From Petroleum to Performance: Understanding the Complete Polyester Manufacturing Process, Market Dynamics, and Sustainable Innovations in 2025

Polyester is one of the most common fabrics in the world, seen in everything from clothing to home furnishings. Polyester is made by turning chemicals, mostly derived from petroleum, into long plastic fibers through a process known as polymerization. These fibers are then stretched and spun into threads that become the fabric used in many products.

The steps in making polyester involve melting plastic pellets, forcing them through tiny holes to form threads, and cooling them to create strong and stable fibers. This process allows manufacturers to shape polyester for different uses, from soft shirts to tough industrial materials.

Global Polyester Market Overview

The polyester industry has become a massive global enterprise. In 2025, the worldwide polyester fiber market is valued at approximately $111-130 billion and is expected to grow at a steady rate of 7-8% each year through 2030. This growth makes polyester one of the most important synthetic materials in modern manufacturing.

Market Size and Regional Distribution

| Region | Market Share | Key Countries | Production Volume |

|---|---|---|---|

| Asia-Pacific | 45.7% | China, India, Japan, South Korea | 42.7 billion tonnes |

| North America | 24.4% | United States, Canada, Mexico | 23.6 billion tonnes |

| Europe | 23.7% | Germany, UK, France, Italy | 23.5 billion tonnes |

| Others | 6.2% | Middle East, Latin America, Africa | 7.8 billion tonnes |

China leads global production with about 63 million tonnes of polyester manufactured in 2022, making up 54% of world production. India is rapidly catching up as the second-largest producer, with government initiatives supporting synthetic fiber growth.

Table of Contents

Key Takeaways

- Polyester is created using chemical processes that form plastic fibers

- Its fibers are made strong through melting, spinning, and stretching methods

- The fabric is used widely in many industries and everyday products

- The global market is worth over $100 billion and growing rapidly

What Is Polyester?

Polyester is a synthetic fiber made from petroleum-based chemicals. It is one of the most widely used fibers in the world because it offers a blend of strength, durability, and resistance to shrinking. These qualities make it popular for clothing, home furnishings, and industrial products.

Is Polyester Synthetic?

Yes, polyester is 100% synthetic. Unlike natural fibers such as cotton or wool that come from plants or animals, polyester is manufactured entirely through chemical processes. The main ingredient comes from petroleum, which undergoes several chemical reactions to create the final fiber.

What Chemicals Are in Polyester?

The main chemicals used to make polyester include:

- Terephthalic Acid (PTA): The backbone chemical that gives polyester its strength

- Ethylene Glycol: A liquid alcohol that helps form the polymer chains

- Antimony or Titanium Compounds: Used as catalysts to speed up chemical reactions

- Various Dyes and Additives: Added for color and special properties

These chemicals are considered safe for consumer use once they become part of the finished polyester fabric.

Types of Polyester

There are several types of polyester, but the most common is polyethylene terephthalate (PET). PET is used to create most polyester fibers found in clothes and textiles today.

Another type is polytrimethylene terephthalate (PTT). This fiber is known for its softness and stretch but is less common than PET. There is also polybutylene terephthalate (PBT), sometimes used for specialty fabrics with unique textures.

Below is a simple list showing the main types:

- PET: Used in clothing, bottles, and packaging

- PTT: Found in carpets and some stretchy fabrics

- PBT: Used in technical and specialty textiles

Each type has its own set of physical properties. However, all polyesters share strong resistance to water, stretching, and chemicals.

Key Properties of Polyester

Polyester is valued for its high durability and strength. It stands up well to repeated washing and does not wrinkle or shrink easily. This makes polyester clothing last longer than many natural fibers.

It is also lightweight and resists mildew, mold, and most stains. Polyester dries quickly, which is useful for sportswear and outdoor clothing.

Key characteristics of polyester fiber:

| Property | Description |

|---|---|

| Durability | Resists wear, tear, and abrasion |

| Strength | High tensile strength |

| Elasticity | Maintains shape |

| Moisture | Dries quickly, low absorbency |

| Cost | Affordable compared to natural fibers |

| Care | Easy to wash and maintain |

Polyester is often blended with cotton or other fibers to add durability and reduce costs while keeping fabric comfortable. The combination of these features has made polyester one of the most used synthetic fibers worldwide.

Raw Materials Used in Polyester Production

Polyester is made from several main chemical compounds, each playing a specific role in the process. The source of these materials is usually petroleum, but some are now being made from renewable resources.

Cost Structure and Economics

The current price of raw polyester fiber averages around $1 per pound, though this changes daily based on oil prices and market demand. Raw material costs typically make up 60-70% of total production expenses, with petroleum price fluctuations directly affecting profitability.

Terephthalic Acid and Dimethyl Terephthalate

Terephthalic acid (PTA) is a white, crystalline powder that forms the backbone of most polyester. It is made from chemical reactions involving petroleum-based substances. PTA is highly valued because of its purity and stability, which help produce strong, high-quality fibers.

Dimethyl terephthalate (DMT) is another important raw material. Some factories use DMT instead of PTA, especially when making specialty polyester types. Both PTA and DMT are forms of aromatic dicarboxylic acids. Their main job is to react with diols, making the long chains that give polyester its durable structure.

The choice between PTA and DMT often depends on the production method, cost, and fiber properties needed by the manufacturer.

Ethylene Glycol and Diol

Ethylene glycol is a clear, odorless liquid that comes from ethylene, a byproduct of petroleum or sometimes natural gas. This liquid acts as the diol, or alcohol component, in polyester production. When it reacts with terephthalic acid or dimethyl terephthalate, it helps form the repeating units that make polyester strong and flexible.

Diol refers to any chemical with two alcohol groups. Ethylene glycol is the most common, but other diols might be used to create special types of polyester with unique qualities. The combination of these chemicals with PTA or DMT leads to the creation of long, sturdy polymer chains.

Because ethylene glycol is made from abundant fossil fuels, it is relatively cheap and easy to produce in large amounts.

Alternative and Bio-Based Inputs

Newer forms of polyester use bio-based raw materials. These include bio-based ethylene glycol, made from renewable resources like corn or sugar cane. Sometimes, plant-derived sources replace petroleum-based chemicals in the process, which helps lower the use of fossil fuels.

Manufacturers are also testing recycled feedstocks, such as waste plastic and used polyester products. This allows for the creation of recycled polyester while cutting down on waste and reliance on new petroleum.

Bio-based and recycled materials can slightly change the properties or environmental footprint of polyester, but the basic chemical reactions remain similar. These alternatives provide options for more sustainable polyester production.

Major Industry Players and Market Competition

The polyester manufacturing industry is dominated by several key players who control significant market share globally.

Leading Global Manufacturers

Reliance Industries Limited leads the Indian market with 45% of domestic production and 4% of global production. The company operates with a production capacity of 2.5 million tonnes per year and offers products including Recron® Staple Fibre and various specialty yarns.

Indorama Ventures ranks among the top global producers, specializing in intermediate petrochemicals and polyester manufacturing across multiple countries. The company has been expanding through strategic acquisitions and capacity increases.

China Petroleum & Chemical Corporation (Sinopec) dominates much of the Chinese market, which produces approximately 63 million tonnes annually. Chinese manufacturers have revolutionized production timelines, building new polyester plants in just 14-15 months compared to the previous 24-month standard.

William Barnet & Son, founded in 1898, remains one of the largest polyester manufacturers in the USA, specializing in fibers, polymers, and yarns for diverse applications.

Regional Competition Dynamics

The competition between China and India has intensified significantly. China maintains its lead through government policies supporting “preferred products,” subsidized power, and easy access to funding through local banks. However, India is rapidly expanding its capacity through government initiatives like the Production-Linked Incentive (PLI) scheme.

Key competitive advantages by region:

- China: Low labor costs, fast construction timelines, integrated supply chains

- India: Assured raw material supply, quality-conscious processes, intellectual property respect

- USA/Europe: Advanced technology, environmental compliance, high-quality specialty products

Polymerization Process

Making polyester involves a series of specific chemical reactions. The most important steps use acids and alcohols to form long polymer chains used in materials like polyethylene terephthalate (PET).

Energy Consumption and Environmental Impact

The polymerization process requires significant energy input, consuming approximately 125 MJ per kilogram of polyester fiber produced. This results in carbon emissions of about 27.2 kg CO2 equivalent per kilogram of polyester woven fabric.

Modern manufacturing facilities are adopting energy-efficient technologies and renewable energy sources to reduce their environmental footprint. Some plants now use cogeneration systems that capture waste heat for additional power generation.

Esterification and Transesterification

Esterification is the starting point for making polyester. In this step, terephthalic acid or dimethyl terephthalate (DMT) reacts with ethylene glycol. Companies often choose DMT for transesterification, where DMT and ethylene glycol combine to produce a compound called a monomer.

Catalysts such as antimony or titanium salts are added to speed up the reaction. This process takes place at high temperatures, usually between 250°C and 280°C (482°F–536°F).

The key product from this step is bis(2-hydroxyethyl) terephthalate. After this, unwanted byproducts like methanol or water are removed. The remaining mixture is ready for the next chemical reaction.

Key chemicals:

- Terephthalic acid

- Dimethyl terephthalate (DMT)

- Ethylene glycol

Condensation and Chemical Reactions

In the condensation step, the monomers join together to make long chains called polymers. This process is called polycondensation. It forms the fiber’s backbone, which is polyethylene terephthalate (PET).

During polycondensation, smaller molecules like water or methanol are released. The process usually takes place in a vacuum to help remove these byproducts and drive the reaction forward. The resulting chains of PET are strong and stable.

At the end, the liquid polymer is cooled and turned into chips or pellets. These are then melted and spun into polyester fibers used in textiles and plastics.

Main Points:

- Long PET polymer chains are formed

- Byproducts (like water) are removed

- The final PET is processed into usable forms

Polyester Manufacturing Process Flow

Polyester Manufacturing Process

From Raw Materials to Finished Fiber Products

Raw Materials & Inputs

Esterification

Polycondensation

Chip Formation

Melt Spinning

Cooling & Solidification

Drawing & Stretching

Crimping

Heat Setting

Final Polyester Products

Melt Spinning and Fiber Formation

Melt spinning is the main method used to create polyester fibers. This process involves turning melted plastic into strong, thin filaments that can be used in textiles.

Extrusion of Polymer Melt

Polyester starts as small, solid beads of polyethylene terephthalate (PET). These beads are heated until they melt, turning into a thick liquid called a polymer melt. Precise temperature control is important because polyester is a thermoplastic, so it softens and flows when heated.

The melted polymer is pushed, or extruded, through a metal device called a spinneret. The spinneret has many tiny holes, and each hole forms one filament. The number and shape of these holes decide the cross-section and thickness of the polyester filaments.

As the polymer passes through the spinneret, it changes from a thick liquid to long, continuous threads. These threads are called polyester filaments and are the building blocks for synthetic fibers used in textiles, carpets, and other materials.

Cooling and Solidification

After extrusion, the hot polyester filaments must cool quickly to keep their shape and strength. The filaments leave the spinneret and enter a controlled air stream or cooling chamber. Here, the temperature drops, causing the liquid filaments to become solid fibers.

The cooling rate affects the fiber’s properties, like strength and flexibility. Fast cooling can make fibers stronger but less stretchy, while slower cooling lets the fibers be more flexible. After cooling, the filaments are grouped, stretched, and wound onto spools for the next steps in making yarn or fabric.

Key steps:

- Rapid cooling to prevent the filaments from sticking

- Solidification ensures the polyester fibers hold their final shape

- Controlled environment supports even fiber quality and performance

Drawing, Crimping, and Heat Setting

These three steps shape polyester fibers, giving them strength, flexibility, and the desired texture. The process involves stretching the fibers, adding crimps for bulk, and using heat to lock in their properties.

Drawing and Stretching

After polyester is spun into long filaments, the fibers pass through a process called drawing or stretching. This means the fibers are pulled out to several times their original length. Drawing aligns the polymer chains inside each fiber so they run parallel to one another.

This alignment increases the fiber’s tensile strength and gives it durability. The drawn fibers become thinner, smoother, and much stronger than their original form. Makers control the drawing rate to get specific fiber diameters and qualities.

Drawing is vital because it impacts how the final fabric will perform. For example, higher drawing ratios often result in stiffer but stronger fibers. The process also helps make the fibers suitable for later steps, such as crimping and heat setting.

Crimping for Texture

After drawing, polyester fibers are usually straight and slippery. To give them bulk and texture, manufacturers add crimps (small, wave-like bends) into the fibers. Crimping mimics natural fibers like wool and helps polyester yarns cling together.

To crimp the fibers, they are sent through special machines where they are heated, compressed, or twisted, then released. As they cool, the crimps are set in place. This step increases softness, elasticity, and gives the fibers a more “springy” feel.

Crimped fibers also improve the insulation and moisture-wicking properties of polyester fabrics. Without this step, polyester would feel flat and not hold together as well during weaving or knitting.

Heat Setting Process

Once polyester fibers are drawn and crimped, they need to be heat set. In this step, the fibers or yarns are exposed to high temperatures, usually between 100°C and 150°C (212°F to 302°F). Heat setting locks in the crimp and stabilizes the fiber’s shape.

During heat setting, fibers become less likely to shrink or lose their structure when washed or exposed to heat later. The process also helps reduce unwanted stretching and twisting of the finished fabric. Heat setting can be done in ovens or with steam.

This treatment ensures the fibers keep their texture and resilience. Proper heat setting results in a fabric that is easier to handle, sew, and wear, and it also maintains its appearance after repeated use.

Quality Control and Testing Standards

Modern polyester manufacturing requires strict quality control measures to ensure consistent product performance across different applications.

Industry Standards and Certifications

Polyester manufacturers must comply with various international standards:

- ASTM D276: Standard test methods for identification of fibers in textiles

- ISO 1675: Plastics – Liquid resins – Determination of density by pyknometer method

- OEKO-TEX Standard 100: Tests for harmful substances in textiles

- GREENGUARD Certification: Indoor air quality standards for low chemical emissions

Testing Procedures

Quality control laboratories test polyester for multiple properties:

Physical Properties:

- Tensile strength and elongation

- Denier (fiber thickness) consistency

- Moisture absorption rates

- Thermal stability

Chemical Properties:

- Molecular weight distribution

- Catalyst residue levels

- Dye uptake capability

- Chemical resistance

Performance Testing:

- Pilling resistance

- Abrasion resistance

- Colorfastness to washing and light

- Dimensional stability

Forms and Types of Polyester Fibers

Polyester fibers come in several different forms, each made for specific uses and properties. These forms include continuous strands, short fibers, soft filling, and ultra-fine threads.

Filament Yarn

Filament yarn is made by spinning liquid polyester into long, continuous strands. Each strand can stretch for miles without breaking. This form is smooth, strong, and has a slight sheen.

Factories often twist several filaments together to make one thread. Filament yarn is used in many fabrics for clothing, linings, and home textiles because it resists wrinkles and holds its shape well.

The continuous nature of filament yarn makes it less likely to pill. It also creates fabric that feels sleek and cool to the touch compared to shorter staple fibers.

Staple Fiber and Fiberfill

Staple fiber is chopped into short lengths, usually between 1 and 4 inches, to mimic the texture of cotton or wool. These short fibers are spun into yarn and then woven or knitted into fabric. This type of polyester yarn feels softer and can make fabric that is bulky or warm.

Fiberfill is another use for staple fiber. Fiberfill polyester is fluffed up and used as filling in products such as pillows, quilts, jackets, and stuffed toys. Fiberfill traps air, providing insulation and comfort.

The cut ends of staple fibers can make the fabric slightly more prone to pilling than filament yarn. However, staple polyester is favored for its soft touch and warmth.

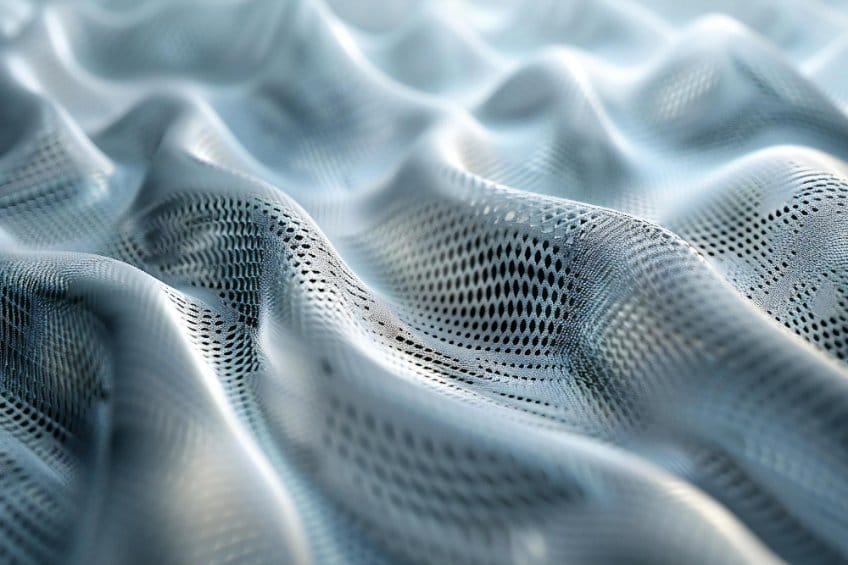

Microfiber

Microfiber is a very fine form of polyester fiber, measuring less than one denier in thickness. This means the fibers are thinner than a strand of silk. Microfiber can be made from polyester alone or blended with other fibers, such as nylon.

The small size of microfiber strands allows fabrics to feel very soft and smooth. Microfiber materials are highly absorbent and often used in cleaning cloths, sportswear, and soft furnishings.

They are also popular for making suede-like fabrics because the fine fibers can be tightly woven. Microfiber polyester is chosen for its light weight and ability to wick moisture away from the skin.

Dyeing and Color Treatment of Polyester

One of the most common questions about polyester is whether it can be dyed and how to achieve vibrant, lasting colors.

Can You Dye Polyester Fabric?

Yes, you can dye polyester fabric, but it requires special techniques because polyester is a synthetic material. Unlike natural fibers that absorb dyes easily, polyester needs specific types of dyes and higher temperatures to achieve good color results.

Can You Dye 100% Polyester?

Absolutely! 100% polyester can be dyed successfully, though it presents more challenges than polyester blends. Pure polyester requires disperse dyes, which are specifically designed for synthetic fibers.

How to Dye Polyester Fabric at Home

Dyeing polyester at home is possible with the right materials and techniques:

Materials Needed:

- Disperse dyes (like Jacquard iDye Poly)

- Large stainless steel pot

- Thermometer

- Rubber gloves

- Salt or dye fixative

Step-by-Step Process:

- Prepare the fabric: Wash the polyester item to remove any finishes

- Heat water: Fill a large pot with water and heat to 200°F (93°C)

- Add dye: Mix the disperse dye according to package instructions

- Submerge fabric: Add the wet polyester item to the hot dye bath

- Maintain temperature: Keep water at 180-200°F for 30-60 minutes

- Stir regularly: Move the fabric around for even color distribution

- Rinse and dry: Cool the fabric gradually, then rinse in cold water

Important Tips:

- Always use disperse dyes for best results

- Higher temperatures produce better color saturation

- Light-colored polyester dyes better than dark colors

- Results may vary compared to natural fiber dyeing

Can You Tie Dye Polyester?

Tie-dyeing polyester is more challenging than cotton but definitely possible. The process requires:

- Special synthetic dyes: Regular tie-dye kits for cotton won’t work well

- Higher heat: Most tie-dye techniques need to be adapted for hot water application

- Modified techniques: Ice dyeing and other cold-water methods don’t work effectively on polyester

- Patience: Colors may appear lighter and take longer to set than on natural fibers

For best tie-dye results on polyester, consider using polyester-cotton blends which combine easier dyeing with good color retention.

Bleaching Polyester Fabric

Can You Bleach Polyester Fabric?

Yes, polyester can be bleached, but it requires careful handling because polyester responds differently to bleach than natural fibers.

How to Bleach Polyester Fabric

Safe Bleaching Method:

- Use oxygen bleach: Avoid chlorine bleach which can damage polyester fibers

- Test first: Always test on a hidden area before treating the entire garment

- Mix solution: Combine oxygen bleach with cool or warm water (not hot)

- Soak time: Let the fabric soak for 30 minutes to 2 hours

- Rinse thoroughly: Remove all bleach residue with clean water

- Air dry: Avoid high heat drying immediately after bleaching

How Long Does It Take to Bleach Polyester?

Bleaching polyester typically takes 30 minutes to 2 hours, depending on:

- Fabric thickness: Thicker polyester takes longer

- Desired lightness: More dramatic color removal requires longer exposure

- Bleach concentration: Stronger solutions work faster but increase damage risk

- Original color: Darker colors need more time than lighter shades

Warning: Never use chlorine bleach on polyester as it can cause permanent damage, yellowing, or weakening of the fibers.

Major Brands and Variants of Polyester

Polyester comes in several notable types, each used for different products and industries. Specific names like Dacron, Terylene, and Polytrimethylene Terephthalate (PTT) set certain polyesters apart because of their unique features and uses.

Dacron and Terylene

Dacron is a trademarked form of polyester developed by DuPont. Terylene was created by British chemists around the same time. Both are made from polyethylene terephthalate (PET).

Dacron and Terylene are strong and resist stretching and shrinking. They are known for their durability and are easy to wash and dry. Many bedding, clothing, curtains, and industrial products use these brands.

Some key features include:

- High resistance to wrinkles

- Retains shape well

- Often blended with cotton or wool

- Used in tire cords and sails due to strength

Both Dacron and Terylene continue to be widely used in textiles because of their long-lasting properties.

Polytrimethylene Terephthalate

Polytrimethylene Terephthalate (PTT) is another type of polyester. It is made from 1,3-propanediol and terephthalic acid. PTT is known for its soft texture and natural stretch.

This variant is popular in carpets, upholstery, and activewear. It bounces back easily after being compressed, making it a good choice for areas with heavy foot traffic.

PTT also stands out because:

- It is more flexible than standard PET polyester

- Has a silkier feel

- Is easily dyed with bright, lasting colors

- Dries quickly and resists stains

PTT gives manufacturers more options, especially when softness and flexibility are important.

Industrial and Consumer Uses of Polyester

Polyester is used in a wide range of products because it is strong, resistant to stretching and shrinking, and easy to care for. Its applications span from clothing to home products and many industries due to its unique mix of properties.

Textiles and Clothing

Polyester is one of the most common fibers found in clothing around the world. It is used in shirts, pants, sportswear, jackets, and dresses.

Manufacturers value polyester because it can be blended with natural fibers like cotton or wool to add durability and reduce wrinkling. These blends are popular in uniforms, activewear, and fashion.

The fabric is easy to wash and rarely shrinks, making it convenient for everyday use. Many people wear polyester clothing for outdoor activities since it is lightweight and dries quickly.

Home Furnishings and Fleece

In homes, polyester is a main material for curtains, bedspreads, pillow covers, and upholstery. It keeps its shape well and is resistant to mildew and stains.

Fleece is a soft fabric made from polyester. Fleece blankets and jackets are popular because they are warm, soft, and machine washable. Polyester fiberfill is often used inside pillows, comforters, and stuffed toys.

Polyester’s ability to stay vibrant after many washes makes it a top choice for printed curtains and bedding. It is also less expensive than many natural fibers, making it an affordable option for home décor.

Automotive Applications

The automotive industry relies heavily on polyester for various components:

- Seat covers and interior fabrics for durability and stain resistance

- Tire cord reinforcement utilizing polyester’s high tensile strength

- Engine compartment components where heat resistance is crucial

- Carpet and floor mats for easy maintenance and longevity

Electrical and Industrial Applications

Industrial uses of polyester are important in many sectors. Polyester is used as an insulating material in electrical wires and cables because it resists moisture and heat.

In factories, polyester is made into conveyor belts, ropes, safety belts, and heavy-duty fabrics that must withstand constant use. It can be spun into strong threads used for sewing industrial textiles and safety equipment.

Polyester film, such as Mylar, is used for packaging, tapes, and even in electronics as a protective layer. Its durability and resistance to chemicals make it useful for a range of industrial tasks.

Medical and Healthcare Uses

Polyester has found important applications in healthcare:

- Surgical sutures that dissolve safely in the body

- Medical implants such as vascular grafts and patches

- Wound dressings that promote healing while resisting bacteria

- Protective clothing for healthcare workers

Lightweight and Quick-Drying Benefits

A key advantage of polyester is that it is lightweight. Clothes made from polyester are easier to pack and carry, which is why they are common in travel wear and outdoor gear.

Polyester absorbs very little water. This means it dries much quicker than cotton or wool. That’s useful for sportswear, raincoats, and clothing that needs frequent washing.

These properties also make polyester suitable for athletic uniforms and swimwear. The ability to dry quickly keeps wearers comfortable and helps reduce the growth of odor-causing bacteria.

Innovation and Technology Advances

The polyester industry continues to evolve with breakthrough technologies and sustainable manufacturing practices.

Smart Fiber Technologies

Recent developments include:

- Moisture-wicking polyester with enhanced performance for athletic wear

- Anti-microbial treatments that prevent odor and bacteria growth

- Shape-memory polyester that returns to original form after stretching

- Conductive polyester fibers for wearable electronics and smart textiles

Automation and Industry 4.0

Modern polyester plants increasingly use:

- Artificial intelligence for quality control and process optimization

- IoT sensors for real-time monitoring of temperature, pressure, and chemical composition

- Robotic systems for material handling and packaging

- Predictive maintenance to reduce downtime and improve efficiency

Bio-Based Innovations

Companies are developing new polyester from renewable sources:

- Plant-based ethylene glycol from corn and sugarcane

- Algae-derived chemicals as petroleum alternatives

- Waste biomass conversion into polyester precursors

- Enzyme-enhanced recycling for better quality recycled polyester

Environmental Impact and Recycling

Polyester production relies on fossil fuels and creates pollution, but recycling can help lower its environmental footprint. Many companies are now reusing plastic bottles and other plastic waste to make recycled polyester, which saves energy and reduces landfill waste.

Carbon Footprint and Energy Use

Manufacturing polyester consumes significant energy resources. Each kilogram of polyester fiber requires about 125 megajoules of energy and produces 27.2 kilograms of CO2 equivalent emissions. However, modern facilities are adopting cleaner technologies:

- Cogeneration systems that capture waste heat for electricity

- Solar and wind power integration in manufacturing facilities

- Process optimization reducing energy consumption by 15-20%

- Heat recovery systems that reuse thermal energy from cooling processes

Water Usage and Treatment

Polyester production requires substantial water for cooling and cleaning processes. Advanced facilities now use:

- Closed-loop water systems that recycle 90% of process water

- Advanced filtration to remove chemicals before discharge

- Zero liquid discharge systems in environmentally sensitive areas

- Rainwater harvesting to reduce freshwater consumption

Polyester Recycling Methods

Polyester can be recycled using two main methods: mechanical recycling and chemical recycling.

Mechanical recycling involves cleaning and shredding polyester items, like clothing or bottles, into flakes. The flakes are then melted and spun into new fibers. This process works best when the polyester is clean and has not been mixed with other materials.

Chemical recycling breaks polyester down to its basic chemicals. This makes it possible to remove dyes and contaminants, so the recycled fiber is similar to new polyester. Chemical recycling can handle mixed or dirty polyester items, but it is more expensive and uses more energy.

Some recycling facilities use a combination of both methods depending on the quality of the waste. Both mechanical and chemical techniques can help reduce the need for new raw materials.

Recycled Polyester and Sustainability

Recycled polyester, often called rPET, is mostly made from recycled PET bottles. Making recycled polyester uses less energy than making new (virgin) polyester.

For example, one study shows recycled polyester production uses about 59% less energy than virgin polyester. This means less carbon dioxide is released into the air. Using recycled polyester also reduces the demand for oil, which is the main ingredient in new polyester.

Recycled polyester is close in quality to virgin polyester. However, tiny plastic fibers, known as microplastics, can still shed from recycled fabrics during washing. This can be harmful to oceans and waterways unless special filters or washing bags are used.

Recycling PET and Plastic Bottles

PET (polyethylene terephthalate) is the main plastic used in water and soda bottles. Plastic bottles labeled with a #1 recycling symbol are usually PET.

Most recycled polyester comes from these bottles. The recycling process involves collecting, sorting, and washing the bottles, then melting them into flakes. These flakes are turned into new fibers for clothing, carpets, or packaging.

Recycling PET bottles keeps plastic out of landfills and the environment. It also helps reduce the need for new resources. Even so, not all PET bottles are recycled, and improving collection rates is important for making recycled polyester more sustainable.

Circular Economy Initiatives

Leading companies are implementing circular economy principles:

- Take-back programs where brands collect used garments for recycling

- Design for recyclability creating products easier to process at end-of-life

- Industrial symbiosis where waste from one process becomes input for another

- Extended producer responsibility making manufacturers accountable for product lifecycle

Recent Developments and Research in Polyester

Polyester production has seen notable advances in technology, research, and efficiency. Focus areas include cleaner manufacturing, improved productivity, and new uses in textile research.

Innovations in Manufacturing

Recent years have brought changes to how polyester is made. Companies are developing new methods to use less energy and reduce pollution. For example, some factories are using recycled PET bottles to make polyester, lowering the need for new crude oil.

Researchers are also improving chemical recycling processes. New techniques allow for breaking polyester down into its building blocks so it can be reused. This helps cut down waste and supports a circular economy in the textile industry.

Cleaner production technologies now use fewer toxic substances. Digital monitoring and automation also help factories reduce errors and produce higher quality polyester.

Recent Breakthrough Technologies:

- Enzyme-catalyzed recycling that works at lower temperatures

- Supercritical CO2 processing for dyeing without water

- 3D printing with polyester filaments for custom applications

- Plasma treatment for improved fiber properties

Strategic Partnerships and Market Developments

In January 2025, Ambercycle and Benma announced a strategic partnership to scale up polyester fiber circularity. This partnership advances the production of Cycora staple fibers, expanding sustainable textile solutions while decreasing the use of virgin resources within the Chinese supply chain.

In June 2024, the textile industry welcomed eased import restrictions of the Quality Control Order (QCO) alongside modifications regarding the certification of imported polyester fibers. This decision enabled exports to occur more freely, greatly benefiting industries within Special Economic Zones.

Productivity and Industry Trends

Productivity in the polyester industry is rising due to better automation and supply chain management. Many plants use advanced machines and computers to speed up production. This makes polyester cheaper to make and buy.

There is a growing demand for recycled polyester, often called rPET. Companies are investing in larger facilities to keep up with orders, especially for the clothing and sportswear industries. The focus is on making more fiber from collected plastic bottles.

The market is also seeing more blends of polyester with other fibers, such as nylon. This leads to new fabrics that have different textures and strengths. As a result, polyester remains a top choice for many manufacturers.

Key Industry Trends:

- Capacity expansion in developing countries

- Vertical integration of supply chains

- Digitalization of production processes

- Sustainability certifications becoming standard requirements

Polyester in Textile Research

Textile researchers are studying ways to improve polyester’s softness, durability, and use in new products. They are testing how to make polyester fabrics more breathable and comfortable for clothing.

Some labs are working on coatings to make polyester resist stains or water. Others are finding ways to use less harmful dyes. Studies also explore mixing polyester with other materials, like nylon, to find better combinations for sports and outdoor wear.

New projects look at how polyester fibers break down in the environment. Scientists hope to create polyester that is easier to recycle or that breaks down faster after use.

Research Focus Areas:

- Biodegradable polyester variants for reduced environmental impact

- Nano-enhanced polyester with improved performance characteristics

- Smart textiles that respond to temperature or moisture

- Medical-grade polyester for healthcare applications

Supply Chain and Global Trade Dynamics

Regional Trade Patterns

The global polyester trade is dominated by several key regions:

Asia-Pacific Export Leaders:

- China: 63% of global exports

- India: 12% of global exports

- South Korea: 8% of global exports

- Taiwan: 5% of global exports

Major Import Markets:

- United States: 28% of global imports

- European Union: 24% of global imports

- Latin America: 15% of global imports

- Middle East: 12% of global imports

Trade Policies and Regulations

Recent trade developments have significantly impacted the polyester market:

Tariff Impacts:

- US tariffs on Chinese polyester textiles have led to production shifts

- Anti-dumping duties in various countries affecting pricing

- Regional trade agreements creating preferential access

Environmental Regulations:

- EU’s proposed ban on certain chemical treatments

- California’s microplastic legislation affecting washing requirements

- Extended Producer Responsibility laws in multiple countries

Supply Chain Resilience

The COVID-19 pandemic highlighted vulnerabilities in polyester supply chains, leading to new strategies:

- Diversification of supplier bases beyond China

- Near-shoring production closer to end markets

- Strategic inventory management for critical materials

- Digital supply chain tracking for better visibility

Economic Analysis and Market Forecasting

Price Volatility and Market Drivers

Polyester prices fluctuate based on several key factors:

Primary Price Drivers:

- Crude oil prices: Direct impact on raw material costs

- Supply-demand balance: Global capacity vs consumption

- Currency fluctuations: Affecting international trade

- Energy costs: Major component of production expenses

Regional Price Variations (2025):

| Region | Price per kg (USD) | Key Factors |

|---|---|---|

| China | $0.95-1.05 | Low labor, high capacity |

| India | $1.10-1.20 | Growing domestic demand |

| USA | $1.35-1.50 | Higher labor and compliance costs |

| Europe | $1.40-1.55 | Environmental regulations |

Investment Trends and Capacity Expansion

Major capacity expansions planned for 2025-2030:

Asia-Pacific:

- India: 3.2 million tonnes additional capacity

- Vietnam: 1.8 million tonnes new plants

- Indonesia: 1.5 million tonnes expansion

Other Regions:

- Middle East: 2.1 million tonnes (leveraging cheap feedstock)

- USA: 0.8 million tonnes (reshoring initiatives)

- Europe: 0.6 million tonnes (sustainable production focus)

Market Forecast Through 2030

Industry analysts project continued growth driven by:

- Emerging market demand: Rising middle-class consumption

- Technical textiles growth: Automotive and industrial applications

- Sustainability requirements: Driving recycled polyester demand

- Population growth: Increasing global fiber consumption per capita

Projected Market Size:

- 2025: $111-130 billion

- 2027: $145-165 billion

- 2030: $180-210 billion

Regulatory Environment and Compliance

International Standards and Certifications

The polyester industry operates under various regulatory frameworks:

Safety and Health Standards:

- OSHA regulations for worker safety in manufacturing

- REACH compliance for chemical safety in Europe

- FDA approvals for food-contact applications

- Medical device standards for healthcare uses

Environmental Compliance:

- ISO 14001 environmental management systems

- Carbon footprint reporting requirements

- Water discharge permits and monitoring

- Waste management regulations for production residues

Emerging Regulations

New regulations affecting the industry include:

Microplastic Legislation:

- Requirements for washing machine filters

- Labeling of synthetic textile products

- Research funding for microplastic reduction

Extended Producer Responsibility:

- Manufacturer responsibility for product end-of-life

- Collection and recycling system requirements

- Financial contributions to waste management

Chemical Safety Updates:

- Restrictions on certain catalysts and additives

- Enhanced worker protection requirements

- Safer alternative development mandates

Future Outlook and Industry Predictions

Technology Roadmap 2025-2030

Near-term Developments (2025-2027):

- Enhanced recycling technologies achieving 95%+ quality retention

- Bio-based feedstock reaching 15% of total raw materials

- AI-driven quality control reducing defects by 80%

- Energy efficiency improvements cutting consumption by 25%

Medium-term Innovations (2027-2030):

- Fully biodegradable polyester for selected applications

- Closed-loop manufacturing with zero waste discharge

- Smart fiber integration with electronic components

- Molecular recycling at commercial scale

Market Transformation Drivers

Sustainability Imperative: The industry faces increasing pressure to address environmental concerns:

- Consumer demand for sustainable products growing 15% annually

- Corporate sustainability commitments driving procurement changes

- Regulatory requirements becoming more stringent globally

- Investment flows favoring environmentally responsible companies

Digital Transformation: Industry 4.0 technologies are reshaping manufacturing:

- Predictive maintenance reducing downtime by 30-50%

- Digital twins optimizing production processes

- Blockchain tracking ensuring supply chain transparency

- Automated quality control improving consistency

Changing Consumer Preferences: Market dynamics are shifting due to:

- Performance requirements in athletic and outdoor wear

- Customization demand for personalized products

- Transparency expectations about production methods

- Circular economy participation through take-back programs

Regional Market Evolution

Asia-Pacific: Expected to maintain dominance but with changing dynamics:

- China: Focus shifting from volume to value-added products

- India: Rapid capacity expansion targeting domestic and export markets

- Southeast Asia: Emerging as cost-competitive manufacturing base

- Japan/South Korea: Leading in high-tech and specialty applications

North America and Europe: Focusing on sustainability and high-value applications:

- Reshoring initiatives bringing production closer to markets

- Recycling infrastructure development accelerating

- Premium product positioning leveraging sustainability credentials

- Regulatory leadership setting global standards

Conclusion

The polyester manufacturing industry stands at a critical juncture in 2025, balancing tremendous growth opportunities with mounting environmental and social responsibilities. As the global market approaches $130 billion in value and continues expanding at 7-8% annually, the industry is undergoing fundamental transformations that will shape its future for decades to come.

Key Industry Takeaways

Market Dominance and Growth: Polyester has firmly established itself as the world’s most important synthetic fiber, comprising 54% of global fiber production. With 63 million tonnes produced annually and projections reaching 85+ million tonnes by 2034, polyester’s role in the global textile ecosystem is undeniable. The industry’s ability to produce high-quality, durable, and cost-effective materials has made it indispensable across applications from basic apparel to advanced technical textiles.

Technological Innovation: The manufacturing process has evolved significantly from basic polymerization to sophisticated, automated production systems. Modern facilities achieve remarkable efficiency gains through AI-driven quality control, energy recovery systems, and advanced material science. The development of bio-based feedstocks, enzyme-enhanced recycling, and smart fiber technologies demonstrates the industry’s commitment to innovation while addressing environmental concerns.

Regional Competition Dynamics: The competitive landscape is shifting as China maintains its production leadership while India rapidly expands capacity through government support and strategic investments. This Asia-Pacific duopoly is pressuring smaller producers globally while creating opportunities for specialization in high-value applications. Western markets are focusing on sustainability, technical innovation, and reshoring initiatives that prioritize quality and environmental compliance over pure cost advantages.

Environmental Evolution: Perhaps the most significant transformation involves the industry’s environmental footprint. With production consuming 125 MJ/kg and generating 27.2 kg CO2 eq/kg of fabric, manufacturers are implementing comprehensive sustainability strategies. Recycled polyester production now uses 59% less energy than virgin fiber, while closed-loop water systems and renewable energy adoption are becoming standard practices. However, challenges remain around microplastic pollution and end-of-life management.

Strategic Recommendations

For Manufacturers:

- Invest in recycling technologies to capture the growing rPET market, which offers both environmental benefits and cost advantages

- Implement digital transformation initiatives to improve efficiency, reduce waste, and enhance quality control

- Develop regional supply chain resilience to mitigate risks from trade disruptions and geopolitical tensions

- Focus on specialty applications where technical performance and sustainability command premium pricing

For Brands and Retailers:

- Integrate sustainability metrics into sourcing decisions, considering lifecycle impacts beyond initial cost

- Develop take-back programs to capture value from used polyester products while supporting circular economy goals

- Invest in consumer education about proper care and disposal of polyester products to maximize lifespan and recyclability

- Partner with innovative suppliers developing bio-based and biodegradable alternatives for appropriate applications

For Policymakers:

- Harmonize international standards for recycled content, chemical safety, and environmental performance

- Incentivize research and development in sustainable polyester technologies through grants and tax policies

- Develop infrastructure for textile collection, sorting, and recycling to support circular economy transition

- Balance trade policies to encourage innovation while maintaining fair competition

For Investors:

- Prioritize companies with strong sustainability credentials and circular economy business models

- Support technology development in areas like molecular recycling, bio-based feedstocks, and fiber-to-fiber recycling

- Consider regional diversification to capture growth in emerging markets while supporting resilience initiatives

- Evaluate ESG performance as a key factor in long-term competitiveness and risk management

Future Outlook

The polyester industry of 2030 will likely be dramatically different from today’s landscape. Successful companies will be those that embrace sustainability not as a compliance requirement but as a competitive advantage. The integration of circular economy principles, advanced recycling technologies, and bio-based materials will become standard practice rather than experimental initiatives.

Consumer awareness and regulatory pressure will continue driving demand for transparency and environmental responsibility throughout the supply chain. Companies that invest in these capabilities now will be best positioned to capture market share in an increasingly conscious marketplace.

The technological convergence of artificial intelligence, biotechnology, and materials science promises breakthrough innovations that could revolutionize polyester manufacturing. From enzyme-enhanced recycling that maintains virgin-quality properties to smart fibers with embedded functionality, the next decade will see polyester evolve from a commodity product to a sophisticated material platform.

The Path Forward: The polyester industry’s future success depends on its ability to maintain the cost-effectiveness and performance advantages that drove its initial growth while addressing environmental and social challenges that threaten its long-term sustainability. Companies, governments, and consumers must collaborate to create systems that support innovation, reward responsible practices, and enable the transition to a truly circular polyester economy.

As we look toward 2030 and beyond, polyester manufacturing will continue playing a crucial role in meeting global textile demand. However, its contribution will be measured not just in volume and value, but in its ability to support sustainable development goals and contribute to a more environmentally responsible global economy. The choices made today by industry leaders, policymakers, and consumers will determine whether polyester becomes a model for sustainable manufacturing or remains a source of environmental concern.

The industry stands ready for this transformation, with the technological capabilities, market demand, and regulatory framework aligning to support fundamental change. Success will require unprecedented levels of collaboration, innovation, and commitment to sustainability principles across the entire value chain.

Frequently Asked Questions (FAQs)

General Questions

What is the difference between polyester and cotton?

Polyester is a synthetic fiber made from petroleum-based chemicals, while cotton is a natural fiber from cotton plants. Polyester is more durable, wrinkle-resistant, and quick-drying, but cotton is more breathable and absorbent.

How long does polyester fabric last?

High-quality polyester can last 5-10 years or more with proper care. Its durability depends on the manufacturing quality, fabric weight, and how it’s used and maintained.

Is polyester safe to wear?

Yes, polyester is safe for clothing when manufactured according to industry standards. However, some people with sensitive skin may prefer natural fibers, and polyester is less breathable than cotton.

Manufacturing Questions

How much does it cost to set up a polyester manufacturing plant?

A modern polyester manufacturing facility typically requires $50-200 million in initial investment, depending on capacity and technology level. Small-scale operations may start with $10-25 million.

What countries produce the most polyester?

China leads with 63 million tonnes annually (54% of global production), followed by India, South Korea, Taiwan, and the United States.

How much energy does polyester production consume?

Polyester manufacturing requires approximately 125 MJ per kilogram of fiber produced, making it more energy-intensive than cotton but less than nylon.

Environmental Questions

Is recycled polyester better for the environment?

Yes, recycled polyester uses 59% less energy than virgin polyester and diverts plastic waste from landfills. However, it still sheds microplastics and isn’t biodegradable.

Can polyester be composted?

No, conventional polyester cannot be composted as it’s not biodegradable. Some new bio-based polyester variants are being developed with better end-of-life properties.

How many plastic bottles make one polyester shirt?

Typically, it takes about 25-30 recycled plastic bottles to make one polyester t-shirt, depending on the shirt’s weight and size.

Care and Maintenance Questions

Can you iron polyester fabric?

Yes, but use low to medium heat settings. Polyester can melt at high temperatures, so always check the care label and test on a hidden area first.

Does polyester shrink in the dryer?

Polyester rarely shrinks because it’s heat-set during manufacturing. However, high heat can cause some shrinkage and may damage the fibers.

How do you remove stains from polyester?

Most stains can be removed with cold water and mild detergent. For stubborn stains, use oxygen bleach (never chlorine bleach) or specialized stain removers designed for synthetic fabrics.