Essential Safety Guide: Types, Applications, Standards & Latest Innovations for 2025

Fire can start quickly and spread fast, making safety a top concern in many places. Fire-resistant fabrics are designed to help protect people by resisting ignition and slowing down the spread of flames. Understanding how these materials work and where they’re used is essential for anyone who wants extra protection at home, work, or in specialized environments.

When we look closer at fire-resistant fabrics, we see that not all of them are made the same way. Some are made from special fibers that don’t catch fire easily, while others are treated with chemicals to give them their protective qualities. This allows them to be used in jobs, clothing, and products where safety matters most.

The global fire-resistant fabrics market has grown significantly, valued at approximately $4.87 billion in 2025 and projected to reach $6.74 billion by 2029. This growth reflects increasing safety awareness across industries and stricter workplace protection standards worldwide.

Table of Contents

Key Takeaways

- Fire-resistant fabrics help prevent clothing and materials from catching fire

- These fabrics use special materials or treatments for extra protection

- They’re used in many industries to improve safety and meet strict rules

- New technologies like nanotechnology and phase change materials are revolutionizing the field

- Use our interactive fabric selection tools to find the perfect solution for your specific needs

What Are Fire-Resistant Fabrics?

Fire-resistant fabrics are designed to help slow or stop the spread of fire. They play an important role in fire safety by helping to keep people and property safer in case of a fire. These fabrics use special materials or treatments to lower the risk of burning.

Defining Fire Resistance

When we talk about fire resistance, we mean the ability of a fabric to avoid catching fire easily and to resist burning even when exposed to heat or flames. Some fabrics are made from fibers that naturally resist fire, while others get special treatments to improve their fire resistance.

The performance of fire-resistant fabrics is usually tested using standards like the NFPA 701. This test checks how well a fabric can stop burning when exposed to flame for a set amount of time. Fabrics that pass these tests help prevent flames from spreading and can self-extinguish once the heat source is removed.

Common fire-resistant materials include aramid fibers, such as Nomex and Kevlar, and some treated cottons. These materials are widely used in uniforms, curtains, or furniture covers where extra protection from fire is needed.

Choosing the right fire-resistant fabric can be complex. Our Fire-Resistant Fabric Decision Tree helps you select the perfect material by analyzing your application, risk level, and budget requirements in just 4 simple steps.

Fire Resistance Versus Flame Retardancy

What Fabric Is Fire-Resistant?

Several types of fabrics offer fire-resistant properties:

Inherently Fire-Resistant Fabrics:

- Aramid fibers (Nomex, Kevlar)

- Modacrylic fibers

- Wool (naturally fire-resistant)

- Certain specialty synthetic fibers

Treated Fire-Resistant Fabrics:

- Treated cotton blends

- Flame-retardant polyester

- Chemically treated natural fabrics

Fire Resistance Versus Flame Retardancy

People sometimes confuse “fire-resistant” and “flame-retardant” fabrics, but they’re not exactly the same. Fire-resistant fabrics are usually made from fibers that don’t burn or that resist burning, even after long exposure to fire. In contrast, flame-retardant fabrics are often made from standard fibers but treated with chemicals to help them resist flames.

Key differences:

| Fire-Resistant | Flame-Retardant |

|---|---|

| Made from special fibers | Made from regular fibers |

| Resistance is built-in | Resistance from chemical treatment |

| Does not wash out easily | May lose protection over time |

| Generally more expensive | Usually more affordable |

| Longer-lasting protection | May need retreatment |

Fire-resistant fabrics keep their fire-blocking abilities over many uses and washes, but flame-retardant coatings can wear off after repeated cleaning. This difference matters when choosing fabrics for areas with high fire safety needs.

Role in Fire Protection

Fire-resistant fabrics are used in many places to improve fire safety. They’re found in firefighter clothing, industrial workwear, school curtains, and seat covers in public transport. These fabrics don’t stop fire from starting, but they slow down the burn and stop flames from spreading quickly.

By using fire-resistant materials, we can help create safer environments where there’s a higher chance of escaping or controlling a fire. In homes, offices, and public places, these textiles can make a real difference in fire emergencies.

Experts often recommend using fire-resistant fabrics in areas where the risk of fire is high or where many people gather. For any setting that demands higher fire safety, choosing fire-resistant over regular materials adds important protection.

How Fire-Resistant Fabrics Work

Fire-resistant fabrics protect wearers by reducing how easily they catch fire and by limiting the spread of flames. To do this, they depend on their unique fiber structures, chemical makeup, and the way they react with heat and oxygen.

Protective Barrier Mechanisms

Fire-resistant fabrics act as a barrier between heat and the wearer. These materials are designed so that, when exposed to a flame, they don’t easily catch fire or melt.

Some fabrics, like wool, naturally resist burning because their fibers self-extinguish after being exposed to heat. Synthetic fire-resistant fabrics are engineered to form a protective layer when heated. This layer may char or thicken and slows heat transfer.

This means heat and flames don’t easily reach the skin. The fabric may also block melted materials from sticking, preventing burns. These barrier mechanisms are key for safety in work environments where fire risks are high.

Common features include:

- Reduced flammability

- Formation of a char layer

- Self-extinguishing properties

- Heat reflection capabilities

Impact of Chemical Structure

The chemical structure of a fabric’s fibers makes a huge difference in fire resistance. Inherently fire-resistant fibers, like aramids (used in Nomex or Kevlar), have strong molecular bonds that need a lot of energy to break. This makes them slow to burn or melt.

Other fabrics become fire-resistant after chemical treatment. For example, cotton can be treated with special chemicals that bond to its fibers. These chemicals change the way the fabric reacts to heat and oxygen.

Here’s a simple comparison:

| Fiber/Fabric | FR By Nature | Needs Treatment | Example |

|---|---|---|---|

| Wool | Yes | No | Wool sweater |

| Aramid (Nomex) | Yes | No | Lab coat |

| Cotton | No | Yes | FR Work shirt |

| Modacrylic | Yes | No | Protective gear |

| Regular Polyester | No | Yes | Treated workwear |

Always check if a fire-resistant fabric’s protection comes from fiber type or chemical treatment. This can affect how long the protection lasts.

Oxidation and Combustion Processes

The way these fabrics interact with oxygen and heat is critical. Fire-resistant fibers often limit oxidation, which is a chemical reaction between oxygen and material that leads to burning.

When a fire-resistant fabric faces high heat, its structure may swell, stiffen, or turn to char rather than fuel a flame. This makes it much harder for the fire to keep going. The fabric might also release gases that dilute oxygen near the flame, slowing the combustion process.

Combustion needs three things: heat, fuel, and oxygen. By disturbing this balance—especially by restricting oxygen or not serving as good fuel—fire-resistant fabrics lower the chance of ignition or further burning.

These processes help keep users safer in dangerous situations by making it hard for flames to spread.

Types of Fire-Resistant Fabrics

Fire-resistant fabrics fall into two main categories, each made to slow down burning or resist catching fire. These materials are often chosen based on how and where they will be used.

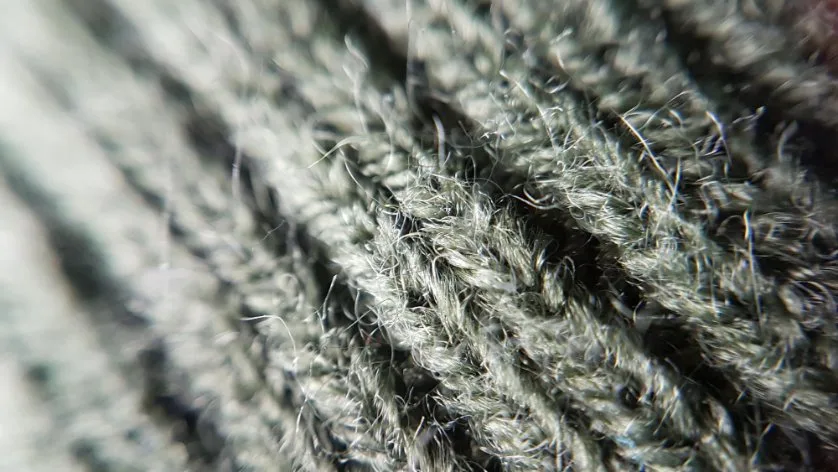

Inherently Fire-Resistant Materials

Inherently fire-resistant fabrics are made from fibers that don’t burn easily by nature. Nomex is one of the best-known examples. Nomex is used in firefighter suits and protective clothing for workers in dangerous jobs. It resists flames without needing extra treatments.

Another group includes fibers like modacrylic and some specialty acrylic fibers. Modacrylic is often blended with cotton or other fibers to make soft and strong fabric. It chars but doesn’t keep burning, which helps slow fires down.

Which Fabric Doesn’t Catch Fire?

While no fabric is completely fireproof, these materials offer the highest natural resistance:

- Aramid fibers (Nomex, Kevlar)

- Modacrylic fibers

- Wool (self-extinguishing)

- Certain ceramic fibers

- Carbon fiber (in specialized applications)

Fabrics made with high amounts of cellulose, such as cotton or rayon, are usually not fire-resistant unless specially treated. However, some new processed cellulose fibers are designed to have better resistance to flames.

Common inherently fire-resistant fibers:

| Fiber | Properties | Common Uses |

|---|---|---|

| Nomex | High flame resistance, durable | Firefighting gear, uniforms |

| Modacrylic | Self-extinguishing, soft, blends well | Carpets, protective apparel |

| Wool | Natural fire resistance, breathable | Military uniforms, blankets |

| Carbon Fiber | Extremely heat resistant | Aerospace, high-temp applications |

Treated Fabrics

Treated fabrics start off as normal, often flammable, materials. They become fire-resistant after chemicals are added during or after manufacturing. Both cotton and synthetic blends can be made flame-retardant when treated.

Cotton fabrics, which are made from cellulose, are a common choice for chemical treatment because cotton by itself catches fire easily. After treatment, the fabric can self-extinguish or burn much more slowly. These chemicals are either sprayed on, applied during the washing process, or built into the fibers.

Is 100% Cotton Fireproof?

No, 100% cotton is not fireproof. In fact, untreated cotton is quite flammable and burns readily. However, cotton can be made fire-resistant through chemical treatments that change how it reacts to heat and flames.

Synthetic fibers like polyester and nylon also receive treatments sometimes. Unlike Nomex or modacrylic, these are not naturally flame-resistant, but treatments can boost their ability to withstand heat.

Is 100% Polyester Fire Retardant?

Standard 100% polyester is not fire retardant. Regular polyester melts and can burn when exposed to high heat. However, polyester can be treated with flame-retardant chemicals or blended with inherently fire-resistant fibers to improve its fire resistance.

Main points about treated fabrics:

- Fire resistance depends on the chemical used and how it’s applied

- Washing or heavy use can sometimes reduce effectiveness

- Treated fabrics are more affordable than inherently fire-resistant fabrics

- May need to be retreated after a while

- Proper care extends the life of the treatment

Advanced Technologies in Fire-Resistant Fabrics

The fire-resistant fabrics industry is rapidly evolving with cutting-edge technologies that enhance both protection and comfort. These innovations are transforming how we think about fire safety in textiles.

Nanotechnology Integration

Nanotechnology is revolutionizing fire-resistant fabrics by incorporating nanoparticles directly into the fabric structure. These tiny particles, including metal oxides, clay minerals, and carbon nanotubes, create powerful barriers that significantly reduce flammability while maintaining breathability.

Key Nanotechnology Applications:

- Metal oxide nanoparticles for enhanced fire resistance

- Clay nanoparticles that form protective barriers when heated

- Carbon nanotube integration for improved strength and heat resistance

- Nano-coatings that don’t affect fabric feel or flexibility

Smart Textiles and Wearable Technology

Modern fire-resistant fabrics are becoming “smart” through the integration of sensors, conductive fibers, and monitoring systems. These advanced textiles can:

- Monitor environmental conditions (temperature, gas levels)

- Track wearer vital signs during emergency situations

- Provide real-time alerts when dangerous conditions are detected

- Integrate with communication systems for emergency response

Phase Change Materials (PCM) in Fire Protection

Phase Change Materials represent a breakthrough in thermal management for fire-resistant clothing. These materials absorb and release heat during phase transitions, providing additional protection and comfort.

How PCM Works in Fire-Resistant Fabrics:

- Heat absorption during phase change prevents temperature rise

- Thermal regulation keeps wearers comfortable longer

- Extended protection time in high-heat environments

- Reduced heat stress for emergency responders

Benefits of PCM Integration:

- Up to 48% reduction in sweat production

- Extended tolerable rescue time for firefighters

- Improved thermal protective performance (TPP)

- Better comfort in moderate conditions

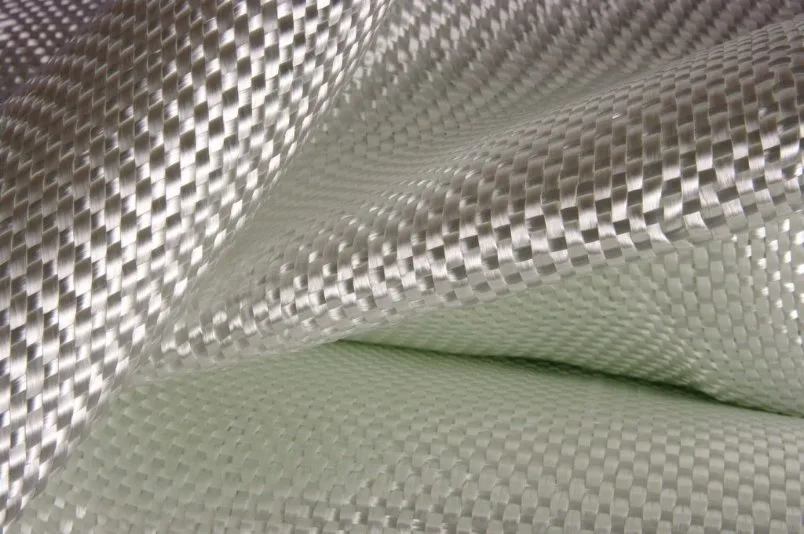

3D Weaving and Manufacturing Innovations

Advanced manufacturing techniques are creating new possibilities for fire-resistant fabric construction:

- 3D weaving technologies for complex protective structures

- Multi-layer integration in single manufacturing processes

- Precision fiber placement for optimized protection zones

- Automated quality control ensuring consistent performance

Key Applications of Fire-Resistant Fabrics

Fire-resistant fabrics play a crucial role in protecting people and property from fire hazards. These materials are used in both personal protective clothing and in the construction of safer buildings.

Protective Clothing and Equipment

Fire-resistant fabrics are widely used in protective clothing for workers in high-risk environments. Industries such as oil and gas, electric utilities, welding, and firefighting rely on these materials. Workers may wear coveralls, jackets, pants, gloves, and hoods made from fire-resistant textiles.

These garments help reduce the risk of burns by resisting ignition and limiting heat exposure. Personal protective equipment (PPE) that features fire-resistant fabrics is sometimes required by safety regulations. For example, electricians wear flame-resistant shirts and pants to guard against electric arc flashes.

In some workplaces, employers provide uniforms made from fire-resistant fibers as the last line of defense in case of a flash fire or electrical event. Lab workers, foundry workers, and military personnel may also need this type of clothing to meet strict safety standards.

Common uses:

- Workwear in petroleum, gas, and electrical fields

- Firefighter suits and accessories

- Military uniforms and gear

- Industrial protective clothing

- Emergency response equipment

Building Materials and Construction

Fire-resistant fabrics are also important in construction and interior design. These materials are used for curtains, wall coverings, and upholstery—especially in public buildings like hospitals, schools, hotels, and theaters.

Using fire-resistant fabrics in these areas helps slow the spread of flames during a fire. Some building codes require materials that meet certain fire resistance standards. Builders may use these fabrics as barriers in ceilings, walls, and HVAC systems.

Is All Upholstery Fabric Fire Retardant?

No, not all upholstery fabric is fire retardant. However, many commercial and public-use upholstery fabrics are required to meet fire safety standards. Residential upholstery may or may not have fire-resistant treatments, depending on the manufacturer and local regulations.

Typical applications:

- Curtain and drapery fabrics in commercial spaces

- Upholstery in public transportation

- Wall liners and partitions in high-occupancy buildings

- Theater and cinema seating

- Hotel and restaurant furnishings

Emerging Applications

Electric Vehicle Industry: The growing electric vehicle market is driving demand for fire-resistant materials in battery thermal management systems and interior components.

Aerospace Sector: Aircraft interiors and protective equipment require advanced fire-resistant materials that meet strict aviation safety standards.

Consumer Electronics: Fire-resistant fabrics are increasingly used in protective cases and thermal management solutions for electronic devices.

By using fire-resistant fabrics in construction, we can help make spaces safer for everyone who uses them. These materials reduce risks for occupants and help emergency services do their jobs more effectively.

Looking for suppliers, testing facilities, or certification bodies? Our Fire-Resistant Fabrics Resource Directory contains contact information for 18+ industry organizations including standards bodies, material suppliers, and testing laboratories worldwide.

Testing and Performance Standards

Fire-resistant fabrics are held to strict rules to make sure they keep people safe. Following these rules helps ensure that clothing or material will perform as needed in dangerous situations.

Overview of Test Methods

There are several main test methods used to see how fabrics respond to fire. One well-known method is ASTM D6413, which measures how long a fabric burns after being exposed to a flame. This test checks for three things: after-flame, char length, and if the fabric melts or drips.

Thermal Mannequin Tests go a step further by exposing a full outfit to flames using a life-sized mannequin. This method shows how fabric performs during a real fire event and helps predict possible skin burns.

Other common tests include:

- Vertical Flame Test

- Small and Large Scale Burn Tests

- After-Flame and After-Glow Times

- Cone Calorimeter Testing

- Oxygen Index Testing

These methods allow comparison of different fabrics and confirm which are safest for each use.

Industry Standards for Fire Safety

Industry standards set clear requirements for fire-resistant fabrics. The National Fire Protection Association (NFPA) has set rules like NFPA 2112 for garments used in workplaces with flash fire risks. These rules make sure clothing resists ignition, stops flames from spreading, and limits heat transfer.

For detailed specifications on flame-resistant garment requirements, the NFPA 2112 standard provides comprehensive guidelines that have become the industry benchmark for protective clothing in flash fire environments. This standard establishes minimum performance requirements that help ensure worker safety across multiple industries.

In the United States, ASTM standards like ASTM D6413, the Standard Test Method for Flame Resistance of Textiles, are often required for certification. International standards, such as those set by ISO, are also widely used.

Key Testing Standards:

| Standard | Application | What It Measures |

|---|---|---|

| NFPA 2112 | Industrial workwear | Flash fire protection |

| ASTM D6413 | General textiles | Flame resistance |

| NFPA 701 | Building materials | Large-scale flame resistance |

| ISO 15025 | Protective clothing | Limited flame spread |

| EN 11612 | Heat protection | Thermal hazard resistance |

Understanding these technical standards is crucial for compliance. Use our Fire Protection Level Calculator to determine which specific standards and protection levels your application requires based on environmental hazards and exposure conditions.

Some settings, like schools and public buildings, may have their own rules. Most standards require testing by third-party labs before a product can be used. Meeting these standards keeps people safe in industries like firefighting, electrical work, and chemical plants.

Market Insights and Industry Trends

The fire-resistant fabrics market is experiencing significant growth driven by increased safety awareness and technological advancement. Understanding these trends helps predict future developments in the industry.

Market Size and Growth

The global fire-resistant fabrics market shows strong growth across all regions:

- Current Market Value: $4.87 billion in 2025

- Projected Growth: Expected to reach $6.74 billion by 2029

- Growth Rate: 8.5% CAGR from 2025-2029

- Regional Leader: Asia Pacific holds 45.86% market share

Key Market Drivers

Industrial Safety Regulations: Stricter workplace safety laws in developed countries are driving demand for protective clothing and materials.

Manufacturing Growth: Global manufacturing output growth of 3-4% annually increases demand for worker protection.

Electric Vehicle Expansion: The growing EV market creates new applications for fire-resistant materials in battery systems.

Infrastructure Development: Building codes increasingly require fire-resistant materials in public spaces.

Major Industry Players

Leading companies in the fire-resistant fabrics market include:

- DuPont (Nomex, Kevlar)

- Solvay

- KANEKA CORPORATION

- Indorama Corporation

- TenCate Protective Fabrics

Regional Market Analysis

Asia Pacific (45.86% market share):

- Rapid industrialization driving demand

- Lower production costs attracting manufacturers

- “Make in India” initiatives supporting growth

North America:

- Strict safety regulations

- Advanced technology adoption

- Focus on multifunctional protective gear

Europe:

- High safety standards

- Environmental sustainability focus

- Innovation in smart textiles

Material-Specific Fire Resistance Guide

Understanding how different materials behave in fire situations helps in making informed choices for specific applications.

Natural Materials and Fire Resistance

What Is a Natural Fire Retardant?

Several natural materials offer inherent fire resistance:

- Wool: Contains natural proteins that char rather than burn

- Hemp: Naturally resistant to ignition

- Flax/Linen: Self-extinguishing properties when treated

- Certain plant-based fibers: Some specialty natural fibers resist flames

Wool as a Fire-Resistant Material: Wool is naturally fire-resistant because its protein fibers char when exposed to flame, forming a protective barrier. This makes wool an excellent choice for blankets, clothing, and furnishings where fire safety is important.

Synthetic Materials and Heat Resistance

What Type of Fabric Is Heat Resistant?

Different synthetic materials offer varying levels of heat resistance:

High Heat Resistance:

- Aramid fibers (Nomex, Kevlar): up to 800°F continuous use

- Carbon fiber: Extremely high temperature resistance

- Ceramic fibers: Highest temperature applications

Moderate Heat Resistance:

- Treated polyester: Improved with chemical treatments

- Modacrylic blends: Good balance of comfort and protection

- Specialty nylon: Enhanced formulations available

The Least Flammable Fabrics

What Are the Least Flammable Fabrics?

Ranking from most to least flammable:

- Most Fire-Resistant:

- Aramid fibers (Nomex, Kevlar)

- Modacrylic

- Treated wool

- Moderately Fire-Resistant:

- Treated cotton

- Flame-retardant polyester

- Specialty synthetic blends

- Naturally Flammable (Require Treatment):

- Regular cotton

- Standard polyester

- Rayon

- Acetate

Material Comparison Chart

| Material | Fire Resistance | Heat Resistance | Durability | Cost |

|---|---|---|---|---|

| Nomex | Excellent | Excellent | High | High |

| Kevlar | Excellent | Excellent | Very High | Very High |

| Modacrylic | Very Good | Good | Good | Medium |

| Treated Cotton | Good | Fair | Good | Low-Medium |

| Wool | Good | Fair | Good | Medium |

| Standard Cotton | Poor | Poor | Good | Low |

| Regular Polyester | Poor | Poor | Good | Low |

Need help understanding these technical terms? Our comprehensive Fire-Resistant Fabrics Glossary provides detailed definitions of materials, testing methods, and industry standards to help you make informed decisions.

Making Fabrics Fire-Resistant

Understanding how fabrics become fire-resistant helps in choosing the right materials and maintaining their protective properties.

How Do You Make Fabric Fire-Resistant?

There are several methods to impart fire resistance to fabrics:

Chemical Treatment Methods:

- Topical Application:

- Spray-on flame retardants

- Padding or dipping processes

- Surface coating technologies

- Chemical Integration:

- Adding flame retardants during fiber production

- Chemical bonding during weaving

- Polymer modification techniques

- Backcoating:

- Applying fire-resistant backing materials

- Multi-layer construction

- Lamination with protective films

Physical Methods:

- Fiber Blending:

- Mixing fire-resistant with regular fibers

- Creating hybrid yarns

- Optimizing blend ratios

- Fabric Construction:

- Special weaving patterns

- Density modifications

- Multi-layer designs

Treatment Effectiveness and Durability

Factors Affecting Treatment Life:

- Washing frequency and methods

- Chemical exposure

- UV light exposure

- Mechanical wear

- Heat exposure

Maintaining Fire-Resistant Properties:

- Use mild detergents

- Avoid bleach and fabric softeners

- Follow manufacturer care instructions

- Regular performance testing

- Professional retreatment when needed

DIY vs. Professional Treatment

Professional Treatment Advantages:

- Guaranteed performance standards

- Proper chemical application

- Testing and certification

- Warranty coverage

Limitations of DIY Methods:

- Uncertain effectiveness

- Potential safety risks

- Lack of testing capability

- Regulatory compliance issues

Regulations and Compliance

Fire-resistant fabrics must meet strict rules before they can be used in clothing and buildings. Understanding the legal and safety guidelines that affect how these fabrics are made, tested, and chosen for both people and structures is crucial for compliance.

Fire Safety Regulations

Fire safety rules focus on how fabrics react to heat and flames. In the United States, the National Fire Protection Association (NFPA) creates standards such as NFPA 2112. This standard lists the minimum tests that flame-resistant fabrics must pass for use in jobs where fire is a risk. These tests check if fabrics resist burning, melting, and dripping.

The Federal Flammable Fabrics Act (FFA) is another important law. It allows the Consumer Product Safety Commission (CPSC) to set and enforce flammability regulations for textile products. Fabrics must go through third-party testing and certification before they reach the market.

Are Children’s Clothes Flame Retardant?

Yes, children’s sleepwear in the United States must meet specific flame retardancy standards under CPSC regulations. However, most regular children’s clothing doesn’t require flame retardant treatment. Children’s clothing safety standards focus primarily on sleepwear due to fire risks during sleep.

Here’s a summary of the main fire safety requirements:

- No melting, dripping, or excessive after-flame

- Third-party testing for certification

- Meets NFPA or federal standards

- Proper labeling and documentation

- Regular compliance monitoring

The Occupational Safety and Health Administration (OSHA) mandates specific flame-resistant clothing requirements for electrical workers, particularly those exposed to arc flash hazards. These federal regulations establish the legal framework that drives demand for certified fire-resistant fabrics in workplace applications.

Failing to meet these rules can lead to recalls and safety risks for workers and consumers.

Building Regulations Impact

Building codes require certain fire-resistant fabrics in public spaces, such as schools, theaters, and hospitals. The focus is often on curtains, upholstery, and wall coverings, which must meet standards like NFPA 701. This code tests whether fabrics can self-extinguish or resist spreading flames if exposed to fire.

Local building codes can be stricter, especially in places with higher fire risk. Architects and builders must select certified textiles for areas that see a lot of people. Regular inspections ensure these materials stay compliant over time.

Always look for labels or certifications that prove a fabric meets code before using it inside public or commercial buildings. This helps reduce fire hazards and protects lives.

Common settings requiring fire-resistant fabrics:

- Theaters and entertainment venues

- Hospitals and healthcare facilities

- Schools and educational institutions

- Hotels and hospitality venues

- Public transportation

- Commercial office buildings

International Standards

European Standards:

- EN 11612: Protective clothing against heat and flame

- EN 14116: Limited flame spread materials

- EN 13501: Fire classification of construction products

ISO Standards:

- ISO 15025: Protective clothing – Protection against flame

- ISO 17493: Clothing and equipment for protection against heat

Regional Variations: Different countries may have specific requirements for fire-resistant fabrics, making international compliance complex for manufacturers and exporters.

Sustainability and Environmental Considerations

The fire-resistant fabrics industry is increasingly focusing on environmental responsibility while maintaining safety performance.

Eco-Friendly Fire Retardants

PFC-Free Alternatives: Traditional per- and polyfluoroalkyl substances (PFCs) are being replaced with safer alternatives that don’t persist in the environment.

Bio-Based Treatments:

- Plant-based flame retardants

- Naturally occurring compounds

- Biodegradable chemical treatments

- Reduced toxicity formulations

Sustainable Manufacturing

Closed-Loop Production:

- Recycling of process chemicals

- Water treatment and reuse

- Energy efficiency improvements

- Waste reduction initiatives

Recycled Content:

- Post-consumer recycled fibers

- Industrial waste utilization

- Circular economy principles

- End-of-life considerations

Environmental Impact Assessment

Life Cycle Analysis: Modern fire-resistant fabrics are evaluated for their total environmental impact from production through disposal.

Chemical Safety: Stricter regulations on chemical treatments ensure worker safety and environmental protection during manufacturing.

Future Trends:

- Carbon-neutral production goals

- Renewable energy in manufacturing

- Biodegradable fire-resistant materials

- Reduced water usage in processing

Care and Maintenance of Fire-Resistant Fabrics

Proper care is essential to maintain the protective properties of fire-resistant fabrics throughout their useful life.

Washing Guidelines

Can Fire-Resistant Properties Be Washed Out?

The answer depends on the type of fire-resistant fabric:

Inherently Fire-Resistant Fabrics:

- Properties don’t wash out

- Made from naturally resistant fibers

- Maintain protection throughout fabric life

- Examples: Nomex, Kevlar, modacrylic

Treated Fire-Resistant Fabrics:

- May lose effectiveness over time

- Proper care extends protection life

- Some treatments are more durable than others

- May require retreatment

Best Practices for Care

Washing Instructions:

- Use mild, flame-retardant-safe detergents

- Avoid bleach and fabric softeners

- Wash in cool to warm water

- Don’t overload washing machines

- Separate from other clothing

Drying Guidelines:

- Air dry when possible

- Use low heat settings if machine drying

- Avoid over-drying

- Don’t use dryer sheets or fabric softeners

Storage Recommendations:

- Store in clean, dry conditions

- Avoid exposure to chemicals

- Protect from UV light

- Maintain proper ventilation

Performance Monitoring

Regular Inspection:

- Check for wear and damage

- Look for changes in fabric appearance

- Test fabric behavior near small flames (professionally)

- Document maintenance history

When to Replace:

- Visible damage or excessive wear

- Failed performance testing

- End of manufacturer-recommended life

- After exposure to chemicals that may compromise protection

Future Trends and Innovations

Fire-resistant fabrics are advancing quickly due to breakthroughs in material science and growing demands for safer, more sustainable products. New technologies are improving both the protection and environmental impact of these textiles.

Advances in Materials Science

Nanotechnology is changing the way fabric resists fire. New fire-resistant fabrics made with nanoparticles, such as metal oxides or clay minerals, are built into the fabric structure. These nanoparticles act as a strong barrier that lowers flammability.

Some companies are using high-performance fibers that not only resist fire but also reduce static, lowering the chance of sparks. These fibers can be found in uniforms for firefighters, factory workers, and military personnel.

Key innovations in materials include:

| Innovation | Benefit |

|---|---|

| Nanoparticle Treatments | Improved fire resistance, durability |

| Conductive Fibers | Less static, reduced fire risk |

| Enhanced Surface Coatings | Faster self-extinguishing, easy cleaning |

| Smart Fiber Integration | Real-time monitoring capabilities |

| Phase Change Materials | Thermal regulation and comfort |

Artificial Intelligence and Manufacturing

AI-Driven Design:

- Predictive modeling for fabric performance

- Optimized fiber arrangements

- Quality control automation

- Predictive maintenance systems

Digital Manufacturing:

- 3D printing of protective structures

- Automated weaving systems

- Real-time performance monitoring

- Customized protection profiles

Smart Textiles Integration

Sensor Technology:

- Temperature monitoring

- Gas detection capabilities

- Structural integrity alerts

- Wearer health monitoring

Communication Systems:

- Emergency alert transmission

- Location tracking

- Voice communication integration

- Data logging capabilities

Sustainability and Environmental Impact

Concerns about the environment have changed how we look at fire-resistant textiles. New fabrics often use eco-friendly materials, like PFC-free water repellents, which avoid harmful chemicals. This shift is better for workers and reduces pollution.

Manufacturers are adopting processes that lower energy use and waste. Many now recycle fibers and use less water during production, which cuts down the environmental footprint.

Important sustainable trends:

- Use of biodegradable or recycled fibers

- Elimination of toxic finishes and additives

- Adoption of closed-loop production systems

- Carbon-neutral manufacturing goals

- Renewable energy integration

Bio-Based Innovations:

- Plant-derived flame retardants

- Mushroom-based protective materials

- Algae-sourced fibers

- Waste material upcycling

These efforts make fire-resistant fabrics safer for both people and the planet, with fewer long-term risks for health and the environment.

Decision-Making Guide: Choosing the Right Fire-Resistant Fabric

Selecting the appropriate fire-resistant fabric requires careful consideration of multiple factors to ensure optimal protection and performance.

Assessment Framework

Step 1: Identify Hazard Level

- Flash fire risk assessment

- Heat exposure duration

- Chemical exposure potential

- Arc flash considerations

Step 2: Regulatory Requirements

- Industry-specific standards (NFPA, OSHA)

- Building code requirements

- International compliance needs

- Insurance requirements

Step 3: Performance Criteria

- Required protection level

- Comfort and breathability needs

- Durability expectations

- Maintenance capabilities

Step 4: Cost Considerations

- Initial investment

- Lifecycle costs

- Replacement frequency

- Training requirements

Application-Specific Selection Guide

Industrial Workwear:

- Assess flash fire risk level

- Consider comfort for long wear periods

- Evaluate laundering requirements

- Check regulatory compliance

Building Materials:

- Review building code requirements

- Consider aesthetic requirements

- Evaluate maintenance needs

- Assess fire load contribution

Emergency Response:

- Maximum protection priority

- Multi-hazard considerations

- Equipment integration needs

- Communication requirements

Cost-Benefit Analysis

Total Cost of Ownership:

| Factor | Inherent FR | Treated FR |

|---|---|---|

| Initial Cost | Higher | Lower |

| Durability | Excellent | Good |

| Maintenance | Lower | Higher |

| Replacement Frequency | Lower | Higher |

| Performance Consistency | Excellent | Variable |

| Total Lifecycle Cost | Often Lower | Often Higher |

Interactive Tools & Resources

Make informed decisions about fire-resistant fabrics with our comprehensive suite of expert tools:

Fabric Selection Decision Tree

Find your perfect fire-resistant fabric with our interactive decision tree. Answer 4 simple questions about your application, risk level, budget, and usage duration to get personalized fabric recommendations with detailed specifications.

Best for: First-time buyers, safety managers, procurement specialists

Protection Level Calculator

Calculate your exact protection requirements by analyzing your working conditions, temperature exposure, and hazard types. Get specific safety standards, fabric recommendations, and compliance requirements.

Best for: Industrial safety managers, facility planners, compliance officers

Technical Glossary

Master fire-resistant fabric terminology with our searchable database of 25+ industry terms, testing standards, and technical definitions. Filter by category or search specific terms.

Best for: Students, new professionals, technical researchers

Industry Resource Directory

Connect with industry experts through our directory of standards organizations, testing facilities, material suppliers, and certification bodies. Includes contact information and specializations.

Best for: Business owners, procurement teams, quality assurance professionals

Frequently Asked Questions

Which Material Is Most Resistant to Fire?

Aramid fibers, particularly Nomex and Kevlar, are among the most fire-resistant materials available. These synthetic fibers can withstand continuous exposure to temperatures up to 800°F (427°C) without losing their protective properties. Carbon fiber and ceramic fibers offer even higher temperature resistance for specialized applications.

What Material Doesn’t Catch on Fire?

No material is completely fireproof, but several materials have extremely high fire resistance:

• Aramid fibers (Nomex, Kevlar)

• Carbon fiber

• Ceramic fibers

• Treated wool

• Modacrylic fibers

These materials either don’t ignite easily or self-extinguish quickly when the heat source is removed.

Is There a Non-Flammable Fabric?

While truly non-flammable fabrics don’t exist, some materials come very close:

• Meta-aramid fibers like Nomex are self-extinguishing

• Para-aramid fibers like Kevlar resist ignition

• Modacrylic blends char but don’t sustain flames

• Treated wool naturally self-extinguishes

What Is Flame Proof Fabric?

“Flame proof” is a marketing term, but technically refers to fabrics that resist ignition and self-extinguish. True flame-proof fabrics include:

• Inherently fire-resistant synthetic fibers

• Chemically treated natural fibers

• Specially engineered blends

• Multi-layer protective systems

Which Fibre Is Fire-Resistant?

Several fibers offer natural fire resistance:

• Aramid fibers (meta and para varieties)

• Modacrylic fibers

• Wool (protein-based natural resistance)

• Certain specialty synthetic fibers

• Treated cellulose fibers

What Material Is Heat and Fire Proof?

For applications requiring both heat and fire resistance:

• Nomex (continuous use to 800°F)

• Kevlar (high strength and heat resistance)

• Carbon fiber (extreme temperature applications)

• Ceramic fiber (highest temperature resistance)

• Multi-layer systems combining different materials

What Is the Difference Between Fire Retardant and Fire-Resistant?

Fire-Resistant:

• Made from inherently protective fibers

• Properties built into the material structure

• Protection doesn’t wash out

• Generally more expensive

• Longer-lasting protection

Fire Retardant:

• Regular fibers treated with chemicals

• Protection from applied treatments

• May lose effectiveness over time

• Usually more affordable

• Requires proper maintenance

Can You Make Fabric Fire-Resistant?

Yes, regular fabrics can be made fire-resistant through several methods:

Chemical Treatments:

• Topical flame retardant application

• Chemical padding processes

• Polymer modification

• Backcoating with protective materials

Physical Methods:

• Blending with fire-resistant fibers

• Multi-layer construction

• Special weaving techniques

• Protective lamination

How Long Do Fire-Resistant Properties Last?

The duration depends on the type of fabric:

Inherently Fire-Resistant Fabrics:

• Last for the life of the garment

• Properties don’t diminish with use

• Maintain protection through hundreds of wash cycles

Treated Fabrics:

• 25-50 wash cycles for basic treatments

• 100+ cycles for advanced treatments

• Professional retreatment may be possible

• Performance testing recommended regularly

Are Fire-Resistant Fabrics Safe for Everyday Wear?

Yes, modern fire-resistant fabrics are safe for regular use:

• Non-toxic when properly manufactured

• Comfortable for extended wear

• Breathable and moisture-wicking options available

• No skin irritation with quality products

• Meet strict safety standards for human contact

Conclusion

Fire-resistant fabrics represent a critical component of modern safety infrastructure, protecting millions of workers and civilians worldwide. As we’ve explored throughout this comprehensive guide, these specialized materials have evolved from basic protective textiles to sophisticated, multi-functional systems that combine safety, comfort, and environmental responsibility.

Key Takeaways

- Technology Evolution: The integration of nanotechnology, phase change materials, and smart textile capabilities is revolutionizing fire protection. Modern fire-resistant fabrics can now monitor environmental conditions, regulate temperature, and provide real-time safety feedback while maintaining their core protective functions.

- Market Growth and Innovation: With the global market projected to reach $6.74 billion by 2029, investment in research and development continues to drive breakthrough innovations. The Asia Pacific region’s dominance reflects both manufacturing capabilities and growing safety awareness in developing economies.

- Regulatory Landscape: Stringent safety standards across industries ensure that fire-resistant fabrics meet rigorous performance criteria. Understanding these requirements is essential for proper selection and compliance, whether for industrial applications or building materials.

- Material Diversity: The distinction between inherently fire-resistant and treated fabrics affects everything from initial cost to long-term performance. Inherently resistant materials like Nomex and Kevlar offer superior durability, while treated options provide cost-effective solutions for many applications.

Recommendations for Different Users

For Industrial Safety Managers:

- Prioritize inherently fire-resistant fabrics for high-risk environments

- Calculate your facility’s protection requirements with our hazard assessment tool

- Implement regular performance testing and maintenance programs

- Stay updated on evolving safety standards and regulations

- Consider total cost of ownership rather than just initial purchase price

For Building Professionals:

- Ensure all specified materials meet local building codes

- Find certified testing facilities in our comprehensive resource directory

- Consider fire-resistant fabrics as part of comprehensive fire safety strategies

- Evaluate both performance and aesthetic requirements

- Plan for regular inspection and maintenance schedules

For Consumers:

- Use our decision tree to find the right fabric for your specific application

- Follow manufacturer care instructions to maintain protective properties

- Consider fire-resistant options for high-risk environments like workshops or kitchens

- Look for certified products from reputable manufacturers

Future Outlook

The fire-resistant fabrics industry stands at the intersection of safety, technology, and sustainability. Emerging trends point toward:

- Smart Integration: Future fabrics will likely incorporate more sophisticated monitoring and communication capabilities, creating protective clothing that actively participates in safety management systems.

- Sustainability Focus: Environmental considerations are driving innovation in bio-based treatments, recycled materials, and closed-loop manufacturing processes. The industry is moving toward solutions that protect both people and the planet.

- Customization and Personalization: Advanced manufacturing techniques will enable more tailored protection solutions, optimizing performance for specific hazards and individual requirements.

- Global Standardization: As international trade increases, harmonization of safety standards will simplify compliance while maintaining high protection levels worldwide.

Final Recommendations

Fire safety should never be compromised by cost considerations alone. The investment in quality fire-resistant fabrics pays dividends in worker safety, regulatory compliance, and potential liability reduction. Whether choosing materials for industrial applications, building construction, or personal protection, prioritize proven performance, proper certification, and appropriate maintenance.

The rapid evolution of fire-resistant fabric technology means that staying informed about new developments is crucial. Regular consultation with safety professionals, material suppliers, and regulatory bodies ensures that protection strategies remain current and effective.

As we look toward the future, fire-resistant fabrics will continue to evolve, offering ever-better protection while addressing environmental concerns and comfort requirements. The key to success lies in understanding these materials’ capabilities and limitations, selecting appropriate solutions for specific applications, and maintaining them properly to ensure continued protection.

The science of fire resistance is complex, but the goal is simple: protecting human life and property from the devastating effects of fire. Through continued innovation, rigorous testing, and proper application of these remarkable materials, we can create safer environments for everyone.

The science of fire resistance is complex, but the goal is simple: protecting human life and property from the devastating effects of fire. Through continued innovation, rigorous testing, and proper application of these remarkable materials, we can create safer environments for everyone.

Ready to find the right fire-resistant fabric solution? Start with our interactive decision tree or calculate your protection requirements using our expert tools. For technical questions, consult our comprehensive glossary or connect with industry professionals through our resource directory.