Complete Guide to Water Resistant Fabric: Types, Testing Standards, DWR Technology & Applications for Every Need

Many people see “water resistant” on fabric products like jackets, outdoor gear, or upholstery, but may not know exactly what it means. Water resistant fabric means that a material can resist some water penetration but will not keep water out completely. This is different from being waterproof, which would block water entirely.

Understanding water resistance in fabrics can help people make better choices when buying products for outdoor activities, sports, or daily use. Different fabrics have different levels of water resistance, and knowing these levels helps set the right expectations. The right fabric can make a big difference in choosing the best product for specific needs.

Table of Contents

Key Takeaways

- Water resistance is the ability of fabric to resist water, but not fully block it

- There are different ratings and treatment methods for various fabric types

- Proper understanding helps buyers match fabrics to their specific applications

- DWR coatings and fabric construction both play crucial roles in performance

What is Water Resistant Fabric?

Water resistant fabric describes textiles that have been engineered to repel water to varying degrees while maintaining breathability and durability. These fabrics are designed to resist water penetration through specialized weaving techniques, chemical treatments, or protective coatings applied during manufacturing.

The term “water resistant” is officially recognized in textile standards and differs significantly from waterproof materials. Water resistant fabrics can handle light rain, splashes, and moisture but will eventually allow water through under prolonged exposure or pressure.

What is Water Resistant

Water resistance in textiles refers to a material’s ability to resist water penetration for a specific period or under certain conditions. This resistance can be achieved through:

- Tight weave construction that limits space between fibers

- Chemical treatments that change the surface properties

- Protective coatings applied to the fabric surface

- Specialized fiber types that naturally repel water

Differences Between Water Resistant and Waterproof Fabrics

Water-resistant fabrics can keep out some water, but not all. Waterproof fabrics are engineered to block water completely for a specific amount of time or at a certain pressure. Being waterproof means the fabric should not let any water inside even during heavy exposure.

Water-resistant is suitable for light splashes or rain. Waterproof materials work for underwater activities or complete submersion. For example, most outdoor jackets are water-resistant, while diving suits use waterproof materials.

| Feature | Water-Resistant | Waterproof |

|---|---|---|

| Use | Light rain, splashes | Swimming, submersion |

| Protection | Partial | Complete (specified limits) |

| Breathability | Usually maintained | Often compromised |

| Common Products | Outdoor jackets, hiking pants | Diving gear, rain boots |

Types of Water Resistant Fabrics

Natural Water-Resistant Fabrics

Wool is naturally water-resistant due to its fiber structure and natural oils. The quality of wool has improved significantly over the years, becoming softer and less irritating. When wool is boiled in hot water before being woven, it increases its water-resistant properties dramatically.

Wool treated with lanolin becomes temporarily waterproof. Lanolin is a natural wax produced by sheep that enhances water repellency. However, this coating needs regular reapplication as it wears off over time.

Tightly Woven Cotton can achieve water resistance through dense weaving. Canvas and duck cloth are traditional examples where the tight weave structure prevents water penetration. ELS (Extra Long Staple) cotton, grown primarily in California, uses longer fibers that allow for an extremely tight weave, making it naturally water-resistant.

Linen has been used historically in oilcloth applications, where the base fabric is treated with oils to create water resistance.

Synthetic Water-Resistant Fabrics

Polyester and Nylon are among the most common synthetic fabrics used for water resistance. These materials have inherently hydrophobic (water-repelling) properties.

Is Polyester Water Resistant?

Yes, polyester fabric is naturally water-resistant due to its synthetic polymer structure. The tight molecular bonds in polyester fibers make it difficult for water molecules to penetrate. However, the level of water resistance depends on several factors:

- Weave density: Tighter weaves provide better resistance

- Fabric weight: Heavier polyester fabrics generally offer more protection

- Finishing treatments: Additional coatings can enhance performance

Is Polyester Waterproof?

Standard polyester is water-resistant but not completely waterproof. Pure polyester fabric will eventually allow water through under pressure or prolonged exposure. However, polyester can be made waterproof through:

- PU coating application

- Lamination with waterproof membranes

- Dense weaving with appropriate treatments

Can You Waterproof Polyester?

Yes, polyester fabric can be made waterproof through several methods:

- Spray-on treatments: Consumer-grade waterproofing sprays

- Professional coating: Industrial-grade polyurethane applications

- Heat treatment: Activating existing DWR coatings

- Wash-in treatments: Laundry additives that restore water repellency

The effectiveness and durability of these treatments vary significantly.

Is Nylon Water Resistant?

Nylon exhibits excellent water resistance properties naturally. The synthetic polymer structure creates a barrier against water penetration. Nylon’s water resistance can be enhanced through:

- Tight weave construction (like ripstop nylon)

- DWR coating application

- Lamination with waterproof membranes

Ripstop nylon features a grid pattern of reinforcing threads that prevent tears while maintaining water resistance.

Advanced Synthetic Fabrics

PUL (Polyurethane Laminate) fabric consists of polyester with a plastic backing coated with a thin waterproof layer. PUL is completely waterproof, very durable, breathable with slight stretch, and comfortable against skin. The fabric side remains soft and flexible while the laminated backing provides complete water protection.

PUL comes in different thicknesses (1mm and 2mm coating options) and can be made from various base fabrics including 100% cotton or polyester blends. The best feature of PUL is its washing durability – it can be laundered repeatedly without losing effectiveness.

TPU (Thermoplastic Polyurethane) serves as an improved alternative to PUL. TPU is softer, more flexible, and considered more environmentally friendly than traditional PUL. It offers similar waterproof properties while providing enhanced comfort and sustainability.

Microfiber achieves water resistance through its unique knitting construction. The extremely fine fibers are woven tightly enough to repel water while maintaining breathability. With PUL coating, microfiber becomes completely waterproof.

Understanding DWR (Durable Water Repellent) Technology

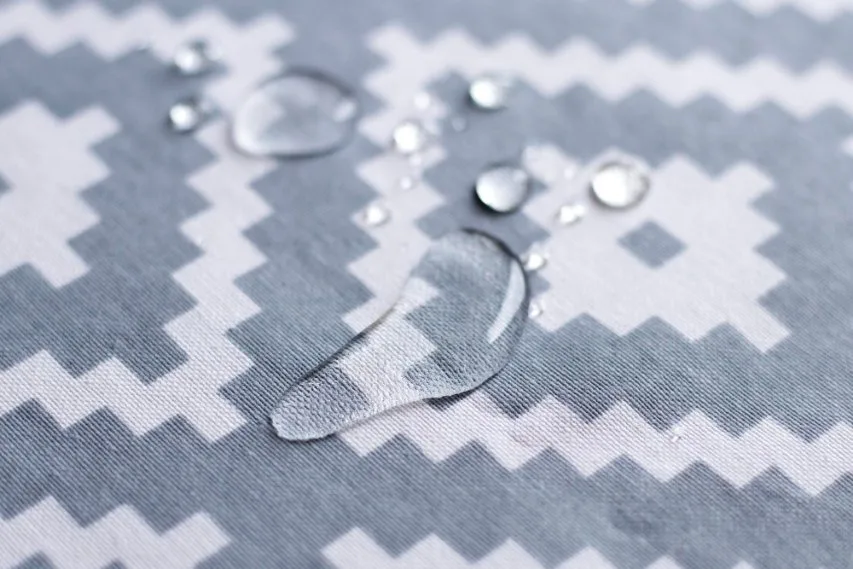

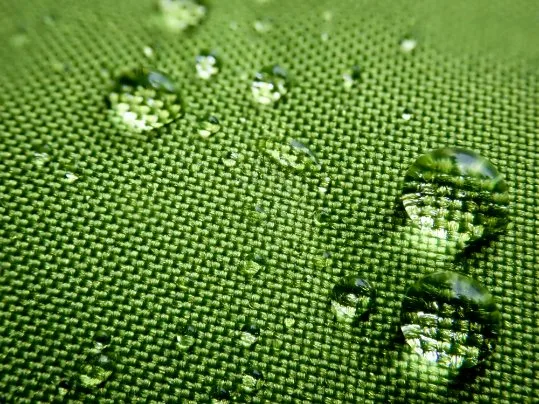

DWR coating represents one of the most important advances in water-resistant fabric technology. This ultra-thin treatment is applied to fabric surfaces to create a protective barrier that causes water to bead up and roll off rather than soaking into the material.

How DWR Works

DWR creates a microscopic landscape of tiny, rigid bristles on the fabric surface. These bristles prevent water droplets from grabbing onto the fabric fibers. Instead, water forms beads that roll across the textured surface without actually contacting the woven fabric underneath.

The effectiveness of DWR depends on the contact angle between water and the fabric surface. An optimized DWR keeps droplets in a rounded, dome-like shape. When DWR degrades, the contact angle decreases, causing water to spread out and eventually penetrate the fabric.

DWR Application Methods

Factory application involves three primary methods:

- Spraying: Direct application of DWR solution onto fabric surface

- Dipping: Immersing fabric in DWR treatment baths

- Chemical Vapor Deposition (CVD): Advanced method requiring less DWR while creating extremely thin, effective layers

CVD offers advantages including reduced environmental impact, lower chemical usage, and minimal effect on fabric feel and appearance.

DWR Durability and Performance

DWR treatments are rated using a two-number system. The first number indicates initial water resistance performance, while the second shows durability after repeated washing. For example, a rating of 80/20 means the treatment maintains 80% of its original effectiveness after 20 wash cycles.

Professional outdoor brands typically test DWR performance after 5 to 20 wash cycles, while domestic brands often only test before washing. This difference explains why some treatments appear to fail quickly after purchase.

| DWR Quality Level | Initial Performance | Wash Durability | Typical Applications |

|---|---|---|---|

| Entry Level | 70-80 | 3-5 washes | Casual outdoor wear |

| Mid-Range | 85-90 | 10-15 washes | Regular hiking gear |

| Professional | 90-95 | 20+ washes | Expedition equipment |

Environmental Considerations

Traditional DWR treatments used C8 fluorocarbons, which proved to be persistent “forever chemicals” that don’t break down in the environment. The industry has transitioned through several generations:

- C8 Chemistry: Highly effective but environmentally persistent

- C6 Chemistry: Less bioavailable and persistent than C8

- C0 (PFC-Free): Contains no fluorocarbon chemistry, environmentally safer

C0 DWR treatments use silicon-based or hydrocarbon-based formulations. While environmental impact is reduced, performance may not match fluorocarbon-based alternatives in extreme conditions.

Water Resistance Testing Standards and Ratings

Professional testing ensures consistent performance standards across different manufacturers and applications. Understanding these standards helps consumers make informed fabric choices.

Fabric Testing Standards

- AATCC 127 (American Standard) measures water resistance by applying increasing water pressure until penetration occurs. This standard is widely used in North American textile manufacturing.

- JIS L1092B (Japanese Standard) provides similar pressure testing but with specific protocols for different fabric types and applications.

- ISO 811 (European Standard) offers the most comprehensive testing methodology, including environmental factors like temperature and humidity during testing.

Water Pressure Testing Methods

Testing involves two primary approaches:

- Pre-Wash Testing: Measures water resistance of new, untreated fabric. Many domestic outdoor brands use only pre-wash testing, which can be misleading since performance typically drops significantly after washing.

- Post-Wash Testing: Evaluates performance after multiple wash cycles. Premium brands often test after 5-20 wash cycles, providing more realistic performance expectations.

Water pressure resistance typically drops 1000-3000mmH2O after washing several times. Manufacturers using post-wash testing must engineer higher initial ratings to meet performance targets after washing.

Breathability Testing

Moisture vapor transmission rate (MVTR) testing measures how well fabric allows water vapor to pass through while blocking liquid water. Two methods are used:

- Positive Cup Method (ASTM E96 A, C, E; JIS L1099 A1): Places water inside a cup covered with fabric sample and measures evaporation rate.

- Inverted Cup Method (ASTM-E96, JIS L1099B1): Places desiccant in cup and measures moisture absorption through fabric.

Results are expressed in g/m²/24hr, indicating grams of water vapor that pass through one square meter of fabric in 24 hours.

Industry Performance Benchmarks

Mid-range performance fabrics typically achieve:

- 5,000mm water resistance: Suitable for moderate rain and outdoor activities

- 5,000g breathability: Adequate moisture vapor transmission for most activities

High-performance fabrics may achieve:

- 20,000-30,000mm water resistance: Suitable for extreme weather conditions

- 20,000-30,000g breathability: Excellent moisture management during intense activity

Fabric Care and Maintenance

Can You Wash Water Resistant Fabric?

Yes, most water-resistant fabrics can be washed, but proper care is essential to maintain their protective properties. Different fabric types require specific washing approaches:

- Natural Fabrics: Wool and cotton-based water-resistant fabrics should be washed with gentle, additive-free detergents. Harsh chemicals can strip natural oils that contribute to water resistance.

- Synthetic Fabrics: Polyester and nylon with DWR treatments require technical fabric cleaners that won’t leave residues. Regular detergents often contain additives that can compromise water-repellent properties.

- Coated Fabrics: PUL and TPU fabrics are the most wash-durable options, maintaining their waterproof properties through numerous wash cycles.

DWR Restoration Process

When DWR treatments begin to fail, they can often be restored through proper care:

- Clean First: Wash with technical fabric cleaner to remove dirt and oils that interfere with DWR function

- Heat Reactivation: Apply gentle heat through tumble drying or ironing to reactivate remaining DWR coating

- Reapplication: If cleaning and heat don’t restore function, apply new DWR treatment via spray-on or wash-in products

Does Water Resistant Wear Off?

Yes, water resistance gradually diminishes over time due to several factors:

- Abrasion: Friction from backpack straps, repeated flexing, or contact with rough surfaces can wear away protective coatings.

- Chemical Exposure: Detergents, body oils, sunscreen, and other chemicals can degrade water-resistant treatments.

- UV Degradation: Extended sun exposure can break down both DWR coatings and fabric fibers.

- Washing: Each wash cycle removes some protective treatment, even with proper care.

Does Water Resistant Mean It Can Get Wet?

Water-resistant fabrics can get wet on the surface without allowing water to penetrate to the inside. This is different from absorbing water into the fabric structure. Key points:

- Surface Wetting: Water may sit on top of the fabric without penetrating

- Saturation Point: Eventually, water resistance will be overcome under pressure or prolonged exposure

- Performance Degradation: Wet outer fabric reduces breathability and comfort even when inner layers stay dry

Applications of Water Resistant Fabrics

Outdoor and Sportswear Applications

- Hiking and Camping Gear: Water-resistant fabrics protect against light rain and morning dew while maintaining breathability during physical activity. Jackets with 5,000-10,000mm ratings work well for most hiking conditions.

- Athletic Wear: The athleisure trend has driven demand for fabrics that transition from gym to street wear. Water-resistant treatments prevent sweat stains and light moisture while maintaining style.

- Cycling and Running Gear: Wind-resistant fabrics with water-repellent treatments protect against weather while allowing heat and moisture to escape during exercise.

Technical and Industrial Applications

- Defense and Public Safety: Military and emergency response gear requires fabrics that maintain protection under extreme conditions. These applications often specify post-wash performance standards.

- Construction Industry: Work wear must resist moisture while providing durability and comfort during extended wear. Water-resistant treatments help maintain worker comfort in various weather conditions.

- Fire-Fighting Applications: Specialized fabrics combine water resistance with heat protection and chemical resistance for emergency response situations.

Medical and Healthcare

- Incontinence Protection: PUL and TPU fabrics provide comfortable, washable protection for mattress covers, adult garments, and medical equipment covers.

- Hospital Textiles: Water-resistant fabrics help maintain hygiene standards while providing comfort for patients and ease of cleaning for staff.

- Sterile Barriers: Medical applications require fabrics that resist fluid penetration while maintaining breathability and comfort.

Home and Lifestyle Applications

- Furniture Protection: Outdoor furniture covers use various water-resistant fabrics depending on exposure requirements and aesthetic preferences.

- Children’s Products: Safety regulations require BPA-free and PVC-free water-resistant fabrics for products intended for children under 12.

- Table Linens and Kitchen Textiles: Easy-care water-resistant fabrics simplify cleaning while maintaining appearance and functionality.

Market Trends and Future Developments

The global waterproof breathable textiles market reached $2.03 billion in 2024 and is expected to grow at 5.9% annually through 2030. This growth is driven by increasing outdoor activity participation and demand for high-performance apparel.

Technology Innovations

- Nanotechnology Integration: Advanced nanoparticle treatments provide longer-lasting water resistance with reduced environmental impact. These treatments can be integrated directly into fabric fibers during manufacturing.

- Smart Textiles: Integration of electronic components with water-resistant fabrics enables performance monitoring and adaptive protection levels.

- Sustainable Solutions: Development of bio-based and recyclable water-resistant treatments addresses environmental concerns while maintaining performance standards.

Regional Market Differences

- North America: Focus on outdoor recreation and sports applications drives demand for high-performance fabrics with superior breathability.

- Europe: Strict environmental regulations accelerate adoption of PFC-free treatments and sustainable manufacturing processes.

- Asia-Pacific: Rapid industrialization and growing middle class increase demand for both technical and consumer water-resistant textiles.

Choosing the Right Water Resistant Fabric

Performance Requirements Assessment

- Activity Level: High-intensity activities require fabrics with superior breathability (15,000g+ MVTR) to prevent overheating and moisture buildup.

- Weather Conditions: Light rain requires basic water resistance (3,000-5,000mm), while extended exposure demands higher ratings (10,000mm+).

- Durability Needs: Frequent use applications benefit from post-wash tested fabrics and durable coatings.

Cost vs. Performance Analysis

- Entry Level: Basic water-resistant treatments suitable for occasional use and mild conditions. Lower initial cost but may require more frequent replacement.

- Mid-Range: Balanced performance and durability for regular outdoor activities. Better long-term value for most consumers.

- Professional Grade: Maximum performance and durability for extreme conditions and commercial applications. Higher initial investment but superior longevity.

Fabric Selection Matrix

| Application | Recommended Fabric | Water Resistance | Breathability | Key Features |

|---|---|---|---|---|

| Casual Outdoor | DWR Polyester | 3,000-5,000mm | 3,000-5,000g | Affordable, easy care |

| Active Sports | DWR Nylon | 10,000mm | 10,000g+ | Lightweight, high breathability |

| Professional Use | Membrane Laminate | 20,000mm+ | 15,000g+ | Maximum protection |

| Medical/Care | PUL/TPU | Waterproof | Moderate | Wash durability, comfort |

Troubleshooting Common Issues

Fabric Performance Problems

- Wetting Out: When outer fabric becomes saturated, it reduces breathability and can feel like leaking. This usually indicates DWR failure rather than membrane damage.

- Reduced Breathability: Dirt, oils, or detergent residue can clog fabric pores. Technical cleaning often restores performance.

- Visible Water Penetration: Actual leaking indicates membrane damage or seam failure requiring professional repair or replacement.

Restoration vs. Replacement

- Restoration Candidates: Fabrics with intact membranes but degraded DWR can often be restored through proper cleaning and retreatment.

- Replacement Indicators: Visible membrane damage, seam failures, or persistent leaking after restoration attempts indicate replacement necessity.

Environmental Impact and Sustainability

PFAS Concerns and Alternatives

Traditional fluorocarbon-based DWR treatments persist in the environment and bioaccumulate in living organisms. The textile industry continues transitioning to safer alternatives:

Silicon-Based Treatments: Offer good performance with reduced environmental persistence. However, durability may be lower than fluorocarbon alternatives.

Hydrocarbon-Based Options: Provide adequate protection for many applications while breaking down more readily in the environment.

Bio-Based Solutions: Emerging treatments derived from natural sources show promise for specific applications.

Sustainable Manufacturing Practices

Reduced Chemical Usage: Advanced application methods minimize chemical consumption while maintaining effectiveness.

Recycling Programs: Some manufacturers offer take-back programs for end-of-life textiles, enabling material recovery and reuse.

Energy Efficiency: Improved manufacturing processes reduce energy consumption and environmental impact.

Testing Water Resistant Fabric at Home

Simple Water Resistance Test

Fill a spray bottle with clean water and spray the fabric surface. Observe the results:

- Good DWR: Water beads up immediately and rolls off when fabric is tilted

- Moderate DWR: Water beads form but some spreading occurs

- Poor DWR: Water soaks into fabric immediately, causing darkening

Advanced Testing Methods

Shake Test: After spraying, shake the fabric vigorously. Water droplets should fly off easily if DWR is functioning properly.

Absorption Test: Place a measured amount of water on fabric surface and time how long before penetration occurs.

Professional Testing: For critical applications, commercial testing services can provide standardized performance measurements.

Conclusion

Water resistant fabrics represent a crucial technology that enables comfort and protection across numerous applications, from outdoor recreation to medical care. Understanding the differences between water resistance, water repellency, and waterproof properties helps consumers make informed choices that match their specific needs.

The key to successful fabric selection lies in understanding that water resistance involves multiple factors working together: base fabric properties, surface treatments like DWR coatings, construction techniques, and proper maintenance. Natural fabrics like wool and tightly woven cotton offer inherent water resistance, while synthetic materials like polyester and nylon can be enhanced with various treatments to achieve superior performance.

DWR technology has revolutionized water-resistant fabrics, but consumers must understand that these treatments require proper care to maintain effectiveness. Regular cleaning with appropriate detergents, heat reactivation, and periodic reapplication of DWR treatments extend fabric life significantly.

The industry continues evolving toward more sustainable solutions as environmental concerns drive innovation in PFC-free treatments. While some performance trade-offs exist with current eco-friendly alternatives, advancing technology promises improved options that balance protection with environmental responsibility.

When selecting water resistant fabrics, consider the intended application, expected exposure conditions, required durability, and maintenance capabilities. Entry-level treatments work well for occasional use, while professional-grade fabrics justify their cost for demanding applications. Testing fabric performance regularly and maintaining treatments properly ensures optimal protection throughout the product’s life.

Market growth in water-resistant textiles reflects increasing consumer awareness of performance benefits and expanding applications across industries. Whether choosing gear for outdoor adventures, protective clothing for work, or comfort solutions for home use, understanding water resistance technology enables better decisions that provide lasting value and protection.

Key Recommendations:

- Match fabric specifications to actual use requirements rather than choosing maximum ratings for all applications

- Invest in quality treatments for frequently used items while accepting basic protection for occasional use

- Maintain DWR treatments through proper washing and reactivation to extend fabric life

- Consider environmental impact when choosing treatments, especially for non-critical applications

- Test fabric performance regularly and address degradation promptly to maintain protection