Understanding Woven and Knit Construction, History, and Applications

Table of Contents

What is Bird’s Eye Fabric?

Bird’s eye fabric refers to textiles featuring a distinctive geometric pattern that resembles a bird’s eye. The pattern consists of small diamond shapes with a dot in the center of each diamond. This creates a subtle texture that adds visual interest while remaining understated enough for both formal and casual applications.

The term “bird’s eye” describes the pattern structure rather than a specific material. These fabrics can be made from cotton, linen, or blends of natural and synthetic fibers. The pattern appears in both woven and knit constructions, which creates confusion in the textile industry since these are fundamentally different fabric types.

Why is it called bird’s eye? The name comes from the pattern’s visual similarity to the eye of a bird. Each small diamond shape contains a raised dot at its center, which resembles the pupil of an eye. When light hits the fabric’s surface, these dots create subtle shadows that reinforce the eye-like appearance.

What is Bird’s Eye Linen Fabric?

Bird’s eye linen fabric specifically refers to linen fibers woven in the bird’s eye pattern using a dobby loom. True linen bird’s eye maintains the natural properties of flax fibers while adding the textured pattern. This combination produces a fabric that is both temperature-regulating and absorbent, making it particularly suitable for warm-weather applications.

Linen bird’s eye differs from cotton bird’s eye in several ways. Linen versions typically feel crisper, wrinkle more readily, and cost more due to the flax fiber’s higher production costs. The pattern appears slightly more pronounced in linen due to the fiber’s natural stiffness.

Woven vs. Knit: Understanding the Difference

Critical Information: “Bird’s eye” can describe two completely different fabric construction methods. Understanding this difference helps avoid confusion when shopping for or working with these textiles.

Woven Bird’s Eye

Woven bird’s eye fabric is created on a dobby loom, which raises and lowers specific warp threads to create the diamond pattern. This construction method produces a stable fabric with minimal stretch. The pattern is permanently locked into the fabric structure during the weaving process.

Characteristics of woven bird’s eye:

- Made on dobby looms

- Little to no stretch unless combined with elastane

- Pattern visible on both sides (though may differ slightly)

- Common in formal wear, table linens, and toweling

- Typically uses cotton or linen fibers

- Historical use dating back to the 18th century

Knit Bird’s Eye (Honeycomb Fabric)

Knit bird’s eye, often called honeycomb fabric, is created on circular knitting machines using a special tuck stitch pattern. This produces a stretchy fabric with raised dots or circles on the surface. The construction allows for better moisture-wicking properties than woven versions.

Characteristics of knit bird’s eye:

- Made on circular knitting machines

- Natural stretch in all directions

- Raised texture more pronounced than woven versions

- Common in sportswear, polo shirts, and activewear

- Typically uses polyester or polyester-cotton blends

- Better moisture management than woven construction

What is the Difference Between Bird’s Eye and Mesh?

Mesh fabrics feature larger, more open holes designed for maximum breathability. Bird’s eye knit fabrics have smaller, more subtle openings created by the pattern structure. Mesh uses synthetic fibers like polyester, nylon, or polypropylene for strength and durability, while bird’s eye can use natural fibers like cotton.

The key differences:

| Feature | Bird’s Eye | Mesh |

|---|---|---|

| Hole Size | Small, subtle openings | Larger, more visible holes |

| Primary Use | Clothing, home textiles | Sports equipment, outdoor gear |

| Comfort | Soft, comfortable against skin | Functional but may feel rough |

| Fiber Options | Cotton, polyester, linen | Primarily synthetic fibers |

| Durability | Good resistance to snagging | Variable, may snag easily |

History and Development

What is the History of Birdseye Fabric?

Bird’s eye patterns emerged in European textile mills during the 18th century, with the Lancashire fabric industry in Northern England playing a significant role in its development. Early manufacturers discovered that the dobby weave pattern created a fabric with better absorbency than plain weaves, making it useful for practical applications.

The fabric initially served functional purposes rather than decorative ones. Manufacturers used it primarily for diaper cloth and toweling because the raised pattern increased surface area for moisture absorption. The small diamond pattern helped the fabric dry faster than smooth cotton cloth while maintaining softness against the skin.

Dobby looms, which made bird’s eye production more efficient, first appeared around 1843. These looms automated the process of raising and lowering specific warp threads, which previously required manual labor. The name “dobby” comes from “draw boy,” referring to the weaver’s assistants who once controlled these threads by hand.

During the early 20th century, bird’s eye fabric gained popularity in men’s fashion, particularly for summer suiting. The pattern’s subtle texture added visual interest without being too bold, while the fabric’s breathability made it comfortable in warm weather. Fashion houses recognized that the pattern worked well with both light and dark colors, making it suitable for formal business wear.

Modern production methods have expanded the range of bird’s eye fabrics available. Computer-controlled dobby looms can now create patterns with greater precision and variety than historical looms. The development of circular knitting technology in the mid-20th century introduced knit versions of the bird’s eye pattern, though these serve different markets than woven versions.

Technical Specifications

At a Glance: Bird’s Eye Specifications

- Pattern Size: Typically 3-8mm diamond shapes

- Thread Count (Woven): 80-120 threads per inch

- Weight (GSM): 150-250 grams per square meter

- Absorbency (Cotton): Up to 25% of fabric weight

- Absorbency (Linen): Up to 20% of fabric weight

- Shrinkage (Cotton): 3-5% after first wash

- Shrinkage (Linen): 4-6% after first wash

- Typical Width: 44-60 inches (110-150 cm)

Dobby Loom Capabilities

Traditional dobby looms with 8 shafts can create 254 different shed combinations (thread raising/lowering patterns). More advanced looms with 16 shafts can produce 65,534 possible combinations. This flexibility allows manufacturers to create variations in the bird’s eye pattern, adjusting the size and prominence of the diamonds.

The pattern repeat in bird’s eye fabric typically occurs every 4-8 picks (passes of the weft thread). This small repeat size makes the pattern appear continuous rather than showing obvious repetition. Manufacturers can adjust the pattern scale by changing the thread spacing and the dobby loom programming.

What is the Composition of Bird’s Eye Fabric?

Bird’s eye fabric composition varies based on intended use:

- 100% Cotton: Most common for baby products, toweling, and summer clothing. Provides maximum absorbency and breathability.

- 100% Linen: Used for high-end table linens, curtains, and summer suiting. Offers superior durability and temperature regulation.

- Cotton-Linen Blends: Typically 55% linen/45% cotton. Balances linen’s durability with cotton’s softness and lower cost.

- Cotton-Polyester Blends: Common in knit versions for sportswear. Usually 65% polyester/35% cotton for moisture-wicking while maintaining some natural fiber comfort.

- 100% Polyester: Found in knit bird’s eye for athletic wear. Provides maximum moisture management and quick drying.

The fiber choice affects the fabric’s properties more than the pattern itself. Cotton versions feel soft and become softer with washing. Linen versions feel crisp and maintain their structure better. Polyester versions resist wrinkles but may retain odors more than natural fibers.

Physical Properties by Fiber Type

| Property | Cotton Bird’s Eye | Linen Bird’s Eye | Polyester Bird’s Eye |

|---|---|---|---|

| Tensile Strength | Good | Excellent (2x cotton) | Very Good |

| Absorbency | High (25% weight) | High (20% weight) | Low (0.4% weight) |

| Drying Time | Moderate | Slow | Fast |

| Wrinkle Resistance | Low | Very Low | Excellent |

| Durability | Good (weakens when wet) | Excellent (strengthens when wet) | Very Good |

| Cost per Yard | $8-15 | $15-30 | $5-10 |

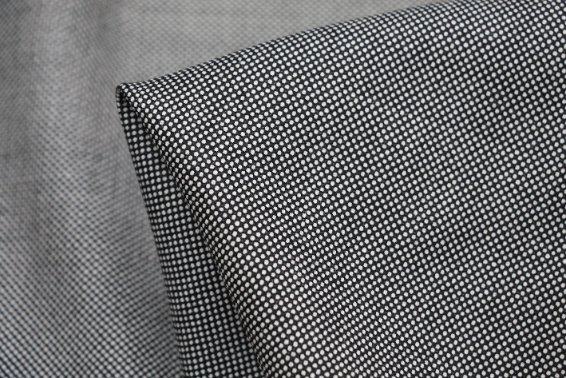

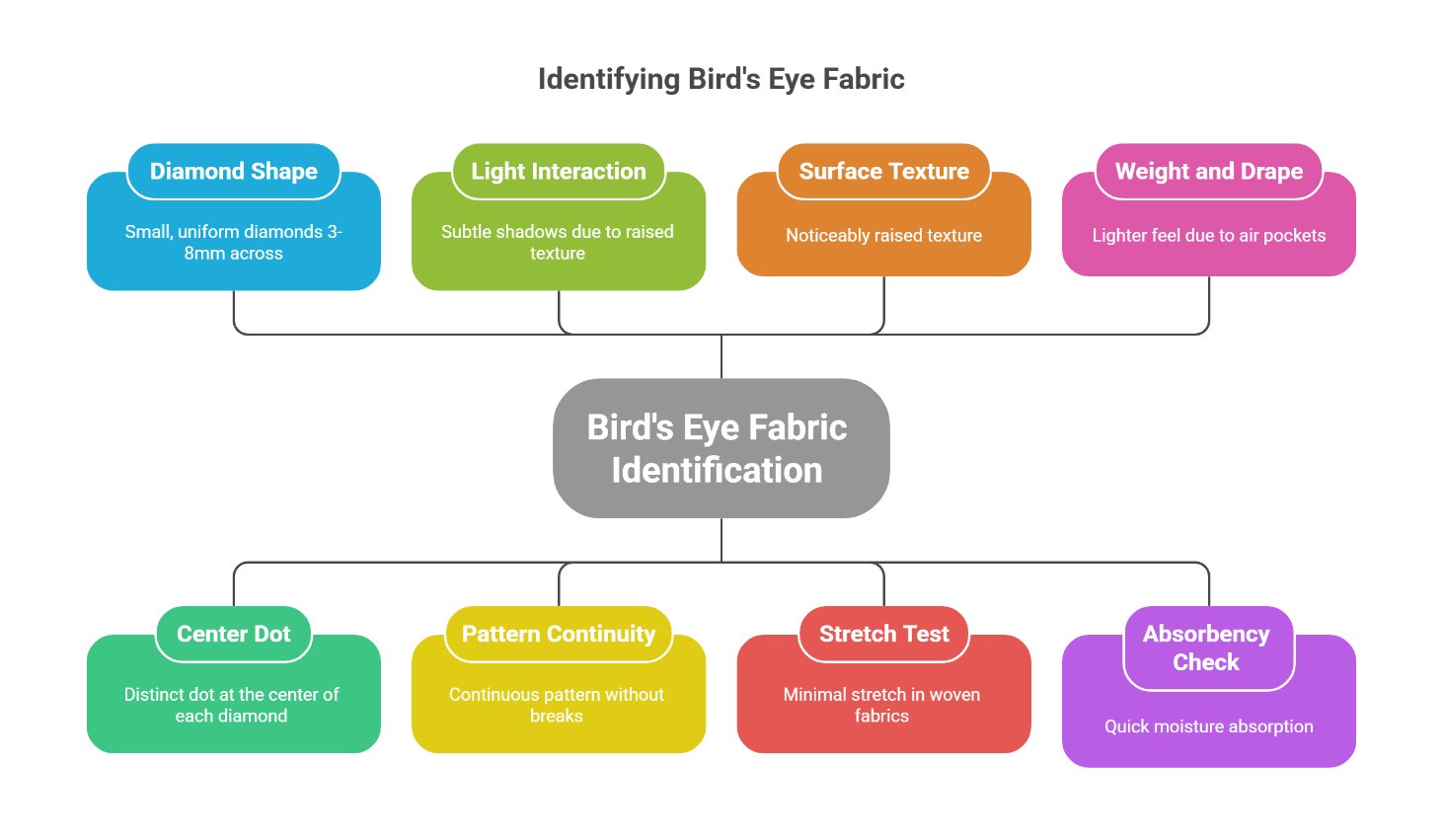

How to Identify Bird’s Eye Fabric

Identifying bird’s eye fabric requires examining both visual pattern and construction method. Many textiles feature small geometric patterns, but true bird’s eye has specific characteristics that distinguish it from similar fabrics.

Visual Identification

Look for these features:

- Diamond Shape: The pattern forms small diamonds, typically 3-8mm across. These diamonds should be uniform in size and evenly spaced.

- Center Dot: Each diamond contains a distinct dot or raised area at its center. This dot should be clearly visible when viewing the fabric at an angle.

- Light Interaction: The raised texture creates subtle shadows that change as the fabric moves or as lighting shifts. This effect distinguishes bird’s eye from printed patterns.

- Pattern Continuity: The pattern should appear continuous without obvious repeats or pattern breaks, indicating a small repeat cycle.

Touch Test

Physical examination reveals construction details:

- Surface Texture: Run your fingers across the fabric. Bird’s eye has a noticeably raised texture compared to plain weaves. The diamonds should feel slightly elevated.

- Stretch Test: Pull the fabric gently in different directions. Woven bird’s eye has minimal stretch, while knit versions stretch significantly. This test immediately reveals the construction method.

- Weight and Drape: Bird’s eye typically feels lighter than its thread count might suggest. The raised pattern creates air pockets that reduce density.

- Absorbency Check: Place a small water droplet on the fabric. True bird’s eye absorbs moisture quickly due to increased surface area from the pattern.

Comparing to Similar Fabrics

| Fabric Type | Pattern | Texture | Common Uses |

|---|---|---|---|

| Bird’s Eye | Diamond with center dot | Subtle raised texture | Suiting, towels, linens |

| Honeycomb | Hexagonal cells | Deep texture, waffle-like | Towels, blankets |

| Waffle Weave | Square grid | Pronounced squares | Kitchen towels, robes |

| Satin Weave | Smooth, lustrous | No raised pattern | Formal wear, bedding |

| Piqué | Various geometric patterns | Raised cords or patterns | Polo shirts, sportswear |

Manufacturing Process

Woven Bird’s Eye Production

Creating woven bird’s eye fabric requires a dobby loom, which controls individual warp threads to form the pattern. The process begins with preparing the warp, where threads are arranged on the loom beam according to the desired pattern density.

The dobby attachment, either mechanical or electronic, receives instructions through punched cards (historical method) or computer programs (modern method). Modern dobby looms typically have 24-48 levers that manage thread groups, allowing for pattern creation without manual intervention.

During weaving, the dobby mechanism raises specific warp threads while lowering others, creating a “shed” through which the weft thread passes. The pattern emerges as this process repeats with different thread combinations. The bird’s eye pattern requires a specific sequence where some threads rise to create the diamond outline while others create the center dot.

Modern production can weave bird’s eye fabric at speeds of 200-400 picks per minute, though exact speed depends on fabric weight and fiber type. Linen requires slower speeds than cotton due to the fiber’s lower flexibility.

Knit Bird’s Eye Production

Knit versions use circular knitting machines with needle beds arranged in a circle. The bird’s eye effect comes from a tuck stitch technique, where some needles hold stitches while others create new loops. This manipulation creates the raised dots characteristic of the pattern.

The knitting process offers faster production than weaving, with some machines producing several meters per minute. The stretchy nature of knit fabric makes it suitable for form-fitting garments, while woven versions work better for structured items.

Who Makes Birdseye Fabric?

Major textile manufacturers worldwide produce bird’s eye fabric:

- European Mills: Traditional producers in Italy, Switzerland, and England focus on high-quality woven versions for luxury markets. These mills often use locally-sourced linen and premium cotton.

- Asian Manufacturers: China, India, and Pakistan produce the majority of global bird’s eye fabric, offering both woven and knit versions across all price points.

- North American Producers: Smaller specialty mills in the United States and Canada manufacture organic and certified versions for premium markets.

- Technical Textile Companies: Manufacturers like Itema (Italy), Stäubli (Switzerland), and LMW (India) produce the dobby looms used to create bird’s eye fabric.

Fabric Comparisons

Bird’s Eye vs. Other Dobby Weaves

| Feature | Bird’s Eye | Huck/Huckaback | Waffle | Damask |

|---|---|---|---|---|

| Pattern Type | Diamond + dot | Looped texture | Square grid | Elaborate figures |

| Absorbency | High | Very High | High | Low-Medium |

| Texture Depth | Subtle | Moderate loops | Deep squares | Minimal |

| Best Use | Multi-purpose | Toweling | Bath textiles | Formal table linens |

| Wrinkle Tendency | Moderate | High | High | Low |

Applications and Uses

Apparel

Bird’s eye fabric appears in various clothing applications, with construction type determining suitability:

Woven Bird’s Eye:

- Summer weight suits and blazers (particularly cotton or linen)

- Dress shirts and formal wear

- Pocket squares and accessories

- Light jackets and unstructured outerwear

Knit Bird’s Eye:

- Polo shirts and casual tops

- Athletic wear and performance clothing

- T-shirts with textured interest

- Underwear and base layers

Home Textiles

The pattern’s absorbency and durability make it popular for household items:

- Kitchen Textiles: Dish towels, tea towels, and cloth napkins benefit from the pattern’s moisture absorption. The texture helps with drying and cleaning tasks.

- Bath Towels: Guest towels and decorative bathroom textiles use bird’s eye for its refined appearance and quick-drying properties.

- Table Linens: Tablecloths, placemats, and runners in linen bird’s eye offer both function and visual interest.

- Window Treatments: The pattern adds texture to curtains and Roman shades without overwhelming room decor.

- Bedding: Lightweight blankets and coverlets use bird’s eye for breathability in warm climates.

Baby Products

Cotton bird’s eye has a long history in infant care products due to its softness and absorbency:

- Cloth diapers and diaper inserts

- Burp cloths and bibs

- Baby blankets and swaddles

- Changing pad covers

- Washcloths for sensitive skin

The fabric’s hypoallergenic properties when made from organic cotton make it safe for newborn skin. The pattern’s natural texture provides gentle surface friction without being abrasive.

What is Special About Bird’s Eyes?

Several factors make bird’s eye fabric stand out:

- Dual Functionality: The pattern provides both visual appeal and functional benefits. The raised texture increases surface area for better absorbency while creating subtle visual interest.

- Timeless Appeal: Unlike trend-driven patterns, bird’s eye remains appropriate across decades. The pattern works in both traditional and modern settings without appearing dated.

- Versatility Across Scales: The same basic pattern works in fine baby clothes and heavy upholstery fabrics. Manufacturers can adjust the scale and prominence to suit different applications.

- Temperature Regulation: The raised pattern creates micro air pockets that improve breathability. This makes the fabric comfortable in varying temperatures.

- Durability: The dobby weave structure reinforces the fabric compared to plain weaves. The interlacing pattern distributes stress more evenly, extending fabric life.

Care and Maintenance

Proper care extends the life of bird’s eye fabrics while maintaining their appearance and texture. Care requirements vary primarily by fiber content rather than pattern type.

Cotton Bird’s Eye Care

Washing:

- Machine wash in warm water (40°C/104°F) for regular cleaning

- Use hot water (60°C/140°F) for towels and items requiring sanitization

- Choose mild detergent without optical brighteners for white items

- Avoid fabric softener, which reduces absorbency over time

- Wash similar colors together to prevent dye transfer

Drying:

- Tumble dry on medium heat or line dry for longer fabric life

- Remove promptly from dryer to minimize wrinkles

- Avoid over-drying, which can damage fibers and increase stiffness

- Expect 3-5% shrinkage after first wash, even with pre-shrunk fabric

Ironing:

- Iron while slightly damp on cotton setting (200°C/392°F)

- Use steam to help remove stubborn wrinkles

- Iron on reverse side to preserve pattern texture

Linen Bird’s Eye Care

Washing:

- Machine wash in cool to warm water (30-40°C/86-104°F)

- Use gentle cycle to minimize fiber stress

- Select pH-neutral detergent designed for natural fibers

- Wash linen items separately from cotton to prevent lint transfer

- Expect 4-6% shrinkage after first wash

Drying:

- Line dry preferred to maintain fiber strength

- If using dryer, select low heat and remove while slightly damp

- Shake items before hanging to reduce wrinkles

- Linen takes longer to dry than cotton due to fiber density

Ironing:

- Iron while damp on linen setting (230°C/446°F)

- Use plenty of steam or spray bottle for stubborn creases

- Press firmly, as linen requires more pressure than cotton

- Note that some wrinkling is characteristic of linen and adds to its appeal

Polyester Bird’s Eye Care

Washing:

- Machine wash in cold to warm water (30°C/86°F maximum)

- Use regular cycle unless garment label specifies otherwise

- Add white vinegar (1/4 cup) occasionally to reduce odor retention

- Avoid chlorine bleach, which can yellow synthetic fibers

Drying:

- Tumble dry on low heat or permanent press setting

- Remove immediately after cycle ends to prevent wrinkles

- Minimal to no shrinkage expected

- Air drying acceptable but takes longer than natural fibers

Ironing:

- Low heat setting (110°C/230°F) if ironing necessary

- Most items don’t require ironing due to wrinkle resistance

- Never iron polyester on high heat, which can melt fibers

Storage Recommendations

Proper storage prevents damage between uses:

- Folding vs. Hanging: Fold heavier items like towels and table linens. Hang garments on padded hangers to maintain shape.

- Environment: Store in cool, dry areas away from direct sunlight, which can fade colors and weaken fibers.

- Moth Protection: For natural fiber items, use cedar blocks or lavender sachets rather than chemical mothballs.

- Rotation: Rotate items in regular use to distribute wear evenly across your collection.

Working With Bird’s Eye Fabric for Sewing

Bird’s eye fabric is generally sewing-friendly, particularly for beginners. The pattern helps hide minor stitching irregularities while the fabric body provides enough structure to handle easily.

Cutting Tips:

- Pre-wash and dry fabric before cutting to account for shrinkage

- Cut on-grain to maintain pattern alignment

- Use sharp scissors or a rotary cutter for clean edges

- Pattern matching is not necessary due to the small repeat

Sewing Recommendations:

- Use a slightly longer stitch length (2.5-3.0mm) for textured weaves

- Test seam techniques on scraps first, as the texture may affect seam appearance

- French seams work well for kitchen and baby items

- Top-stitching shows nicely against the textured background

- Press seams open for flatter results on heavier weights

Beginner-Friendly Projects:

- Kitchen towels and tea towels (simple hemming practice)

- Cloth napkins and placemats (square construction)

- Baby burp cloths and washcloths (small, quick projects)

- Simple tote bags (practice with seams and handles)

- Pillowcase covers (envelope or zippered styles)

Sourcing and Pricing

How Much Does Birdseye Cost?

Bird’s eye fabric pricing varies significantly based on fiber content, quality, and production location:

| Fabric Type | Price Range (per yard) | Quality Indicators |

|---|---|---|

| Cotton Bird’s Eye (Standard) | $8-12 | 45″ width, 150-180 GSM, basic quality |

| Organic Cotton Bird’s Eye | $12-18 | GOTS certified, 180-220 GSM |

| Linen Bird’s Eye | $15-25 | European flax, 200-250 GSM |

| Premium Linen Bird’s Eye | $25-35 | Belgian/French linen, fine thread count |

| Polyester Bird’s Eye (Knit) | $5-8 | Athletic wear quality, moisture-wicking |

| Cotton-Linen Blend | $10-16 | 55/45 blend, balanced properties |

Wholesale prices typically run 40-60% of retail pricing for orders of 50+ yards. Custom-dyed or custom-woven bird’s eye carries premium pricing, often 50-100% above standard options.

Quality Indicators When Buying

Assess fabric quality before purchase using these criteria:

- Pattern Consistency: Check that the diamond pattern maintains uniform size and spacing across the entire fabric width. Irregularities indicate poor loom tension or quality control issues.

- Thread Count: Higher thread counts (100+ TPI) generally indicate better quality in woven versions. The fabric should feel substantial without being heavy.

- Hand Feel: Quality bird’s eye feels soft but substantial. Avoid fabrics that feel papery or excessively stiff from chemical finishes.

- Color Depth: Well-dyed fabric shows consistent color across the entire piece. Check the reverse side for color penetration.

- Edge Quality: Selvage edges should be finished cleanly without loose threads or unraveling.

Certification Standards

Look for these certifications when choosing bird’s eye fabric:

- OEKO-TEX Standard 100: Tests for harmful substances in textiles. Particularly important for baby products and items contacting skin.

- GOTS (Global Organic Textile Standard): Certifies organic status and ethical production practices for cotton and linen.

- Masters of Linen: Guarantees European flax and maintains quality standards throughout processing.

- Bluesign: Certifies safe manufacturing processes and reduced environmental impact.

Where to Purchase

Bird’s eye fabric is available through several channels:

- Online Fabric Retailers: Sites like Fabric.com, Fashion Fabrics Club, and Mood Fabrics carry selections suitable for home sewers. These typically offer swatches before committing to yardage.

- Local Fabric Stores: Independent fabric shops often stock bird’s eye for quilting and home decor projects. Staff can provide in-person guidance on fiber selection.

- Wholesale Suppliers: Businesses requiring larger quantities can work directly with mills or through textile wholesalers for better pricing.

- Specialty Linen Shops: Retailers focusing on linen products usually carry high-quality bird’s eye options in both fabric yardage and finished goods.

Frequently Asked Questions

Yes, bird’s eye fabric works well for beginners, especially woven cotton versions. The fabric has enough body to handle easily while feeding through sewing machines smoothly. The pattern hides small stitching imperfections better than plain fabrics. Start with simple projects like towels, napkins, or baby blankets to build confidence before attempting garments.

No, the bird’s eye pattern is structural rather than printed, so it cannot wear off. The pattern is created during the weaving or knitting process and remains as long as the fabric itself lasts. Color may fade with repeated washing and sun exposure, but the physical pattern stays intact. In fact, the texture often becomes more pronounced and softer after multiple washes.

Natural fiber bird’s eye (cotton or linen) can be dyed at home using fiber-reactive or natural dyes. The raised pattern creates interesting dye variations, with the recessed areas potentially taking dye differently than raised areas. Polyester versions require disperse dyes and higher temperatures, making home dyeing more challenging. Always pre-wash fabric to remove any sizing before dyeing, and follow dye manufacturer instructions for best results.

Bird’s eye offers thinner, faster-drying towels compared to terry cloth. Terry cloth absorbs more water per use due to its looped pile construction, but takes longer to dry and occupies more storage space. Bird’s eye works better for tea towels and guest hand towels where quick drying and refined appearance matter more than maximum absorbency. Many people keep both types, using terry for bath towels and bird’s eye for kitchen and decorative purposes.

Yes, natural fiber bird’s eye shrinks on first washing. Cotton versions shrink 3-5%, while linen shrinks 4-6%. Purchase extra yardage to account for shrinkage if exact dimensions matter. Pre-washing fabric before cutting and sewing prevents size changes in finished items. Polyester bird’s eye experiences minimal to no shrinkage. Some manufacturers offer pre-shrunk versions, though these still may shrink slightly during initial washing.

Absolutely. Bird’s eye fabric, particularly cotton and linen versions, excels in hot weather. The raised pattern creates air pockets that improve breathability. The fabric feels lighter on skin than plain weaves of similar weight. Historically, bird’s eye gained popularity for summer suiting precisely because it kept wearers cooler than smooth fabrics. Choose lighter weight versions (150-180 GSM) for maximum comfort in heat.

While you can iron the patterned side, ironing the reverse side better preserves the raised texture. Direct pressure on the pattern can flatten the raised areas over time, reducing the fabric’s visual and tactile interest. If you must iron the patterned side, use a press cloth between the iron and fabric. Light steaming works better than direct pressure for removing wrinkles while maintaining texture.

Use a universal needle in size 80/12 for lightweight bird’s eye (150-180 GSM) or size 90/14 for heavier weights (200-250 GSM). Cotton and linen bird’s eye work with standard sharp or universal needles. For polyester knit versions, use a ballpoint or stretch needle to prevent skipped stitches. Match thread weight to fabric weight, using all-purpose thread for most projects and heavier thread only for very heavyweight fabrics.

Conclusion

Understanding Bird’s Eye Fabric

Bird’s eye fabric represents a successful marriage of function and design in textile manufacturing. The distinctive diamond-with-dot pattern creates a texture that improves absorbency and breathability while adding visual interest without overwhelming other design elements. Whether woven on traditional dobby looms or knit on modern circular machines, this pattern has proven its worth across centuries of use.

The most important distinction to remember is the difference between woven and knit bird’s eye fabrics. Woven versions serve traditional applications like formal wear, table linens, and toweling. Knit versions excel in athletic wear and casual clothing where stretch and moisture management take priority. Understanding this difference prevents purchasing mistakes and ensures the fabric performs as expected for its intended use.

Quality in bird’s eye fabric depends primarily on fiber choice and manufacturing precision rather than the pattern itself. Cotton provides softness and absorbency for baby products and kitchen textiles. Linen offers durability and temperature regulation for high-end table linens and summer suiting. Polyester delivers moisture-wicking properties for athletic applications. Each fiber type brings different characteristics while maintaining the pattern’s basic structure and benefits.

The pattern’s longevity in textile production testifies to its practical advantages. Unlike trendy patterns that fall out of fashion, bird’s eye remains appropriate across decades and design styles. The subtle texture works equally well in modern minimalist settings and traditional formal contexts. This flexibility makes it a sound choice for items meant to last years rather than seasons.

Care requirements follow fiber content more than pattern type. Natural fibers need attention to prevent shrinkage and maintain softness. Synthetic versions resist wrinkles but may retain odors. Following proper care guidelines extends fabric life significantly, with well-maintained bird’s eye items lasting decades in regular use.

Key Takeaways

When Choosing Bird’s Eye Fabric:

- Identify whether you need woven (stable, formal) or knit (stretchy, casual) construction

- Match fiber content to use: cotton for absorbency, linen for durability, polyester for athletic performance

- Check for certifications (OEKO-TEX, GOTS) when buying for baby products or sensitive skin

- Expect natural fiber versions to shrink 3-6% on first washing

- Look for consistent pattern spacing and clean selvage edges as quality indicators

For Best Results:

- Pre-wash fabric before cutting and sewing to account for shrinkage

- Avoid fabric softener on items where absorbency matters

- Iron on the reverse side to preserve pattern texture

- Store in cool, dry locations away from direct sunlight

- Rotate items in regular use to distribute wear evenly

Remember:

- The pattern is structural, not printed, so it won’t wear off

- Bird’s eye works well for beginners due to its forgiving nature

- The fabric performs better after several washes as fibers soften

- Higher thread counts generally indicate better quality in woven versions

- Price varies significantly based on fiber type and quality certifications

Whether you’re selecting fabric for home sewing projects, choosing linens for your household, or evaluating garment quality, understanding bird’s eye fabric’s characteristics helps make informed decisions. The pattern’s combination of practical benefits and timeless appearance continues to make it a reliable choice across diverse applications, from baby blankets to business suits. As with any textile, matching the fabric type to its intended use and following proper care guidelines ensures you get maximum value and satisfaction from bird’s eye fabric products.

References

- Britannica. “Dobby weave.” Encyclopedia Britannica.

- Wikipedia. “Dobby loom.” Wikipedia, February 2025.

- The Fabric of Our Lives. “Bird’s Eye Fabric | Types of Cotton Fabrics.” Cotton Incorporated, May 2022.