Everything you need to know about maintaining, restoring, and choosing durable water repellent treatments for outdoor gear

Last Updated: February 12, 2026

Quick Answer

Durable Water Repellent (DWR) coating is a surface treatment that makes water bead up and roll off your outdoor gear instead of soaking in. While it’s not true waterproofing, DWR is what keeps your rain jacket’s outer fabric dry and allows the waterproof membrane underneath to breathe properly. Without it, your jacket feels cold and clammy even when it’s not leaking.

Table of Contents

- What Is DWR Coating?

- Why Is My Rain Jacket Not Waterproof Anymore?

- Does DWR Mean Waterproof?

- Understanding Wetting Out

- How DWR Works in Your Gear

- Testing Your DWR Coating

- How Long Does DWR Coating Last?

- How to Make Your Jacket Waterproof Again

- Care and Maintenance

- How Often to Reapply DWR

- Types of DWR Treatments

- Is DWR Toxic to Humans?

- Applications and Uses

- Product Recommendations 2026

- Brand-Specific Care Guides

- Troubleshooting Common Problems

- Cost Benefits of Maintenance

- Environmental Impact

- Climate-Specific Recommendations

- Frequently Asked Questions

What Is DWR Coating?

DWR stands for Durable Water Repellent. It’s a thin chemical coating applied to the outside of outdoor fabrics that makes water bead up and roll off instead of soaking into the material. Think of it as an invisible shield on your jacket’s outer layer.

Here’s what DWR actually does:

- Creates a microscopic spiky surface that water can’t grab onto

- Forces water droplets to stay round like beads

- Lets those beads roll right off your jacket

- Keeps the outer fabric from getting saturated

- Allows your gear’s waterproof membrane to breathe properly

Important: DWR only treats the outer fabric fibers, not the entire surface. This means air can still pass through for breathability, but water stays out.

Why You Need DWR

Your waterproof jacket actually has two layers of protection. The outer fabric has DWR coating, and underneath is a waterproof membrane (like Gore-Tex). Both work together to keep you dry and comfortable.

Without DWR, the outer fabric soaks up water like a sponge. Even though the waterproof membrane still works, you’ll feel:

- Cold and clammy as the wet fabric sits against the membrane

- Like your jacket is heavier and sagging

- Sweaty inside because moisture can’t escape through the wet outer layer

Why Is My Rain Jacket Not Waterproof Anymore?

Uneven wetting can signal contamination or reduced coating effectiveness.

This is the question that brings most people to this guide. You’re out in the rain, and suddenly you realize your “waterproof” jacket is soaking through. Before you panic and think you need a new jacket, there’s good news: 90% of the time, your jacket isn’t actually leaking.

The Real Problem: DWR Failure, Not Membrane Failure

When your jacket stops keeping you dry, it’s almost always because the DWR coating has worn off, not because the waterproof membrane failed. The membrane can last for decades if properly cared for, but DWR needs regular maintenance.

Diagnose Your Jacket Problem

YES → DWR is working fine

NO → Continue to Step 2

YES → Check for tears, broken zippers, or seam damage

NO → Your DWR just needs reactivation or reapplication

Common Causes of DWR Failure

| Cause | What Happens | How to Fix |

|---|---|---|

| Dirt and Body Oils | Build up on the fabric and block DWR from working | Wash with technical cleaner |

| Wrong Detergent | Leaves residue that attracts water | Rewash with proper cleaner |

| Abrasion | Backpack straps rub off DWR in high-wear areas | Reapply DWR treatment |

| UV Exposure | Sun breaks down chemical bonds over time | Reapply DWR treatment |

| Age | DWR naturally degrades after 20-40 wash cycles | Reapply DWR treatment |

Don’t Make This Mistake: Most people try to fix their jacket by washing it with regular laundry detergent. This actually makes the problem worse because detergents leave behind residue that attracts water. Always use a technical fabric cleaner designed for outdoor gear.

Does DWR Mean Waterproof?

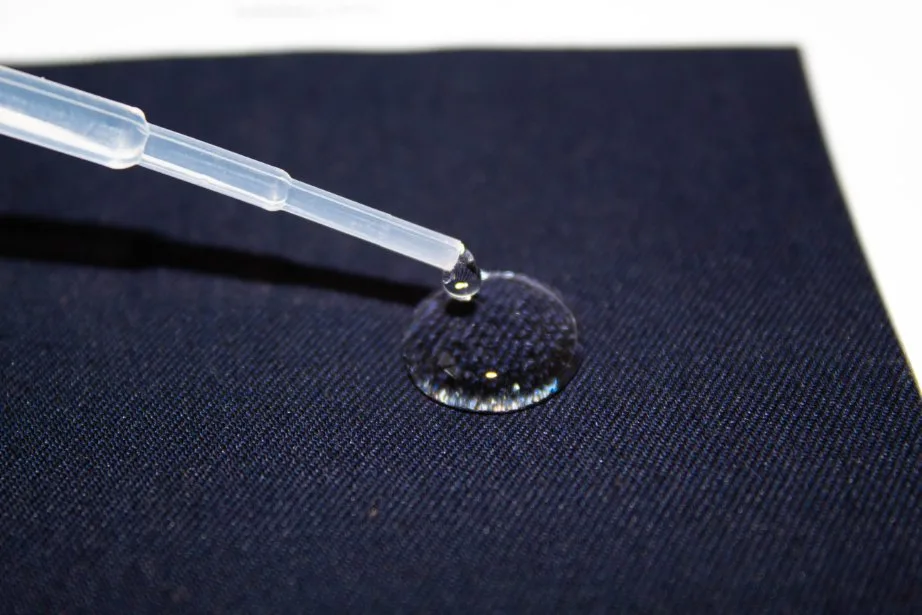

DWR helps water bead up but does not make a garment fully waterproof.

No, DWR is not the same as waterproof. This is one of the biggest misunderstandings about outdoor gear, so let’s clear it up.

The Difference

Water Repellent (DWR): Makes water bead up on the surface and roll off. Great for light rain or short periods, but will eventually let water through under pressure.

Waterproof: Completely blocks water from passing through, even in heavy rain or under pressure. This comes from the membrane layer underneath the DWR-treated fabric.

| Feature | Water Repellent (DWR) | Waterproof (Membrane) |

|---|---|---|

| Location | Outer fabric surface | Inner membrane layer |

| Purpose | Keep outer fabric dry | Block water completely |

| Durability | Wears off over time | Lasts for years |

| Maintenance | Needs regular reapplication | Minimal maintenance |

| Breathability Impact | Helps maintain breathability | Provides breathability |

| Water Column Rating | 1,000-5,000mm | 10,000mm+ |

How They Work Together

Think of your rain jacket like a house:

- DWR coating = The roof shingles that shed water

- Waterproof membrane = The solid roof deck underneath

If your roof shingles get damaged (DWR fails), water sits on the roof deck. The deck still keeps water out, but now it can’t breathe properly, and you get condensation inside. That’s why maintaining your DWR is so important.

Understanding Wetting Out: The Real Problem

“Wetting out” is the term for when your jacket’s outer fabric gets saturated with water. This is what happens when DWR fails, and it’s the main reason your jacket feels like it’s not working anymore.

What Happens During Wetting Out

- Water stops beading on the surface

- The outer fabric soaks up water like a regular cotton t-shirt would

- The wet fabric blocks breathability because moisture can’t escape through the saturated layer

- You feel cold and clammy from condensation building up inside

- Your jacket feels heavier from all the water weight in the fabric

Here’s the confusing part: your jacket is still waterproof. The membrane underneath is doing its job. But because the outer fabric is soaked, you feel wet and uncomfortable, so you think your jacket is leaking.

How to Tell If You’re Experiencing Wetting Out

Signs of wetting out:

- Dark wet patches on the outside of your jacket, especially on shoulders and arms

- The fabric feels heavy and saggy

- You feel damp and cold, but when you check, the inside isn’t actually wet

- Your jacket takes forever to dry after getting wet

Signs of actual leaking:

- Water droplets on the inside of the jacket

- Wet spots that correspond to tears or damaged seams

- Moisture coming through at zippers or pocket areas

How DWR Works in Your Gear

DWR allows the outer layer to shed water while inner membranes maintain breathability.

DWR works by changing the way water interacts with fabric at a microscopic level. Here’s the science made simple:

The Contact Angle Effect

DWR creates a microscopically rough surface on fabric fibers. When water touches this surface, it can’t spread out flat. Instead, it forms tight beads that sit on top of the fabric’s peaks.

High contact angle (good DWR):

- Water forms dome-shaped beads

- Beads roll off easily with gravity or movement

- Fabric stays dry

Low contact angle (worn DWR):

- Water spreads out flat like a puddle

- Moisture seeps into fabric fibers

- Fabric gets saturated

Why Breathable Membranes Need DWR

Your jacket’s waterproof membrane has microscopic pores that are small enough to block liquid water but large enough to let water vapor (sweat) escape. This is what makes it breathable.

But here’s the catch: if the outer fabric gets soaked, those pores get blocked. The membrane itself still works, but moisture from inside can’t escape because the saturated outer fabric is in the way.

This is why maintaining DWR is just as important as the waterproof membrane itself. They’re a team.

Testing Your DWR Coating

A simple water drop test can reveal whether DWR remains effective.

Before you spend money on new DWR products, test your current coating. This simple test takes 30 seconds and tells you exactly what your gear needs.

The Water Bead Test

-

Clean your jacket first

Sometimes dirt is blocking your DWR, not the coating failing. If your jacket is dirty, wash it with technical cleaner and let it dry completely before testing. -

Spray water on multiple areas

Focus on high-wear spots like shoulders (where backpack straps sit), elbows, and cuffs. These areas wear out first. -

Watch what happens

- Perfect DWR: Water forms tight beads that roll off when you tilt the jacket

- Weak DWR: Water beads up but doesn’t roll off easily

- Failed DWR: Water spreads out and the fabric darkens as it soaks in

-

Shake test

Give your jacket one good shake. If most of the water flies off, your DWR is still working. If water stays on the fabric, it needs attention.

What Your Results Mean

- Good beading everywhere: Your DWR is fine, no action needed

- Some areas bead, others don’t: Try heat reactivation first (see below)

- No beading anywhere: You need to reapply DWR

- Beading after cleaning: Your DWR was just dirty, regular maintenance is working

Use Our Water Repellent Treatment Flowchart

How Long Does DWR Coating Last?

Longevity of water repellency depends on care and usage.

There’s no single answer because DWR life depends on how you use and care for your gear. But here are realistic expectations:

Factory-Applied DWR

The DWR coating that comes on new gear lasts the longest:

Home-Applied DWR Treatments

When you reapply DWR at home, it won’t last quite as long as factory treatments:

- Spray-on: 10-15 wash cycles or 3-6 months of regular use

- Wash-in: 15-20 wash cycles or 4-8 months of regular use

- Professional reapplication: 25-30 wash cycles or 8-12 months of regular use

What Affects DWR Lifespan

| Factor | Impact Level | Why It Matters |

|---|---|---|

| Washing frequency | High | Each wash removes a bit of coating |

| Type of detergent | High | Wrong detergent strips DWR faster |

| Physical abrasion | High | Backpack straps, climbing, rubbing |

| UV exposure | Medium | Sun breaks down chemicals |

| Heat exposure | Medium | Too much heat damages coating |

| Storage conditions | Low | Humid storage reduces effectiveness |

How to Make DWR Last Longer

- Wash only when needed – Not after every use

- Use proper detergent – Technical cleaners only

- Apply heat after washing – Reactivates existing DWR

- Brush off dirt – Before it grinds into fabric

- Store properly – Cool, dry place, not compressed

- Avoid fabric softener – It destroys DWR permanently

How to Make Your Jacket Waterproof Again

Here’s the good news: in most cases, you can restore your jacket’s water repellency at home for less than $20. You don’t need to buy a new jacket.

There are two main approaches, and which one you use depends on your test results from above.

Method 1: Heat Reactivation (Try This First)

Best for: Jackets that have some beading but not as much as they used to. The DWR is still there but needs to be “woken up.”

Cost: Free (just electricity for your dryer)

Time: 30-40 minutes total

Why Heat Works

DWR chemicals need heat to bond properly to fabric fibers. Over time and washing, these bonds weaken. Applying controlled heat helps the existing coating redistribute and reattach to the fibers.

-

Wash your jacket with technical cleaner

Use products like Nikwax Tech Wash or Grangers Performance Wash. Regular detergent won’t work for this. Wash on gentle cycle in warm water (30-40°C). -

Run an extra rinse cycle

Make sure all detergent residue is gone. Residue blocks DWR from working. -

Check your care label

Make sure your jacket can go in the dryer. Most can, but some require air drying. -

Tumble dry on low heat for 20 minutes

This is the magic step. The heat reactivates the DWR coating. Use low or medium heat, never high. -

Test the results

Once cooled, do the water bead test again. If water beads nicely, you’re done! If not, move to Method 2.

Don’t Have a Dryer? Alternative Methods

- Hair dryer: Hold 6-8 inches away, medium heat, move constantly to avoid hot spots

- Iron with towel: Place a thin towel over jacket, iron on medium heat (no steam), keep the iron moving

- Hot water rinse: Final rinse with the hottest water your fabric can handle (check care label)

- Direct sunlight: Hang in bright sun on a hot day (works but takes longer)

Warning: Never use high heat or leave an iron in one spot. You can damage your jacket’s waterproof membrane.

Method 2: Reapplying DWR Treatment

Best for: Jackets where heat reactivation didn’t work, or when DWR is completely worn off in high-abrasion areas.

Cost: $10-20 for treatment products

Time: 1-2 hours total

Freshly treated material regains strong water beading ability.

Choosing: Spray-On vs. Wash-In

Spray-On (Like Nikwax TX.Direct Spray)

Best for:

- Targeting specific worn areas

- Jackets with fleece or insulation inside

- Quick touch-ups

- When you need precision

Pros:

- Control where it goes

- Won’t coat the inside

- No washing machine needed

Wash-In (Like Nikwax TX.Direct Wash-In)

Best for:

- Even coverage all over

- Shell jackets without insulation

- Multiple garments at once

- Convenience

Pros:

- Easy application

- Even coating

- Great for full retreatment

How to Apply Spray-On DWR

-

Clean your jacket thoroughly

Wash with technical cleaner and let dry completely. DWR only works on clean fabric. -

Work outside or in a well-ventilated area

Even PFC-free treatments have fumes you don’t want to breathe. -

Hang your jacket

Use a hanger so you can spray all sides easily. -

Shake the spray bottle well

The chemicals need to be mixed properly. -

Spray 6-8 inches away

Too close and you get drips. Too far and you waste product. Keep the bottle moving in a sweeping motion. -

Pay extra attention to high-wear areas

Shoulders, elbows, cuffs, and anywhere a backpack touches. Give these spots a second coat. -

Wipe off any drips immediately

Use a lint-free cloth to smooth out any runs or puddles. -

Let dry completely

Usually takes 6-12 hours depending on humidity. -

Apply heat to cure

Tumble dry on low for 20 minutes or use iron method. This bonds the treatment to the fabric.

How to Apply Wash-In DWR

-

Clean jacket first

You can do this in a separate wash or add wash-in treatment to the same wash as Tech Wash (check product instructions). -

Make sure detergent drawer is clean

Old detergent residue will interfere with the treatment. -

Close all zippers and fasten all velcro

This protects zippers and ensures even treatment. -

Add product to washing machine

Follow bottle instructions for amount. Usually 1-2 capfuls per garment. -

Wash on warm/gentle cycle

30-40°C water temperature works best. -

Skip the spin cycle if possible

Or use lowest spin setting. This helps treatment absorb evenly. -

Do NOT rinse

You want the treatment to stay on the fabric. -

Tumble dry on low for 20-30 minutes

Or air dry and apply heat later. Heat is required for proper bonding.

Common Mistake: Many people rinse after using wash-in DWR or don’t apply heat. Both mistakes mean the treatment won’t work properly. Follow all steps for best results.

Calculate Your DWR Treatment Costs

Care and Maintenance of DWR Coatings

Proper washing and drying help maintain durable water repellent finishes.

The best way to make your DWR last longer is proper maintenance. Here’s what actually works.

How to Wash DWR-Treated Gear

Most Important Rule: Never use regular laundry detergent, fabric softener, or bleach. These destroy DWR coating permanently.

What to use instead:

- Nikwax Tech Wash

- Grangers Performance Wash

- Gear Aid Revivex Pro Cleaner

- REI Co-op Technical Wash

The Right Way to Wash

-

Empty pockets and close all closures

Check every pocket. Close zippers, velcro, and snaps. -

Brush off dirt first

Use a soft brush to remove mud, dust, and debris before washing. -

Use technical cleaner only

Follow bottle instructions for amount. Usually 1-2 oz per garment. -

Wash on gentle cycle, warm water

30-40°C is ideal. Cold water doesn’t clean as well. Hot water can damage membranes. -

Add an extra rinse cycle

This is important. You want zero detergent residue left behind. -

Tumble dry on low or air dry

Check your care label. Most jackets can go in the dryer. -

Apply heat to reactivate DWR

This should happen after every wash. 20 minutes on low heat.

How Often Should You Wash?

This depends on how you use your gear:

| Usage Level | Washing Frequency | DWR Check |

|---|---|---|

| Daily use (commuting, dog walking) | Every 2-3 weeks | Monthly |

| Weekly adventures (hiking, skiing) | Every 4-6 uses | Every 2 months |

| Monthly outings | Every 8-10 uses | Every 3 months |

| Occasional use | Once per season or when dirty | Every 6 months |

Between-Wash Maintenance

Keep your DWR working longer with these simple habits:

- Brush off dirt after each use – Don’t let it grind into the fabric

- Hang to air out – Prevents mildew and odors

- Spot clean when possible – Use a damp cloth for small stains

- Store loosely – Don’t stuff into a tiny bag for long-term storage

- Keep away from heat sources – Don’t store near heaters or in hot cars

What Damages DWR

Avoid these DWR killers:

- Regular detergent – Leaves residue that attracts water

- Fabric softener – Coats fibers and blocks DWR completely

- Bleach – Destroys both DWR and waterproof membranes

- Stain removers – Most contain chemicals that strip DWR

- Dryer sheets – Same effect as fabric softener

- Rubbing alcohol – Breaks down DWR chemical bonds

- Acetone/nail polish remover – Dissolves DWR coating

- DEET insect repellent – Damages both DWR and fabric

- Sunscreen – Oils clog DWR; rinse off promptly

How Often to Reapply DWR

Regular inspection helps determine when retreatment is necessary.

The answer depends on how hard you use your gear. Here are realistic schedules based on actual outdoor use:

By Activity Level

| Activity Type | Frequency | Reapplication Schedule |

|---|---|---|

| Backcountry Skiing (weekly) | Heavy abrasion + snow exposure | Every 3-4 months |

| Regular Hiking (2-4x/month) | Moderate wear + variable weather | Every 4-6 months |

| Daily Commuting | Consistent light use | Every 6-8 months |

| Bike Touring | High mileage + rain exposure | Every 3-5 months |

| Trail Running | High motion + sweat | Every 4-5 months |

| Camping/Backpacking | Multi-day exposure | Every 5-7 months |

| Occasional Use (monthly or less) | Minimal wear | Once per year |

Signs You Need to Reapply Now

Don’t just go by time. Watch for these warning signs:

- Water soaks into fabric instead of beading (most obvious sign)

- Dark wet patches that don’t dry quickly

- Fabric feels heavy when wet

- You feel clammy inside even though it’s not leaking

- Heat reactivation doesn’t restore beading anymore

- High-wear areas (shoulders, elbows) look different than the rest of the jacket

Maintenance Timeline

Here’s a practical year-round schedule for active outdoor users:

Wash, test DWR, reapply if needed

Test DWR, heat reactivation if needed

Wash thoroughly, reapply DWR, store properly

Types of DWR Treatments

Various DWR chemistries influence how easily moisture rolls off.

Not all DWR treatments are created equal. The outdoor industry has gone through major changes in recent years, moving away from harmful chemicals to more eco-friendly options.

The Evolution of DWR Chemistry

C8 (Long-chain fluorocarbons) – Banned 2016

These were the original DWR chemicals. They worked great but contained PFOA and PFOS, which are toxic “forever chemicals” that don’t break down in the environment. You won’t find these on new gear anymore, but older jackets might still have them.

C6 (Short-chain fluorocarbons) – Current standard

After C8 was banned, the industry switched to C6 chemistry. It’s less harmful than C8 but still contains some PFAS. Most outdoor brands use this now, but they’re working to phase it out.

C0 (PFC-Free/Fluorocarbon-Free) – The future

These are the newest treatments made without any fluorocarbons. They’re based on silicones, hydrocarbons, waxes, or plant-based materials. They’re better for the environment but don’t last quite as long as C6.

Performance Comparison

| Treatment Type | Water Repellency | Oil Repellency | Durability | Environmental Impact |

|---|---|---|---|---|

| C8 (Old) | Excellent | Excellent | Very High | Very Bad (Banned) |

| C6 (Current) | Excellent | Very Good | High | Concerning |

| PFC-Free | Good to Very Good | Fair to Good | Medium | Much Better |

Types of PFC-Free Treatments

Silicone-Based

- Good water repellency

- Breathable

- More durable than other PFC-free options

- Example: Nikwax products

Hydrocarbon-Based

- Moderate performance

- Cost-effective

- Less durable than silicone

- Gets contaminated by oils more easily

Wax-Based

- Natural option

- Good for certain fabrics (canvas, cotton)

- Requires frequent reapplication

- Can affect breathability

Bio-Based Polymers

- Made from plant materials

- Improving performance with new technology

- Most sustainable option

- Still being refined

Which Should You Choose?

If you’re buying aftermarket DWR treatments, here’s what to consider:

Choose PFC-Free (C0) if:

- You care about environmental impact (you should!)

- You’re okay with more frequent reapplication

- You mainly face rain, not oil/grease

- You want safer chemicals around your family

C6 might be necessary if:

- You need maximum oil resistance (working around machinery)

- You do extreme alpine climbing where gear failure is dangerous

- You need the absolute longest durability between treatments

For most people, modern PFC-free treatments work great. The performance gap has closed significantly in recent years.

Is DWR Toxic to Humans?

Water beads on a DWR treated jacket, often discussed in relation to human safety.

This is an important question, especially if you’re concerned about your health and your family’s safety.

The Short Answer

DWR on finished clothing is safe to wear. By the time a jacket reaches you, the chemicals have been heat-cured and bonded to the fabric. You’re not absorbing them through your skin during normal wear.

The concerns about DWR toxicity mainly relate to:

- Manufacturing workers exposed to raw chemicals

- Environmental contamination from production facilities

- Applying DWR spray without proper ventilation

- Long-term buildup of PFAS in drinking water

Understanding PFAS (“Forever Chemicals”)

PFAS (per- and polyfluoroalkyl substances) are a group of chemicals that:

- Don’t break down in the environment

- Can accumulate in your body over time

- Have been linked to health concerns in some studies

- Are found in many products beyond outdoor gear (non-stick pans, food packaging, carpets)

The old DWR (C8): Contained the worst PFAS compounds (PFOA, PFOS). These are now banned in the US and EU.

Current DWR (C6): Uses shorter-chain PFAS that break down faster and are less likely to accumulate in your body. Still not ideal, but much better than C8.

PFC-Free DWR: Contains no PFAS at all. These are the safest option for human health and the environment.

Safety Tips When Using DWR Products

When applying spray-on DWR:

- Always work outside or in a well-ventilated area

- Wear a mask if you’re sensitive to fumes

- Don’t spray near food or where kids/pets play

- Wash your hands after handling

- Let gear dry completely before wearing (24 hours is best)

Choosing Safer Products

Look for these labels when buying DWR treatments:

- “PFC-Free” or “PFAS-Free”

- “Fluorocarbon-Free”

- “C0 Chemistry”

- Bluesign® approved

- OEKO-TEX® certified

Brands making safe DWR products:

- Nikwax (all products PFC-free)

- Grangers (PFC-free line)

- Gear Aid Revivex (PFAS-free options)

What About Old Gear?

If you have a jacket from before 2016, it might have C8 DWR. Don’t panic. The coating is bonded to the fabric and won’t transfer to your skin in any meaningful amount. If you’re concerned:

- Wash the jacket with technical cleaner

- Reapply with PFC-free DWR treatment

- This replaces most of the old coating with safer chemicals

Applications and Uses of DWR Coating

DWR coatings are widely used on outerwear, bags, and performance textiles.

DWR isn’t just for rain jackets. You’ll find it on almost all outdoor gear. Understanding where it’s used helps you maintain all your equipment properly.

Outdoor Clothing

Rain Jackets and Shell Layers

This is the most common use. Every waterproof jacket needs DWR to work properly. Without it, the outer fabric gets saturated and blocks breathability.

Rain Pants

Same principle as jackets. DWR keeps them light and breathable in wet conditions.

Soft Shell Jackets

These aren’t fully waterproof but have DWR for light rain protection while maintaining breathability.

Down Jackets and Insulation

DWR protects down from getting wet, which destroys its insulating ability. Even light moisture makes down clump and lose loft.

Hiking Pants and Shorts

Many technical pants have DWR to shed light rain and dry faster after water crossings.

Hats and Gloves

DWR helps these stay dry and maintain warmth in wet conditions.

Technical Gear and Equipment

Tents

The rain fly on your tent has DWR to shed rain and prevent the fabric from sagging when wet. Water-resistant fabrics in tents rely heavily on proper DWR maintenance.

Backpacks

Most outdoor packs have DWR to protect your gear from rain and make the pack lighter when wet.

Sleeping Bags

The outer shell has DWR to protect insulation from tent condensation and light moisture.

Stuff Sacks and Dry Bags

DWR adds an extra layer of protection for gear storage.

Gaiters

These need DWR to shed snow and rain while hiking.

Bivvy Bags

DWR is important for minimalist shelters to handle moisture.

Footwear

Hiking Boots

Leather and fabric hiking boots often have DWR treatment, especially around seams and fabric panels.

Trail Runners

Many technical running shoes use DWR for wet trail conditions.

Home and Lifestyle

Outdoor Furniture

Cushions and umbrellas often use DWR to resist rain and sun damage.

Strollers and Baby Carriers

Weather covers and fabric components often have DWR treatment.

Pet Gear

Dog coats, beds, and carrier bags frequently use DWR fabrics.

Brand-Specific DWR Applications

| Brand | DWR Type | Special Features |

|---|---|---|

| Patagonia | PFC-free on most products | Early adopter of safe chemistry |

| Arc’teryx | Transitioning to PFC-free | Long-lasting factory treatment |

| The North Face | Mix of C6 and PFC-free | Different levels by product line |

| REI Co-op | PFC-free on new products | Value-focused, reliable performance |

| Columbia | OutDry (permanent waterproofing) | Different technology, doesn’t need DWR |

Product Recommendations and Buying Guide 2026

Retail environment where shoppers compare water repellent outerwear options.

Here are the best DWR products available right now, tested and recommended for different needs.

Best Overall DWR Treatments

1. Nikwax TX.Direct Spray-On – Best All-Around

Price: $12-18 for 10 oz

Type: PFC-free spray

Best for: Most users and general outdoor gear

Why we recommend it:

- Water-based formula safe for you and the environment

- Works on all technical fabrics including Gore-Tex

- Easy to apply with consistent results

- Doesn’t require heat activation (but works better with it)

- One bottle treats 2-3 jackets

Performance: Lasts 10-15 washes or 4-6 months of regular use

2. Gear Aid Revivex Durable Water Repellent – Best Premium Option

Price: $15-20 for 16.9 oz

Type: PFAS-free spray

Best for: High-performance gear and serious outdoor athletes

Why we recommend it:

- Superior durability compared to other PFC-free options

- Professional-grade performance

- Large bottle size gives better value

- Works on Gore-Tex, eVent, and all technical fabrics

- Maintains breathability better than competitors

Performance: Lasts 12-18 washes or 5-7 months of regular use

3. Grangers Performance Repel – Best Budget Pick

Price: $10-15 for 10.1 oz

Type: Fluorocarbon-free spray

Best for: Budget-conscious users and occasional outdoor enthusiasts

Why we recommend it:

- Lowest cost per application

- Good performance for the price

- Compatible with all outdoor fabrics

- Easy to find at most outdoor retailers

Performance: Lasts 8-12 washes or 3-5 months of regular use

Best Wash-In Treatments

Nikwax TX.Direct Wash-In

Price: $12-16 for 10 oz

Best for: Shell jackets without insulation, treating multiple items

Pros:

- Even coverage across entire garment

- Can treat multiple items at once

- Convenient application in washing machine

- PFC-free and environmentally safe

Cons:

- Coats inside of jacket too (can affect breathability)

- Not ideal for insulated garments

- Uses more product than spot treatment

Additional Quality DWR Treatments

4. Atsko Silicone Water Guard

Price: $8-12 for 10.5 oz

Type: Silicone-based spray

Best for: Budget-friendly option for tents and backpacks

Performance: Lasts 6-10 washes or 3-4 months of regular use

5. Granger’s Clothing Repel

Price: $14-18 for 10.1 oz

Type: PFC-free wash-in

Best for: Treating multiple garments at once

Performance: Lasts 10-15 washes or 4-6 months of regular use

6. Storm Waterproofing Wash-In

Price: $11-15 for 10 oz

Type: Fluorocarbon-free wash-in

Best for: Eco-conscious users wanting convenience

Performance: Lasts 8-12 washes or 3-5 months of regular use

7. McNett ReviveX Spray

Price: $12-16 for 10 oz

Type: Water-based spray

Best for: Quick touch-ups and spot treatment

Performance: Lasts 8-12 washes or 3-5 months of regular use

8. Scotchgard Heavy Duty Water Shield

Price: $9-13 for 10.5 oz

Type: Spray treatment

Best for: Outdoor furniture and non-technical fabrics

Performance: Lasts 5-8 washes or 2-4 months

Best Cleaning Products

Remember: proper cleaning is just as important as DWR treatment.

Nikwax Tech Wash

Price: $10-14 for 10 oz

Our pick for: Regular cleaning of all outdoor gear

Safe for:

- All waterproof fabrics

- Down and synthetic insulation

- Soft shells and fleece

- Won’t strip existing DWR

Grangers Performance Wash

Price: $10-13 for 10.1 oz

Our pick for: Heavy dirt and serious cleaning

Best for:

- Really dirty gear

- Removing stubborn oils

- Pre-treatment before DWR application

REI Co-op Technical Wash

Price: $8-11 for 12 oz

Our pick for: Best value for regular maintenance

Features:

- Affordable house brand alternative

- Works on all technical fabrics

- Doesn’t leave residue

- Great for frequent washers

Sport-Wash by Atsko

Price: $7-10 for 18 oz

Our pick for: Hunters and those needing scent-free cleaning

Special features:

- Removes human scent

- No perfumes or UV brighteners

- Safe for all outdoor fabrics

- Biodegradable formula

Shopping Checklist

When buying DWR products, look for:

- ✓ PFC-free or PFAS-free label

- ✓ Compatible with your fabric type (check your gear’s care label)

- ✓ Spray for targeted application, wash-in for full coverage

- ✓ Technical cleaner to pair with treatment

- ✓ Recent manufacture date (DWR products can degrade in the bottle)

Complete Product Comparison Matrix

Compare all recommended products side by side:

| Product | Type | Price | Longevity | Eco Rating | Best Use |

|---|---|---|---|---|---|

| Nikwax TX.Direct Spray | Spray | $12-18 | 10-15 washes | Excellent (PFC-free) | All-around best |

| Gear Aid Revivex DWR | Spray | $15-20 | 12-18 washes | Excellent (PFAS-free) | Premium performance |

| Grangers Performance Repel | Spray | $10-15 | 8-12 washes | Good | Budget choice |

| Atsko Silicone Water Guard | Spray | $8-12 | 6-10 washes | Good | Tents, packs |

| Granger’s Clothing Repel | Wash-in | $14-18 | 10-15 washes | Excellent (PFC-free) | Multiple items |

| Nikwax TX.Direct Wash-In | Wash-in | $12-16 | 10-15 washes | Excellent (PFC-free) | Shell jackets |

| Storm Waterproofing | Wash-in | $11-15 | 8-12 washes | Excellent | Eco-conscious |

| McNett ReviveX | Spray | $12-16 | 8-12 washes | Good | Quick touch-ups |

| Scotchgard Heavy Duty | Spray | $9-13 | 5-8 washes | Fair | Non-technical gear |

Brand-Specific Care Guides

Different outdoor brands use different technologies. Here’s what you need to know for proper care.

Gore-Tex Products

DWR Type: Transitioning to PFC-free (older products may have C6)

Special care instructions:

- Can be machine washed on regular cycle (30-40°C)

- Always tumble dry on medium heat after washing

- Heat is required to reactivate DWR – don’t skip this step

- Can withstand more frequent washing than other membranes

- Compatible with all PFC-free DWR treatments

Common mistake: People skip the dryer because they’re afraid of heat. Gore-Tex needs heat to maintain performance.

Patagonia Gear

DWR Type: PFC-free across most product lines since 2016

Special care instructions:

- Use only PFC-free DWR treatments (Nikwax recommended)

- Wash in cold to warm water (not hot)

- Tumble dry on low heat

- More frequent DWR maintenance needed than with C6 treatments

Note: Patagonia’s environmental commitment means their DWR is safer but may need reapplication every 4-6 months with regular use.

Arc’teryx Products

DWR Type: Premium factory-applied (transitioning to PFC-free)

Special care instructions:

- Factory DWR is exceptionally durable

- Can go 30-40 washes before reapplication

- Follow care label precisely – different models have different requirements

- Professional cleaning recommended for high-end pieces

Note: Arc’teryx gear costs more but the factory DWR lasts significantly longer.

Columbia OutDry

Technology: Completely different approach – waterproof membrane on outside

Special considerations:

- Doesn’t use traditional DWR coating

- Permanently waterproof – won’t wet out

- Still needs cleaning to maintain breathability

- Heavier and less breathable than traditional designs

- Best for cold weather or low-intensity activities

This technology eliminates DWR maintenance entirely but has trade-offs in weight and breathability.

The North Face

DWR Type: Variable by product line (check specific item)

Product tiers:

- Summit Series: Premium DWR, longest durability

- FutureLight: New membrane technology with PFC-free DWR

- Standard line: Mix of C6 and PFC-free

Care varies: Always check the care label on your specific item as The North Face uses different technologies across their range.

REI Co-op Brand

DWR Type: PFC-free on all new products

Value-focused care:

- Good performance for the price

- May need more frequent DWR maintenance

- Standard care instructions work well

- Compatible with all aftermarket DWR treatments

Troubleshooting Common DWR Problems

When things go wrong with your DWR treatment, here’s how to fix it.

Problem: DWR Spray Left Streaks or Spots

Cause: Uneven application or spraying too close

Solution:

- Wash the jacket with tech wash to remove the streaky DWR

- Let dry completely

- Reapply DWR spray, holding bottle 6-8 inches away

- Use sweeping motions for even coverage

- Wipe any drips immediately with a lint-free cloth

Problem: Water Still Soaks In After Treatment

Possible causes:

- Didn’t clean thoroughly first

- Didn’t apply heat to cure the treatment

- Used wrong type of treatment for your fabric

- Fabric is damaged or contaminated

Solution:

- Strip existing DWR with deep cleaning (2x wash cycles)

- Dry completely

- Reapply DWR carefully

- Apply heat (tumble dry 20 minutes on low)

- Test again

Problem: Jacket Feels Stiff After DWR Application

Cause: Too much product applied or product not fully absorbed

Solution:

- Wash with tech wash to remove excess

- Tumble dry on low with tennis balls (helps restore fabric movement)

- Next time use less product – light, even coats work better

Problem: DWR Only Lasted 2-3 Weeks

Likely causes:

- Heavy contamination from dirt, body oils, or sunscreen

- Washed with regular detergent after treatment

- Didn’t heat-cure the treatment

- Very high abrasion environment

Prevention:

- Clean gear more frequently

- Always use technical cleaner

- Apply heat every time you wash

- Consider more durable product (like Revivex)

Problem: Inside of Jacket Feels Clammy

This might not be a DWR problem!

Possible causes:

- Normal condensation: You’re working hard and producing more moisture than can escape

- Wrong layering: Too much insulation trapping sweat

- Blocked breathability: Inner liner is dirty or damaged

- Failed DWR: Outer fabric is saturated and blocking vapor escape

Diagnosis:

- Check if outside is wet (DWR failure)

- Check if you’re sweating heavily (normal)

- Try with fewer layers (test breathability)

Problem: Can’t Get DWR to Bead on Shoulders

Cause: Backpack straps have abraded the coating away and ground oils into the fabric

Solution:

- Scrub shoulder areas with soft brush and tech wash

- Rinse thoroughly

- Apply extra coats of DWR spray to these areas

- Heat cure carefully

- Accept that high-wear areas will need frequent retreatment

Prevention: Clean these areas more often, even if the rest of the jacket doesn’t need washing.

Cost Benefits of Maintaining DWR

Water beading highlights the protective benefits of a durable water repellent finish.

Maintaining your DWR isn’t just about performance – it’s about saving money. Let’s look at the real numbers.

The $20 Treatment That Saves $300

Example scenario: You own a $300 rain jacket

| Option | Initial Cost | Maintenance | 5-Year Total |

|---|---|---|---|

| No Maintenance | $300 | Replace after 2 years: $300 Replace again: $300 | $900 |

| With DWR Care | $300 | Cleaner: $10/year DWR spray: $15 × 2/year | $500 |

| Savings | $400 over 5 years | ||

Cost Per Use Comparison

Scenario: Weekend hiker using jacket 2x per month

Without maintenance:

- Jacket lasts 2 years = 48 uses

- Cost per use: $300 ÷ 48 = $6.25 per use

With proper care:

- Jacket lasts 5+ years = 120+ uses

- Total cost: $300 + $200 (maintenance) = $500

- Cost per use: $500 ÷ 120 = $4.17 per use

- Savings: $2.08 per use

Annual Maintenance Budget

Here’s what you’ll actually spend on DWR care:

Breakdown:

- Technical cleaner: $12 (lasts 8-10 washes)

- DWR spray: $15 × 2-3 per year = $30-45

- Total: $42-57 per year

This maintains 2-3 pieces of gear (jacket, pants, maybe a tent or pack).

DIY vs. Professional Treatment

| Service | DIY Cost | Professional Cost | Best For |

|---|---|---|---|

| Basic cleaning + heat reactivation | $2-3 | $15-25 | Regular maintenance – DIY |

| DWR reapplication | $8-12 | $25-40 | Most situations – DIY |

| Full restoration service | $15-20 | $40-60 | Expensive gear or end-of-season – Professional |

Hidden Costs of Not Maintaining DWR

Beyond just replacing gear, poor DWR costs you:

- Discomfort: Cold, clammy feeling makes activities less enjoyable

- Safety risk: Wet, cold conditions in backcountry can be dangerous

- Trip disappointment: Cut outings short because gear isn’t working

- Environmental impact: More gear in landfills from premature replacement

Environmental Impact and Sustainability

The outdoor industry is going through a major shift toward more sustainable DWR treatments. Here’s what’s actually happening.

The PFAS Problem

PFAS chemicals (found in older DWR treatments) are called “forever chemicals” because they:

- Don’t break down in nature – ever

- Accumulate in water, soil, and animals

- Have contaminated drinking water worldwide

- Pass through wastewater treatment unchanged

- Spread globally through water and air

Current PFAS statistics:

What’s Changed

2016: US bans long-chain PFAS (C8) in manufacturing

2020-2023: Major brands commit to PFC-free by 2025

2024-2026: Industry transition to fluorocarbon-free alternatives

Current brand commitments:

| Brand | PFC-Free Goal | Current Status |

|---|---|---|

| Patagonia | Achieved 2016 | 100% PFC-free |

| Vaude | Achieved 2020 | 100% PFC-free |

| Jack Wolfskin | 2025 | 90%+ PFC-free |

| The North Face | 2025 | 85%+ PFC-free |

| Arc’teryx | 2025 | 80%+ PFC-free |

| Salomon | 2026 | 70%+ PFC-free |

Making Sustainable Choices

When buying new gear:

- Look for “PFC-Free” or “Fluorocarbon-Free” labels

- Check brand websites for PFAS policies

- Support companies with strong environmental commitments

- Consider Bluesign® or OEKO-TEX® certified products

When maintaining gear:

- Choose PFC-free DWR treatments (Nikwax, Grangers PFC-free)

- Properly dispose of old DWR products (check local hazardous waste)

- Use water-based cleaners

- Wash less frequently to reduce chemical release

The Performance Trade-off

PFC-free DWR does require more maintenance:

- Traditional C6: Reapply every 6-8 months

- PFC-free: Reapply every 4-6 months

But the gap is closing as technology improves. For most outdoor users, PFC-free performance is now good enough.

Your Environmental Impact

By properly maintaining one jacket for 5 years instead of replacing:

- Save 20-30 lbs of textile waste from landfills

- Avoid carbon emissions from manufacturing 2 new jackets

- Reduce water consumption (hundreds of gallons per jacket)

- Prevent chemical pollution from production

Proper care isn’t just about your gear – it’s about reducing your overall environmental footprint.

Climate-Specific DWR Recommendations

Different climates may require different strengths of water repellent protection.

Where you live and play affects how you should care for your DWR. Different climates have different challenges.

Pacific Northwest (Heavy Rain)

Climate challenges:

- Persistent rain and drizzle

- High humidity

- Cool temperatures

- Long wet seasons

DWR strategy:

- Choose most durable treatments (Revivex or premium options)

- Reapply every 4-6 months

- Test water repellency monthly during wet season

- Consider professional treatment once a year

- Keep backup gear treated and ready

Recommended products: Gear Aid Revivex (best durability for constant rain)

Northeast (Variable Conditions)

Climate challenges:

- Four distinct seasons

- Freeze-thaw cycles stress DWR

- Mix of rain and snow

- High summer humidity

DWR strategy:

- Seasonal maintenance schedule

- Reapply at start of fall and spring

- Mid-winter check and heat reactivation

- Focus on versatile treatments

Recommended products: Nikwax TX.Direct (good all-around performance)

Mountain West (High Altitude Sun)

Climate challenges:

- Intense UV exposure

- Rapid temperature changes

- Low humidity

- Mix of rain and snow

DWR strategy:

- UV-stable formulations preferred

- More frequent reapplication due to sun damage (every 3-4 months)

- Store gear out of direct sunlight when not in use

- Test DWR before every major trip

Recommended products: Grangers Performance Repel (UV-resistant formula)

Southeast (Heat and Humidity)

Climate challenges:

- Extreme humidity

- Frequent washing due to sweat

- Mold and mildew risk

- Intense summer storms

DWR strategy:

- Wash more frequently (clean gear = working DWR)

- Always dry completely before storing

- Reapply every 6-8 months

- Heat reactivation after every wash

- Air out gear after every use

Recommended products: Nikwax products (won’t promote mildew growth)

Desert Southwest (Arid Conditions)

Climate challenges:

- Very low humidity

- Intense sun and heat

- Infrequent but heavy monsoons

- Dust and fine particles

DWR strategy:

- DWR lasts longer in dry conditions

- Clean off dust regularly (dry brush)

- Reapply annually or before monsoon season

- UV protection is priority

Recommended products: Any quality PFC-free treatment works well

Alaska/Extreme Cold

Climate challenges:

- Snow more than rain

- Extreme temperature swings

- Frequent freeze-thaw

- Long storage periods

DWR strategy:

- Pre-season treatment before winter

- Mid-season check and reactivation

- Store with fresh DWR for summer

- Focus on snow-shedding performance

Frequently Asked Questions

Conclusion

Taking care of your outdoor gear doesn’t have to be complicated. At its core, DWR maintenance comes down to three simple habits: clean your gear properly, apply heat to reactivate the coating, and reapply treatment when needed. These basic steps can extend your jacket’s life by years and save you hundreds of dollars.

The most important thing to remember is that DWR failure doesn’t mean your gear is broken. When your jacket starts feeling wet and clammy, it’s almost always the surface coating wearing off, not the waterproof membrane failing. A $15 bottle of DWR spray can make your jacket work like new again in less than an hour.

Key Takeaways

What you need to know:

- DWR is not waterproofing – it’s a surface treatment that helps waterproof membranes work properly by keeping the outer fabric dry

- Heat reactivation is free – try this first before buying new DWR products. 20 minutes in the dryer often restores performance

- Regular detergent destroys DWR – only use technical cleaners designed for outdoor gear. This is the #1 mistake people make

- Most “leaks” are actually wetting out – when the outer fabric gets saturated, you feel wet and cold even though water isn’t actually getting through

- Test your DWR regularly – spray water on your jacket every few months. If it doesn’t bead up, take action before your next adventure

- PFC-free works great now – environmental concerns are real, and modern fluorocarbon-free treatments offer excellent performance

- High-wear areas need extra attention – shoulders, elbows, and cuffs wear out first. Give them extra coats when reapplying

- Proper care saves money – spending $40-60 per year on maintenance can extend a $300 jacket’s life from 2 years to 5+ years

Your Action Plan

Do this today:

- Test your current gear with the water bead test

- Order technical cleaner and DWR spray if you don’t have them

- Set a reminder to check DWR at the start of each season

This season:

- Clean gear with proper technical wash

- Apply heat reactivation after every wash

- Reapply DWR to any items that fail the bead test

For the long term:

- Choose PFC-free treatments for health and environment

- Maintain gear regularly rather than waiting for problems

- Support brands committed to safer chemistry

- Buy quality gear once and maintain it properly

Final Thoughts

The outdoor gear industry has made amazing progress in recent years. You no longer have to choose between performance and environmental responsibility. Modern PFC-free DWR treatments work well for most outdoor activities, and they’re getting better every year.

But all the technology in the world doesn’t matter if you don’t maintain it. The difference between gear that lasts 2 years and gear that lasts 7+ years comes down to spending 30 minutes a few times a year on basic care.

Your jacket was designed to keep you comfortable in challenging conditions. Give it the simple maintenance it needs, and it’ll keep you dry and happy for years to come. The $20 and one hour you invest in DWR care will pay you back many times over in gear that works when you need it most.

Now get out there and enjoy your adventures, knowing your gear will keep working as hard as you do.

Ready to Get Started?

Calculate Your Maintenance Costs

Use Our Treatment Selection Tool

For more information on caring for technical fabrics, check out our guides on washing and caring for different fabrics and caring for synthetic fabrics.

References and Further Reading

- Gore-Tex Official DWR Care Guide – Manufacturer guidance on maintaining DWR treatments

- REI Expert Advice: DWR Coating Care – Comprehensive guide from outdoor retail experts

- EPA PFAS Information – Environmental Protection Agency resources on PFAS chemicals and health impacts