Everything you need to know about sheep wool fabrics, from worsted suits to woolen tweeds

Table of Contents

- Introduction to Sheep Wool Fabric

- Why Sheep Wool Dominates the Textile Industry

- Understanding Sheep Wool Terminology

- The Two Fabric Worlds: Worsted vs Woolen

- Major Sheep Wool Fabric Types

- From Fleece to Fabric: The Manufacturing Process

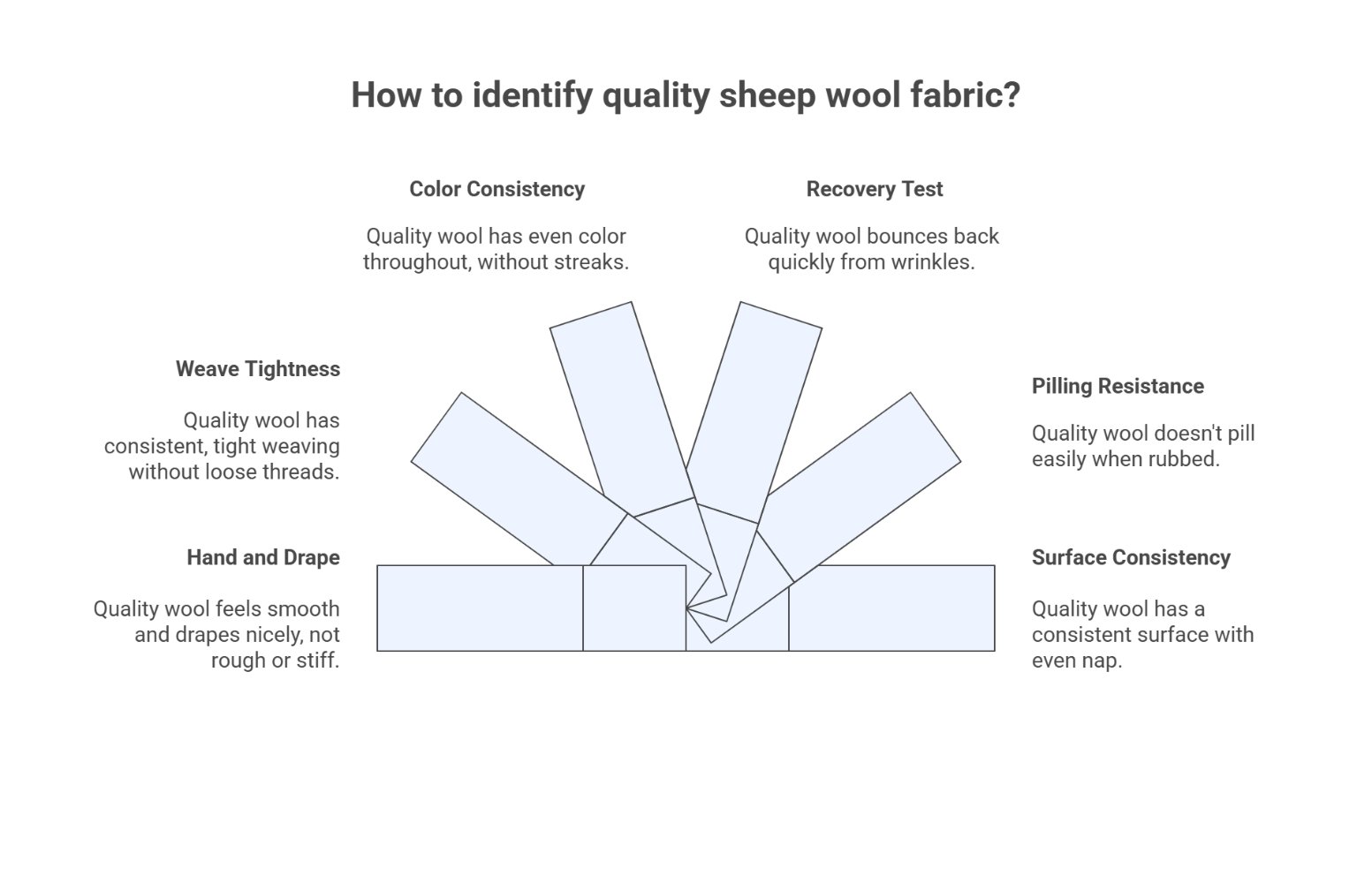

- How to Identify Quality Sheep Wool Fabric

- Fabric Weights and Seasonal Guide

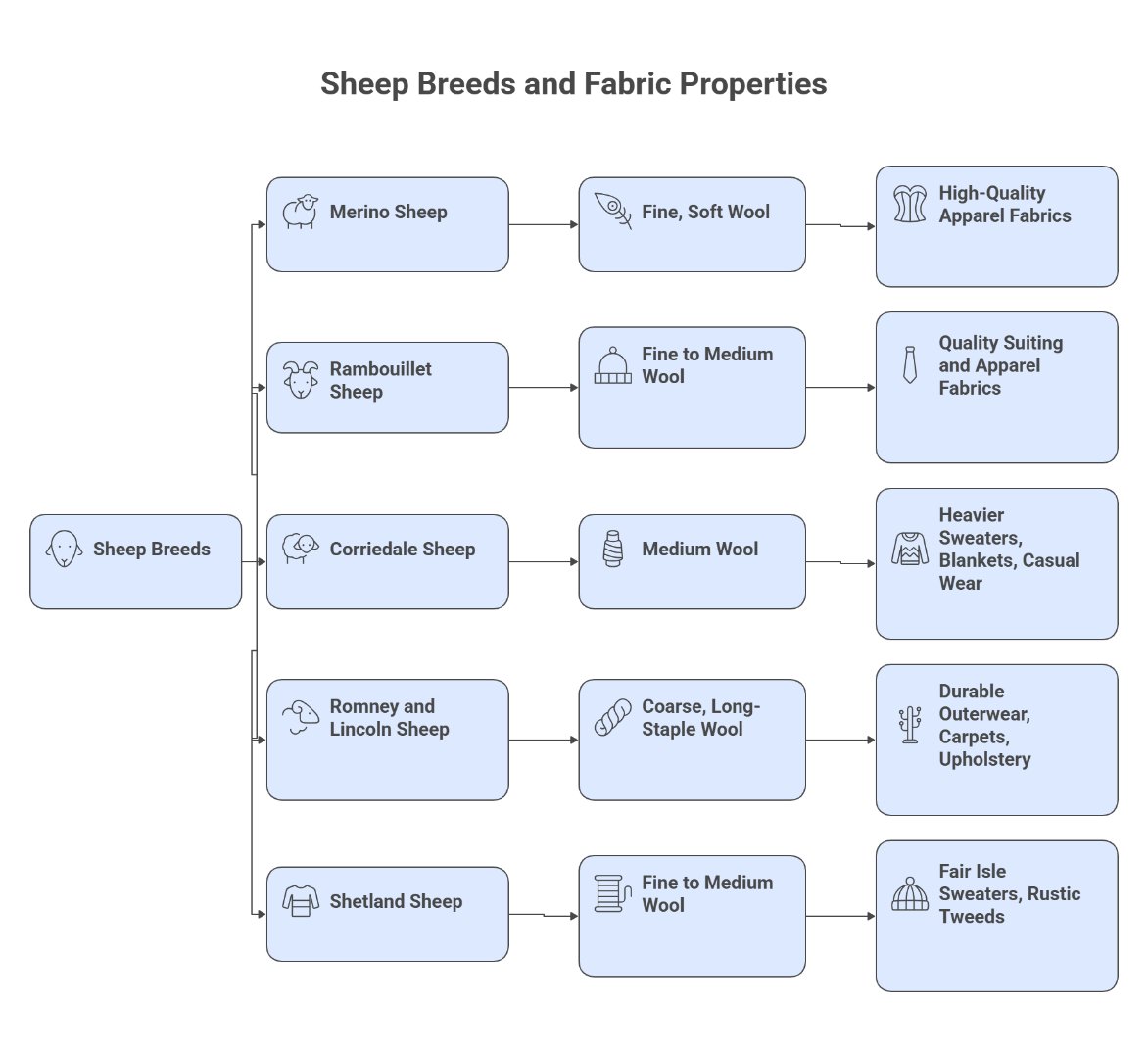

- Sheep Breeds and Their Fabrics

- Understanding Sheep Wool Fabric Pricing

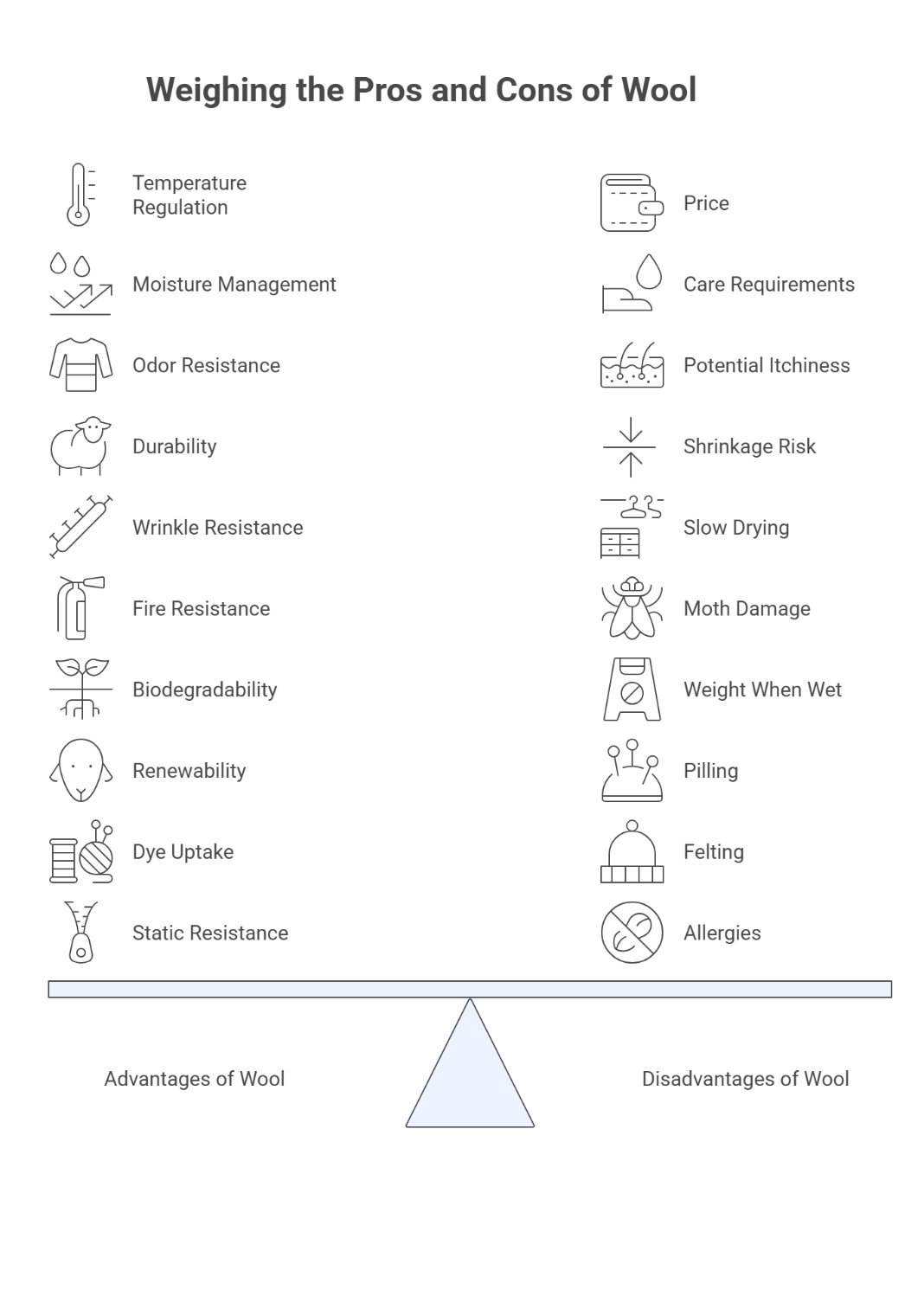

- Advantages and Disadvantages of Sheep Wool

- Caring for Sheep Wool Fabrics

- Applications by Fabric Type

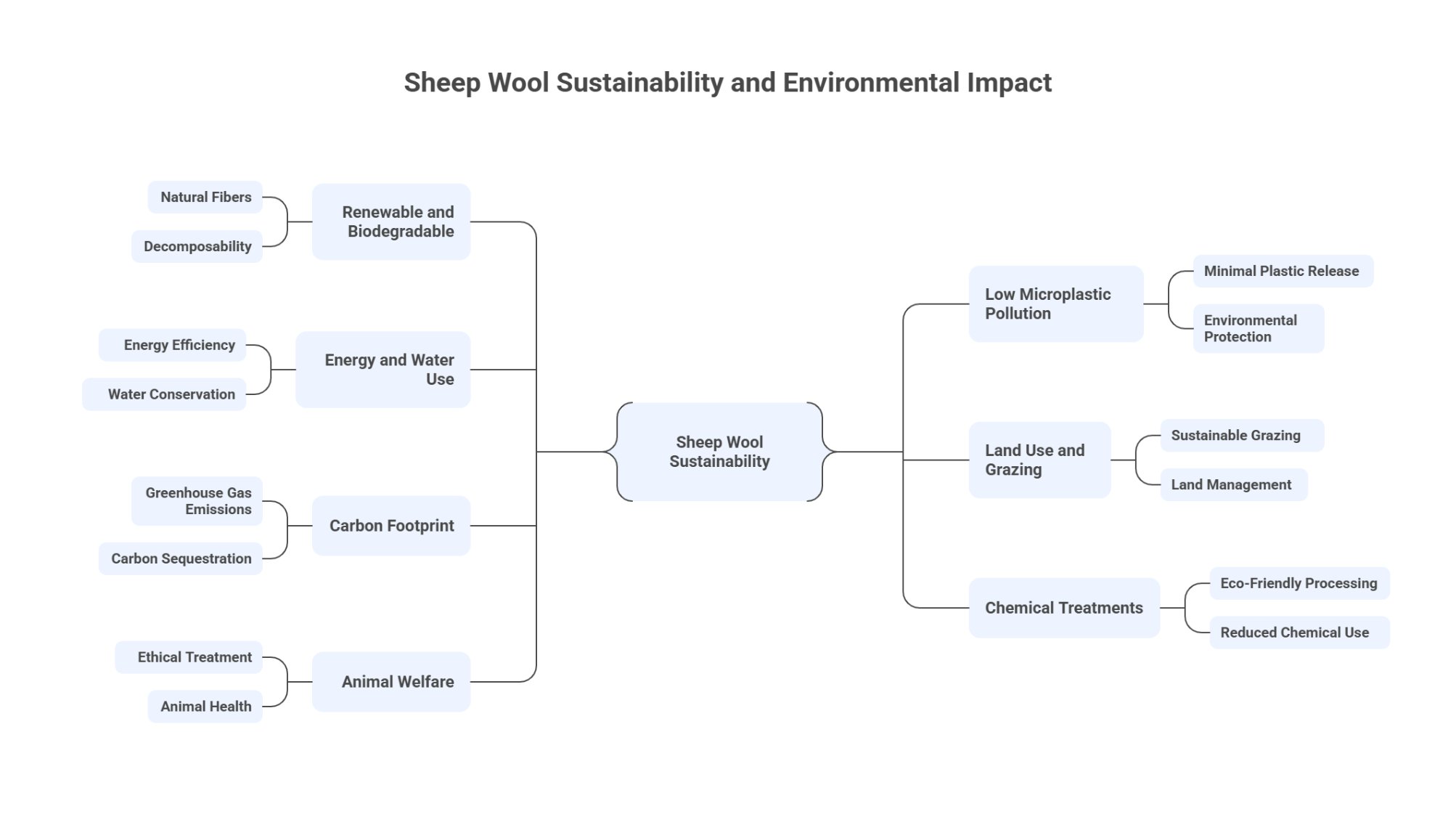

- Sustainability and Environmental Impact

- Buying Guide for Sheep Wool Fabrics

- Frequently Asked Questions

- Conclusion

Introduction to Sheep Wool Fabric

Natural sheep wool fabric showing softness and fiber structure

When most people think of wool, they picture a cozy sweater or a warm winter coat. But sheep wool fabric is much more than just warmth. It’s a world of different textures, weights, and constructions that have shaped fashion and function for over 10,000 years.

Unlike our general guide to wool fabric, which covers all wool types including alpaca, cashmere, and mohair, this article focuses specifically on fabrics made from sheep’s wool. We’ll explore the technical side of how these fabrics are made, what makes them different from each other, and how to choose the right one for your needs.

Sheep wool isn’t just a single type of fabric. It’s actually dozens of distinct fabrics, each with unique properties. From smooth, crisp worsted suits to fuzzy, warm flannel shirts, the variety is huge. Understanding these differences will help you make better choices whether you’re buying clothes, selecting fabric for a project, or just trying to understand what makes quality wool worth the investment.

Why Sheep Wool Dominates the Textile Industry

Sheep wool accounts for about 95% of all wool fabric production worldwide. That’s not an accident. While luxury fibers like cashmere and alpaca get attention, sheep wool remains the foundation of the wool industry for several practical reasons.

First, there’s scale. With 1.2 billion sheep globally producing around 2 million tonnes of wool annually, sheep provide a reliable, consistent supply. A single sheep produces about 4.5 kg of wool per year, enough to make six sweaters or three full suits. According to the International Wool Textile Organisation, wool accounts for less than 1% of global fiber production but remains important for quality textiles.

Second, sheep wool offers incredible versatility. Depending on the breed, sheep produce fibers ranging from ultra-fine 15-micron Merino (softer than cashmere) to coarse 40-micron wools perfect for durable carpets and outerwear. This range means sheep wool can be used for everything from delicate dress shirts to heavy-duty work pants.

Third, the infrastructure exists. Centuries of breeding, processing, and manufacturing knowledge have created a sophisticated global supply chain. Australia produces 25-30% of the world’s wool, with New Zealand, China, and the United States also being major producers.

Understanding Sheep Wool Terminology

Sheep wool fabric texture illustrating common wool terminology

What is Sheep Wool Called?

Sheep wool goes by different names depending on its source and quality. “Fleece” refers to the wool coat shorn from a living sheep. “Virgin wool” or “new wool” means wool that has never been processed or used before. “Lambswool” comes from a sheep’s first shearing, typically before seven months of age, and is softer and finer than wool from older sheep.

“Wool” without any qualifier typically means sheep’s wool. When wool comes from other animals like goats (cashmere, mohair), alpacas, or camels, it’s usually specified. “Recycled wool” or “shoddy” refers to wool reclaimed from old garments and reprocessed.

Is Sheep Wool Hair or Fur?

Technically, sheep wool is neither hair nor fur in the traditional sense. It’s a specialized fiber that grows from follicles in the sheep’s skin. The scientific term is “wool fiber,” and it has a unique structure that sets it apart from both hair and fur.

Wool fibers have a scaly outer layer called the cuticle, which creates the natural crimp you see in wool. This structure is what gives wool its insulating properties and ability to felt. Hair, like human hair or horse hair, is smoother and straighter. Fur is typically shorter and denser than wool.

The protein that makes up wool is keratin, the same protein in human hair and nails. But wool’s crimped structure and overlapping scales make it behave very differently from hair when spun into yarn and woven into fabric.

The Two Fabric Worlds: Worsted vs Woolen

Woolen fabric compared with worsted fabric to show texture differences

This is the single most important distinction in sheep wool fabrics. Every wool fabric falls into one of two categories: worsted or woolen. Understanding this difference will instantly make you better at identifying and selecting wool fabrics.

Quick Distinction

Worsted: Smooth, flat, crisp, shows the weave pattern clearly. Think business suits.

Woolen: Fuzzy, textured, lofty, weave obscured by nap. Think flannel shirts and tweed jackets.

Worsted Fabrics Explained

Worsted fabrics are made from long-staple wool fibers, typically 2 to 8 inches in length. These fibers go through an extra step called “combing” that removes all the short fibers and aligns the long ones parallel to each other.

The result is yarn that’s smooth, tight, and strong. When woven, worsted fabrics have a clear, defined weave pattern. You can see the individual threads crossing each other. The surface is smooth and somewhat shiny, with minimal fuzziness.

Worsted fabrics are generally more expensive because of the extra processing and the requirement for longer, higher-quality fibers. They’re also more durable and hold their shape better than woolens. This makes them ideal for garments that need structure, like suits and dress trousers.

Common Worsted Fabrics:

- Gabardine (diagonal twill weave, water-resistant finish)

- Tropical wool (lightweight, open weave for summer)

- Serge (even diagonal lines on both sides)

- Sharkskin (two-tone appearance, lustrous)

- Barathea (slightly pebbled texture, formal wear)

- Fresco (open weave, highly breathable)

Woolen Fabrics Explained

Woolen fabrics use shorter fibers, typically 1 to 3 inches long. These fibers are “carded” but not combed, meaning they’re straightened somewhat but still point in many directions in the yarn.

This creates a yarn that’s softer, airier, and less tightly twisted than worsted yarn. When woven, woolen fabrics have fibers poking out in all directions, creating a fuzzy texture. The weave pattern is often completely hidden by this “nap.”

Woolen fabrics are warmer than worsteds of the same weight because the random fiber orientation traps more air. They’re softer and more casual-looking, but also less durable and more prone to pilling. They’re perfect for casual wear, outerwear, and anything where warmth and texture are priorities.

Common Woolen Fabrics:

- Flannel (brushed surface, soft hand)

- Tweed (rough texture, multiple colored yarns)

- Melton (heavily felted, windproof)

- Loden (fulled fabric, water-resistant)

- Homespun (rustic appearance, loose weave)

- Shetland (rough texture, traditional patterns)

Worsted vs Woolen: Direct Comparison

| Feature | Worsted Fabrics | Woolen Fabrics |

|---|---|---|

| Fiber Length | 2-8 inches (long staple) | 1-3 inches (short staple) |

| Processing | Carded and combed | Carded only |

| Yarn Twist | Tight twist | Loose twist |

| Surface Texture | Smooth, flat, crisp | Fuzzy, napped, soft |

| Weave Visibility | Clearly visible | Obscured by nap |

| Weight Feeling | Dense, compact | Light, airy, lofty |

| Warmth | Less warm for weight | Very warm for weight |

| Durability | More durable | Less durable |

| Price Range | Generally higher | Generally lower |

| Best Uses | Suits, dress pants, formal wear | Casual jackets, outerwear, winter garments |

Major Sheep Wool Fabric Types

Now that you understand the worsted versus woolen distinction, let’s look at specific fabric types. These are the fabrics you’ll encounter when shopping for wool clothing or selecting fabric for sewing projects.

Smooth Worsted Fabrics

Examples of smooth worsted wool fabrics for tailoring

Gabardine

Gabardine is a tight twill weave with a distinctive diagonal rib on the face. It’s smooth, durable, and naturally water-resistant due to its tight weave. The fabric drapes well and resists wrinkles. You’ll find gabardine in business suits, dress trousers, and raincoats. It’s one of the most versatile worsted fabrics.

Tropical Wool

Despite its name, tropical wool is made for hot weather. It’s a lightweight worsted fabric with an open weave that allows air to circulate. The weave is loose enough to be breathable but tight enough to maintain structure. Tropical wool suits are standard in summer business wear. They typically weigh 7-9 oz per yard, much lighter than regular suiting.

Serge

Serge is a twill weave fabric with even diagonal lines visible on both sides. It has a smooth, slightly lustrous surface. Serge is tough and hard-wearing, which is why it’s been used for military uniforms for centuries. Today, you’ll find it in business suits, school uniforms, and work pants.

Sharkskin

Sharkskin wool has a distinctive two-tone appearance created by weaving together yarns of different colors (traditionally black and white). When light hits it, the fabric seems to shimmer slightly. It’s smooth, lightweight, and has a subtle elegance that works well for business suits. Despite the name, it has nothing to do with actual sharks.

Fresco

Fresco is an open-weave worsted fabric with a slightly rough, pebbled surface. The open weave makes it extremely breathable, ideal for summer suits. The fabric is crisp and maintains its structure despite being lightweight. It’s more casual-looking than gabardine or tropical wool due to the visible weave texture.

Textured Woolen Fabrics

Textured woolen fabrics used for outerwear and casual clothing

Tweed

Tweed is the most famous woolen fabric, traditionally woven in Scotland and Ireland. It’s thick, rough-textured, and made with multiple colored yarns woven together to create distinctive patterns. The fabric is incredibly durable and weather-resistant.

Different regions produce different types of tweed:

- Harris Tweed: Hand-woven in Scotland’s Outer Hebrides, legally protected by origin. Known for flecked appearance and medium weight.

- Donegal Tweed: From Ireland, features colorful slubs (thick spots) throughout the fabric.

- Shetland Tweed: Softer and lighter than Harris, with a more refined texture.

- Saxony Tweed: Made from Merino wool, offering a softer hand than traditional tweeds.

Tweed is perfect for casual sport coats, country jackets, and cold-weather wear. It’s the go-to fabric for that classic British countryside look.

Flannel

Wool flannel is woven and then brushed to raise a soft nap on one or both sides. This creates an incredibly soft, warm fabric with a fuzzy surface. Flannel can be made from either worsted or woolen yarn, though woolen flannel is more traditional and loftier.

The fabric is milled (beaten and agitated) after weaving, which creates the characteristic texture. Flannel comes in various weights, from lightweight shirt flannel to heavy coating flannel. It’s used for everything from casual shirts and pajamas to suit jackets and dress trousers.

Flannel is warmer than smooth worsteds of the same weight and has a casual, relaxed appearance. It’s perfect for fall and winter wear.

Melton

Melton is a heavily felted woolen fabric with an extremely dense, smooth surface. It’s made by fulling (shrinking and matting) the fabric until individual fibers can barely be seen. The result is a thick, warm fabric that’s highly wind-resistant and water-repellent.

Melton is traditionally used for heavy overcoats, pea coats, and stadium blankets. It’s one of the warmest wool fabrics you can buy, perfect for extreme cold weather. The fabric is thick and heavy, typically 20-32 oz per yard.

Loden

Loden is a traditional Austrian fabric that’s fulled like melton but retains more texture. It’s thick, water-resistant, and has a slightly fuzzy surface. The fabric is often dyed green (the traditional loden color) but comes in other colors too.

Loden is perfect for outdoor wear, hiking jackets, and casual coats. It’s warm, durable, and has a rustic, outdoorsy look. The fabric breathes well despite its density, making it comfortable for active wear.

Specialized Constructions

Boiled Wool

Boiled wool fabric showing thickness and compact structure

Boiled wool is knitted wool fabric that’s been “boiled” (actually washed in hot water) to shrink and felt it. The process creates a dense, stretchy fabric that’s water-resistant and warm. Unlike melton, which is woven, boiled wool retains some stretch from its knit construction.

You’ll find boiled wool in casual jackets, slippers, and craft projects. It’s easy to work with because the edges don’t fray, and it can be cut without finishing. The fabric has a cozy, handmade appearance.

Wool Crepe

Wool crepe fabric showing fluid movement and fine grain texture

Wool crepe has a crinkled, pebbled surface created by using highly twisted yarns. The fabric has good drape and a subtle texture that hides wrinkles well. It’s used in women’s dresses, skirts, and flowing garments. Crepe can be made from worsted or woolen yarn, with worsted crepe being more common for dressmaking.

Wool Jersey

Wool jersey fabric highlighting softness and flexibility

Wool jersey is a knit fabric rather than a woven one. It’s stretchy, soft, and drapes beautifully. Jersey is used for casual sweaters, dresses, and t-shirts. The fabric is comfortable for everyday wear and comes in various weights. Fine Merino jersey is soft enough to wear next to the skin.

From Fleece to Fabric: The Manufacturing Process

Understanding how sheep wool becomes fabric helps you appreciate the complexity and quality of what you’re buying. The process hasn’t changed dramatically in centuries, though modern machinery has made it faster and more efficient.

Wool Fabric Production Process

1. Shearing and Sorting

Sheep are shorn once or twice a year. A skilled shearer can shear a sheep in 2-3 minutes. The fleece comes off in one piece and is immediately sorted by quality. The best wool comes from the sides and back. Lower-quality wool from the belly and legs is separated.

2. Scouring

Raw wool contains lanolin (sheep oil), dirt, and vegetable matter. Scouring is basically washing the wool in hot water with detergent. This removes up to 50% of the weight of raw wool. The cleaned wool is called “scoured wool” or “clean wool.”

3. Carbonizing (Optional)

For wool with a lot of vegetable matter (seeds, burrs), carbonizing uses dilute sulfuric acid to dissolve plant material without damaging the wool. Not all wool goes through this step.

4. Carding

Large cylinders covered with fine wire teeth straighten the wool fibers and blend them together. This creates a thin web of fibers called a “sliver” (pronounced sly-ver). All wool is carded.

5. Combing (Worsted Only)

For worsted fabrics, the carded wool goes through combs that remove short fibers and perfectly align the long ones. This step is what makes worsted yarn smooth and lustrous. About 15-20% of the fiber is removed as “noils” (short fibers that can be used for woolen yarn).

6. Drawing and Roving

The sliver is drawn out thinner and thinner, blending the fibers. The thin strand is called a “roving.” This prepares the wool for spinning.

7. Spinning

The roving is spun into yarn by twisting it. Worsted yarn is tightly twisted, creating a smooth, strong yarn. Woolen yarn is loosely twisted, creating a soft, airy yarn. Two or more single yarns are often twisted together to make stronger yarn.

8. Weaving or Knitting

The yarn is woven on looms (for woven fabrics) or knitted on machines (for jersey and knit fabrics). The weave pattern determines many of the fabric’s characteristics. Common weaves include plain weave, twill, and satin.

9. Finishing

Raw fabric from the loom needs finishing treatments. This is where the magic happens. Finishing can include:

- Fulling/Milling: Shrinking and matting the fabric in water to create density

- Napping/Raising: Brushing the surface to raise fibers (for flannel)

- Shearing: Cutting raised fibers to a uniform height

- Pressing: Setting the final appearance and hand

- Decatizing: Steam treatment to add luster and stability

How to Identify Quality Sheep Wool Fabric

Visual guide to identifying high quality sheep wool fabric

Not all wool fabrics are created equal. Quality varies widely, and price doesn’t always reflect quality. Here’s what to look for when evaluating sheep wool fabric.

Quality Indicators

Understanding Super Numbers

You’ll often see wool fabrics labeled as “Super 100s,” “Super 120s,” “Super 150s,” and so on. These numbers refer to the fineness of the wool fiber used, measured in microns.

Here’s what the numbers mean:

| Super Number | Fiber Diameter (Microns) | Characteristics | Best Use |

|---|---|---|---|

| Super 80s – 100s | 19.5 – 21.5 microns | Durable, good wrinkle resistance | Everyday suits, work wear |

| Super 110s – 120s | 17.5 – 19.5 microns | Smooth, comfortable, good balance | Quality business suits |

| Super 130s – 150s | 16.5 – 17.5 microns | Very soft, luxurious feel | Premium suits, special occasions |

| Super 160s – 180s | 15.5 – 16.5 microns | Extremely soft, delicate | Luxury suits, formal wear |

| Super 200s+ | Under 15.5 microns | Ultra-soft, very delicate | Highest-end formal wear |

Higher numbers mean finer, softer wool. But there’s a trade-off: the finer the wool, the more delicate it is. Super 200s feels amazing but won’t last as long as Super 100s with daily wear. For most people, Super 110s to 130s offers the best balance of comfort and durability. The United States Department of Agriculture maintains official wool grading standards that provide detailed specifications for each grade.

Fabric Weights and Seasonal Guide

Wool fabric weight is measured in ounces per yard (in the US) or grams per meter (elsewhere). The weight tells you how heavy the fabric is and helps determine what season it’s appropriate for.

| Weight Category | Oz per Yard | Season | Typical Uses |

|---|---|---|---|

| Lightweight | 7-9 oz | Spring/Summer | Summer suits, tropical wool, dress shirts |

| Medium Weight | 10-13 oz | Year-round | Business suits, dress trousers, most garments |

| Medium-Heavy | 14-16 oz | Fall/Winter | Winter suits, heavier trousers, casual jackets |

| Heavyweight | 17-20 oz | Winter | Winter sport coats, thick trousers |

| Overcoating | 20-32 oz | Winter outerwear | Overcoats, peacoats, heavy outdoor wear |

Most men’s business suits are made from 10-12 oz fabric. This weight works well in most climates and seasons (though it might be too warm for summer in hot climates). Women’s suiting tends to be lighter, typically 8-10 oz.

Sheep Breeds and Their Fabrics

Sheep breeds mapped to wool fabric types and common uses

Different sheep breeds produce different qualities of wool, which affects the final fabric. While most commercial wool is a blend from multiple breeds, understanding breed characteristics helps explain fabric properties.

Merino Sheep

Merino sheep produce the finest, softest wool, typically 15-24 microns in diameter. This wool is used for high-quality apparel fabrics, from suits to base layers. Merino wool is soft enough to wear next to the skin without itching. Australia produces about 80% of the world’s Merino wool, with the finest grades coming from Australia and New Zealand.

Merino fabrics have excellent drape, take dye beautifully, and feel luxurious. They’re used in everything from business suits to performance activewear. The fiber’s natural crimp gives fabrics good wrinkle resistance.

Rambouillet Sheep

Rambouillet (ram-boo-YAY) sheep are a French breed that produces fine to medium wool, similar to Merino but slightly coarser. The fiber is 18-24 microns. Rambouillet is the most common breed in the United States. The wool is versatile and used in quality suiting and apparel fabrics.

Corriedale Sheep

Corriedale is a New Zealand breed that produces medium wool (25-30 microns). The fiber has good staple length and strength, making durable fabrics. Corriedale wool is used in heavier sweaters, blankets, and casual wear. It’s less soft than Merino but more durable and affordable.

Romney and Lincoln Sheep

These British breeds produce coarse, long-staple wool (32-40 microns). The fiber is lustrous and strong, perfect for durable outerwear, carpets, and upholstery. Romney and Lincoln wools are not soft enough for next-to-skin wear but excel in applications where durability matters more than softness.

Shetland Sheep

From Scotland’s Shetland Islands, these small sheep produce fine to medium wool with a slightly rough texture. Shetland wool is traditional for Fair Isle sweaters and rustic tweeds. The fiber has character and warmth, making distinctive casual fabrics.

Understanding Sheep Wool Fabric Pricing

Why is Sheep Wool So Expensive?

Quality wool fabric costs significantly more than synthetic alternatives for several reasons. First, production is expensive. Raising sheep, shearing them, and processing the wool involves substantial labor and land. A sheep must be cared for year-round but produces wool only once or twice a year.

Second, processing costs are high. The journey from fleece to fabric involves many steps, each requiring specialized equipment and skilled workers. Worsted fabrics, in particular, require extra processing that adds cost.

Third, supply is limited. Unlike synthetic fibers that can be produced in unlimited quantities, wool production is constrained by the number of sheep and land available for grazing. Fine Merino wool is especially limited.

Finally, wool’s performance justifies the price. It lasts longer than most synthetics, needs less washing, regulates temperature naturally, and biodegrades at end of life. When you calculate cost per wear over a garment’s lifetime, quality wool often costs less than cheap synthetics that need frequent replacement.

How Much is Sheep Wool Worth?

Wool fabric prices vary enormously based on quality, weight, and origin. Here’s what you can expect to pay in the United States and United Kingdom:

| Quality Level | Price per Yard (US) | Price per Meter (UK) | Characteristics |

|---|---|---|---|

| Entry Level | $20-40 | £15-30 | Basic woolens, wool blends, heavier weights |

| Mid-Range | $40-100 | £30-75 | Quality worsteds, specialty woolens, Super 100s-120s |

| Premium | $100-250 | £75-180 | Super 150s+, heritage mills, distinctive patterns |

| Luxury | $250-500+ | £180-350+ | Super 200s+, rare constructions, top Italian/British mills |

Raw Wool Prices

If you’re curious about raw wool prices (wool before processing into fabric), here are current market rates:

How much does 1kg of sheep wool cost? Raw, unwashed fleece directly from farmers typically sells for $3-15 per kilogram ($1.50-7 per pound) depending on quality and market conditions. Fine Merino wool commands the highest prices, while coarse crossbred wool sells for less.

However, raw fleece weight includes grease and dirt. After scouring, you lose about 50% of the weight, so 1kg of raw fleece yields only about 500g of clean wool. Scoured wool (clean, ready to spin) costs $15-40 per kilogram.

The dramatic increase in price from raw fleece to finished fabric reflects all the processing, labor, and expertise required to transform wool into wearable textiles.

Can You Buy Sheep Wool?

Yes, you can buy sheep wool at many stages:

- Raw fleece: Direct from farmers or at fiber festivals for hand-spinning

- Cleaned and carded wool: From fiber suppliers for spinning or felting

- Yarn: From yarn shops for knitting or weaving

- Fabric by the yard: From fabric stores for sewing

- Finished garments: From clothing retailers

For most people, buying finished fabric or garments makes sense. Only fiber artists typically buy raw fleece. When buying fabric, look for reputable fabric stores or online suppliers that provide details about fiber content, weight, and origin.

Advantages and Disadvantages of Sheep Wool

Visual overview of the pros and cons of sheep wool fabric

Sheep wool fabric has both strengths and limitations. Understanding these helps you make informed choices about when wool is the right material and when alternatives might work better.

Advantages

- Temperature regulation: Wool keeps you warm in cold weather and cool in warm weather by wicking moisture and allowing air circulation.

- Moisture management: Wool can absorb up to 30% of its weight in moisture while still feeling dry. It wicks sweat away from skin.

- Odor resistance: Wool naturally resists odors and can be worn multiple times between washes, unlike synthetics that smell after one wear.

- Durability: Quality wool garments last decades with proper care. Wool fibers can bend 20,000 times without breaking.

- Wrinkle resistance: Wool’s natural elasticity means it resists wrinkling and bounces back to shape.

- Fire resistance: Wool is naturally flame-resistant and self-extinguishing, unlike synthetics that melt.

- Biodegradable: Wool decomposes naturally in months, not centuries like synthetics.

- Renewable: Sheep grow new fleece every year, making wool a sustainable resource.

- Dye uptake: Wool takes both acid and basic dyes beautifully, allowing rich, lasting colors.

- Static resistance: Unlike synthetics, wool doesn’t build up static electricity.

Disadvantages

- Price: Wool costs significantly more than cotton or synthetics, especially quality wool.

- Care requirements: Many wool fabrics require dry cleaning or careful hand washing. Machine washing can cause shrinkage.

- Potential itchiness: Coarser wools (over 24 microns) can feel scratchy against skin, though fine Merino doesn’t have this issue.

- Shrinkage risk: Wool can shrink dramatically if washed in hot water or agitated too much.

- Slow drying: Wool takes longer to dry than synthetics or cotton.

- Moth damage: Moths and carpet beetles eat wool, requiring preventive measures during storage.

- Weight when wet: Wool absorbs water and becomes heavy when thoroughly soaked.

- Pilling: Lower quality wool and areas subject to friction can develop pills (small fiber balls).

- Felting: Unintended felting can occur with improper washing, permanently altering the fabric.

- Allergies: Some people are allergic to wool, though this is often actually a reaction to residual lanolin or harsh processing chemicals.

Caring for Sheep Wool Fabrics

Proper care extends the life of wool garments and fabrics. Different wool fabrics need different care approaches based on their construction. For comprehensive wool care instructions, check our wool care guide.

General Wool Care Principles

First and most important: wool needs less washing than other fabrics. The fiber’s natural antimicrobial properties and moisture-wicking abilities mean wool resists odors and stays fresh longer. Many wool garments can be worn 5-10 times before needing washing.

Between wears, air out wool garments by hanging them in a well-ventilated area for a few hours. This allows moisture to evaporate and odors to dissipate. A steamer can refresh wool without washing.

Care by Fabric Type

Worsted Fabrics (Suits, Dress Trousers)

Worsted fabrics typically need dry cleaning to maintain their crisp appearance. The tight weave and finishing treatments don’t respond well to water washing. Between cleanings, use a garment brush to remove surface dust and dirt. Press with a steam iron (using a press cloth) to remove wrinkles.

Don’t over-dry-clean. Once or twice per season is usually sufficient unless the garment is stained. Excessive dry cleaning wears down fibers.

Woolen Fabrics (Flannel, Tweed)

Woolen fabrics are more forgiving of water washing, though still need gentle treatment. Hand wash in cool water (around 85°F/30°C) with wool-specific detergent. Never use regular laundry detergent, which contains enzymes that break down wool protein.

To wash: submerge the garment, gently squeeze water through (don’t rub or twist), soak for 5-10 minutes, drain, and rinse twice in clean cool water. Press out excess water by laying flat on a towel and rolling it up. Never wring.

Dry flat on a clean towel, reshaping the garment to its proper dimensions. Never hang wet wool—the weight will stretch it permanently.

Knit Wool (Sweaters, Jersey)

Knit wool garments need the gentlest care because the knit structure is prone to stretching. Hand wash only, even if the label says machine washable. Always dry flat, never hanging.

Store knit wool folded, not hanging. Hangers will create shoulder bumps and stretch the garment out of shape.

Common Wool Care Mistakes

- Using hot water: Always use cool or lukewarm water, never hot. Hot water causes immediate felting and shrinkage.

- Agitation: Don’t rub, wring, or twist wool. The friction causes felting.

- Wrong detergent: Regular detergent contains enzymes that digest protein (which wool is made of). Use wool-specific or baby shampoo.

- Machine drying: Never put wool in the dryer. The heat and tumbling will felt it into a tiny, hard mass.

- Hanging wet wool: This stretches the garment permanently.

- Over-washing: Wool doesn’t need frequent washing. Over-washing wears it out faster.

Dealing with Pills

Pilling (small fiber balls on the surface) happens with wear, especially on lower-quality wool. Remove pills with a sweater comb or fabric shaver. Work gently in one direction, following the fabric’s grain. High-quality wool pills less and any initial pilling usually stops after the loose surface fibers are removed.

Storage

Clean wool before storing for summer. Moths are attracted to body oils and stains, not clean wool. Store in breathable fabric bags (not plastic) with cedar blocks or lavender sachets. Mothballs work but leave a strong smell.

For more detailed care instructions specific to different wool types and how to care for other fabric types like satin clothing, consult specific care guides.

Applications by Fabric Type

Wool suiting fabric showcasing structure and elegance in tailored clothing

Different wool fabrics suit different purposes. Choosing the right fabric type for your intended use ensures the best performance and longevity.

Suiting Fabrics

Business Suits: Choose worsted fabrics like gabardine, serge, or plain weave in medium weights (10-13 oz). Super 110s to 130s offers good durability with comfortable softness. Navy, charcoal, and medium gray are classic colors that work year-round.

Summer Suits: Tropical wool, fresco, or lightweight worsteds (7-9 oz) in lighter colors. Open weaves provide breathability.

Winter Suits: Heavier worsteds or flannel (13-16 oz) in darker colors. Flannel suits are warm and have a casual, comfortable appearance.

Casual Suits: Tweed, flannel, or textured woolens. These fabrics have more character and work for sport coats and unmatched jacket-trouser combinations.

Trousers

Worsted gabardine and serge make excellent dress trousers. They’re durable, hold creases well, and resist wrinkling. Flannel trousers are more casual and comfortable for everyday wear. Tweed trousers are sturdy for outdoor activities and country wear.

Outerwear

Overcoats: Melton, heavy worsteds, or coating tweeds (20-32 oz) provide warmth and weather protection. Melton is traditional for peacoats and dress coats.

Sport Jackets: Tweed is the classic choice. Flannel and textured woolens also work well. These casual fabrics have character and durability.

Technical Outerwear: Loden and boiled wool combine wool’s natural properties with modern outdoor functionality.

Home Textiles

Upholstery: Heavy worsted fabrics and durable woolens stand up to daily use. Wool naturally resists staining and crushing.

Blankets: Woolen fabrics, especially melton and heavy flannels, make warm, long-lasting blankets.

Carpets: Coarse long-staple wool (Romney, Lincoln) is used in carpets. It’s durable, fire-resistant, and naturally soil-resistant.

Technical and Industrial

Wool felt (non-woven wool) is used for acoustic panels, piano hammers, polishing wheels, and industrial gaskets. Loose wool fiber serves as insulation in buildings. Wool’s flame resistance makes it valuable for fire-resistant applications.

Sustainability and Environmental Impact

Visual overview of sheep wool sustainability and environmental impact

Sheep wool is one of the most sustainable textile fibers available, though like all materials, it has environmental impacts worth understanding.

Renewable and Biodegradable

Sheep regrow their fleece annually, making wool truly renewable. As long as grass grows and rain falls, wool can be produced. A wool garment buried in soil will completely biodegrade in 3-4 months, releasing valuable nitrogen back into the earth. Compare this to synthetic fabrics like polyester, which can take 20-200 years to decompose.

Low Microplastic Pollution

When synthetic garments are washed, they shed microplastic fibers that flow into waterways and eventually the ocean. An estimated 300,000 tons of microplastics from textiles enter the ocean annually. Wool fibers that wash away are biodegradable protein, not plastic. They break down naturally and don’t accumulate in marine life. Textile Exchange research shows wool’s environmental advantages over synthetic alternatives throughout the product lifecycle.

Energy and Water Use

Wool processing uses less energy than producing synthetic fibers from petroleum. Natural fibers require 95% less energy to produce than mineral wool insulation. However, scouring and dyeing wool does use water and chemicals. Modern wool processing increasingly uses closed-loop systems that recycle water and chemicals.

Land Use and Grazing

Sheep farming requires significant land for grazing. When managed well, sheep grazing can actually benefit landscapes by maintaining grasslands and preventing wildfire fuel buildup. However, overgrazing can cause soil erosion and degradation. Regenerative grazing practices that rotate sheep and allow land to recover are increasingly common.

Carbon Footprint

Wool production has a lower carbon footprint than many synthetic alternatives over the full life cycle of a garment. Wool’s durability means garments last longer, reducing the need for replacement. Wool’s biodegradability also means it doesn’t add to landfill problems like synthetics.

Chemical Treatments

Some wool undergoes chemical treatments like mothproofing and superwash processing. Superwash wool (machine-washable wool) is treated with chlorine or coated with polymer resin, reducing its biodegradability. These treatments add convenience but at an environmental cost.

Look for wool with minimal chemical treatment if sustainability is important to you. Certifications like GOTS (Global Organic Textile Standard) ensure environmentally friendly processing.

Animal Welfare

Ethical concerns about sheep welfare, particularly practices like mulesing (removing skin folds to prevent parasites), have led to improved standards. The Responsible Wool Standard (RWS) certifies wool from farms with good animal welfare practices. ZQ Merino wool from New Zealand is also certified for animal welfare and environmental stewardship.

Buying Guide for Sheep Wool Fabrics

Selecting quality sheep wool fabric for tailored clothing

Whether you’re buying fabric by the yard or finished garments, knowing what to look for ensures you get good value.

Reading Labels

“100% Wool” or “Pure Wool”: The fabric is entirely wool fiber from sheep (unless otherwise specified). This is what you want for quality.

“Virgin Wool” or “Pure New Wool”: Wool that has never been processed or used before. This is higher quality than recycled wool.

“Lambswool”: From a sheep’s first shearing. Softer and finer than regular wool.

“Merino Wool”: From Merino sheep. Fine, soft, high-quality.

“Wool Blend”: Contains wool mixed with other fibers (often polyester, nylon, or cotton). Blends are usually less expensive but don’t perform as well as pure wool.

“Recycled Wool” or “Shoddy”: Wool reclaimed from old garments and reprocessed. Lower quality than virgin wool but more sustainable.

Selecting by Use

Fabric Selection Guide

For Business Suits:

- Choose worsted fabrics (gabardine, plain weave, tropical)

- Weight: 10-13 oz for year-round; 7-9 oz for summer

- Super number: 110s-130s for durability; 150s+ for luxury

- Colors: Navy, charcoal, medium gray are most versatile

For Casual Wear:

- Woolen fabrics (flannel, tweed) for character and warmth

- Weight: 12-16 oz for jackets; 10-14 oz for shirts

- Patterns: Checks, herringbone, plaids add visual interest

For Outerwear:

- Heavy woolens (melton, loden, coating tweed)

- Weight: 20-32 oz for winter coats

- Look for fulled/felted fabrics for weather resistance

For Home Projects:

- Upholstery: Heavy worsted or durable woolen (14-20 oz)

- Blankets: Soft flannel or melton (16-24 oz)

- Pillows: Tweeds, flannels with interesting textures

Where to Buy

Fabric Stores: Local fabric stores often carry wool fabrics by the yard. Look for stores specializing in apparel fabrics or upholstery.

Online Fabric Retailers: Many online stores offer wide selections with detailed descriptions of weight, content, and weave. Read reviews to gauge color accuracy and quality.

Specialty Wool Shops: These focus specifically on wool and often have staff knowledgeable about different fabric types.

Mill Shops: In traditional textile regions (like Yorkshire, England or parts of Italy), mills sometimes sell direct to consumers at discounted prices.

For Garments: When buying finished clothing, examine the fabric as described in the quality section. Feel the hand, check the weave, and look at the label for fiber content and super numbers.

Frequently Asked Questions

“Wool fabric” is a general term that can include wool from sheep, goats (cashmere, mohair), alpacas, camels, and other animals. “Sheep wool fabric” specifically refers to fabrics made from sheep’s wool only. When a label just says “wool” without qualification, it usually means sheep’s wool since that’s the most common type.

Sheep wool is generally warmer than synthetics for the same weight because of its crimped structure that traps air. Wool also stays warm even when damp, unlike many synthetics. However, wool’s biggest advantage is temperature regulation: it keeps you warm in cold weather but breathable in moderate temperatures, while synthetics often trap heat and moisture uncomfortably.

It depends on the fabric type. Woolen fabrics (flannel, tweed) can usually be hand-washed at home with cool water and wool-specific detergent. Worsted fabrics (suits, dress trousers) typically need dry cleaning to maintain their crisp appearance. Always check the care label. Never use hot water or machine dry wool, as this causes immediate shrinkage and felting.

Itchiness depends on fiber diameter measured in microns. Wool fibers over 24 microns feel prickly against skin because individual fibers are thick enough to activate touch receptors. Fine Merino wool (15-20 microns) is thinner than human hair and doesn’t trigger that response. The Super number system helps identify fine wool: Super 110s and higher are typically comfortable for most people.

With proper care, quality sheep wool garments can last 10-30 years or more. Wool fibers can bend 20,000 times without breaking, making them extremely durable. Worsted fabrics last longer than woolens due to their tighter construction. The key is proper care: avoiding over-washing, storing correctly, and repairing minor damage promptly.

100% wool typically performs better and lasts longer than blends. Pure wool provides superior temperature regulation, odor resistance, and durability. Wool blends (often with polyester) are less expensive and sometimes easier to care for, but sacrifice wool’s best qualities. The exception is wool with a small percentage of nylon or elastane (2-5%) added for extra durability or stretch, which can actually improve performance.

Yes, lightweight sheep wool fabrics work well in summer. Tropical wool and fresco, typically 7-9 oz, are designed for warm weather. Wool’s moisture-wicking properties keep you drier than cotton or linen, and its breathability allows air circulation. Many tropical and subtropical regions traditionally use lightweight wool for warm-weather clothing.

Sheep wool can shrink dramatically if exposed to heat, agitation, and moisture simultaneously. This process is called felting. Wool exposed to hot water and movement (like a washing machine) will shrink permanently. However, properly cared-for wool maintains its size. Use cool water, minimal agitation, and air dry flat to prevent shrinkage.

Conclusion

Sheep wool fabric represents one of humanity’s most successful partnerships with the natural world. For over 10,000 years, we’ve refined the process of turning fleece into fabric, creating everything from delicate dress shirting to heavy overcoats that last generations.

The variety within sheep wool fabrics is what makes them so versatile. The fundamental distinction between worsted and woolen fabrics shapes everything else: worsted fabrics are smooth, structured, and formal; woolen fabrics are textured, casual, and warm. Within these categories, specific fabrics like gabardine, tweed, flannel, and melton each serve distinct purposes.

Essential Points to Remember

Quality matters more than price alone. A Super 120s suit at mid-range pricing will serve you better than a cheap Super 180s that pills and wears out quickly. Look for fabric with good hand, consistent weaving, and appropriate weight for your use.

Different fabrics need different care. Worsted suits typically need dry cleaning, while woolen sweaters and casual garments can be hand-washed. The care you provide directly affects how long your wool lasts. Wool needs less frequent washing than other fabrics, which actually extends its life.

Fiber diameter determines comfort. If you’ve avoided wool because of itchiness, try fine Merino (Super 110s or finer). The fiber diameter, not the fabric type, determines whether wool feels soft or scratchy against skin.

Weight guides seasonal appropriateness. Lightweight fabrics (7-9 oz) work for summer, medium weights (10-13 oz) handle year-round wear, and heavy fabrics (14+ oz) excel in winter. Choosing the right weight makes wool comfortable in any season.

Sustainability is real but not perfect. Wool is renewable, biodegradable, and has a lower carbon footprint than synthetics over a garment’s lifetime. However, sheep farming uses land and water, and some processing treatments reduce wool’s eco-friendliness. Look for certifications like RWS or GOTS if sustainability is a priority.

Making Smart Purchases

When buying sheep wool fabric or garments, start with your intended use. Business suits need worsted fabrics in appropriate weights and conservative colors. Casual wear benefits from the character and warmth of woolens. Outerwear requires heavy, weather-resistant fabrics.

For everyday suits, Super 110s to 130s in 10-13 oz weight offers the best balance of comfort, durability, and value. Save Super 150s and higher for special occasions when you want luxury feel but can accept more delicate fabric.

For casual wear and projects, don’t overlook woolen fabrics. Flannel, tweed, and textured woolens have character that smooth worsteds lack. They’re often more affordable and actually perform better for casual use.

Long-Term Value

Quality sheep wool fabric costs more upfront but delivers value over time. A well-made wool suit can be worn weekly for a decade with proper care. Compare this to fast fashion suits that look worn after a season. Calculate cost per wear, and wool often wins.

Wool’s durability, combined with its biodegradability, makes it environmentally sound. You buy less often, and when a garment finally wears out, it doesn’t sit in a landfill for centuries.

Final Thoughts

Sheep wool fabric isn’t just one material. It’s a whole family of textiles, each optimized for specific uses. Understanding the differences between worsted and woolen, knowing quality indicators, and matching fabric to purpose will help you make choices that serve you well for years.

The traditional wool fabrics—gabardine suits, flannel shirts, tweed jackets, melton coats—persist because they work. Modern textile technology hasn’t created anything that matches wool’s combination of performance, durability, and comfort. The centuries-old techniques for processing wool into fabric continue because they produce superior results.

Whether you’re buying your first wool suit, selecting fabric for a sewing project, or just trying to understand what makes quality wool worth the investment, the key is knowing what you’re looking at. With the knowledge from this guide, you can evaluate sheep wool fabrics confidently, choose appropriate types for your needs, and care for them properly to maximize their longevity.

Sheep wool fabric has earned its place in our wardrobes through performance, not marketing. Give it proper care, and it will serve you well for decades.

Your Next Steps

Ready to explore more? Try our Wool Type Selector Quiz to find your perfect wool match, or use our Wool Care Calculator to get personalized washing instructions for your wool garments.