Discover everything about this ancient, sustainable material from its 6,500-year history to modern applications

Table of Contents

- What is Wool Felt Fabric?

- Is Wool Felt the Same as Felt Fabric?

- The Ancient History of Wool Felt

- How Wool Felt is Made

- Types and Quality Levels

- Properties and Characteristics

- Uses and Applications

- Sustainability and Environmental Impact

- Comparing Wool Felt to Other Fabrics

- Care and Maintenance Guide

- How to Choose Quality Wool Felt

- Why Wool Felt is Expensive

- Frequently Asked Questions

- Conclusion

What is Wool Felt Fabric?

Wool felt fabric is a special type of textile that stands out from most other fabrics you know. Unlike regular wool fabric that’s woven or knitted, wool felt is made by matting and pressing wool fibers together using heat, moisture, and pressure. This creates a dense, sturdy material without any weaving or knitting involved.

Think of it like this: when you accidentally throw a merino wool sweater in the hot wash and it comes out smaller and denser, that’s felting in action. But wool felt fabric is made intentionally through a controlled process that creates a smooth, uniform material.

Quick Definition: Wool felt is a non-woven fabric created by compressing wool fibers together. The natural scales on wool fibers lock together when exposed to heat, moisture, and agitation, creating a solid piece of fabric without any threads or weaving.

Wool felt has some unique qualities that make it special. It doesn’t fray when you cut it, holds its shape well, and has natural insulation properties. It’s also one of the oldest fabrics known to humans, with evidence of its use dating back over 6,500 years.

Is Wool Felt Real Wool?

Yes, authentic wool felt is made from real sheep wool. The best quality wool felt comes from fine wool breeds, particularly Merino sheep, which produce soft, fine fibers perfect for felting. However, not all felt labeled as “wool felt” contains 100% wool.

Here’s what you need to know:

- 100% Pure Wool Felt: Made entirely from natural wool fibers, usually Merino. This is the highest quality and most expensive option.

- Wool Blend Felt: Contains 20-40% wool mixed with rayon (viscose) or other fibers. Still good quality but more affordable.

- Labeled Confusion: Some products say “wool felt” but contain very little actual wool. Always check the fiber content.

When shopping for wool felt, look for clear labeling that states the exact wool percentage. Certifications like Oeko-Tex Standard 100 can also indicate quality and safety standards.

Is Wool Felt the Same as Felt Fabric?

No, they’re not exactly the same thing, though people often use these terms interchangeably. Let me clear up the confusion.

“Felt fabric” is an umbrella term that includes all types of felt, regardless of what material it’s made from. Wool felt is just one specific type within this larger category.

What is the Difference Between Felt and Wool Felt?

The main difference comes down to the material used:

Felt Fabric (General Term): Can be made from various materials including wool, acrylic, polyester, rayon, or blends. When someone says “felt fabric,” they could mean any type.

Wool Felt (Specific Type): Made specifically from wool fibers or wool blends. It’s a premium type of felt known for its natural properties and durability.

| Felt Type | Material | Quality Level | Best For |

|---|---|---|---|

| 100% Wool Felt | Pure wool fibers | Premium | Heirloom crafts, toys, quality garments |

| Wool Blend Felt | 20-40% wool + rayon | Good | Most crafts, accessories, general use |

| Acrylic Felt | Synthetic acrylic fibers | Budget | Kids’ crafts, temporary projects |

| Polyester Felt | Polyester fibers | Budget | Industrial uses, decorations |

Think of it like this: “Fabric” is the general term, while “cotton fabric” is a specific type. Similarly, “felt fabric” is general, while “wool felt” is specific.

When people search for “felt,” they might be looking for cheap craft felt from the dollar store or premium wool felt for serious projects. Understanding this difference helps you choose the right material and avoid disappointment when your $2 synthetic felt doesn’t perform like $15 wool felt.

The Ancient History of Wool Felt

Wool felt fabric representing its ancient history and traditional use

Wool felt holds the distinction of being possibly the world’s first fabric. Before humans figured out how to spin yarn and weave it, they discovered that wool fibers naturally mat together to create a usable textile. This accidental discovery changed human history.

Legends and Origins

Many cultures have origin stories about felt. One Christian legend tells of Saint Clement and Saint Christopher fleeing persecution. They stuffed their sandals with wool to prevent blisters, and by the end of their journey, the constant pressure, moisture from sweat, and friction had turned the wool into felt socks.

While we can’t verify these legends, archaeological evidence tells us the real story. The oldest felt artifacts have been found in Siberian tombs dating back to between the 7th and 2nd century BCE. These weren’t simple pieces either. They featured complex dyed patterns, detailed stitching, and showed amazing craftsmanship for their time. Learn more about the history of felt on Wikipedia.

Nomadic Cultures and Felt

Central Asian nomadic peoples, particularly Mongols, Kazakhs, and Kyrgyz tribes, perfected the art of feltmaking. For them, felt wasn’t just a fabric; it was survival. Living on the treeless Eurasian steppes with harsh winters and scorching summers, they needed materials that could withstand extreme conditions.

These nomads used wool felt to create:

- Yurts (Gers): The traditional portable homes were covered with thick felt for insulation

- Clothing: Coats, hats, and boots that provided warmth without excessive weight

- Rugs and floor coverings: Decorated felt rugs that added comfort and beauty

- Horse blankets and saddle pads: Protecting their most valuable animals

- Bags and containers: For carrying and storing goods

The traditional feltmaking methods used by these cultures are still practiced today, passed down through generations. The process involves laying out wool, wetting it with soapy water, and rolling it repeatedly until the fibers bond together.

Felt in Different Cultures

As feltmaking spread across Europe and Asia, different cultures adopted and adapted the technique. In ancient Greece and Rome, felt was used for hats, shoes, and military equipment. Medieval Europeans wore felt hats that indicated social status. By the 18th and 19th centuries, beaver felt top hats became a fashion symbol for gentlemen in the Western world.

The hat-making industry actually drove some interesting historical events. The high demand for beaver pelts for felt hats was one factor that pushed European exploration and colonization of North America, where beavers were abundant.

How Wool Felt is Made

Step by step visual guide explaining how wool felt is made

Making wool felt is a process that takes advantage of wool’s natural properties. The scales on wool fibers act like tiny hooks that catch and lock together when conditions are right. Here’s how it works:

The Wet Felting Process

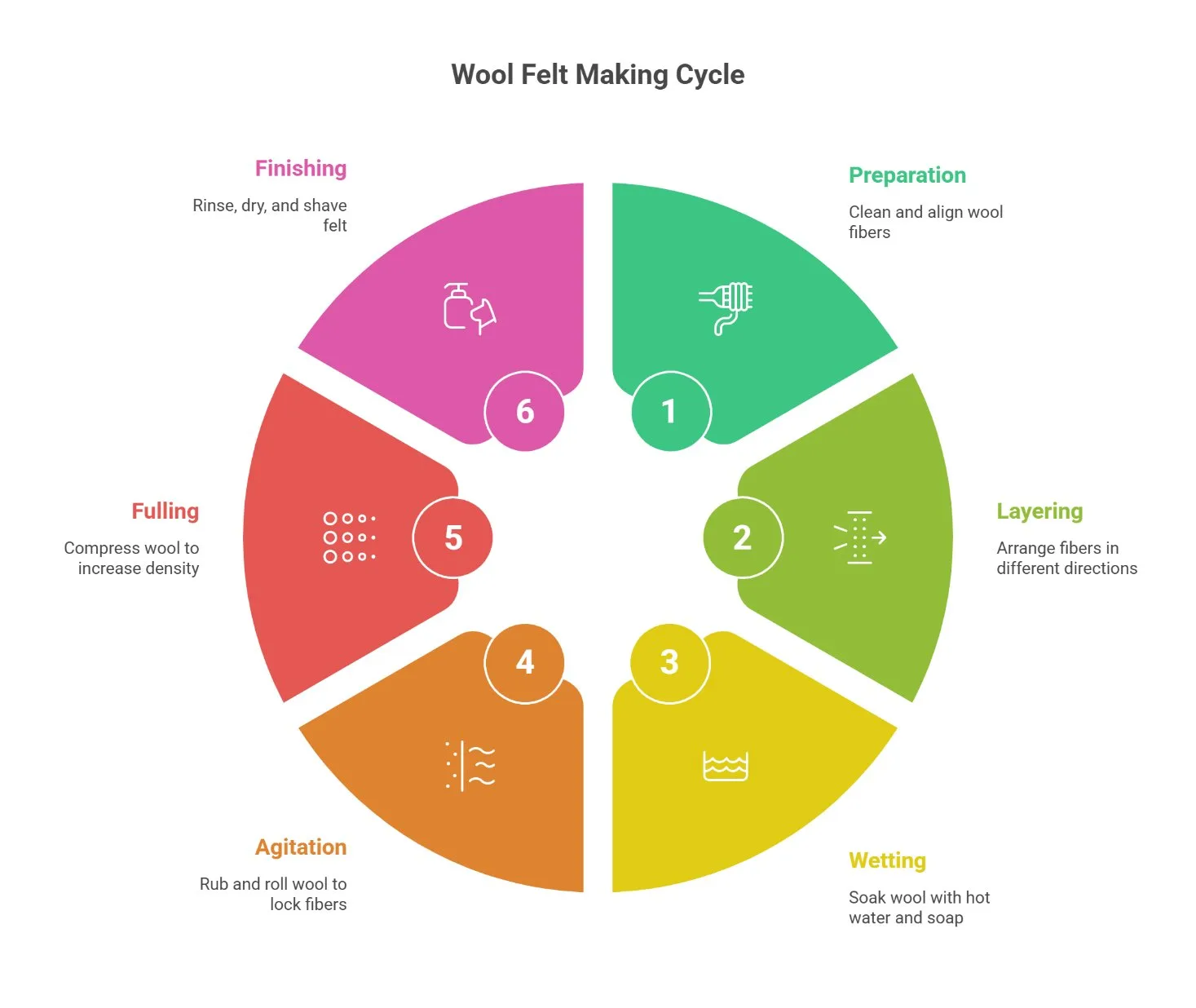

This is the traditional method that’s been used for thousands of years:

- Preparation: Raw wool is cleaned to remove dirt, oils, and debris. Then it’s carded, which means passing it through rollers with fine teeth that align the fibers.

- Layering: The carded wool is laid out in thin layers, with each layer going in a different direction. This creates strength in all directions.

- Wetting: The wool is soaked with hot water and soap. The soap helps the fibers slip past each other initially.

- Agitation: The wet wool is rubbed, rolled, and pressed repeatedly. This friction causes the scales on the wool fibers to open and lock together.

- Fulling: Continued rolling and pressing makes the felt denser and stronger.

- Finishing: The felt is rinsed, dried, and sometimes shaved to create an even surface.

Needle Felting Process

Modern industrial production often uses needle felting, where special barbed needles punch through layers of wool, tangling the fibers together mechanically. This method is faster and can create felt of varying densities and thicknesses.

Both methods create a non-woven fabric, which is what makes felt unique. Unlike woven fabrics that can unravel if a thread is cut, felt maintains its structure when cut because the fibers are locked together throughout the entire piece.

Can You Sew Wool Felt?

Yes, absolutely! Wool felt is actually wonderful to sew with. Since it doesn’t fray, you don’t need to finish the edges with hems or serging. You can cut shapes and sew them directly, which makes it perfect for appliqué work, crafts, and decorative projects.

When sewing wool felt:

- Use a regular sewing needle (size 80/12 or 90/14 works well)

- All-purpose thread is fine for most projects

- You can hand sew or machine sew equally well

- No need to backstitch at edges since felt won’t unravel

- Sharp scissors give the cleanest cuts

Many crafters prefer wool felt over synthetic felt for sewing because it’s easier to pierce with a needle and holds stitches better without pulling or distorting.

Types and Quality Levels of Wool Felt

Not all wool felt is created equal. Understanding the different types and quality levels helps you choose the right felt for your project and budget.

100% Pure Merino Wool Felt

This is the top tier of wool felt. Made entirely from Merino sheep wool, it offers the softest feel and best durability. Merino fibers are finer than regular wool, which creates a smoother, more uniform felt.

Characteristics:

- Incredibly soft and smooth texture

- Won’t pill or fuzz with normal use

- Rich, even colors that are lightfast

- Dense and durable

- Natural water resistance

- Best for heirloom projects and items that will be handled frequently

Premium brands to look for: A Child’s Dream, Benzie Design’s Bellwether line, The Felt Pod, and Felt On The Fly. These are often made in Europe from Australian or New Zealand Merino wool and meet Oeko-Tex Standard 100 certification.

Wool Blend Felt

This middle-ground option contains 20-40% wool (usually Merino) mixed with rayon or viscose. Rayon is a semi-synthetic fiber made from wood pulp, which gives it some natural qualities while keeping costs lower.

Why blend? The combination creates felt that’s:

- More affordable than 100% wool

- Still soft and workable

- Available in more colors

- Durable enough for most projects

- Good for projects where you need larger quantities

Be careful with labeling though. Some products marketed as “wool felt” contain as little as 10-15% wool. Always check the fiber content. A good quality blend should have at least 20% wool.

Popular wool blend brands include Benzie Design’s regular line, National Nonwovens, and many European manufacturers. These typically come in 1-2mm thickness.

Is Wool Felt 100% Wool?

Not always. This is where confusion happens. The term “wool felt” doesn’t automatically mean 100% wool content. Here’s what to watch for:

- “100% Wool Felt” or “Pure Wool Felt”: Should be all wool, no blends

- “Wool Felt”: Could be anywhere from 10-100% wool. Check the label!

- “Premium Wool Felt”: Marketing term that doesn’t guarantee wool percentage

- “Merino Wool Felt”: Good indication of quality, but check if it’s 100% or a blend

The quality difference is real. Pure wool felt will outlast blends, maintain its appearance longer, and perform better in terms of natural properties like water resistance and fire retardance.

Specialty Wool Felts

Beyond the basic categories, you’ll find specialty options:

- Fur Felt: Made from animal fur like beaver or rabbit. Extremely fine and used for high-end hats.

- Printed Wool Felt: Features patterns or designs printed on the surface

- Glitter or Metallic Wool Felt: Has decorative elements bonded to the surface

- Thick Wool Felt: 3mm or more, used for structural projects

- Designer Wool Felt: From brands like Kvadrat or Maharam, used for upholstery and design applications

Understanding Quality Indicators

When evaluating wool felt quality, look for:

- Micron Count: Measures fiber fineness. Lower numbers mean softer felt. Merino ranges from 15-24 microns. Regular wool is 25-40 microns.

- Density: Quality felt should feel substantial, not thin or flimsy. Hold it up to light; it shouldn’t be see-through.

- Thickness Consistency: Good felt has even thickness throughout. Poor quality may have thin spots.

- Color Evenness: Quality felt has uniform color with no streaks or light spots.

- Surface Smoothness: Premium felt has a smooth surface without excessive fuzz or rough patches.

- Edge Quality: When cut, edges should be clean and crisp, not fuzzy or loose.

Properties and Characteristics of Wool Felt

Key properties and characteristics of wool felt explained visually

Wool felt has unique properties that make it stand out from other fabrics. Understanding these characteristics helps explain why it’s been valued for thousands of years.

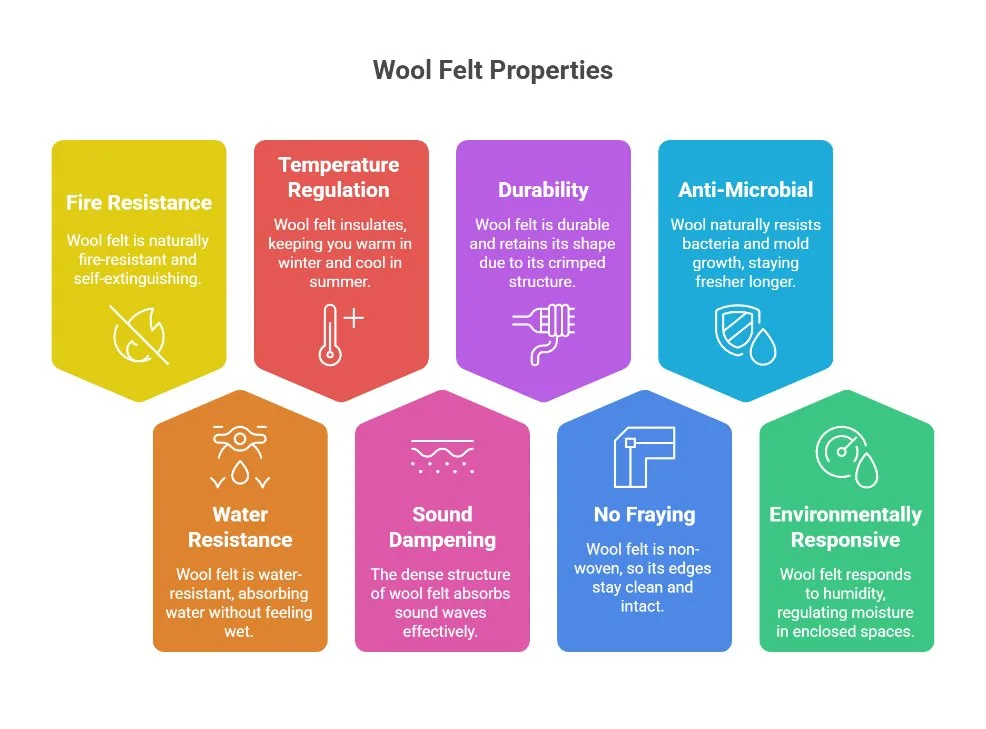

Fire Resistance

One of wool felt’s most impressive properties is its natural fire resistance. Wool requires more oxygen than is available in air to ignite, making it self-extinguishing. If a flame does touch wool felt, it will smolder but not burst into flames like synthetic materials.

This makes wool felt useful for applications where fire safety matters, like:

- Theater curtains and stage equipment

- Children’s toys and bedding

- Protective equipment

- Home insulation

For more information on fire-resistant properties, check out our guide on fire-resistant fabrics.

Is Wool Felt Waterproof?

Wool felt isn’t completely waterproof, but it is naturally water-resistant. Here’s the interesting part: wool can absorb up to 30% of its weight in water without feeling wet to the touch. The water gets trapped inside the fibers while the surface remains relatively dry.

This property makes wool felt:

- Naturally moisture-wicking

- Resistant to light rain and snow

- Good for outdoor applications

- Slow to become saturated

However, if you need truly waterproof material, wool felt isn’t the answer. Heavy rain will eventually soak through. For water-repellent properties in outdoor gear, manufacturers often treat wool felt with additional coatings. Learn more about water-resistant fabrics and treatments.

Temperature Regulation

Wool felt is an excellent insulator. The dense matted structure traps tiny pockets of air, which prevents heat transfer. This means wool felt keeps you warm in winter, but here’s the cool part (literally): it also helps keep you cool in summer.

How? Wool fibers can absorb moisture vapor from your skin, which creates a cooling effect through evaporation. This breathability prevents that clammy feeling you get with synthetic materials.

Sound and Vibration Dampening

The dense structure of wool felt makes it great at absorbing sound waves. This is why you’ll find wool felt used in:

- Piano hammers (the parts that strike the strings)

- Recording studios for acoustic treatment

- Automotive interiors to reduce road noise

- Under rugs to dampen footsteps

- Industrial machinery to reduce vibration

Durability and Shape Retention

Quality wool felt is remarkably durable. The interlocked fibers resist tearing and wear. Wool also has natural elasticity due to its crimped structure, which means felt can compress and then spring back to its original shape thousands of times without losing integrity.

This resilience makes wool felt perfect for items that get heavy use, like wool and cashmere accessories, shoe insoles, and padding.

No Fraying or Unraveling

Since wool felt is non-woven, it doesn’t have threads that can come loose. When you cut it, the edges stay clean and intact. You don’t need to hem, serge, or otherwise finish the edges. This makes it beginner-friendly for sewing and crafts.

Anti-Microbial Properties

Wool naturally resists bacteria and mold growth. The fiber structure makes it difficult for microorganisms to thrive, which means wool felt stays fresher longer and is less likely to develop odors. This is one reason wool felt is used in applications where hygiene matters.

Environmentally Responsive

Wool felt responds to humidity in the environment. It can absorb moisture when humidity is high and release it when humidity drops. This natural buffering helps regulate moisture in enclosed spaces, which is why wool felt was traditionally used in homes and portable dwellings like yurts.

What is Wool Felt Fabric Used For?

Wool felt fabric used for crafts, decor, and functional products

Wool felt’s unique properties make it useful for an amazing range of applications. Let’s look at how this versatile material is used today.

Crafting and Art Projects

This is probably the most common use most people think of. Wool felt is a favorite among crafters because it’s easy to work with and creates professional-looking results.

Popular craft uses include:

- Toys and Dolls: Stuffed animals, finger puppets, and soft toys. Wool felt is safe for children and holds up to play.

- Ornaments: Holiday decorations, seasonal items, and gift tags. The material doesn’t fray, so cut shapes look clean and finished.

- Appliqué and Embroidery: Adding decorative elements to fabric projects. Wool felt creates nice dimension and texture.

- Jewelry: Beads, pendants, and brooches made by needle felting or cutting shapes.

- Home Decor: Coasters, trivets, placemats, and wall hangings. Wool felt adds warmth and texture to spaces.

- Needle Felting: Using barbed needles to sculpt wool into 3D figures and artwork.

Try our interactive Fabric Comparison Tool to see how wool felt compares to other craft fabrics.

Fashion and Accessories

Wool felt has a long history in fashion, particularly for accessories that benefit from its structure and warmth.

Common fashion uses:

- Hats: From classic fedoras to winter beanies. Felt hats can be steamed and shaped, then hold their form.

- Bags and Purses: Tote bags, clutches, and handbags. Wool felt provides structure without needing extra support.

- Slippers and Shoes: Comfortable house shoes and boot liners. The insulation keeps feet warm.

- Scarves and Wraps: Decorative neckwear that provides warmth without bulk.

- Belts and Headbands: Accessories that need to hold their shape.

- Patches and Embellishments: Adding design elements to garments.

If you’re interested in wool fabrics for fashion, explore our guides on wool tweed and boiled wool fabrics.

Industrial and Technical Applications

Many people don’t realize wool felt has serious industrial uses. Its unique properties make it perfect for technical applications.

Industrial applications include:

- Musical Instruments: Piano hammers, drum mallets, and cymbal felts. The density provides the right touch and sound dampening.

- Automotive Industry: Sound dampening panels, vibration reducers, and polishing pads. Helps make cars quieter and absorbs road vibration.

- Machinery: Gaskets, seals, and bearing pads. Wool felt can be impregnated with oils or other substances for specific uses.

- Polishing: Buffing wheels and polishing pads for metalwork, jewelry, and woodworking. Wool felt holds polishing compounds well.

- Filtration: Air and liquid filters in various industries. The dense fiber structure traps particles effectively.

- Insulation: Thermal and acoustic insulation in buildings. Natural, breathable, and effective.

- Green Roofs: As a growing medium and drainage layer for rooftop gardens. The water retention and drainage properties are perfect for this application.

Home and Interior Design

Designers love wool felt for bringing texture and warmth to spaces. High-end felt from manufacturers like Kvadrat and Maharam is used in:

- Upholstery for furniture

- Wall panels for acoustic control

- Window treatments and curtains

- Decorative pillows and throws

- Area rug pads and backing

- Room dividers and partitions

Educational and Children’s Items

Wool felt’s safety and tactile qualities make it great for children:

- Flannel board pieces for storytelling

- Educational toys and counting materials

- Quiet books and activity pages

- Waldorf school craft materials

- Baby mobiles and nursery decor

For parents looking for safe materials, check out our guide on best fabrics for newborn clothing.

Sustainability and Environmental Impact

Visual overview of wool felt sustainability and environmental impact

In today’s world where fast fashion and sustainability are hot topics, wool felt stands out as an environmentally responsible choice. Let’s look at why.

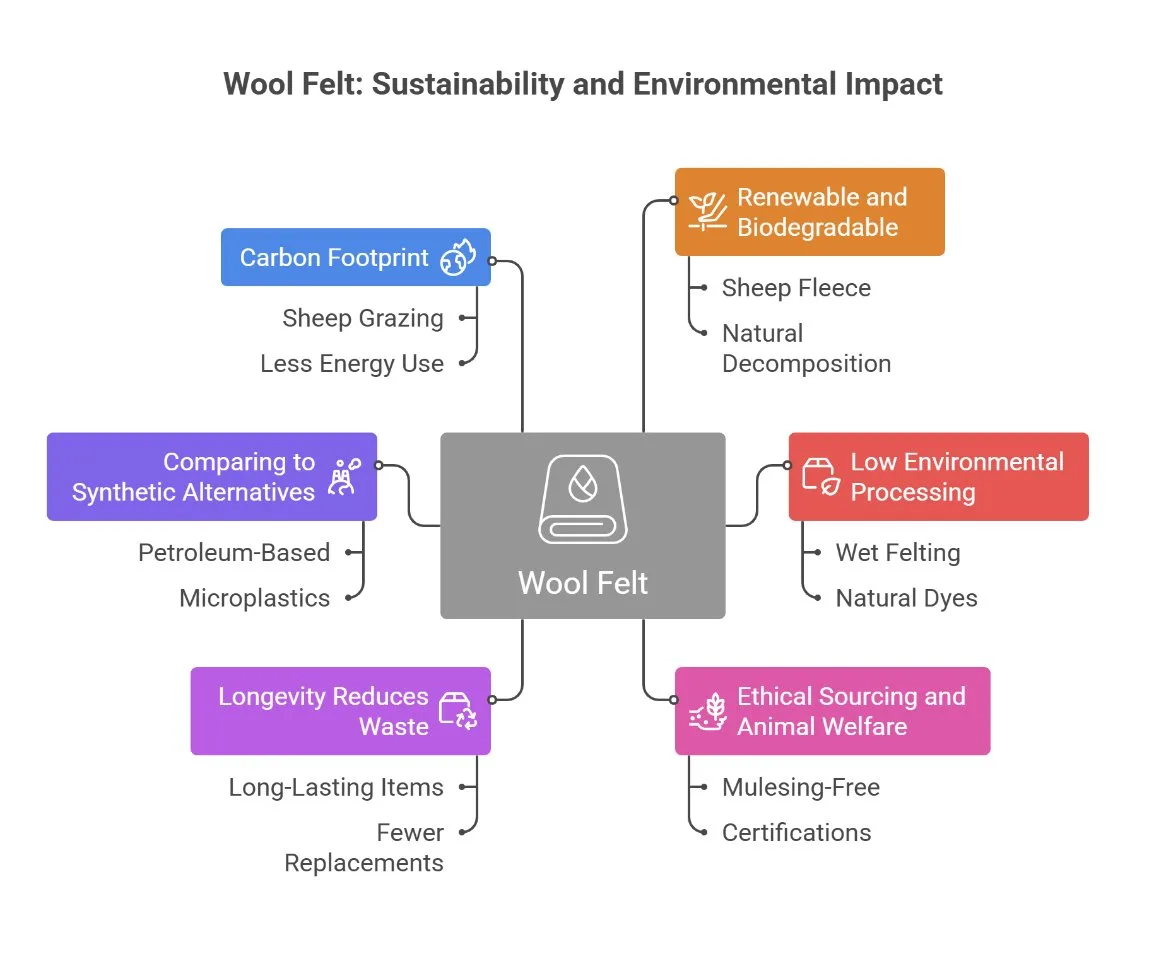

Renewable and Biodegradable

Wool is a renewable resource. Sheep produce a new fleece every year, and with proper animal husbandry, this can continue for the sheep’s lifetime. Unlike synthetic fibers derived from petroleum, wool doesn’t depend on finite fossil fuel resources. The International Wool Textile Organisation provides comprehensive information about sustainable wool production practices.

When wool felt eventually reaches the end of its useful life, it biodegrades naturally. In soil, wool will decompose within a few years, returning nutrients to the earth. Compare this to synthetic felt, which can take hundreds of years to break down and releases microplastics as it does.

Low Environmental Processing

The felting process is relatively simple and doesn’t require harsh chemicals. Traditional wet felting uses water, soap, and physical agitation. While modern commercial production may use some processing chemicals, it’s far less intensive than the production of synthetic fabrics.

Quality wool felt manufacturers increasingly use:

- Natural dyes or low-impact dyes

- Biodegradable soaps for processing

- Water recycling systems

- Solar or renewable energy for production facilities

Ethical Sourcing and Animal Welfare

The ethics of wool production matter. Look for wool felt that’s certified mulesing-free. Mulesing is a painful practice used on some sheep farms that animal welfare advocates oppose. Many quality felt producers now source wool from farms with high animal welfare standards.

Certifications to look for:

- Oeko-Tex Standard 100: Ensures the felt is free from harmful chemicals

- GOTS (Global Organic Textile Standard): For organic wool felt

- Responsible Wool Standard (RWS): Addresses animal welfare and land management

- ZQ Merino: Ensures ethical and environmental standards

Longevity Reduces Waste

One of the most sustainable things about quality wool felt is how long it lasts. A well-made wool felt item can last for decades with proper care. This longevity means fewer replacements and less waste over time.

Consider a wool felt hat that lasts 20 years versus a synthetic felt hat that needs replacing every 2 years. Even if the wool felt costs three times as much initially, you’re creating less waste and using fewer resources over time.

Comparing to Synthetic Alternatives

Synthetic felt made from acrylic or polyester has these environmental issues:

- Petroleum-based production with high carbon footprint

- Releases microplastics when washed

- Takes centuries to decompose

- Often treated with formaldehyde or other chemicals

- Production creates more pollution

That said, some synthetic felt is now made from recycled plastic bottles (rPET), which is better than virgin polyester. However, it still has the microplastic and non-biodegradable issues.

Carbon Footprint

Wool felt has a relatively low carbon footprint compared to most synthetic fabrics. Sheep grazing can even have positive environmental effects when managed properly, as grasslands sequester carbon. The processing of wool into felt uses less energy than synthetic fiber production.

For readers interested in sustainable fabric choices, our article on natural vs synthetic fabrics provides more comparison information.

Comparing Wool Felt to Other Fabrics

Understanding how wool felt stacks up against other materials helps you make informed choices for your projects.

Wool Felt vs Regular Wool Fabric

Both start with wool fibers, but the manufacturing process creates very different results.

Wool felt vs regular wool fabric highlighting structure and finish differences

| Characteristic | Wool Felt | Woven Wool Fabric |

|---|---|---|

| Structure | Non-woven, matted fibers | Woven threads in a pattern |

| Edges | Don’t fray when cut | Fray and need finishing |

| Drape | Stiff, holds shape | Soft, flows naturally |

| Elasticity | Minimal stretch | Some stretch, especially on bias |

| Best Uses | Crafts, structure, padding | Garments, draping, fashion |

| Thickness Options | Usually uniform thickness | Wide range from sheer to heavy |

Learn more about traditional woven wool in our guides to wool flannel and wool gabardine.

Wool Felt vs Boiled Wool

These two are often confused because both involve wool and a felting-like process. However, they’re quite different.

Boiled wool vs wool felt showing distinct manufacturing and texture differences

Wool Felt: Starts with raw wool fibers that are never spun or woven. The fibers are matted directly together.

Boiled Wool (Felted Wool): Starts as woven or knitted wool fabric that’s then shrunk and felted through washing in hot water. The original fabric structure is still visible, even though it’s now denser.

Boiled wool typically:

- Has more drape than wool felt

- Still shows some of the original weave or knit pattern

- Is softer and more flexible

- Works better for clothing

- Can still have slight fraying, though much less than unwashed wool

For more details, read our complete guide to boiled wool fabric.

Wool Felt vs Acrylic Felt

This comparison matters because many people first encounter felt through cheap acrylic craft felt, then wonder why “better” felt costs so much more.

Wool felt vs acrylic felt comparison highlighting natural and synthetic differences

| Feature | Wool Felt | Acrylic Felt |

|---|---|---|

| Material | Natural wool fibers | Synthetic plastic fibers |

| Texture | Soft, natural feel | Can be rough or slippery |

| Durability | Very durable, long-lasting | Pills and wears quickly |

| Fire Safety | Fire resistant | Highly flammable, melts |

| Color Options | Good range, natural depth | Huge range, bright colors |

| Environmental | Biodegradable, sustainable | Petroleum-based, not biodegradable |

| Price | Higher cost | Very affordable |

| Best For | Quality projects, heirlooms | Kids’ crafts, temporary use |

The price difference reflects the material quality. Acrylic felt might cost $0.50-$1 per sheet, while wool felt can be $3-$8 per sheet of the same size. But wool felt will last many times longer and perform better.

Wool Felt vs Cotton Fabric

These are quite different materials suited for different purposes.

Wool felt vs cotton fabric differences in structure and performance

Wool felt advantages:

- Doesn’t require hemming

- Natural water resistance

- Better insulation

- Holds shape without structure

Cotton fabric advantages:

- Softer against skin

- Better for breathable clothing

- Machine washable without special care

- Generally more affordable

- Wider variety of patterns and prints

For most clothing, cotton wins. For crafts requiring structure or for accessories needing shape retention, wool felt is better. Learn more in our complete cotton fabric guide.

Care and Maintenance Guide

Wool felt fabric illustrating proper care and maintenance considerations

Proper care keeps wool felt looking good and performing well for years. Here’s what you need to know.

Washing Wool Felt

The general rule: be gentle. Wool felt can shrink and become denser if treated roughly, which is exactly how felt is made in the first place!

Hand Washing (Recommended):

- Fill a basin with cool or lukewarm water (never hot)

- Add a small amount of wool-safe detergent or gentle soap

- Submerge the felt and gently press the water through

- Don’t rub, wring, or agitate vigorously

- Soak for 5-10 minutes maximum

- Drain and rinse with cool water until soap is gone

- Press (don’t wring) to remove excess water

- Roll in a towel to absorb more moisture

- Lay flat to dry on a clean towel, reshaping as needed

Machine Washing (Use Caution):

Machine washing wool felt is risky. If you must do it:

- Use the delicate or wool cycle

- Cold water only

- Wool-safe detergent

- Place items in a mesh laundry bag

- Never use fabric softener

- Expect some shrinkage (20-30% possible)

- The texture will change, becoming thicker and bumpier

Some crafters intentionally machine wash wool fabric to create felted wool, which is different from wool felt but has its own uses.

For comprehensive care instructions for wool products, see our wool care guide.

Drying

Never put wool felt in the dryer. The heat and tumbling will cause severe shrinkage and damage.

Proper drying method:

- Lay flat on a clean, dry towel

- Reshape the item to its original dimensions

- Keep away from direct heat or sunlight

- Turn occasionally to ensure even drying

- Allow plenty of time – thick felt can take 24-48 hours to fully dry

Removing Stains

Act quickly when stains happen:

- Blot (don’t rub) fresh stains immediately with a clean cloth

- For water-based stains, dab with a damp cloth and a tiny bit of wool-safe detergent

- For oil-based stains, sprinkle with cornstarch to absorb the oil, let sit for several hours, then brush off

- For tough stains, consider professional cleaning

- Never use bleach or harsh stain removers

Dealing with Pilling

Quality wool felt shouldn’t pill much, but if you notice fuzzy balls forming:

- Use a fabric shaver or sweater comb to gently remove pills

- A fine-grade sandpaper can also work for stubborn fuzz

- Be gentle to avoid damaging the felt surface

- Excessive pilling often indicates lower quality felt

Ironing Wool Felt

If your wool felt becomes wrinkled:

- Use a low to medium heat setting

- Always use a pressing cloth between the iron and felt

- Never place the iron directly on felt

- Press gently, don’t slide the iron

- Steam can help reshape wool felt – use a garment steamer or iron with steam

- Be aware: heat can make wool felt shinier, so test on a hidden area first

Storage Tips

Proper storage prevents damage and keeps wool felt fresh:

- Keep it clean: Always store clean felt. Dirt and oils attract moths.

- Moth protection: Store with cedar blocks, lavender sachets, or moth repellent. Wool is a favorite food for moths.

- Flat storage preferred: Store flat rather than folded to prevent permanent creases.

- Breathable containers: Use fabric storage bags or boxes with air circulation. Avoid plastic bins that trap moisture.

- Cool, dry location: Keep away from humidity, heat, and direct sunlight.

- Check periodically: Look for signs of moths or mildew every few months.

Use our Wool Care Calculator for personalized washing instructions based on your specific wool felt item.

Preventing Shrinkage

The key factors that cause wool felt to shrink are:

- Hot water

- Agitation

- Rapid temperature changes

To prevent shrinkage:

- Always use cool or lukewarm water

- Handle gently without rubbing or wringing

- Don’t switch between hot and cold water

- Skip the dryer completely

If you want to pre-shrink wool felt before starting a project, wash it once before cutting. Just know the texture will change and become denser.

How to Choose Quality Wool Felt

Quality wool felt sheets showing density, texture, and uniform thickness

Not all wool felt is the same quality. Here’s how to make smart buying decisions.

Reading Labels and Descriptions

Pay attention to the fiber content. Look for:

- Exact wool percentage: “100% Merino Wool” or “35% Wool, 65% Rayon”

- Thickness: Usually listed in millimeters. 1-2mm is standard for crafts.

- Country of origin: European-made felt (especially from Germany, Netherlands, or Austria) tends to be high quality.

- Certifications: Oeko-Tex Standard 100, GOTS, or other quality certifications.

- Wool type: Merino is softer than generic wool.

Be wary of vague descriptions like “wool-like” or “wool-type” – these usually mean synthetic.

Where to Buy

Online Specialty Retailers:

- Benzie Design

- The Felt Pod

- A Child’s Dream

- Felt On The Fly

- Weir Crafts

- National Nonwovens

Marketplaces:

- Etsy (check descriptions carefully)

- Amazon (wide variety, read reviews)

Craft Stores:

- Local fabric shops (call ahead about wool felt availability)

- Quilting shops often carry felted wool

For upholstery-grade felt:

- Kvadrat

- Maharam

- Camira

- Designtex

Price Expectations

Wool felt pricing varies significantly based on quality:

- Budget acrylic felt: $0.50-$1.50 per 9×12″ sheet

- Wool blend felt: $1.50-$3.00 per 9×12″ sheet

- 100% wool felt: $3.00-$8.00 per 9×12″ sheet

- Premium Merino felt: $6.00-$12.00 per 9×12″ sheet

- By the yard: $15-$45 per yard depending on width and quality

- Upholstery-grade: $50-$150+ per yard

Remember: higher price usually indicates better quality that will last longer and perform better.

Testing Before You Buy

If buying in person, test the felt:

- Touch test: Quality felt feels smooth and substantial, not thin or scratchy.

- Stretch test: Pull gently. It should have minimal stretch and bounce back.

- Light test: Hold it up to light. You shouldn’t see through it.

- Cut edge test: Look at cut edges. They should be clean, not fuzzy or loose.

- Burn test (if possible): Wool smells like burning hair and self-extinguishes. Synthetics smell like plastic and melt.

Buying for Specific Projects

Match the felt quality to your project needs:

For heirloom toys or keepsakes: 100% Merino wool felt

For regular crafts and sewing: Quality wool blend felt (20-35% wool)

For children’s simple crafts: Acrylic felt is fine and saves money

For structural items (bags, hats): Thicker wool felt (2-3mm)

For appliqué or detailed work: Thinner wool felt (1mm)

For upholstery or design projects: Commercial-grade wool felt from design manufacturers

Buying in Bulk

If you use wool felt regularly, buying larger quantities saves money:

- By the yard instead of pre-cut sheets

- Multi-sheet packs or bundles

- Remnant boxes from felt manufacturers

- Directly from manufacturers for even better pricing

Many suppliers offer bulk discounts for larger orders. Check if they have a wholesale program if you’re running a business.

Why is Wool Felt So Expensive?

Wool felt fabric highlighting quality factors behind its higher price

This is a common question, especially when you compare $7 wool felt to $1 acrylic felt. The price difference isn’t arbitrary. Several factors contribute to wool felt’s higher cost.

Raw Material Costs

Quality wool, particularly Merino, is expensive. Sheep must be raised, fed, and cared for. Shearing is labor-intensive. The wool must be cleaned, sorted, and prepared. All of this costs money.

Compare this to synthetic felt made from petroleum-based fibers that can be manufactured in large quantities with automated processes. The raw materials for synthetic felt are much cheaper.

Processing Complexity

Making quality wool felt requires:

- Multiple washing and cleaning steps

- Careful carding to align fibers

- Controlled felting process with proper temperature and timing

- Quality control to ensure even thickness and density

- Finishing processes including shaving and smoothing

Each step adds labor and cost. High-quality felt manufacturers take pride in their work and can’t rush the process without affecting quality.

Scale of Production

Acrylic felt is mass-produced in enormous quantities for the craft market. This scale allows for very low per-unit costs.

Wool felt production is smaller scale, often by specialty manufacturers. Without the economies of scale that mass production provides, prices remain higher.

Natural Material Variations

Unlike synthetic fibers that are identical every time, natural wool varies. Some fleeces are finer, cleaner, or better suited for felting. Sorting and selecting quality wool adds to the cost.

Ethical and Environmental Standards

Quality wool felt manufacturers increasingly follow ethical practices:

- Fair wages for workers

- Animal welfare standards

- Environmental protection measures

- Sustainable farming partnerships

- Chemical safety testing

These responsible practices cost more but produce a better product that you can feel good about buying.

Longevity Justifies the Cost

Here’s the important perspective: wool felt is more expensive upfront but cheaper over time.

Example calculation:

- Acrylic felt toy: $10 to make, lasts 2 years = $5/year

- Wool felt toy: $25 to make, lasts 20 years = $1.25/year

The wool felt toy costs less per year and creates less waste. This is where the value shows up.

Quality Indicators That Justify Price

What you’re paying for with quality wool felt:

- No pilling or fuzzing

- Color that stays vibrant

- Material that doesn’t thin or wear out quickly

- Natural properties like fire resistance and water repellency

- Biodegradability at end of life

- Safe for children (no toxic chemicals)

- Pleasant to work with (easier on your hands and tools)

Frequently Asked Questions

Can wool felt be used outdoors?

Yes, wool felt can be used outdoors. Its natural water resistance helps it withstand light rain and moisture. However, it’s not waterproof, so prolonged exposure to heavy rain will eventually soak it. For outdoor applications, consider treating wool felt with a water-repellent spray designed for natural fibers. The material’s natural durability and resistance to UV damage make it suitable for outdoor decorations, garden art, and temporary installations.

How do you identify real wool felt vs synthetic?

The burn test is most reliable: carefully burn a small piece in a safe area. Real wool smells like burning hair, chars slowly, and self-extinguishes. The ash crumbles easily. Synthetic felt smells like burning plastic, melts instead of burning, and leaves hard, plastic-like residue. Other indicators include texture (wool feels natural and softer), price (real wool costs more), and label information. Quality wool felt also has more depth to its color and doesn’t have the slight plastic sheen that synthetic felt shows.

Does wool felt shrink?

Yes, wool felt can shrink significantly if exposed to hot water, agitation, and temperature changes. These are the same conditions that create felt in the first place, so they’ll cause existing felt to become even more compressed. You can expect 20-30% shrinkage if you machine wash wool felt in hot water and tumble dry it. To prevent shrinkage, always wash wool felt in cool water by hand, handle it gently, and lay flat to dry. Some crafters intentionally shrink wool felt before projects to prevent later size changes.

What thickness of wool felt should I buy?

The right thickness depends on your project. For most crafts, appliqué, and sewing projects, 1-2mm thickness works well. It’s easy to cut, sew, and manipulate. For projects needing more structure like bags, hats, or sturdy toys, choose 2-3mm felt. For very detailed work or items that need to stay soft and pliable, 1mm or thinner works best. For industrial uses or heavy-duty applications, felt can be 3mm or thicker. Many suppliers sell sample packs so you can test different thicknesses before committing to larger purchases.

Can you glue wool felt?

Yes, wool felt works well with adhesives. For crafts, fabric glue or craft glue like Aleene’s Tacky Glue works great. For stronger bonds, try E6000 or similar industrial-strength adhesives. Hot glue also works but can soak through thin felt and may look messy. For precision work, double-sided tape or fabric adhesive sheets give clean results. Always test your adhesive on a scrap piece first, as some adhesives can leave marks or change the felt’s appearance. For washable projects, sewing is more reliable than glue.

Is wool felt safe for babies and young children?

High-quality wool felt is generally safe for babies and children. Look for felt with Oeko-Tex Standard 100 certification, which ensures it’s tested for harmful substances. Avoid felt with loose glitter, sequins, or small decorations that could be choking hazards. The natural fire resistance of wool felt adds a safety benefit. Synthetic felt is not recommended for baby items as it can be flammable and may contain chemicals. Always supervise young children with felt toys, and make sure any items you create have secure stitching with no loose threads. For baby projects, choose 100% wool felt when possible, as it has the best safety profile.

How is wool felt different from fleece fabric?

While both are warm materials, they’re quite different. Fleece fabric is typically made from synthetic polyester and has a fluffy, soft texture with a definite right and wrong side. Wool felt is made from natural wool, has the same texture on both sides, and doesn’t fray when cut. Fleece is usually woven or knitted, while felt is non-woven. Fleece is better for warm clothing and blankets, while felt is better for crafts, structure, and applications requiring non-fraying edges.

Can wool felt be dyed?

Yes, you can dye wool felt using acid dyes (like Kool-Aid or professional acid dyes) or natural dyes. The process is similar to dyeing regular wool. However, dyeing felt can cause additional shrinkage and may make the felt denser. For best results, use cool water, gentle handling, and be prepared for the felt to change texture slightly. Many crafters prefer to buy felt in the desired color rather than dyeing it, as the color selection from manufacturers is excellent. If you do dye felt, always test on a small piece first.

Conclusion

After exploring everything from ancient history to modern applications, one thing becomes clear: wool felt is a remarkable material that has stood the test of time for good reason. Its unique combination of properties – fire resistance, water resistance, sound dampening, durability, and ease of use – makes it useful for an incredible range of applications.

Key Takeaways

Let’s recap the most important points to remember about wool felt fabric:

Quality Matters: Not all felt is created equal. The difference between 100% Merino wool felt and cheap acrylic felt is like comparing a handcrafted wooden toy to a plastic dollar store version. If your project matters to you, invest in quality wool felt. It will last longer, look better, and perform better in every way.

Understand What You’re Buying: Don’t be fooled by labels. “Wool felt” doesn’t always mean 100% wool. Check the fiber content, look for certifications like Oeko-Tex, and buy from reputable suppliers. The few extra dollars for quality felt pays off in results.

Match Material to Purpose: For kids’ temporary crafts, acrylic felt is fine and saves money. For heirloom projects, toys that will be loved for years, or professional work, choose quality wool felt. For most general crafting, a good wool blend (20-35% wool) offers the sweet spot of performance and affordability.

Care Properly: Wool felt lasts for decades with proper care. Remember the golden rule: cool water, gentle handling, lay flat to dry. Never put wool felt in the washing machine on hot or in the dryer unless you want it to shrink dramatically. Store it protected from moths, and your felt will serve you well for many years.

Sustainability Counts: In a world increasingly concerned with environmental impact, wool felt stands out as a responsible choice. It’s renewable, biodegradable, and when sourced ethically, has a relatively low environmental footprint. Choosing wool felt over synthetic alternatives is a small but meaningful way to reduce your environmental impact.

When to Choose Wool Felt

Wool felt is your best choice when you need:

- Material that won’t fray when cut

- Natural fire resistance for safety

- Structure and shape retention without support

- Natural insulation and temperature regulation

- A material that will last for years or decades

- Sustainable, biodegradable fabric

- Something safe for children’s items

- Professional-looking craft results

When to Choose Something Else

Wool felt isn’t the answer for every project. Choose other materials when you need:

- Soft draping fabric for clothing (try silk or cotton)

- Very inexpensive material for temporary projects (acrylic felt is fine)

- Machine-washable, low-maintenance fabric

- Stretchy material (look at knits instead)

- Waterproof protection (wool felt resists water but isn’t waterproof)

Looking Forward

The future of wool felt looks bright. As consumers become more environmentally conscious and interested in quality over quantity, natural materials like wool felt are experiencing renewed appreciation. The craft and maker movement has introduced a new generation to the joys of working with quality materials.

We’re also seeing innovation in wool felt production. New dyeing techniques create colors that weren’t possible before. Partnerships between felt manufacturers and sustainable wool producers ensure ethical sourcing. Design brands are finding new applications for wool felt in architecture and interior design.

Your Next Steps

If you’re new to wool felt, start with a small purchase of quality material to see the difference for yourself. Many suppliers sell sample packs with multiple colors in small sizes. Try a project or two to get familiar with how wool felt behaves.

For experienced crafters, consider upgrading from wool blend to 100% wool felt for your special projects. The difference in results justifies the cost increase.

Use our Wool Type Selector Quiz to find the perfect type of wool felt for your specific project needs.

Remember that choosing wool felt connects you to thousands of years of human textile history. Every time you work with this ancient material, you’re participating in a craft tradition that predates written history. That’s something special.

Whether you’re making a simple ornament, creating an heirloom toy, or working on a professional design project, quality wool felt will serve you well. It’s a material that rewards those who invest in it with beautiful results that last.

Final Recommendation

My recommendation after years of working with textiles? Invest in at least a few pieces of quality wool felt. Experience the difference yourself. Feel how it cuts cleanly, sews beautifully, and holds its shape. Notice how colors stay vibrant and the material doesn’t pill or wear thin.

Once you work with quality wool felt, you’ll understand why it has remained popular for over 6,000 years. It’s simply a beautiful material that does its job exceptionally well.

For more information about wool fabrics and textiles, explore our comprehensive guides on wool fabric, cashmere, and other natural fibers. Understanding the full range of wool products helps you make the best choice for each project.

Happy creating with wool felt!