unique Aging and Character Development

Unlike synthetic fabrics that simply wear out, cotton denim develops character over time. The indigo dye gradually fades in areas of high friction, creating whiskering at the hips, honeycombs behind the knees, and other patterns unique to your body and habits. This personalized aging process is why many people form emotional attachments to their favorite denim items.

Color Retention and Fading

Indigo dye bonds deeply with cotton fibers, maintaining color through many washes. However, this same property allows controlled fading that creates the beloved worn-in look. You have control over how much your denim fades based on how you wash and care for it.

Is Cotton Denim Soft?

Raw or rigid denim starts out stiff and becomes softer with wear and washing. This breaking-in period can take several weeks to months. Pre-washed or enzyme-treated denim feels soft immediately. Some people prefer the stiffness of raw denim because it provides structure, while others want the immediate comfort of washed denim.

How Can You Tell if Denim is 100% Cotton?

Check the care label first, which legally must list fiber content. For unlabeled fabric, try these tests:

- Burn test: Cotton burns with a steady flame and smells like burning paper, leaving soft gray ash. Synthetic fibers melt into hard beads

- Feel test: 100% cotton feels slightly rougher and less slippery than blends with synthetics

- Stretch test: Pure cotton has minimal stretch and recovery compared to blends with elastane

- Water test: Cotton absorbs water quickly, while synthetic blends may bead up initially

Sustainability and Environmental Impact

The fashion industry faces growing pressure to address environmental concerns, and denim production is no exception. Traditional denim manufacturing is resource-intensive, but innovative approaches are changing the landscape.

Is Cotton Denim Sustainable?

Whether cotton denim is sustainable depends on how it’s produced. Conventional cotton farming and traditional denim manufacturing have significant environmental impacts, but sustainable alternatives are increasingly available.

Environmental Challenges

- Water consumption: Growing cotton requires substantial water, and dyeing processes use thousands of gallons per pair of jeans

- Chemical use: Pesticides in conventional cotton farming and chemicals in dyeing/finishing processes pollute waterways

- Energy intensity: Manufacturing, especially heat-intensive processes like dyeing and drying, consumes significant energy

- Microfiber pollution: Cotton denim sheds microfibers during washing, though these biodegrade faster than synthetic alternatives

Sustainable Denim Innovations

The industry is responding with several eco-friendly approaches:

Key Sustainability Certifications

| Certification | What It Means | What to Look For |

|---|---|---|

| GOTS | Global Organic Textile Standard | Organic fibers, strict environmental and social criteria |

| OCS | Organic Content Standard | Verifies organic material content in products |

| Cradle to Cradle | Holistic sustainability assessment | Material health, recyclability, renewable energy use |

| RCS | Recycled Claim Standard | Verifies recycled content and chain of custody |

| Bluesign | Chemical and resource management | Safe chemistry, reduced water and energy use |

Is Denim Organic Cotton?

Not all denim is made from organic cotton, but organic denim is increasingly available. Brands focusing on sustainability often use certified organic cotton and advertise this prominently. Organic denim typically costs more due to higher raw material costs and stricter production requirements, but many consumers consider the environmental benefits worth the premium.

Apparel Applications

Classic Jeans and Pants

Denim’s most famous application remains jeans. The fabric’s durability makes it perfect for pants that withstand daily wear. Modern jean styles range from rigid raw denim that breaks in over months to soft stretch varieties that feel comfortable immediately.

Can denim jeans be 100% cotton? Absolutely. Many premium brands and vintage-inspired lines use 100% cotton for authentic feel and fading characteristics. However, stretch blends dominate the market due to consumer preference for comfort and flexibility.

What Are Levi Jeans Made Of?

Levi’s produces jeans in various compositions depending on the style. Their classic 501 line is available in 100% cotton for traditionalists. However, many of their modern fits include 1-3% elastane for stretch. Premium lines may use organic cotton or recycled fibers. Always check the specific product label, as Levi’s offers hundreds of styles with different fabric compositions.

Jackets and Outerwear

Denim jackets benefit from the fabric’s structure and durability. Midweight denim (10-12 oz) works well for classic trucker jackets, while lighter weights suit bomber-style jackets. The fabric holds its shape, creating clean lines and structured collars that soften with wear but maintain integrity.

Shirts and Tops

Lightweight denim (4-8 oz) creates comfortable shirts with a casual aesthetic. These work well for chambray-style button-ups or western shirts. The fabric’s texture adds visual interest compared to standard cotton shirting.

Skirts and Dresses

Denim’s natural stiffness makes it excellent for structured skirts that hold pleats or A-line shapes without excessive lining. For dresses, designers often combine different weights, using heavier denim for bodices and lighter weights for flowing skirts.

Accessories

The fabric’s durability extends its usefulness to accessories including bags, hats, shoes, and wallets. These items benefit from denim’s resistance to wear while developing character through use.

Home Decor and Other Uses

Upholstery Applications

Midweight to heavyweight denim (12-14 oz) works exceptionally well for furniture upholstery. The tight weave resists pet claws and daily wear better than many traditional upholstery fabrics. Dining chairs, ottomans, and even sofas benefit from denim’s durability and texture.

The fabric’s natural stain-hiding properties make it practical for family spaces. Light marks often blend into the texture, and the fabric’s tendency to fade gracefully means slight discoloration from use adds character rather than appearing damaged.

Curtains and Window Treatments

Denim curtains offer substantial light filtering without complete blackout. The fabric’s weight prevents billowing and creates clean lines. Midweight denim (8-10 oz) drapes well while providing enough structure to maintain shape. The material’s fade resistance helps colors stay true even in sunny windows, though some gradual lightening adds to the lived-in aesthetic.

Decorative Accents

DIY enthusiasts appreciate denim for craft projects including throw pillows, storage bins, table runners, and wall hangings. The fabric’s workability makes it suitable for home sewing projects, while its texture brings industrial charm to residential spaces.

Buying Guide: How to Choose Quality Denim

Understanding quality indicators helps you select denim that will perform well and last for years. Whether you’re buying fabric for a sewing project or finished garments, these guidelines will help you make informed decisions.

Watch this comprehensive guide to sewing with denim, covering everything from choosing the right fabric to finishing techniques, including tips for working with raw, stretch, and selvedge denim.

How Can You Tell Good Quality Denim?

Thread Density and Weight

Higher thread count generally indicates better quality. Look for tightly woven fabric without visible gaps between threads when held up to light. The weight should feel appropriate for the intended use. Lightweight fabric that feels flimsy likely won’t hold up well.

Dye Penetration

Quality denim has deep dye penetration. Check the wrong side of the fabric – it should show some color transfer, not remain pure white. However, the contrast between the dyed face and lighter reverse is what creates characteristic denim fading.

Selvage Edges

While not always necessary, selvage edges indicate production on traditional looms and often correlate with higher quality. The self-finished edge with colored thread (usually red, but sometimes other colors) shows attention to detail and traditional manufacturing methods.

Consistent Weave

Run your hand over the fabric surface. It should feel smooth and consistent without thick or thin spots. Irregularities indicate quality control issues that may lead to uneven wear or weak spots.

Color Consistency

While some variation in indigo depth creates character, dramatic color differences across the same bolt suggest dyeing problems. Quality denim shows subtle depth variations rather than obvious splotches or streaks.

Weight Selection Guide

| Weight Range | Feel | Best Applications | Season |

|---|---|---|---|

| 4-6 oz | Soft, drapey, lightweight | Summer shirts, lightweight jackets, dresses | Spring/Summer |

| 7-9 oz | Flexible, comfortable | Casual jeans, skirts, light upholstery | All seasons |

| 10-12 oz | Medium weight, structured | Classic jeans, jackets, furniture | Fall/Winter |

| 13-16+ oz | Heavy, stiff initially | Raw denim, workwear, heavy upholstery | Winter |

Price vs. Quality Considerations

While price doesn’t always guarantee quality, extremely cheap denim often reflects corners cut in materials or manufacturing. Expect to pay:

- Budget fabric: $5-10 per yard (mass-produced, synthetic blends)

- Mid-range fabric: $15-25 per yard (quality cotton, standard production)

- Premium fabric: $30-50+ per yard (selvage, organic, specialty mills)

Red Flags to Avoid

- Fabric that feels papery or overly stiff from chemical treatments

- Visible flaws like broken threads or skipped weaving

- Strong chemical smell indicating excessive processing

- Dramatic price differences from comparable products without clear reason

- Vague fiber content descriptions or missing care labels

Care and Maintenance Guide

Proper care extends the life of your denim significantly. The maintenance approach depends on whether you’re working with raw denim that you want to develop natural fading or pre-washed denim you simply want to keep clean.

General Washing Guidelines

How Often Should You Wash Denim?

Wash denim only when necessary, approximately every 10 wears for regular jeans, unless visibly soiled or smelly. Over-washing accelerates wear and fading. Between washes, air out your denim by hanging it outside or in a well-ventilated area. Spot clean small stains with mild soap and a damp cloth.

Machine Washing Steps

- Turn inside out: This protects the outer surface from friction and direct detergent exposure

- Close all fasteners: Zip up zippers and button buttons to prevent snagging

- Use cold water: Hot water causes more shrinkage and color loss

- Select gentle cycle: Reduces wear and tear on fabric fibers

- Use mild detergent: Specially formulated for dark colors if washing dark denim

- Skip fabric softener: It leaves residue that affects texture and may reduce absorbency

- Wash separately initially: New dark denim may bleed, especially in first few washes

Hand Washing Method

For delicate or premium denim, hand washing offers the gentlest care:

- Fill a tub or sink with lukewarm water

- Add small amount of mild detergent

- Submerge denim and gently agitate for 3-5 minutes

- Let soak for 15-20 minutes

- Drain and rinse thoroughly with cool water

- Gently squeeze out excess water without wringing

Drying Your Denim

Air Drying (Recommended)

Air drying preserves the fit, prevents shrinkage, and extends fabric life. Hang jeans inside out in a shady location to prevent sun fading. Use a drying rack or clothesline, ensuring good air circulation. For faster drying, place near (not on) a heat source or use a fan.

Machine Drying (When Necessary)

If you must use a dryer, follow these precautions:

- Use low or no heat setting

- Remove while slightly damp to prevent over-drying

- Don’t overload the dryer

- Stop halfway through and finish air drying

Raw Denim Care

Raw denim requires special consideration if you want to develop distinctive fade patterns:

Initial Soak vs. No Soak

Many raw denim enthusiasts prefer to wear their jeans for 6-12 months before the first wash to develop high-contrast fades. Others do an initial soak to remove starch and excess indigo. There’s no wrong approach – it depends on your preferences.

For an initial soak, fill a tub with lukewarm water (no detergent), submerge the jeans for 30-45 minutes, drain, and hang dry. Expect 1-2 inches of shrinkage in length.

First Wash Timing

When you finally wash raw denim, use cold water and minimal agitation. The longer you wait, the more dramatic the contrast between faded and dark areas. However, don’t sacrifice hygiene – if they smell or have visible dirt, it’s time to wash.

Stain Removal

| Stain Type | Treatment | Method |

|---|---|---|

| Oil/Grease | Dish soap or baking soda | Apply to dry stain, let sit 30 min, gently scrub, rinse |

| Grass | White vinegar or rubbing alcohol | Blot stain, apply solution, dab with clean cloth, rinse |

| Ink | Rubbing alcohol or hairspray | Place cloth underneath, apply to stain, blot, repeat |

| Blood | Cold water and hydrogen peroxide | Soak in cold water, apply peroxide, let bubble, rinse |

| Wine/Juice | Club soda or white wine | Blot immediately, pour over stain, blot again, rinse |

Storage and Maintenance

- Hang or fold: Both work fine. Hanging on sturdy hangers prevents creasing, while folding saves closet space

- Avoid direct sunlight: Prolonged sun exposure causes uneven fading

- Use cedar or lavender: Natural moth deterrents for long-term storage

- Repair promptly: Fix small tears or loose hems before they worsen

- Rotate wear: Give denim a day to rest between wears to maintain shape

Professional Dry Cleaning

Dry cleaning isn’t typically necessary for denim, but it’s useful for specialty fabrics with coatings or embellishments. The process uses chemical solvents instead of water, preventing shrinkage and fading. Eco-friendly dry cleaners using carbon dioxide systems offer a more sustainable option.

Repair and Upcycling

Don’t discard worn denim. Simple repairs extend its life significantly:

- Patches: Cover knee holes or thin spots with iron-on or sewn patches

- Darning: Reinforce thinning areas before they become holes

- Hemming: Shorten long jeans or repair frayed bottoms

- Repurposing: Turn old jeans into shorts, bags, or craft projects

Current Trends for 2025

The denim landscape in 2025 balances nostalgia with innovation. Understanding current trends helps you make purchases that will remain stylish and relevant.

Silhouettes and Fits

Wide-leg and barrel-leg jeans dominate women’s fashion, moving away from the skinny jean era. These relaxed fits prioritize comfort and ease of movement. For men, straight-leg styles lead the market, offering a classic look with modern refinement.

Oversized and baggy fits influenced by 1990s and early 2000s fashion continue gaining popularity. However, these aren’t sloppy – they’re carefully proportioned for flattering drape while maintaining structure.

Fabric Innovation

Comfort stretch without synthetic fibers has become a priority. Mills are developing fabrics that offer 15-20% stretch using innovative cotton treatments and construction techniques, eliminating the need for elastane. This addresses sustainability concerns while meeting consumer demand for flexible fabrics.

Recycled content is increasingly standard rather than premium. Many mainstream brands now offer options with 20-40% post-consumer or post-industrial waste content without compromising quality or significantly increasing price.

Washes and Finishes

Authentic vintage character drives wash preferences. Consumers want jeans that look lived-in without appearing costume-like. Mills are perfecting techniques that create subtle, realistic fading patterns reminiscent of 1960s-1980s denim.

Clean, minimal washes also remain strong for those preferring understated style. Dark indigo and black denim with minimal distressing offer versatility for dressier occasions.

Sustainability Focus

Circular fashion principles are moving from niche to mainstream. Brands increasingly offer take-back programs, repair services, and products designed for eventual recycling. Transparency about supply chains and environmental impact becomes a competitive advantage.

Water-saving production methods and plant-based alternative fibers (hemp, lyocell, organic cotton) gain market share as consumers prioritize environmental considerations alongside style and comfort.

Denim Beyond Jeans

Coordinated denim sets (matching shirts and pants or jackets and skirts) are experiencing renewed popularity. Modern interpretations avoid the dated “Canadian tuxedo” stereotype through thoughtful styling and varied washes.

Denim dresses, jumpsuits, and outerwear expand the fabric’s applications. Designers are pushing boundaries with structured blazers, evening wear, and accessories that showcase denim’s versatility.

Frequently Asked Questions

Denim is the fabric, while jeans are the garment. Think of it this way: denim is like leather, and jeans are like a leather jacket. Denim is a twill-woven cotton fabric with a distinctive diagonal ribbing pattern. Jeans are pants made from denim fabric. You can also make jackets, skirts, shirts, and many other items from denim, but when it’s specifically pants with rivets and specific styling, we call them jeans. Learn more about the difference between denim and jeans.

Denim isn’t always blue, but indigo blue is traditional and most common. Originally, indigo was chosen because the dye was readily available, relatively inexpensive, and created a pleasing color. The dye also has unique properties that allow it to fade gradually with wear, creating the characteristic worn look people love. Today, you can find denim in black, white, gray, brown, and even bright colors, but the classic indigo blue remains most popular due to tradition and its flattering, versatile appearance.

“Better” depends on your priorities. 100% cotton denim offers authentic feel, natural breathability, and classic fading characteristics. It’s ideal if you want traditional denim that develops unique character over time. However, cotton-blend denim with small amounts of elastane (1-3%) provides stretch and comfort that many people prefer for everyday wear. Blends with polyester offer easy care and wrinkle resistance. Neither is objectively better – choose based on whether you prioritize authenticity and natural fibers or comfort and easy maintenance.

The cotton used in denim comes from cotton plants grown in warm climates worldwide. Major cotton-producing countries include China, India, the United States, Pakistan, Brazil, and Turkey. After harvesting, the cotton is processed into yarn and woven into denim fabric. While the cotton may come from one country, it’s often processed and woven in another. Most denim production now occurs in China, Bangladesh, Turkey, and Pakistan, though specialty mills in Japan, Italy, and the United States produce premium denim using both domestic and imported cotton.

Chambray is the fabric most commonly confused with denim. Both are cotton fabrics with blue coloring, but chambray uses a plain weave (where warp and weft threads alternate evenly) rather than denim’s twill weave. This makes chambray lighter, softer, and less durable than denim. Chambray also doesn’t develop the same fading characteristics because both the warp and weft threads are typically dyed. Other denim look-alikes include cotton twill in dark colors and certain knitted fabrics designed to mimic denim’s appearance while offering more stretch. Check out our guide to chambray cotton to understand the differences.

No, cotton canvas and denim are different fabrics despite both being durable cotton textiles. Canvas uses a plain weave where threads cross over and under each other in a simple pattern, creating a uniform, heavy fabric. Denim uses a twill weave with a diagonal pattern. Canvas is typically heavier and stiffer with no inherent stretch or drape, making it ideal for bags, tents, and heavy-duty applications. Denim has more flexibility and develops character through fading. Both are strong fabrics, but they have distinct appearances, feels, and best uses. Learn more about canvas cotton fabric.

Cotton transforms into denim through several steps. First, cotton bolls are harvested and the fibers separated from seeds. These fibers are carded (combed) to align them and remove impurities. Next, they’re spun into yarn – the strength of this yarn significantly affects final fabric quality. For denim, warp yarns are typically dyed with indigo while weft yarns remain undyed. These yarns are then woven on a loom using the 3×1 twill pattern where the weft passes under one warp thread and over three, creating the diagonal ribs. Finally, the fabric may be treated, washed, or finished depending on the desired final product.

Traditional denim is 100% cotton, but modern denim varies widely. Most stretch denim contains 97-99% cotton with 1-3% elastane for flexibility. Performance denim may include higher synthetic content, with some fabrics containing 60-80% cotton blended with polyester, lyocell, or other fibers. Sustainable denim might incorporate recycled cotton (typically 20-40% of total fiber content). Always check the care label for specific fiber content, as it dramatically affects the fabric’s behavior, care requirements, and durability.

Yes, you can sew denim at home with the right tools and techniques. Use a heavy-duty or denim needle (size 90/14 to 100/16 depending on fabric weight), strong thread (polyester or cotton-wrapped polyester), and lengthen your stitch to 3-3.5mm. A regular sewing machine can handle lightweight to midweight denim (up to 12 oz), though you may need to sew slowly through thick seams. For heavy denim, consider using a denim hammer or wooden clapper to flatten seams before sewing. Check out our sewing machine buying guide to ensure your machine can handle denim projects.

Yes, 100% cotton denim stretches with wear and doesn’t return to original size until washed. This is why raw denim enthusiasts often buy jeans that fit snugly initially, knowing they’ll relax. Areas of high stress (knees, seat, waistband) stretch most noticeably. Denim with elastane (stretch denim) resists this permanent stretching better because the elastic fibers help fabric recover its shape. However, even stretch denim will relax slightly with wear. If your jeans feel loose, washing and drying can help them regain their original dimensions.

Conclusion

Denim cotton fabric’s enduring popularity stems from its unique combination of durability, versatility, and character development. Whether you’re selecting fabric for a sewing project, choosing jeans that will last for years, or considering denim for home decor, understanding the fabric’s properties and variations helps you make informed decisions.

Key Takeaways

For Buyers: Choose 100% cotton for authentic fading and breathability, or opt for blends with 1-3% elastane if you prioritize comfort and stretch. Pay attention to weight (measured in ounces) to ensure the fabric suits your intended use. Look for quality indicators like tight weave, good dye penetration, and selvage edges when possible.

For Sustainability: Seek out organic cotton, recycled content, and certifications like GOTS or OCS. Support brands using water-saving production methods and transparent supply chains. Remember that the most sustainable denim is the denim you already own – proper care and repair extend the life of existing garments significantly.

For Care: Wash denim infrequently (every 10 wears or when visibly dirty), always in cold water, inside out. Air dry whenever possible to prevent shrinkage and extend fabric life. Address stains promptly with spot cleaning rather than washing the entire garment. Don’t discard worn denim – repair, repurpose, or recycle it.

For Fashion: 2025 trends favor relaxed fits, authentic vintage washes, and sustainable production. However, denim’s timeless nature means classic styles remain relevant. Invest in quality basics that suit your body and lifestyle rather than chasing every trend.

Final Recommendations

If you’re new to working with denim, start with midweight fabric (8-12 oz) for the best balance of workability and durability. This weight range works for most applications and isn’t too challenging for home sewing projects.

For garment purchases, don’t hesitate to try different brands and styles. Denim fit varies significantly between manufacturers due to different cuts, stretch levels, and rises. What works for one person may not work for another, regardless of price or brand reputation.

Consider building a small denim wardrobe with varied weights and styles: lightweight for summer, midweight for everyday wear, and perhaps one premium or raw denim piece that will develop unique character over years of use.

Most importantly, appreciate denim for what it is – a working fabric that improves with age and use. The small imperfections, fades, and wear patterns that develop tell the story of your life in the garment. This character development is what separates denim from disposable fast fashion and explains why well-loved denim pieces become treasured possessions.

Whether you’re creating a new garment, refreshing your wardrobe, or simply maintaining your existing denim collection, the principles covered in this guide will help you get the best performance and longevity from this remarkable fabric. Denim has survived and thrived for over 150 years because it combines practicality with style in a way few other textiles can match.

Helpful Tools and Resources

To help you work with denim more effectively and make informed decisions, use these free interactive tools:

- Fabric Weight Calculator – Choose the perfect denim weight for your project based on intended use

- Fabric Yardage Calculator – Calculate exact fabric needs for sewing projects and avoid waste

- Denim Care Quiz – Discover your denim type and get personalized care recommendations

- Denim Care Schedule Calculator – Create a custom maintenance timeline for your denim wardrobe

- Fabric Care Calculator – Get personalized washing instructions based on your specific denim type

- Cotton Type Selector Quiz – Find your perfect cotton fabric match for any project

For more information on related fabrics and sewing techniques, explore our comprehensive guides on cotton fabric, common fabric types, and fabric care.

External Resources

For additional research and information about denim production and sustainability:

- Sewport Denim Fabric Directory – Comprehensive resource on denim production and sourcing

- Levi’s Denim Care Guide – Official care recommendations from a historic denim manufacturer

- Sourcing Journal Denim – Industry news and trends in denim manufacturing