Everything you need to know about this premium Italian wool fabric, from its rich history to modern applications

Table of Contents

- What is Venetian Wool?

- The Rich History of Venetian Textiles

- How Venetian Wool is Made

- Characteristics and Properties

- Venetian Wool vs. Other Wool Fabrics

- Uses and Applications

- Sustainability and Ethical Considerations

- Quality Indicators and Authenticity

- Care and Maintenance

- Where to Buy and Pricing Guide

- Working with Venetian Wool: Sewing Tips

- Venetian Wool in Modern Fashion

- Frequently Asked Questions

- Conclusion

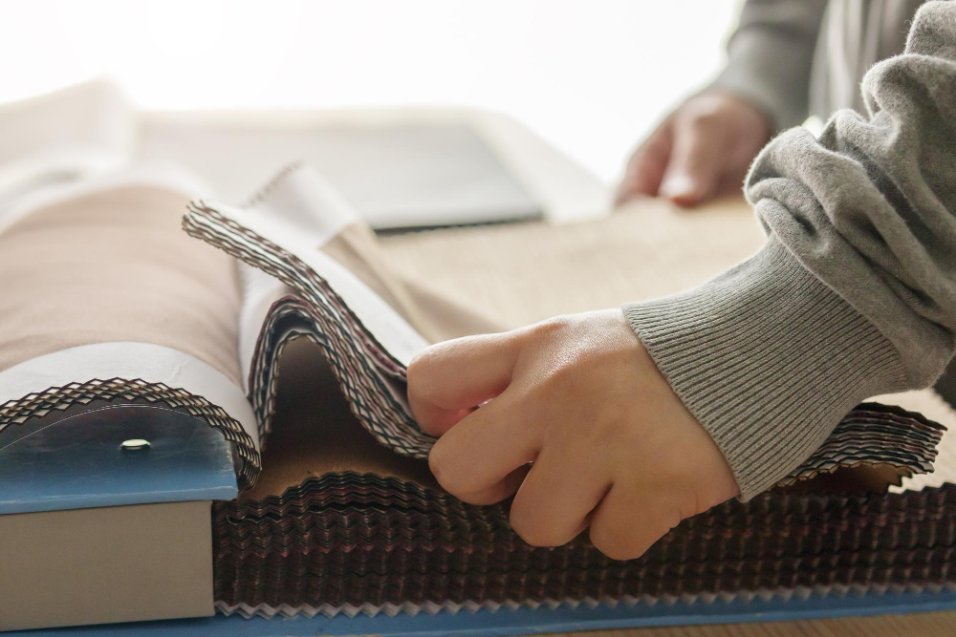

When you run your hand across a piece of Venetian wool, you’ll immediately notice something different. The fabric has a smooth, almost satin-like surface that catches the light with a gentle luster. It feels firm yet refined, with a weight that promises durability without bulk. This is Venetian wool, a fabric that has been gracing the finest suits and formal wear for centuries.

If you’re looking to create a tailored suit that will last for years, designing high-end home furnishings, or simply want to understand what makes this fabric so special, you’re in the right place. This guide will take you through everything you need to know about Venetian wool, from its origins in Italy’s textile workshops to practical advice on working with this beautiful material.

What is Venetian Wool?

Venetian wool is a high-quality worsted wool fabric known for its smooth surface, subtle luster, and excellent drape. The name refers to both the fabric’s construction method and its historical connection to Venice, Italy’s long tradition of textile production.

At its core, Venetian wool combines fine wool fibers with a specific weaving technique. The fabric uses a satin or twill weave structure, which creates its characteristic smooth finish. This isn’t just any wool, it’s made from carefully combed, long-staple wool fibers that are tightly twisted and then woven to create a dense yet surprisingly light fabric.

Technical Definition

From a technical standpoint, Venetian wool is classified as a worsted wool fabric. This means the wool fibers go through a combing process that removes short fibers and aligns the remaining long fibers parallel to each other. The result? A smooth, flat surface that’s quite different from the fuzzy texture of woolen fabrics like flannel or tweed.

The weave structure typically follows either a satin weave (where weft yarns float over multiple warp yarns) or a twill weave (creating subtle diagonal lines). Both methods produce that signature lustrous finish that makes Venetian wool stand out from other wool suiting fabrics.

Key Identifying Features

How can you recognize Venetian wool when you see it? Look for these characteristics:

- Surface finish: Smooth and slightly lustrous, but not as shiny as true satin. The fabric has a subtle sheen that changes as light hits it from different angles.

- Weight: Medium-weight, typically ranging from 250-350 GSM (grams per square meter). It’s substantial enough for structure but not heavy or bulky.

- Drape: Falls beautifully with a heavier, more controlled drape than lighter wools. This quality makes it perfect for tailored garments that need to hold their shape.

- Texture: Firm and compact to the touch, with a smooth hand feel that’s cool against the skin.

- Appearance: One side is typically more matte, while the other shows more sheen, though both sides have that characteristic smooth finish.

Quick Identification Tip

If you’re trying to determine if a fabric is Venetian wool, check the weave closely. You should see a tight, organized structure with very little fuzziness. The fabric should feel smooth and slightly cool, with a weight that feels substantial but not heavy. If it has a satin-like finish on one side and feels silky to the touch, you’re likely looking at Venetian wool.

What Makes It Different from Regular Wool?

You might be wondering: isn’t this just regular wool fabric? Not quite. While Venetian wool starts with the same raw material as other wool fabrics, several factors set it apart:

First, the fiber selection is more strict. Only fine, long-staple wool fibers make the cut, usually from high-quality breeds like Merino sheep. These longer fibers (typically 3-4 inches or more) can be combed and aligned to create a smoother finish.

Second, the processing method is different. Regular woolen fabrics use shorter fibers that point in all directions, creating that fuzzy, warm texture we associate with winter sweaters. Venetian wool, as a worsted fabric, has all its fibers running parallel, producing a sleeker result.

Third, the weaving technique matters. The satin or twill weave used in Venetian wool creates that lustrous surface and heavier drape that you won’t find in plain-weave wool fabrics.

The Rich History of Venetian Textiles

To understand Venetian wool, we need to step back in time to the bustling textile workshops of medieval Italy. Venice wasn’t always synonymous with silk and velvet, the region has a wool production history that stretches back thousands of years.

Ancient Beginnings: Altino’s Wool Legacy

Before Venice rose from the lagoon, there was Altino, a thriving Roman city that served as one of the towns where Venice’s history began. From the 2nd century BC to the 5th century AD, Altino was a major trading center, and wool production was a cornerstone of its economy.

The Roman writer Pliny the Elder even mentioned Altino’s wool in his writings, describing it as “delicate, shining white and extremely fine.” This wasn’t just any wool, it was considered one of the top three wools in the entire Roman Empire. The quality came from the specific breeds of sheep raised in the region and the advanced textile processing techniques the Romans had developed.

When barbaric invasions and rising sea levels forced Altino’s population to abandon the mainland in the 5th and 6th centuries, they didn’t leave their textile skills behind. These craftspeople moved to the islands of the lagoon, bringing their knowledge to places like Torcello, and eventually, to Venice itself.

Medieval Venice: The Shift to Silk

By the 13th century, Venice had become a maritime superpower with extensive trade connections throughout the Mediterranean and beyond. Through its relationship with Byzantium, Venice gained access to luxury silk fabrics and, more importantly, the knowledge of how to produce them.

The famous travels of Marco Polo and other Venetian merchants brought back new techniques and designs from China, revolutionizing the city’s textile industry. In 1265, the Arte dei Samiteri (the guild of silk weavers) was established, marking Venice’s official entry into luxury silk production.

While silk took center stage, wool production didn’t disappear. It moved to the Venetian mainland, where cities like Padua, Vicenza, and Verona specialized in different stages of wool processing. Venice kept the most delicate finishing work in the city, maintaining quality control over the final products.

The Golden Age: 14th to 18th Century

During this period, Venice became Europe’s fashion capital. The city’s textile manufacturers produced everything from basic wool cloth to elaborate silk velvets and brocades. Venetian fabrics were exported throughout Europe, especially to Germany and Scandinavia, where they commanded premium prices.

The quality was no accident. Venice established the Corte del Parangon, an institution dedicated to quality control. Before any textile could be sold, it had to be compared against carefully made model pieces to ensure it met the city’s strict standards. This attention to quality built Venice’s reputation as a source of the finest textiles in Europe.

During this time, Venetian wool fabrics were known for their superior quality. The city initially used imported “Frankish” wools (from France and Flanders), but gradually shifted to using local short-fiber wools from the mainland. The combination of quality raw materials, skilled craftspeople, and strict quality control created fabrics that were in demand across the continent.

Decline and Revival

The fall of the Venetian Republic in 1797, combined with the industrial revolution’s mechanization, dealt a serious blow to Venice’s artisanal textile industry. Throughout the 19th and early 20th centuries, the once-flourishing workshops gradually closed as they couldn’t compete with large-scale industrial production.

However, the tradition didn’t die completely. In the late 1800s, a movement toward reviving applied arts and traditional crafts gave new life to Venetian textile production. Companies like Tessitura Luigi Bevilacqua, founded in the 1800s, kept the flame alive by continuing to use traditional hand-weaving techniques on historical looms.

Today, several manufacturers in the Veneto region continue to produce high-quality wool fabrics using methods that blend traditional craftsmanship with modern technology. While the massive textile workshops of medieval Venice are gone, the region’s reputation for quality wool fabrics, including Venetian wool, remains strong.

The Name “Venetian Wool”

Interestingly, the term “Venetian wool” as we use it today likely developed after Venice’s golden age of textile production. The name reflects both the fabric’s smooth, almost satin-like finish (reminiscent of the luxurious silks Venice was famous for) and the region’s historical connection to high-quality textile production.

Modern Venetian wool might be produced in England, Italy, or elsewhere, but the name carries with it the legacy of centuries of Italian textile tradition and the pursuit of quality that defined Venetian craftsmanship.

How Venetian Wool is Made

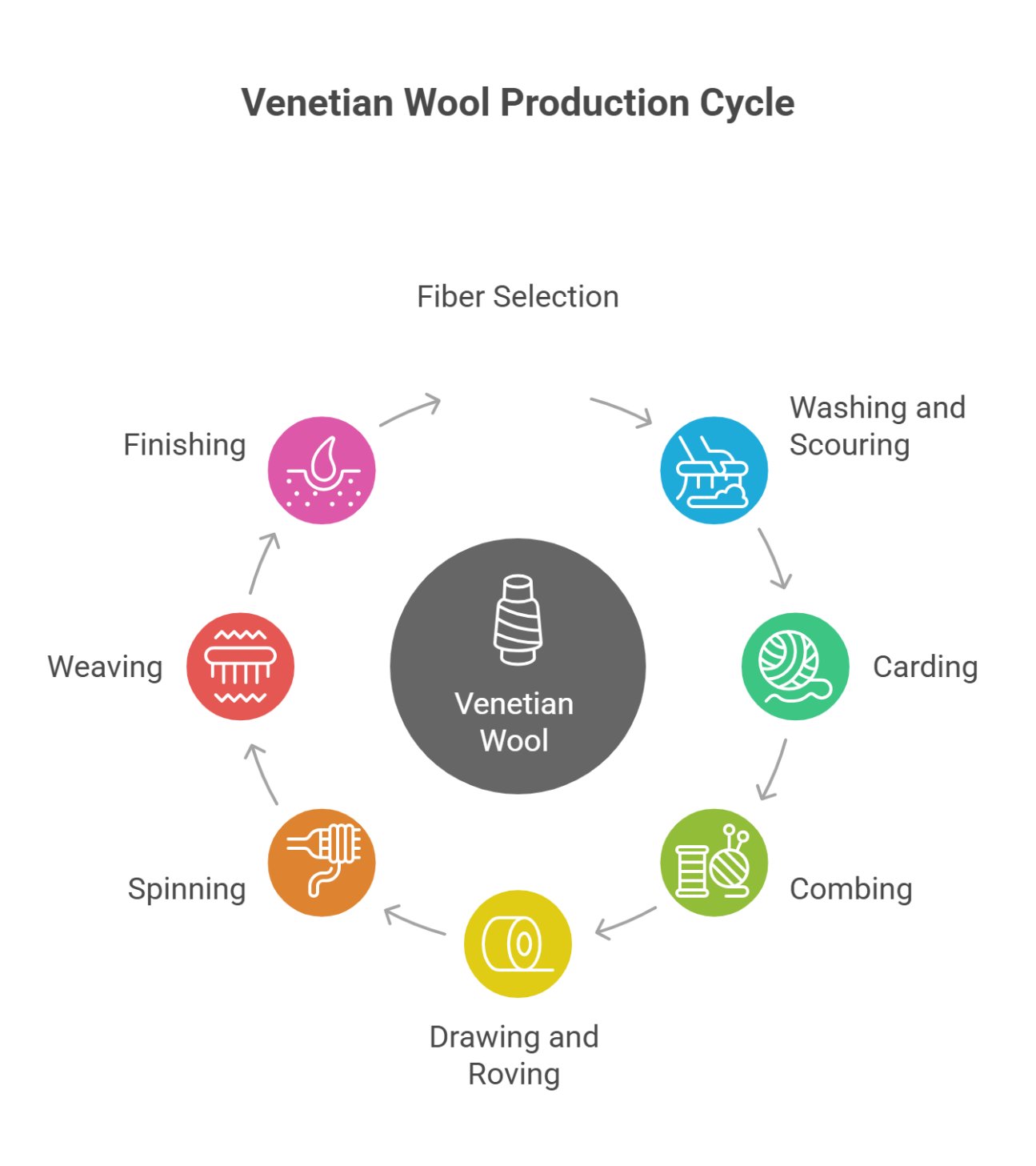

Understanding how Venetian wool is made helps explain why this fabric has such distinctive properties. The production process involves several carefully controlled steps, each contributing to the final product’s quality.

Step 1: Fiber Selection

Everything starts with choosing the right wool. Manufacturers typically select fine, long-staple wool fibers, often from Merino or similar high-quality breeds. The fibers need to be at least 3-4 inches long to work well in the worsted spinning process.

The fiber diameter matters too. Finer fibers (measured in microns) create softer, more luxurious fabrics. For Venetian wool, manufacturers usually choose fibers in the 18-24 micron range, striking a balance between softness and durability.

Step 2: Washing and Scouring

Raw wool comes off the sheep covered in lanolin (natural oils), dirt, and other impurities. The first step in processing involves thorough washing and scouring to remove these substances. This step is done at high temperatures using specialized detergents, though modern processes avoid the harsh chemicals that were common in earlier times.

Step 3: Carding

After washing, the wool fibers need to be untangled and roughly aligned. This process, called carding, uses machines with fine wire teeth to separate the fibers and remove any remaining short or damaged fibers. After carding, the wool emerges as a thin web of loosely aligned fibers.

Step 4: Combing (The Worsted Process)

Here’s where Venetian wool diverges from regular woolen fabrics. The carded wool goes through a combing process, which is what makes it a “worsted” wool. Industrial combs with fine teeth pull the fibers through, removing any remaining short fibers (called “noils”) and perfectly aligning the long fibers parallel to each other.

This step is what gives worsted wools, including Venetian wool, their smooth appearance. All the fibers lie in the same direction, creating a sleek surface rather than the fuzzy texture of uncombed woolen fabrics.

Step 5: Drawing and Roving

After combing, the aligned fibers are drawn out into a continuous strand called a roving. This process further aligns the fibers and reduces the strand to the desired thickness before spinning.

Step 6: Spinning

The roving is then spun into yarn. For Venetian wool, the yarn is tightly twisted, which contributes to the fabric’s smooth finish and durability. The high twist also makes the yarn stronger and gives the final fabric its characteristic firm hand feel.

Depending on the desired weight and characteristics of the final fabric, manufacturers might create different yarn weights and twist levels. A Super 100s yarn (referring to the fiber fineness) will produce a different fabric than a Super 150s, even with the same weaving pattern.

Step 7: Weaving

This is where Venetian wool gets its distinctive look. The spun yarn is woven using either a satin weave or a twill weave structure:

Satin weave: In a satin weave, the weft (horizontal) yarns float over multiple warp (vertical) yarns before going under one. This creates a smooth surface with a natural luster. The long floats catch and reflect light, giving the fabric its subtle sheen.

Twill weave: Some Venetian wools use a twill weave, which creates subtle diagonal lines across the fabric. The weave structure is still tight and smooth, just with a slightly different surface texture than the satin weave.

The weaving is done on specialized looms, with the tension and density carefully controlled to create the desired fabric weight and hand feel.

Step 8: Finishing

After weaving, the fabric goes through several finishing processes:

- Scouring: The woven fabric is washed again to remove any oils or dirt from the weaving process.

- Fulling (controlled shrinking): The fabric is agitated in warm water to tighten the weave and improve the fabric’s body and hand feel.

- Pressing or calendering: Heat and pressure are applied to the fabric to enhance its luster and create the smooth surface finish that characterizes Venetian wool.

- Final inspection: Quality control checks ensure the fabric meets the required standards for color, weight, and finish.

The entire process, from raw wool to finished fabric, can take several weeks. Each step requires skill and precision, which is why high-quality Venetian wool commands premium prices.

Italian vs. English Production

While historically connected to Italy, Venetian wool is produced in several countries today. Italian manufacturers, particularly those in the Veneto region and Biella (in Piedmont), are known for their fashion-forward colors and finishes. English manufacturers, on the other hand, often focus on more traditional colors and heavier weights suitable for classic menswear.

Both traditions produce excellent fabric, but they often have slightly different characteristics. Italian Venetian wool tends to have a softer hand and more contemporary drape, while English versions might be slightly heavier with a more structured feel.

Characteristics and Properties

Now that we understand how Venetian wool is made, let’s look at what makes this fabric perform the way it does. These characteristics explain why Venetian wool has remained popular for formal tailoring for so many years.

Weight and Drape

Venetian wool typically falls into the medium-weight category, ranging from about 250 to 350 grams per square meter (GSM). This weight makes it substantial enough to hold a tailored shape but not so heavy that it feels bulky or restricts movement.

The drape is one of Venetian wool’s standout features. Unlike lighter wool voile or challis, which float and flutter, Venetian wool falls with a controlled, weighted drape. When you make a jacket or coat from this fabric, it hangs beautifully on the body, creating clean lines and a structured silhouette.

This drape quality comes from the combination of the tight weave, the worsted processing, and the fabric’s medium weight. It’s heavy enough to fall gracefully but not so heavy that it pulls or sags.

Surface Finish and Luster

The smooth, slightly lustrous finish is probably Venetian wool’s most recognizable characteristic. When light hits the fabric, you’ll see a gentle sheen that changes as the fabric moves. It’s not as shiny as satin fabric or silk, but it has more luster than a plain weave wool.

This quality comes from the satin or twill weave structure. The long float yarns on the surface reflect light more than they would in a plain weave. The combed, parallel fibers also contribute to the smoothness, as there are no short fibers sticking out to scatter light.

The surface typically shows two slightly different finishes: one side with more sheen (the face side, which goes on the outside of garments) and one with a more matte appearance (the back side). Both sides are smooth, though, unlike some fabrics where one side is notably rougher.

Texture and Hand Feel

When you touch Venetian wool, it feels firm and compact. There’s no fluffiness or fuzziness, just a smooth, cool surface. The fabric has a slight crispness to it, meaning it doesn’t collapse or cling but maintains some body and structure.

This texture makes Venetian wool particularly good for tailored garments. The fabric cooperates during sewing, doesn’t stretch out of shape easily, and holds pressed edges and pleats well. It’s also less likely to pill (form little fabric balls on the surface) than softer, fuzzier wools.

Temperature Regulation

Like all wool fabrics, Venetian wool has excellent temperature-regulating properties. Wool fibers can absorb up to 30% of their weight in moisture without feeling damp, which means they wick sweat away from your body effectively.

However, because Venetian wool is a tightly woven worsted fabric with parallel fibers, it’s not as warm as loftier woolen fabrics like flannel. The tight weave leaves less air space between fibers, and those air pockets are what provide insulation. This makes Venetian wool a good choice for year-round suits or garments that need to work in temperature-controlled indoor environments.

In summer, the smooth fabric won’t trap heat like a fuzzy wool would. In winter, it provides moderate warmth while still breathing well. If you need serious cold-weather protection, you’d want to layer or choose a warmer fabric, but for most indoor situations, Venetian wool hits a sweet spot.

Breathability

Despite its tight weave, Venetian wool remains breathable. Wool fibers naturally allow air and moisture to pass through, preventing that clammy feeling you get with synthetic fabrics. You can wear a Venetian wool suit all day without feeling suffocated or sweaty (assuming it fits properly).

This breathability is one reason why wool suits remain popular despite the availability of lighter, more “technical” fabrics. Natural fibers simply perform better when it comes to comfort during extended wear.

Durability and Resilience

Venetian wool is built to last. The long, combed fibers are strong, and the tight weave creates a robust fabric that resists tearing and abrasion. The high twist in the yarn adds to the durability, as tightly twisted yarns are stronger than loosely twisted ones.

The fabric is also naturally wrinkle-resistant. Wool fibers have a natural crimp that helps them spring back to their original shape after being compressed. While you’ll still want to hang your Venetian wool garments properly and press them occasionally, they won’t wrinkle as easily as linen or cotton.

With proper care, a well-made garment from Venetian wool can last for decades. The fabric doesn’t wear out quickly, and the tight weave resists snagging. This longevity makes the higher initial cost more reasonable when you calculate the per-wear value.

Color Retention

Wool takes dye beautifully, and Venetian wool is no exception. The smooth, even surface shows colors clearly and richly. The slight luster adds depth to the colors, so that a navy Venetian wool looks richer and more complex than a flat navy cotton.

The colors also tend to stay true over time. Unlike some fabrics that fade quickly with washing or sun exposure, properly cared-for Venetian wool maintains its color well. The tight weave and quality processing help protect the dyed fibers from degradation.

| Property | Rating | Notes |

|---|---|---|

| Weight | Medium | 250-350 GSM, substantial but not heavy |

| Warmth | Moderate | Good for 3-season wear, less warm than flannel |

| Breathability | Excellent | Natural fibers allow air and moisture passage |

| Durability | Excellent | Long-lasting with proper care |

| Wrinkle Resistance | Very Good | Naturally resilient, springs back to shape |

| Luster | Moderate-High | Subtle sheen, not as shiny as satin |

| Softness | Moderate | Smooth but firm, not fluffy |

Venetian Wool vs. Other Wool Fabrics

To really understand where Venetian wool fits in the world of textiles, it helps to compare it directly with other popular wool fabrics. Each type has its strengths and ideal uses, and choosing the right one depends on what you’re making and what properties you prioritize.

Venetian Wool vs. Wool Gabardine

Wool gabardine is probably the closest cousin to Venetian wool in terms of structure and use. Both are worsted wools with smooth surfaces and excellent draping properties. However, there are some key differences.

Weave structure: Gabardine uses a steep twill weave (usually at a 45-degree or higher angle), creating clear diagonal lines on the fabric surface. Venetian wool uses either a satin weave or a gentler twill, giving it a smoother, more lustrous appearance with less obvious texture.

Surface finish: Venetian wool typically has more sheen than gabardine. While both are smooth, the satin weave of Venetian wool catches light differently, creating that subtle glow that gabardine doesn’t have.

Drape and weight: Both fabrics drape beautifully, but Venetian wool often has a slightly heavier, more controlled drape. Gabardine can be made in lighter weights and tends to be a bit crisper.

Durability: Gabardine’s tight twill weave makes it extremely durable and resistant to abrasion. Venetian wool is also durable, but the longer yarn floats in a satin weave can be slightly more prone to snagging (though this is rarely a practical concern).

Best for: Choose gabardine if you want a very crisp, structured look with excellent durability. Choose Venetian wool if you prefer a slightly more luxurious appearance with that subtle luster.

Venetian Wool vs. Wool Flannel

Wool flannel sits at the opposite end of the spectrum from Venetian wool in many ways. The two fabrics have completely different personalities.

Processing: Flannel is a woolen fabric (not worsted), meaning it uses shorter fibers that aren’t combed and aligned. After weaving, flannel is brushed to raise a soft nap on the surface. Venetian wool is worsted-spun with parallel fibers and a smooth, unbrushed surface.

Texture: Flannel is soft, fuzzy, and has a matte finish. It feels cozy and warm to the touch. Venetian wool is smooth, firm, and slightly lustrous. It feels cooler and more formal.

Weight and warmth: Flannel is generally warmer than Venetian wool because the loose fiber structure and raised nap trap more air. Flannel is your go-to for cold weather comfort. Venetian wool works better for three-season wear or temperature-controlled environments.

Formality: Venetian wool reads as more formal due to its smooth, refined appearance. Flannel has a softer, more casual look despite being used in suits.

Drape: Venetian wool has a heavier, more controlled drape that creates structured silhouettes. Flannel tends to be softer and more relaxed in its drape.

Best for: Choose flannel for winter suits, casual blazers, or when comfort and warmth are priorities. Choose Venetian wool for formal suits, structured garments, or when you want a polished, professional appearance.

Venetian Wool vs. Sharkskin

Wool sharkskin (not to be confused with actual shark leather) is another smooth worsted suiting fabric with its own distinct characteristics.

Appearance: Sharkskin has a very fine two-tone effect created by weaving together yarns of two slightly different colors, usually white and another color. This creates a subtle pattern that looks almost pearlescent. Venetian wool is usually solid-colored without this effect.

Sheen: Sharkskin has a distinct shiny appearance that’s more pronounced than Venetian wool’s subtle luster. Some people love this look; others find it too flashy.

Weight: Sharkskin is typically lighter than Venetian wool, making it a good choice for summer suiting. Venetian wool’s medium weight works better as a year-round option.

Texture: Both are smooth, but sharkskin often has a slightly slippery feel, while Venetian wool has more grip and substance.

Best for: Choose sharkskin if you want a lighter-weight summer suit with a distinctive appearance. Choose Venetian wool if you prefer a more subtle look with better year-round versatility.

Venetian Wool vs. Wool Serge

Wool serge is another twill-weave worsted wool, but with a different character than Venetian wool.

Weave pattern: Serge shows clear diagonal ridges from its twill weave, while Venetian wool’s satin or gentle twill weave creates a smoother surface.

Luster: Venetian wool typically has more sheen than serge, which tends toward a more matte finish despite being smooth.

Uses: Serge is often used for military uniforms and work clothing due to its durability and practical nature. Venetian wool is more commonly used in formal suiting and high-end menswear.

Best for: Choose serge for practical, hard-wearing garments. Choose Venetian wool when appearance and formality matter more.

Venetian Wool vs. Wool Crepe

Wool crepe offers yet another texture in the worsted wool family.

Surface texture: Crepe has a pebbly, slightly crinkled surface created by using high-twist yarns. Venetian wool is completely smooth.

Drape: Crepe typically has a softer, more fluid drape than Venetian wool. It moves differently on the body, with more flow and less structure.

Wrinkle resistance: Both are naturally wrinkle-resistant, but crepe’s textured surface hides wrinkles particularly well. Venetian wool’s smooth surface can show creasing more easily, though it still performs well.

Best for: Choose crepe for flowing, draped garments or when you want that distinctive textured surface. Choose Venetian wool for structured, tailored pieces.

| Fabric Type | Surface | Weight | Warmth | Best For |

|---|---|---|---|---|

| Venetian Wool | Smooth, subtle luster | Medium | Moderate | Formal suits, structured coats |

| Gabardine | Smooth with diagonal twill | Light-Medium | Moderate | Trousers, versatile suits |

| Flannel | Soft, brushed, matte | Medium-Heavy | Very Warm | Winter suits, casual blazers |

| Sharkskin | Smooth, shiny, two-tone | Light-Medium | Light | Summer suits, dressy events |

| Serge | Diagonal ridges, matte | Medium | Moderate | Uniforms, workwear |

| Crepe | Pebbly, textured | Light-Medium | Moderate | Draped garments, women’s wear |

Not Sure Which Wool Type is Right for You?

If you’re trying to decide between Venetian wool and other wool fabrics, try our Wool Type Selector Quiz to get personalized recommendations based on your project needs.

Uses and Applications

Venetian wool’s combination of smooth finish, beautiful drape, and durability makes it suitable for a range of applications. While it’s most commonly associated with men’s tailoring, this fabric has found its way into various other uses over the years.

Men’s Tailored Suits

This is Venetian wool’s primary domain. The fabric creates beautifully structured suits that hold their shape throughout the day while draping elegantly on the body. The subtle luster adds a touch of refinement without being too flashy for professional settings.

Venetian wool suits work particularly well for:

- Business and professional wear

- Formal events and occasions

- Evening wear (in darker colors)

- Year-round suiting (especially in medium weights)

The fabric takes pressing well and maintains sharp creases, which is important for that polished, professional look. It also resists bagging at the knees and elbows better than softer wools, keeping its crisp appearance even after hours of wear.

Formal Coats and Jackets

Venetian wool makes excellent outerwear, particularly for dress coats and formal jackets. The medium weight provides enough substance for structure and warmth without feeling bulky. Common uses include:

- Topcoats for business wear

- Formal blazers

- Dress overcoats

- Structured car coats

The fabric’s durability stands up to regular wear, and its wrinkle resistance means your coat will look fresh even after being worn all day.

Tailored Trousers

While Venetian wool can be used for full suits, some tailors and home sewers also use it for separate trousers. The fabric holds creases beautifully, creating those sharp front pleats that are the hallmark of well-tailored pants.

The smooth surface also means less friction against itself and other fabrics, so your trousers won’t wear out as quickly at stress points. The fabric’s natural wrinkle resistance helps the pants maintain their appearance throughout the day.

Women’s Formal Wear

While historically more common in menswear, Venetian wool has found its place in women’s tailoring too. It works beautifully for:

- Structured blazers and jackets

- Tailored dresses with defined silhouettes

- Formal skirts

- Professional workwear

The fabric’s ability to hold shape makes it perfect for garments with structured details like sharp shoulders, defined waists, or architectural elements.

High-End Home Decor

Venetian wool isn’t just for clothing. Its durability and refined appearance make it a premium choice for home furnishings:

Draperies and curtains: The fabric’s weight creates beautiful folds and drapes beautifully from curtain rods. The slight sheen adds visual interest, and the tight weave provides good light control.

Upholstery: While not as common as purpose-made upholstery fabrics, Venetian wool can be used for accent chairs, headboards, or decorative panels. Its durability and resistance to pilling make it practical for furniture that won’t see heavy daily use.

Decorative pillows and cushions: The refined look and feel make Venetian wool a luxurious choice for decorative home accessories.

Specialty Uses

Some less common but interesting applications include:

Uniforms: The durability and professional appearance make Venetian wool suitable for high-end uniforms in hospitality, corporate settings, or formal service industries.

Religious vestments: The fabric’s formal appearance and beautiful drape make it appropriate for ceremonial robes and vestments.

Historical costumes: Theater and film costume departments use Venetian wool to recreate period garments, as it can simulate the appearance of historical fabrics.

Project Ideas for Home Sewers

If you’re a home sewer interested in working with Venetian wool, here are some projects that really showcase the fabric’s strengths:

- Classic blazer: The structured drape and smooth finish create a polished, professional look

- Straight-leg trousers: The fabric holds creases beautifully and resists bagging

- A-line skirt: The controlled drape creates clean lines

- Structured coat dress: The fabric supports architectural details

- Tailored vest: A great way to try the fabric without committing to a full suit

Sustainability and Ethical Considerations

As we become more aware of fashion’s environmental and social impact, it’s important to understand where Venetian wool fits in the sustainability picture. Like all wool production, there are both positive aspects and areas of concern.

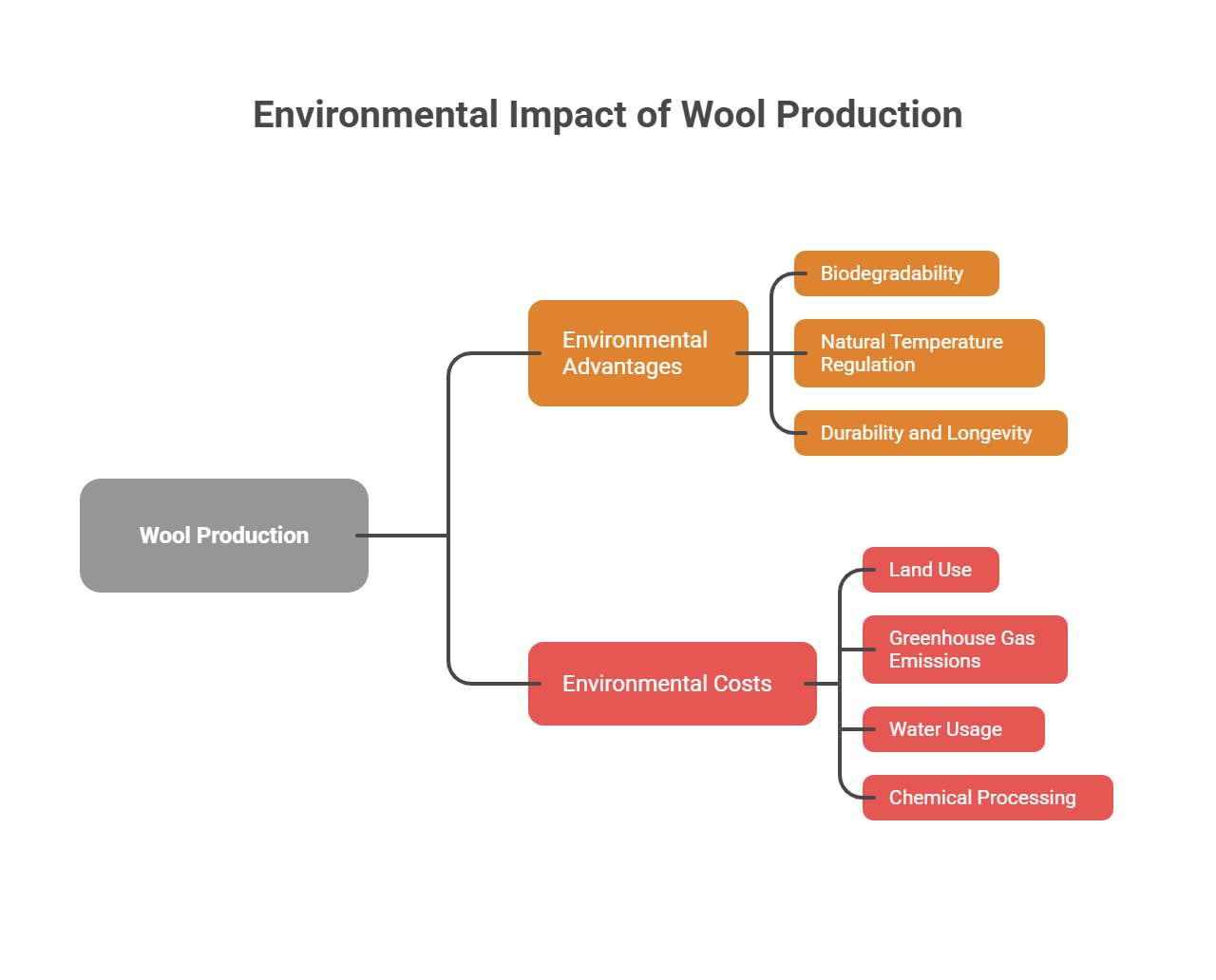

Environmental Impact of Wool Production

Wool is a natural, renewable fiber that offers several environmental advantages over synthetic alternatives:

Biodegradability: Unlike polyester or other synthetic fabrics that can take hundreds of years to break down, wool is completely biodegradable. When a wool garment reaches the end of its life, it will decompose naturally, returning nutrients to the soil without leaving microplastics behind.

Natural temperature regulation: Wool’s ability to keep you warm in winter and cool in summer means you need fewer climate-control resources. A good wool suit can work across multiple seasons, reducing the need for an extensive wardrobe.

Durability and longevity: Venetian wool garments, when properly cared for, can last for decades. This longevity dramatically reduces the per-wear environmental impact compared to fast-fashion items that wear out after a season or two.

However, wool production also has environmental costs:

Land use: Sheep farming requires significant land resources. Pasture land for grazing needs to be maintained, and in some regions, this has led to deforestation or habitat loss.

Greenhouse gas emissions: Sheep produce methane (a potent greenhouse gas) as part of their digestive process. According to research from Good On You’s comprehensive wool sustainability guide, some studies suggest that producing a wool garment generates significantly more emissions than a cotton equivalent, though this is partly offset by wool’s longer lifespan.

Water usage: While wool processing uses less water than cotton growing, it still requires water for washing raw fleece and finishing the fabric.

Chemical processing: Traditional wool processing can involve harsh chemicals for washing, dyeing, and finishing. However, many modern manufacturers have adopted cleaner processes.

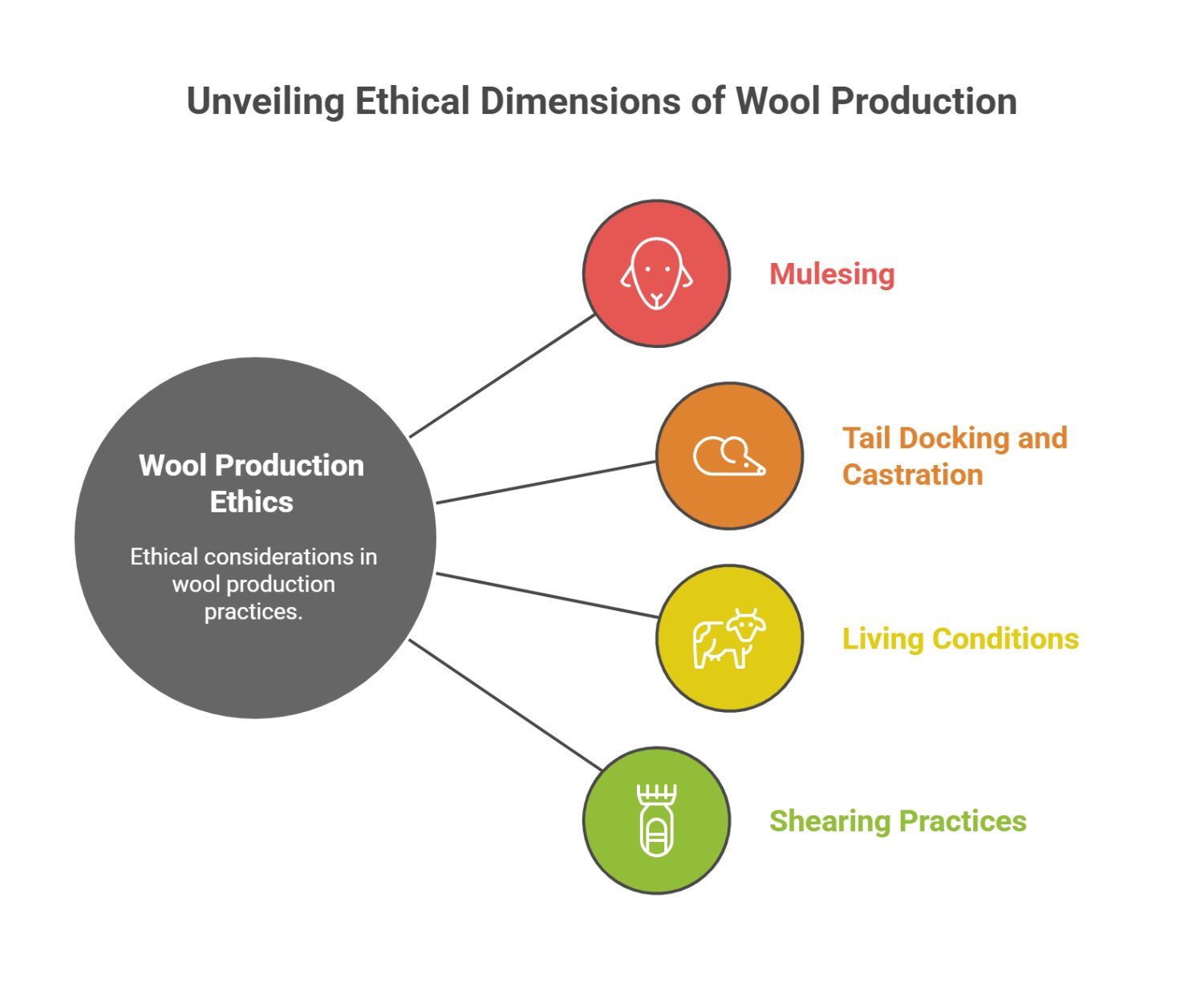

Animal Welfare Concerns

The ethics of wool production center on how the sheep are treated. There are legitimate animal welfare concerns in some parts of the wool industry:

Mulesing: This controversial practice, still common in Australia (which produces about 25% of the world’s wool), involves removing strips of skin from a lamb’s hindquarters without anesthetic to prevent flystrike (a parasitic infection). While it prevents a painful condition, the procedure itself causes suffering. New Zealand has banned the practice, and some Australian farmers are moving away from it.

Tail docking and castration: These procedures are often performed on young lambs without pain relief. While considered standard practice in the industry, they raise ethical questions about animal suffering.

Living conditions: Sheep on large commercial farms may not have the idyllic life we imagine. Issues can include overcrowding, inadequate shelter, and rough handling during shearing.

Shearing practices: While shearing is necessary for domesticated sheep (they’ve been bred to produce more wool than they can naturally shed), it can be done roughly, causing cuts and stress to the animals. Some operations pay shearers by the number of sheep processed, which can lead to speed over care.

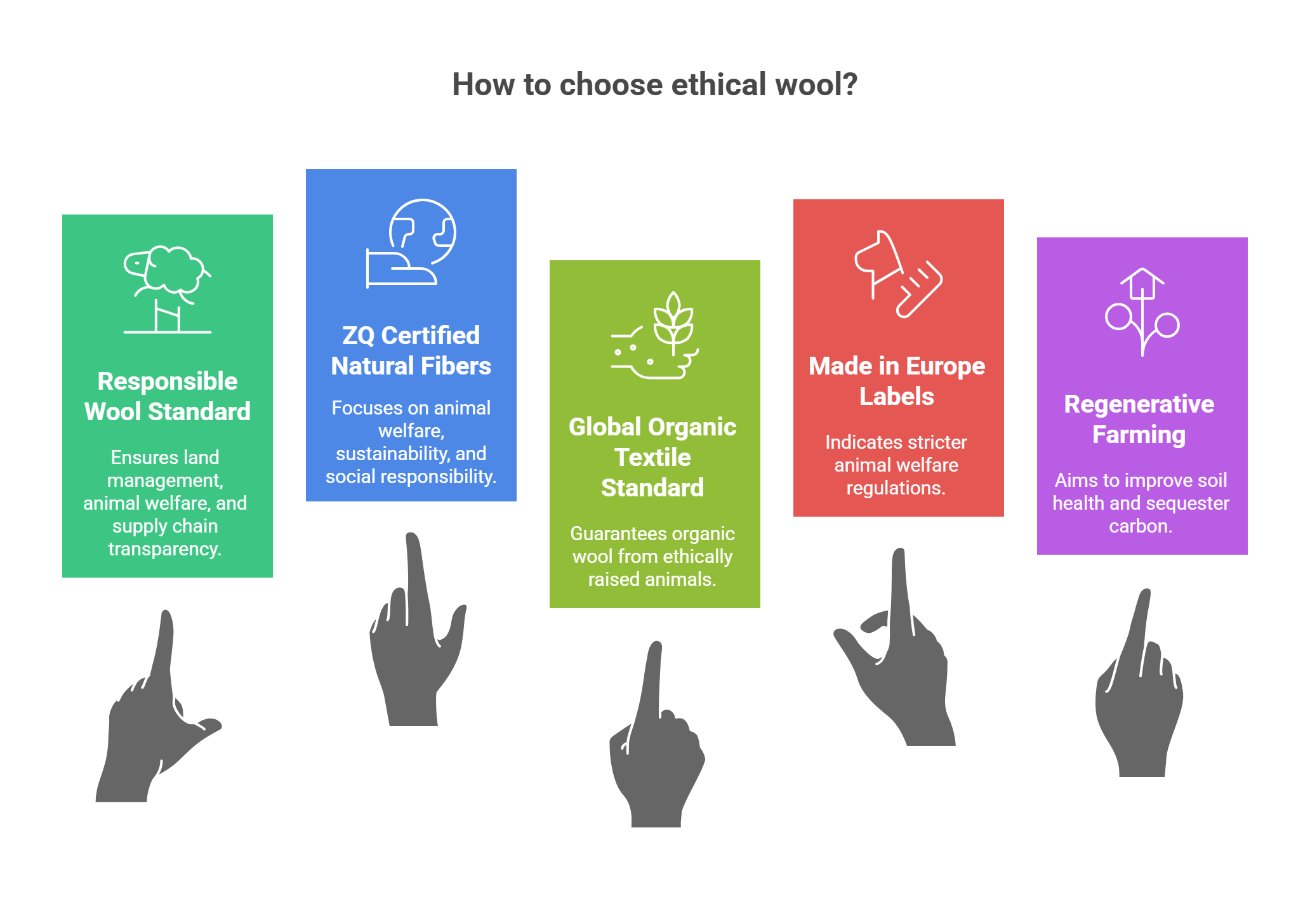

How to Choose More Ethical Wool

If you want to use Venetian wool but have concerns about sustainability and animal welfare, look for these certifications and practices:

Responsible Wool Standard (RWS): This certification, administered by Textile Exchange, ensures that wool comes from farms that practice land management, respect animal welfare, and maintain transparency throughout the supply chain. RWS farms must meet requirements for sheep welfare, including prohibiting mulesing.

ZQ Certified Natural Fibers: This New Zealand-based certification focuses on animal welfare, environmental sustainability, and social responsibility. All ZQ wool is mulesing-free.

Global Organic Textile Standard (GOTS): For organic wool, GOTS certification ensures the wool comes from organically raised animals and is processed using environmentally and socially responsible practices.

Made in Europe labels: European wool production generally has stricter animal welfare regulations than some other regions. Italian and British wool, in particular, often comes from smaller operations with better animal care standards.

Regenerative farming practices: Some farms practice regenerative agriculture, which aims to improve soil health, increase biodiversity, and sequester carbon. These practices can make wool production carbon-negative rather than carbon-positive.

Recycled Wool Options

One of the most sustainable options is recycled wool. This involves collecting pre-consumer waste (scraps from manufacturing) or post-consumer wool garments, breaking down the fibers, and spinning them into new yarn.

Recycled wool dramatically reduces the environmental impact:

- No new sheep farming needed (eliminating emissions, land use, and animal welfare concerns)

- Significantly less water and energy used in processing

- Diverts textile waste from landfills

- Produces fewer greenhouse gas emissions

The main limitation is that recycled wool fibers are shorter than virgin fibers, so they often need to be blended with some virgin wool or other fibers to maintain strength and quality. Still, even a blend with 30-50% recycled content makes a significant positive impact.

Care and Longevity: The Hidden Sustainability Factor

Perhaps the single biggest factor in Venetian wool’s sustainability is how long you keep and use your garments. A suit that lasts 15-20 years has a much lower per-wear environmental impact than cheap clothing replaced every year or two.

This means proper care isn’t just about maintaining appearance, it’s an environmental issue. By following proper wool care practices, you extend your garment’s life and reduce the need for replacement.

Making Sustainable Choices

When shopping for Venetian wool, consider these sustainability priorities:

- Buy less, choose better: One well-made Venetian wool suit is better than three cheap suits

- Look for certifications: RWS, ZQ, or GOTS labels indicate better practices

- Consider Italian or British wool: Generally higher welfare standards

- Explore recycled options: Check for fabrics with recycled wool content

- Care properly: Extend the life of what you own

- Repair, don’t replace: Find a good tailor for repairs and alterations

- Choose classic styles: Avoid trendy cuts that date quickly

The Bigger Picture

No fabric is perfect from a sustainability standpoint. Wool has both advantages (natural, biodegradable, long-lasting) and challenges (land use, emissions, animal welfare). The key is making informed choices and understanding the trade-offs.

Compared to fast-fashion synthetic alternatives, a well-made Venetian wool garment that lasts 15-20 years is almost certainly the more sustainable choice. The initial environmental cost is higher, but it’s spread across many years of use. Compared to organic cotton or hemp, the picture is more complex, with different environmental and ethical considerations in play.

Ultimately, choosing quality wool and cashmere and caring for it properly is one of the most sustainable fashion choices you can make.

Quality Indicators and How to Identify Authentic Venetian Wool

Not all Venetian wool is created equal. Quality can vary significantly based on the fiber source, manufacturing process, and finishing techniques. Here’s how to spot high-quality Venetian wool and avoid lower-grade alternatives.

Understanding Super Numbers

You’ll often see Venetian wool labeled with “Super” numbers like Super 100s, Super 120s, or Super 150s. These numbers refer to the fineness of the wool fiber measured in microns (one millionth of a meter).

Here’s what the numbers mean:

- Super 100s: 18.5 microns, good quality, durable and practical

- Super 120s: 18 microns, softer and more refined

- Super 150s: 17 microns, very soft and luxurious

- Super 180s and above: Under 16 microns, extremely soft but more delicate

A common misconception is that higher numbers always mean better quality. That’s not necessarily true. Yes, higher numbers indicate finer, softer fibers. But they also mean more delicate fabric that’s prone to pilling and wearing out faster.

For most people, Super 100s to Super 120s offers the best balance of softness, durability, and practicality. Super 150s and above might feel more luxurious, but they require more careful handling and won’t last as long with regular wear.

Visual Quality Checks

When examining Venetian wool, look for these signs of quality:

Even surface: Hold the fabric up to the light and examine the surface. Quality Venetian wool should have an even, consistent appearance with no thick or thin spots. The weave should be tight and regular.

Consistent luster: The sheen should be uniform across the fabric. Patches of different luster levels can indicate uneven yarn quality or processing problems.

Clean color: The color should be rich and even, with no fading, streaking, or inconsistency. Quality dyeing is expensive, and cheap wool often shows it in uneven coloring.

Smooth surface: Run your hand across the fabric. It should feel consistently smooth with no rough patches or visible flaws.

Touch and Feel Tests

The crumple test: Gently squeeze a section of the fabric in your hand, then release. Quality Venetian wool should spring back to its original shape with few or no wrinkles. If it stays crumpled or shows deep creases, it may be lower quality or poorly finished.

The weight check: Quality Venetian wool should feel substantial but not heavy. If it feels too light and flimsy, it might be lower grade. If it feels stiff and board-like, it’s probably over-processed or contains too much sizing (starch).

The drape test: Hold a corner of the fabric and let it hang. It should fall in smooth, controlled folds, not hang limp or stand out stiffly.

Surface smoothness: Rub your hand gently across the surface. Quality Venetian wool feels smooth and cool, not rough or scratchy. The fibers should be well-aligned with minimal pilling potential.

“Made in Italy” and Other Origin Labels

A “Made in Italy” label generally indicates higher quality, especially for Venetian wool. Italian wool mills, particularly those in Biella and the Veneto region, have centuries of experience and maintain high standards.

However, the label alone doesn’t guarantee quality. Some manufacturers produce the fabric elsewhere and finish it in Italy to get the label. Look for “woven in Italy” or “milled in Italy” for more assurance.

British wool mills, particularly those in Yorkshire, also produce excellent Venetian wool. While British manufacturers often focus on more traditional weights and colors, their quality is typically very high.

Red Flags for Poor Quality

Watch out for these warning signs:

- Very cheap prices: Quality wool is expensive. If the price seems too good to be true, the fabric is probably low-grade or blended with cheaper fibers

- Excessive shine: If the fabric looks more like satin than wool, it might be treated with chemical finishes to fake a luster it doesn’t naturally have

- Stiff, board-like feel: This suggests too much sizing or poor-quality finishing

- Fuzzy surface: Venetian wool should be smooth. Fuzziness indicates short fibers or poor processing

- Uneven weave: Look closely at the fabric structure. Irregular spacing or tension suggests manufacturing problems

- Chemical smell: Strong chemical odors indicate poor-quality dyeing or finishing

Reputable Manufacturers

While many manufacturers produce quality Venetian wool, some names carry particular weight in the industry:

Italian mills:

- Vitale Barberis Canonico (one of the oldest wool mills, founded in 1663)

- Cerruti 1881

- Loro Piana

- Ermenegildo Zegna

British mills:

- Scabal

- Holland & Sherry

- Huddersfield Fine Worsteds

Fabrics from these mills cost more, but you’re paying for consistent quality, excellent processing, and materials that will last.

Fiber Content Labels

Read the fiber content label carefully. Authentic Venetian wool should be 100% wool or may contain a small percentage (up to 5%) of nylon for added strength. Be wary of:

- Polyester blends (unless specifically looking for easy-care fabric)

- High percentages of other fibers

- Vague descriptions like “wool blend” without specifics

A small amount of synthetic fiber isn’t necessarily bad, especially for trousers that need extra durability. But the majority should be quality wool for authentic Venetian wool characteristics.

Quick Quality Checklist

Before buying Venetian wool, check these points:

- ☑ Smooth, even surface with consistent luster

- ☑ Springs back after the crumple test

- ☑ Feels substantial but not stiff

- ☑ Drapes beautifully when held

- ☑ Even, rich color throughout

- ☑ Clear fiber content label (100% wool or with minor nylon content)

- ☑ Price reflects quality (not suspiciously cheap)

- ☑ From a reputable source or mill

Need more guidance? Use our Wool Quality Assessment Checklist to rate fabric quality before purchasing.

Care and Maintenance

Proper care is what transforms a Venetian wool garment from a nice purchase into a long-term wardrobe investment. The good news is that while wool requires specific care, it’s not as high-maintenance as you might think.

Professional Dry Cleaning: The Gold Standard

For Venetian wool suits, jackets, and coats, professional dry cleaning is the recommended care method. Here’s why:

Dry cleaning uses solvent-based cleaning instead of water, which prevents the wool fibers from felting or shrinking. The process also removes oils and dirt that water washing might not handle as effectively.

However, you don’t need to dry clean after every wear. In fact, excessive dry cleaning can break down the fibers over time. A better approach:

- Occasional wear (once a month or less): Clean once or twice a year

- Regular wear (2-3 times per week): Clean 2-4 times per year

- Frequent wear (daily for work): Clean every 2-3 months

Between cleanings, spot-clean small stains and air out garments to keep them fresh.

Choose Your Dry Cleaner Wisely

Not all dry cleaners are equal. For expensive Venetian wool garments, find a cleaner who specializes in fine fabrics. Look for someone who: hand-finishes garments rather than using only machines, uses quality pressing equipment, understands how to handle wool properly, and is willing to discuss their process with you. The cheapest option is often not the best choice for your investment pieces.

Home Care Between Cleanings

Proper hanging: Always use wide, shaped hangers for jackets and coats. Wire hangers will distort the shoulders. For trousers, use clip hangers or fold over a sturdy hanger bar. Hang garments immediately after wearing to allow them to air out and wrinkles to release naturally.

Airing out: After wearing, hang your garment in a well-ventilated area (not in a closed closet) for at least 24 hours before wearing again. This allows moisture to evaporate and odors to dissipate.

Brush regularly: Use a natural-bristle clothes brush to remove dust and surface dirt. Brush in one direction following the fabric’s nap. This simple step can dramatically extend the time between cleanings.

Rotate your wardrobe: Don’t wear the same garment two days in a row. Wool needs time to rest and recover its shape. Having at least 3-4 items in rotation ensures each piece gets adequate rest time.

Spot Cleaning Stains

When you get a small stain, quick action with proper technique can prevent permanent damage:

- Blot immediately: Use a clean, white cloth to blot (don’t rub) the stain. Work from the outside in to prevent spreading.

- Test first: Before applying any cleaning solution, test it on an inconspicuous area (inside seam, under collar) to ensure it doesn’t damage or discolor the fabric.

- Use cool water: For most stains, dab with a cloth dampened with cool water. Hot water can set protein-based stains.

- Gentle soap if needed: For oily stains, use a tiny amount of wool-safe detergent or dish soap mixed with water. Apply sparingly and blot.

- Rinse carefully: Use a clean, damp cloth to remove any soap residue.

- Dry flat: Lay the garment flat on a towel and let it air dry naturally. Don’t hang wet wool as it can stretch.

For stubborn or large stains, take the garment to a professional. Attempting aggressive home treatment can make things worse.

Can You Wash Venetian Wool at Home?

While professional cleaning is always safest, you can hand wash some Venetian wool items at home if you’re very careful. This works best for items like scarves or lighter garments, not structured suits or coats.

If you decide to hand wash:

- Fill a basin with cool water: Temperature should be cool to the touch, never warm or hot.

- Add wool-specific detergent: Use a product designed for wool. Regular detergents can damage the fibers.

- Submerge gently: Press the garment down into the water without agitating or rubbing.

- Soak briefly: Leave for 3-5 minutes, no longer.

- Drain and rinse: Empty the basin and refill with clean cool water. Press the garment gently to rinse, changing water until soap is removed.

- Remove excess water: Never wring or twist. Press gently or roll in a towel to absorb water.

- Dry flat: Reshape the garment and lay it flat on a clean towel on a flat surface. Turn occasionally until fully dry.

Never Machine Wash

Even on gentle cycles, washing machines are too rough for Venetian wool. The agitation causes felting (when the fibers mat together permanently), and you’ll end up with a shrunken, ruined garment. Similarly, never put Venetian wool in a dryer, even on low heat. The combination of heat and tumbling will felt the wool and potentially shrink it several sizes.

Pressing and Steaming

Venetian wool responds beautifully to pressing, which is one reason it works so well for tailored garments. Here’s how to press it properly:

Iron temperature: Use a medium to warm setting (wool setting on most irons). Test on a seam allowance first to ensure the temperature isn’t too high.

Use a pressing cloth: Always place a clean cotton cloth (or professional pressing cloth) between the iron and the wool. This prevents shine marks and protects the fabric.

Use steam: Steam is your friend with wool. It helps set creases and remove wrinkles without applying too much direct heat.

Press, don’t iron: Lower the iron straight down onto the fabric, press for a few seconds, then lift straight up. Don’t slide the iron across the fabric like you would with cotton, as this can distort the weave.

Let it cool: After pressing, hang the garment and let it cool completely before wearing or storing. This allows the fibers to set in their new shape.

A garment steamer is also excellent for Venetian wool. It refreshes garments and removes light wrinkles without the risk of creating shine marks from direct contact with an iron.

Get Personalized Care Instructions

Use our Wool Care Calculator to get specific washing and care recommendations based on your garment type and wool quality.

Storage Tips

Season storage: When storing Venetian wool garments for the off-season, clean them first (moths are attracted to body oils and food residues). Store in breathable garment bags, never plastic, as wool needs air circulation. Add cedar blocks or lavender sachets to deter moths naturally.

Protect from moths: Moths can devastate a wool wardrobe. Besides proper cleaning before storage, check stored items periodically. If you notice any signs of moth damage (small holes, webbing, or the moths themselves), act immediately. Freeze affected items for 72 hours to kill any eggs or larvae, then clean thoroughly.

Avoid direct sunlight: Prolonged sun exposure can fade even quality-dyed wool. Store garments in a dark place or use closet covers to protect them.

Quick Reference Care Chart

| Care Task | Frequency | Method |

|---|---|---|

| Airing out | After each wear | Hang in ventilated area for 24 hours |

| Brushing | Weekly (with regular wear) | Natural bristle brush, one direction |

| Professional cleaning | 2-4 times per year | Quality dry cleaner |

| Pressing | As needed | Warm iron with pressing cloth and steam |

| Moth inspection | Monthly (in storage) | Visual check, cedar/lavender protection |

Where to Buy and Pricing Guide

Now that you understand what makes quality Venetian wool, where do you actually find it? And what should you expect to pay? Let’s break down the options.

Price Ranges

Venetian wool prices vary significantly based on quality, origin, and where you buy:

Budget range (£40-60 per meter): At this price point, you’ll find lower-grade Venetian wool, often with lower Super numbers (around 80s-100s) or from less prestigious mills. The fabric will still be usable but may not have the same softness or durability as higher grades.

Mid-range (£60-100 per meter): This is where you find good quality Venetian wool suitable for most purposes. Expect Super 100s to 120s fabrics from reputable manufacturers. This range offers the best value for most sewers and tailors.

Premium range (£100-200+ per meter): Top-tier Venetian wool from famous Italian or British mills. These fabrics feature Super 120s and above, beautiful hand feel, and superior finishing. If you’re making a once-in-a-lifetime suit or have the budget for the very best, this is where to look.

Designer/luxury range (£200-400+ per meter): Ultra-premium fabrics from the most prestigious mills, often with proprietary finishes or exclusive patterns. These are found in high-end bespoke tailoring and luxury fashion.

For context, you’ll need approximately:

- 2.5-3.5 meters for a jacket

- 1.5-2 meters for trousers

- 3-4.5 meters for a full suit

- 3-4 meters for a coat

So a mid-range suit would cost £180-450 in fabric alone, before any labor costs.

Where to Buy: Online Retailers

Specialty fabric stores: Dedicated fabric retailers, both physical and online, are your best bet for variety and expertise. Staff at these shops usually know their fabrics well and can advise on what works for your project.

In the UK, look for:

- Macculloch & Wallis (London-based, excellent selection)

- Fabric Godmother (online, good range of designer fabrics)

- The Fabric Store (online, international shipping)

- Yorkshire Fabric (specializes in quality suitings)

Direct from mills: Some Italian and British mills sell directly to consumers, though often with minimum quantities. This option works best if you’re a professional tailor or buying for multiple projects.

Etsy and independent sellers: You can find Venetian wool on marketplaces like Etsy, often from sellers who buy deadstock or remnants from mills. Prices can be good, but quality varies. Read reviews carefully and don’t hesitate to ask for detailed photos or samples.

Physical Fabric Stores

If possible, buy fabric in person, especially for your first Venetian wool project. Being able to touch and see the fabric makes a huge difference in understanding what you’re getting.

London has excellent options:

- Soho’s fabric district (Berwick Street and surrounding areas)

- Liberty London (higher-end options)

- Cloth House (multiple locations)

Outside London, check for quality fabric shops in major cities. Even if they don’t stock Venetian wool regularly, many can order it for you.

Getting Samples

Before committing to several meters of fabric, order samples. Most reputable sellers offer small sample swatches (usually 10x10cm) for a few pounds or sometimes free. This lets you:

- Feel the fabric quality in person

- See the true color (which can look different from photos)

- Test how it responds to pressing

- Compare different qualities side-by-side

- Make sure it matches with other fabrics or linings

The small cost of samples is money well spent when you’re about to invest £100+ in fabric.

What to Ask Sellers

Whether buying online or in person, ask these questions:

- “What’s the Super number?” (This tells you fiber fineness)

- “Where is it milled?” (Italian and British mills generally indicate quality)

- “What’s the weight?” (GSM helps you understand if it suits your project)

- “Is it 100% wool or blended?” (Know what you’re getting)

- “What’s your return policy?” (Important if buying sight unseen)

- “Do you have more of this fabric?” (In case you need extra later)

Good sellers will answer these questions readily. If they can’t or won’t, that’s a red flag.

Buying Deadstock and Remnants

Fabric deadstock (excess inventory from manufacturers or fashion houses) can offer excellent value. You might find top-quality Venetian wool at 30-50% off retail prices.

However, there are considerations:

Pros:

- Significant cost savings

- Often from prestigious mills

- Unique fabrics not available elsewhere

- More sustainable than buying new

Cons:

- Limited quantities (might not be enough for your project)

- Can’t reorder if you need more

- May have storage-related issues (check carefully for damage)

- Less predictable quality (inspect thoroughly)

Budget Tips

If you’re working with a limited budget but want quality Venetian wool:

Start with a smaller project: Make a vest or simple skirt rather than a full suit. This lets you experience the fabric without the major investment.

Watch for sales: Fabric stores often have seasonal sales. Sign up for newsletters to catch these opportunities.

Buy in groups: If you know other sewers, split a larger purchase to get better per-meter prices.

Consider mid-range: Super 100s-120s fabrics offer excellent quality at more accessible prices than super high-number fabrics.

Focus on classic colors: Navy, charcoal, and mid-grey Venetian wool will get more use than unusual colors, making them better investments.

Working with Venetian Wool: Sewing Tips

Venetian wool is actually quite forgiving to sew compared to some other fabrics, but there are specific techniques that will give you professional results. Whether you’re an experienced sewer or working with wool for the first time, these tips will help.

Pre-Washing and Pre-Treatment

Here’s an important point: don’t pre-wash Venetian wool. Unlike cotton or linen, you don’t want to wash wool fabric before sewing.

Instead, you may want to pre-shrink it:

- Lay the fabric flat on a clean surface

- Hold a steam iron 2-3 inches above the fabric (don’t touch the fabric)

- Apply steam across the entire piece

- Let it dry completely (at least 24 hours) before cutting

This light steaming releases any tension from the fabric being rolled on bolts and can prevent minor shrinkage during later pressing.

Cutting Venetian Wool

Prepare your space: Use a large, flat surface. A carpeted floor works fine if you don’t have a big cutting table. Vacuum first to ensure there’s no debris that could snag the fabric.

Respect the grain: Venetian wool should be cut on-grain for proper drape and wear. The lengthwise grain (parallel to the selvage) should run vertically in your garment. Take time to align your pattern pieces correctly.

Use a rotary cutter or sharp scissors: Dull scissors can push the fabric rather than cut cleanly, distorting your pieces. If using scissors, take long, smooth cuts rather than short snips.

Use weights, not pins (for cutting): Pattern weights let you cut more accurately than pinned patterns. Pins can leave small holes in the fabric or cause it to shift. However, you’ll still need pins for actual sewing.

Mark carefully: Use tailor’s chalk or chalk pencils that brush off easily. Test on a scrap first. Avoid markers or anything that could permanently mark the fabric.

Choosing Thread and Needles

Thread: Use quality polyester thread or cotton-wrapped polyester. Pure cotton thread can be too weak for the durability of the fabric. Match the thread color to your fabric, choosing slightly darker if you can’t find an exact match (thread appears lighter when sewn).

Machine needles: Use a Universal or Microtex needle in size 70/10 to 80/12 for most Venetian wool. The smooth, firm fabric doesn’t need a ballpoint needle. Change your needle before starting your project; a fresh needle makes cleaner stitches.

Hand sewing needles: If doing any hand finishing, use sharps in size 8 or 9.

Machine Settings

Stitch length: Use a slightly longer stitch than for cotton, around 2.5-3mm. This prevents the fabric from puckering and creates stronger seams.

Tension: Start with normal tension and test on scraps. You want the stitches to look even on both sides with no puckering or looping.

Presser foot pressure: If your machine allows adjustment, reduce the presser foot pressure slightly. Venetian wool’s smooth surface can feed unevenly with too much pressure.

Speed: Sew at a moderate, steady pace. Wool isn’t slippery like satin, but you want consistent seams.

Seam Finishes

Venetian wool doesn’t fray badly, but you’ll still want to finish seams for durability and a professional look:

For unlined garments:

- Serge or overlock seam edges

- Use Hong Kong finish (bias binding on each seam edge) for a luxury look

- Flat-fell seams work for casual garments

For lined garments (most tailored pieces):

- Press seams open and leave raw (the lining will cover them)

- Pink the edges with pinking shears to minimize bulk

Pressing as You Go

This is the secret to professional-looking results with Venetian wool: press every seam as you sew it.

- Press the stitching line first: This sets the stitches into the fabric

- Press the seam open (or to one side as appropriate): Use the tip of your iron

- Use steam generously: Wool responds beautifully to steam

- Press from the wrong side first: This prevents shine marks

- Use a pressing cloth: Even from the wrong side, a thin pressing cloth adds protection

- Let it cool: Don’t handle pressed areas until they’ve cooled completely

A tailor’s ham (a firmly stuffed pressing pad) is incredibly useful for pressing curved seams like armholes and collars. A sleeve board helps with narrow areas.

Handling Darts and Ease

Venetian wool is excellent for shaped garments because it holds darts and eased areas well.

For darts: Stitch accurately, press well with steam, and consider cutting away excess fabric on long darts (leaving 1cm seam allowance) to reduce bulk.

For ease: When easing a sleeve cap or similar area, use steam to shrink out the fullness. Hold the iron above the fabric and direct steam at the eased area while gently shaping with your hands.

Interfacing Choices

For structured areas (jacket fronts, collars, cuffs), you’ll need interfacing.

For suits and formal wear: Use woven or weft-insertion fusible interfacing. These have some give in one direction, which works better with wool than non-woven interfacings. Test the fusible on a scrap first to ensure it bonds well and doesn’t create unwanted stiffness.

For softer looks: Consider sew-in interfacings like hair canvas or organza, which create structure without the stiffness of fusibles.

Application tips: When fusing interfacing, use a damp pressing cloth and hold the iron down for 10-15 seconds at a time rather than moving it around. This creates a better bond.

Choosing Linings

Proper lining makes a huge difference in how your garment wears and feels.

Bemberg (cupro) rayon: The traditional choice for luxury garments. It breathes well, feels silky, and drapes beautifully. More expensive but worth it for investment pieces.

Polyester lining fabric: More affordable and durable. Modern polyester linings are much better than older versions. Look for ones specifically designed for suiting.

Silk: The ultimate luxury, but expensive and can be slippery to work with. Usually reserved for very special garments.

Whatever you choose, pre-shrink the lining (by washing or steaming) before use, as it may shrink more than the wool.

Common Challenges and Solutions

Shine marks from pressing: Always use a pressing cloth. If you do get shine, try steaming it from the wrong side or very gently brushing with a soft clothes brush while the fabric is still warm.

Stretched-out areas: If you’ve pulled the fabric while sewing, steam and press the area while gently easing it back into shape.

Skipped stitches: Try a fresh needle, adjust your tension slightly, or slow down your sewing speed.

Bulk at seam intersections: Trim seam allowances at corners and grade seam allowances (trim different amounts from each layer) where multiple layers meet.

Essential Sewing Supplies for Venetian Wool

Before you start your project, gather these tools:

- Sharp fabric shears or rotary cutter

- Universal or Microtex needles (70/10 to 80/12)

- Quality polyester thread

- Pattern weights

- Tailor’s chalk or marking pencils

- Iron with good steam function

- Pressing cloth

- Tailor’s ham

- Appropriate interfacing

- Quality lining fabric

Venetian Wool in Modern Fashion

While Venetian wool has deep historical roots, it continues to be relevant in contemporary fashion. Understanding how designers and fashion houses use this fabric today can inspire your own projects and help you appreciate its versatility.

Current Design Trends

Venetian wool appears regularly on runways and in high-end ready-to-wear collections, though it’s often not specifically labeled as “Venetian wool” in marketing materials. Designers simply select it for its properties and use it where it works best.

Tailored minimalism: The current trend toward clean-lined, precisely tailored garments plays to Venetian wool’s strengths. Brands focusing on investment wardrobe pieces often choose this fabric for its crisp appearance and long-lasting quality.

Sustainable luxury: As fashion moves toward slower, more sustainable practices, the durability and timeless appearance of Venetian wool align with these values. Several high-end sustainable brands feature it in their collections.

Gender-neutral tailoring: The rise of unisex and gender-neutral fashion has increased interest in traditional tailoring fabrics like Venetian wool. Its structure works equally well for any body type and styling approach.

Where You’ll See It

Bespoke and made-to-measure tailors: Savile Row tailors and their counterparts worldwide regularly offer Venetian wool as an option for suits. It’s particularly popular for clients who want something that looks impressive but isn’t as bold as sharkskin.

High-street premium lines: While you won’t find Venetian wool at fast-fashion price points, premium lines from major brands occasionally use it for special collections or flagship products.

Contemporary workwear brands: Companies making high-quality professional clothing for both men and women often choose Venetian wool for its combination of comfort, durability, and professional appearance.

Celebrity and Red Carpet Appearances

While it’s rare for celebrity stylists to specify fabric types publicly, many red carpet suits that feature that distinctive smooth, lustrous appearance are made from Venetian wool or similar worsted wools. The fabric photographs well under bright lights without looking overly shiny.

Award shows, premieres, and formal events regularly showcase suits in Venetian wool, particularly when the wearer wants a polished, professional look rather than a more casual or trendy appearance.

Color Trends

While Venetian wool is available in many colors, certain shades prove perennially popular:

Classic navy: Still the most popular color for business and formal wear. Navy Venetian wool reads as professional and versatile.

Charcoal and mid-grey: These neutral tones work for almost any occasion and coordinate with many colors.

Black: For formal evening wear and tuxedos, black Venetian wool offers a sophisticated alternative to traditional wool.

Rich jewel tones: Recent years have seen increased interest in deeper colors like forest green, burgundy, and sapphire blue, particularly for women’s tailoring.

Earth tones: Camel, rust, and warm browns have grown in popularity as fashion moves away from strictly corporate color palettes.

Modern Applications Beyond Traditional Suiting

While suits remain the primary use, contemporary designers have found creative ways to use Venetian wool:

Statement coats: Long, structured coats in bold colors showcase the fabric’s draping ability and visual impact.

Wide-leg trousers: The current popularity of wide-leg pants works beautifully with Venetian wool’s controlled drape.

Tailored dresses: Shift dresses and structured shirt dresses benefit from the fabric’s ability to hold shape without stiffness.

Mixed-material looks: Pairing Venetian wool pieces with contrasting textures (like chunky knits or soft silks) creates interesting visual contrasts.

Styling Contemporary Venetian Wool Pieces

Modern fashion encourages mixing formal pieces with casual items, and Venetian wool adapts well to this approach:

Suit jacket with jeans: A well-cut Venetian wool blazer elevates casual denim for a smart-casual look that works in many settings.

Tailored trousers with sneakers: The juxtaposition of formal fabric with casual footwear creates a contemporary, relaxed vibe.

Suit vest as outerwear: Wearing a Venetian wool vest over a shirt or even a t-shirt creates an interesting layered look.

Breaking up suits: Rather than wearing the full suit, pair the jacket with different trousers or wear the trousers with a casual top.

The Investment Perspective

In an era of fast fashion and disposable clothing, Venetian wool represents a different approach. Fashion commentators and style experts increasingly recommend investing in fewer, higher-quality pieces rather than constantly buying and discarding cheaper items.

A well-made Venetian wool suit embodies this philosophy. While the initial cost is higher, the per-wear cost over 10-15 years of regular use can be lower than buying cheaper suits every few years. The classic appearance also means the garment won’t look dated as trends shift.

Frequently Asked Questions

Generally, no. Venetian wool is a worsted fabric made from long, fine fibers that have been combed smooth. This processing creates a smooth surface that’s much less likely to irritate skin than rougher woolen fabrics. The quality does matter though. Higher-grade Venetian wool (Super 100s and above) uses finer fibers that feel softer. If you have very sensitive skin, you might want to test a sample against your skin before committing to a project. Also, note that most tailored jackets are worn over shirts, so direct skin contact is limited anyway.

Venetian wool provides moderate warmth, making it a good three-season fabric. It’s warmer than summer-weight tropical wool but not as warm as flannel or heavy coating wools. The tight worsted weave means there’s less air trapped in the fabric, and air pockets are what provide insulation. This makes Venetian wool comfortable in temperature-controlled indoor environments year-round. For cold outdoor weather, you’d want to layer or choose a heavier wool fabric. For hot summer weather, you might prefer a lighter-weight worsted wool.

No, you should not machine wash Venetian wool, even on gentle or wool cycles. Machine washing will likely cause the fabric to felt (when fibers mat together permanently) and shrink, ruining the garment. The agitation and water temperature changes are too harsh for wool. Instead, have tailored garments professionally dry cleaned, or hand wash very carefully in cool water if the item is small and unstructured. Most Venetian wool garments should be dry cleaned for best results.

With proper care, a well-made Venetian wool suit can easily last 15-20 years or more. The durability depends on several factors: the quality of the original fabric, how well the suit was constructed, how often you wear it (rotating between multiple suits extends life), and how well you care for it. Regular airing out, proper storage, occasional professional cleaning, and prompt repairs of small damage all contribute to longevity. Many people still wear Venetian wool suits that are several decades old.

Venetian wool is a specific type of wool suiting characterized by its smooth surface and subtle luster from a satin or twill weave. Regular wool suiting is a broader category that includes many different weave structures and finishes. Venetian wool is always a worsted fabric (made from long, combed fibers), while “wool suiting” could be either worsted or woolen. The key distinguishing features of Venetian wool are the smooth finish, slight sheen, and heavier drape compared to many other suitings.

For tailored garments you plan to wear regularly, Venetian wool is generally worth the investment. It breathes better than polyester (so you’ll be more comfortable), drapes more beautifully, lasts longer with proper care, and maintains a more professional appearance. Wool blends can offer some benefits of both materials, but pure Venetian wool provides the best performance and longevity. Calculate the cost per wear over the garment’s lifetime rather than just looking at the upfront price. A £400 suit that lasts 15 years costs less per wear than a £100 suit you replace every two years.

While Venetian wool has a formal appearance, you can absolutely use it for more casual pieces. The smooth finish and subtle luster create a polished look even in casual styles. Consider it for items like unstructured blazers, wide-leg trousers, or simple A-line skirts. The fabric’s refined appearance means your casual pieces will still look put-together. Just keep in mind that the fabric itself has a dressy quality, so it works best for smart-casual rather than very relaxed styles.

For a first project, choose navy, charcoal grey, or mid-grey. These versatile colors work for almost any occasion and coordinate with many other colors in your wardrobe. Navy is particularly versatile, working for both business and more formal events. These colors also hide minor soiling better than lighter colors, which is helpful if you’re learning to care for wool garments. Once you’ve successfully completed a project in a classic color, you can experiment with more unusual shades.

The best method is steaming. Hold a garment steamer or steam iron a few inches from the fabric and apply steam, letting the fabric hang naturally. For stubborn wrinkles, press with a warm iron and pressing cloth. Never apply a hot iron directly to Venetian wool as this can create permanent shine marks. Many wrinkles will also release naturally if you hang the garment in a humid bathroom while you shower, though this method is slower.

Yes, Venetian wool tailors very well, which is one reason it’s popular for suits. The fabric can be let out or taken in, hemmed, sleeves shortened or lengthened, and otherwise altered by a skilled tailor. The tight weave means it holds new stitching well and doesn’t show old stitch holes as obviously as some fabrics. However, major alterations that significantly change the garment’s shape or structure should be done by an experienced tailor who understands working with wool.

Conclusion

Venetian wool stands as a testament to centuries of textile tradition, combining Old World craftsmanship with modern performance. From its roots in the wool workshops of ancient Altino to today’s fashion-forward Italian mills, this fabric has maintained its reputation for quality, durability, and refined elegance.

What makes Venetian wool special isn’t any single feature, it’s the combination of qualities that work together. The smooth, lustrous surface catches light beautifully without looking flashy. The medium weight provides structure and drape without bulk. The worsted processing creates a fabric that resists wrinkles, holds shape, and wears well year after year. These characteristics explain why Venetian wool remains a go-to choice for quality tailoring more than a century after the golden age of Venetian textile production ended.

Whether you’re a home sewer planning your first tailored jacket, a professional considering fabric options for a client, or simply someone who wants to understand what makes a quality suit, understanding Venetian wool gives you an appreciation for craftsmanship and materials. In a world of disposable fashion, this fabric represents a different approach: investing in quality pieces that last, that feel good to wear, and that maintain their appearance through years of use.

The fabric isn’t perfect. Like all wool production, it raises questions about environmental impact and animal welfare that thoughtful consumers need to consider. But compared to most alternatives, especially fast-fashion synthetics, a well-made Venetian wool garment that lasts 15-20 years represents a more sustainable choice. By choosing certified wool, caring for your garments properly, and treating them as long-term investments rather than seasonal purchases, you can minimize the negative impacts while enjoying the benefits.

Working with Venetian wool does require some knowledge and care. You need to understand pressing techniques, choose appropriate patterns, and commit to proper maintenance. But the learning curve isn’t steep, and the results reward your effort. There’s real satisfaction in creating or wearing a garment that looks professional, feels comfortable, and carries the weight of textile history.

Key Takeaways

- Venetian wool is a worsted wool fabric characterized by its smooth surface, subtle luster, and beautiful drape, typically woven in a satin or twill structure