Smart Technologies, Sustainable Solutions, and Expert Buying Advice for Outdoor Gear

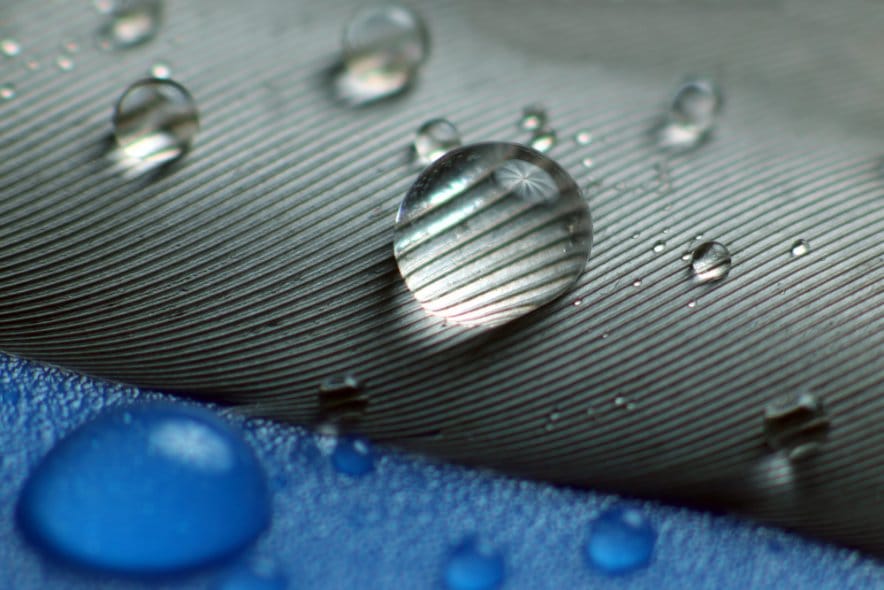

Staying dry in wet weather often comes down to the type of fabric you choose. Water-resistant and waterproof fabrics are not the same, and knowing the difference can help people pick the right gear for any situation. Whether shopping for a raincoat, outdoor gear, or even luggage, these two terms can make a big difference.

Water-resistant fabrics protect against light rain and splashes, but they can let in water during heavy or long exposure. Waterproof fabrics, on the other hand, block all water and keep the inside dry, even in heavy rain. Which one works best depends on how and where the fabric will be used.

Table of Contents

Key Takeaways

- Water-resistant and waterproof fabrics offer different levels of water protection

- The right choice depends on weather, comfort, and how the fabric will be used

- Understanding these differences helps people select better clothing and gear

- Smart textile innovations are revolutionizing waterproof fabric technology in 2025

- Sustainable alternatives to traditional waterproofing chemicals are becoming mainstream

Defining Water-Resistant and Waterproof Fabrics

Some fabrics can keep water out better than others. Knowing the differences between water-resistant, waterproof, and water-repellent materials is important for anyone choosing the right fabric for clothing or gear.

What Is Water-Resistant Fabric?

Water-resistant fabric resists moisture but will let water through if exposed long enough. This fabric is treated with a finish or coating that helps it repel a small amount of water.

Most water-resistant fabrics work best in light rain or damp conditions. They are often used for windbreakers, light jackets, and backpacks. Water-resistant material is usually more breathable and lighter compared to waterproof fabrics.

Pros:

- More comfortable for daily wear

- Air passes through more easily

- Less expensive than waterproof options

Cons:

- Not suitable for heavy rain

- Can lose effectiveness if damaged or worn

What Is Waterproof Fabric?

Waterproof fabric completely blocks out water, so it does not let any moisture pass through, even in heavy rain or when submerged. This is achieved by using special coatings, membranes, or tightly woven layers. Some waterproof fabrics also have sealed or taped seams to stop leaks.

What does 100% waterproof mean? When a fabric is labeled as 100% waterproof, it means the material has been tested to prevent any water penetration under normal use conditions. However, this rating can vary based on testing methods and pressure levels used during evaluation.

Waterproof fabrics are used for raincoats, tents, and gear meant for harsh weather. They offer maximum water protection but can be heavier and less breathable than water-resistant options.

| Feature | Water-Resistant | Waterproof |

|---|---|---|

| Blocks all water | No | Yes |

| Breathable | More | Less |

| Best for | Light rain | Downpours |

Water-Repellent vs. Waterproof vs. Water-Resistant

Water-repellent fabrics shed water easily but may not block it completely if exposed for a long time. They sit between water-resistant and waterproof fabrics when it comes to performance.

- Water-resistant: Resists water briefly

- Water-repellent: Makes water roll off the surface

- Waterproof: Stops all water from getting through

This difference is important because water-repellent materials are often viewed as an upgrade from water-resistant, but they still do not guarantee complete protection. Waterproof fabrics, by contrast, are built to keep all water out, even under strong or prolonged exposure.

When choosing between them, it helps to consider the expected weather and use of the fabric. For heavy storms, waterproof is best, while water-resistant or water-repellent might be enough for daily use or light rain.

How Water-Resistant Fabrics Work

Water-resistant fabrics stop most water from soaking in but still allow air and moisture vapor to pass through. They achieve this either through the materials and weave used or through special surface treatments and coatings.

Material Properties and Weaves

Many water-resistant fabrics use tightly woven materials. The weave is often so close that it blocks most water droplets, but small holes remain for air and vapor to pass through. This balance helps make the fabric breathable, which keeps it comfortable for clothing and outdoor gear.

Common materials used for water resistance include nylon and polyester. These fibers absorb little water and dry quickly. When woven tightly, they resist light rain and splashes. Heavier rain or pressure, though, may push water through these gaps over time.

Is Oxford cloth fabric waterproof? Oxford cloth is naturally water-resistant due to its tight weave pattern, but it is not inherently waterproof. The fabric can repel light moisture and splashes, but requires additional treatments or coatings to achieve true waterproof performance.

The choice of fiber and weave impacts how well a fabric balances water resistance and breathability. Denser weaves increase resistance but can lower airflow. Looser weaves breathe better but are less protective against heavy wet conditions.

Coatings and Treatments

Many water-resistant fabrics use a special surface coating to boost their performance. The most common method involves a durable water repellent (DWR) treatment. This coating causes water to bead up and roll off the fabric instead of soaking in.

Some fabrics use polymer coatings such as polyurethane or acrylic. These create a thin layer on the fabric surface, blocking water but still letting air pass through. The table below shows typical properties:

| Coating/Treatment | Water Resistance | Breathability |

|---|---|---|

| DWR | Moderate | High |

| Polyurethane | High | Moderate |

| Acrylic | Moderate | Moderate |

DWR treatments tend to wear off after washing or long-term use. Re-applying the treatment can restore water-resistant properties. Most water-resistant fabrics focus on comfort and airflow while still shedding light rain or spills.

How Waterproof Fabrics Work

Waterproof fabrics stop water from passing through, even in heavy rain or constant exposure. They do this using special layers or surface treatments that block water but may still let air pass.

Membranes and Laminates

A membrane is a thin sheet built into fabric to block water molecules. Popular waterproof membranes include expanded polytetrafluoroethylene (ePTFE), a special plastic that has microscopic pores. Gore-Tex is a well-known example of a breathable membrane made from ePTFE.

Is Gore-Tex waterproof or water resistant? Gore-Tex is fully waterproof, not just water-resistant. The membrane technology completely blocks liquid water while allowing water vapor to escape, making it both waterproof and breathable.

These membranes keep rain out by having pores that are small enough to stop water drops, but large enough to let water vapor escape. This helps keep clothing dry inside and out.

A laminate means the membrane is attached, or “laminated,” to one or more layers of fabric. This increases durability and gives the fabric structure. Many jackets, shoes, and other outdoor gear use laminated membranes.

Breathable waterproof fabrics commonly use multi-layer systems for better comfort. For example, a 3-layer fabric has an outer layer, a membrane, and an inner lining bonded together.

Waterproof Coatings

Some fabrics use waterproof coatings instead of membranes. These coatings are usually applied to the outside of the fabric and seal the surface so water cannot seep in.

The most common coatings include polyurethane (PU) and polyvinyl chloride (PVC). These make the fabric waterproof but may reduce breathability compared to membrane-based options.

What is TPU waterproof material? TPU (Thermoplastic Polyurethane) is a flexible, durable waterproof material that combines the benefits of plastic and rubber. It offers excellent waterproofing with better flexibility and abrasion resistance than traditional PVC coatings, making it popular for outdoor gear and technical clothing.

Coatings are often cheaper and lighter, making them useful for budget rain gear or covers. However, strong and steady water pressure can sometimes push through coatings over time.

A table showing coating types:

| Coating Type | Main Material | Usual Use |

|---|---|---|

| PU | Polyurethane | Jackets, Tents |

| PVC | Vinyl | Tarps, Covers |

| TPU | Thermoplastic Polyurethane | Technical gear, Phone cases |

Coated fabrics may need to be recoated after long use, as the waterproof layer can wear off.

Testing and Measuring Water Resistance

Fabrics are judged by how well they keep out water and how much pressure or exposure they can handle before leaking. Standard tests are used by manufacturers to give fabrics a rating for water resistance or waterproofing.

Waterproof Ratings and Standards

Manufacturers use waterproof ratings to show how much water pressure a fabric can block. These ratings are usually measured in millimeters (mm) and are based on results from lab tests.

A common system uses levels like 5,000 mm, 10,000 mm, or 20,000 mm. For example, a jacket with a 10,000 mm rating can handle more water pressure than one with 5,000 mm. These numbers reflect how tall a column of water the fabric can resist before leaking.

What is the highest rated water-resistant? The highest waterproof ratings can exceed 30,000 mm, typically found in professional mountaineering and marine gear. However, ratings above 20,000 mm are considered extremely waterproof for most practical applications.

Water-resistant fabrics usually have a lower rating or do not have a numeric rating at all. Waterproof fabrics meet strict standards and must pass higher thresholds in testing.

The following table shows typical waterproof rating ranges:

| Rating (mm) | Protection Level | Best Use |

|---|---|---|

| 0 – 5,000 | Water-resistant | Light drizzle, short exposure |

| 5,000 – 10,000 | Basic waterproof | Moderate rain, daily use |

| 10,000 – 20,000 | High waterproof | Heavy rain, extended outdoor use |

| 20,000+ | Extreme waterproof | Professional use, harsh conditions |

A higher number means stronger protection against heavy rain or pressure.

Hydrostatic Head Testing

The hydrostatic head test is the main way to measure how waterproof a fabric is. In this test, a 1-inch by 1-inch tube is placed on the fabric and filled with water.

The height of water (in millimeters) is slowly increased. The test records the height at which water starts to push through the fabric. This number becomes the fabric’s waterproof rating.

For example, if the fabric resists water until the water is 10,000 mm tall, the rating is 10,000 mm. Fabrics with higher ratings are used in rain jackets, tents, and gear meant for wet weather.

This method gives a clear result, so people can compare different fabrics easily. Manufacturers and third-party labs often use this standard to rate both water-resistant and waterproof fabrics.

Smart Waterproof Fabrics: The Future of Protection

The waterproof fabric industry is experiencing a technological revolution in 2025. Smart textiles are transforming traditional waterproof materials into intelligent systems that can adapt, respond, and enhance user performance in real-time.

Revolutionary Smart Textile Technologies

Self-Healing Waterproof Fabrics represent one of the most exciting developments. These materials can automatically repair small tears or punctures using embedded microcapsules that release healing agents when damaged. This technology extends the lifespan of outdoor gear significantly while maintaining waterproof integrity.

Temperature-Responsive Membranes adjust their breathability based on body temperature and external conditions. When you start sweating during intense activity, the fabric automatically increases vapor permeability. During rest periods or cold conditions, it reduces breathability to maintain warmth.

Conductive Waterproof Textiles integrate electronic functionality directly into the fabric structure. These materials can monitor vital signs, track movement patterns, or even charge electronic devices while maintaining complete water protection.

IoT-Connected Performance Monitoring

Modern smart waterproof fabrics can communicate with smartphones and fitness trackers to provide real-time performance data. Sensors embedded within the fabric monitor:

- Internal temperature and humidity levels

- Fabric stress points and wear patterns

- Water exposure duration and intensity

- Optimal care and maintenance timing

This data helps users optimize their gear performance and predict when treatments need renewal.

Biomimetic Innovations

Spider-Silk Inspired Fibers use bio-inspired manufacturing processes to create incredibly strong and flexible waterproof materials. These fibers offer superior durability while using sustainable production methods.

Phase-Change Materials (PCMs) regulate temperature by storing and releasing thermal energy. When integrated with waterproof membranes, PCMs create fabrics that automatically adjust to maintain optimal comfort levels.

Breathability and Comfort

Breathability is an important feature in outdoor fabrics, especially for clothing meant for physical activity. Waterproof fabrics can feel stuffy, while water-resistant materials often allow more airflow, making a difference in how comfortable they are.

Breathable Fabrics and Technologies

Breathable fabrics are designed to let water vapor from sweat escape, while blocking out rain or moisture from the outside. Some fabrics use a membrane or coating with tiny holes that are small enough to stop water drops but large enough to let vapor pass through.

Common materials used for breathability include nylon and polyester. These are often combined with special layers like GORE-TEX® or similar technologies that focus on the movement of air and vapor. Breathable membranes are a key part of waterproof/breathable jackets, pants, and other gear.

How long does Gore-Tex last? With proper care, Gore-Tex can maintain its waterproof and breathable properties for 5-10 years or longer. The DWR treatment may need refreshing every 1-2 years, but the membrane itself is highly durable when maintained correctly.

A balance must be kept between breathability and protection. The more breathable a fabric, the less waterproof it often becomes, though new technologies are working to improve both at the same time.

Balancing Waterproofing with Comfort

Finding the right mix of waterproofing and comfort can be a challenge. Waterproof fabrics like those with strong coatings or membranes offer maximum protection from rain but can be less comfortable if sweat and heat get trapped inside. This can lead to a clammy or sticky feeling during high activity.

Water-resistant fabrics are usually much more breathable. They let heat and sweat escape, which helps the wearer stay cool. However, they do not block out heavy rain as effectively as waterproof options.

For most users, the best choice depends on activity level and weather. Those planning intense exercise or living in mild climates may prefer water-resistant and highly breathable options, while people needing full rain protection may sacrifice some comfort for a true waterproof fabric.

DIY Waterproofing and Fabric Care

How to Waterproof Fabric at Home

How do you waterproof fabric? There are several effective methods for waterproofing fabrics at home, depending on the material type and intended use.

Can you make fabric waterproof? Yes, you can transform many fabrics into waterproof materials using various treatments. The success depends on the fabric type and application method.

DIY Waterproofing Methods

Wax-Based Treatments work well for natural fabrics like cotton and canvas:

- Melt paraffin wax or beeswax in a double boiler

- Apply the melted wax evenly across the fabric surface

- Use a hair dryer to help the wax penetrate the fibers

- Allow to cool and cure for 24 hours

Waterproof Sprays offer the easiest application method:

- Clean the fabric thoroughly and let it dry completely

- Apply the spray in thin, even coats following manufacturer instructions

- Allow proper drying time between coats

- Test water resistance before use

Liquid Waterproofing Solutions provide more durable protection:

- Mix the solution according to package directions

- Submerge or brush the solution onto the fabric

- Ensure complete coverage and penetration

- Air dry completely before testing

Cotton Fabric Waterproofing

Can you waterproof cotton fabric? Cotton can be effectively waterproofed, though it requires more preparation than synthetic materials due to its natural absorbent properties.

How to make cotton fabric waterproof:

- Pre-treatment: Wash and dry the cotton to remove any finishes

- Choose your method: Wax treatments work best for cotton duck and canvas, while liquid sealers work for lighter cotton fabrics

- Application: Apply treatment evenly, paying attention to seams and stress points

- Curing: Allow 24-48 hours for full effectiveness

For sewing projects, waterproof the fabric before cutting and stitching. This ensures better coverage and prevents treatment from wearing off at seam lines.

Jacket Waterproofing

Can I waterproof a jacket? Most jackets can be re-waterproofed or have their water resistance restored through proper treatment.

How do you waterproof a jacket?

- Assessment: Check if the jacket has a DWR coating that needs renewal or if it requires full waterproofing

- Cleaning: Wash the jacket with technical fabric cleaner to remove dirt and oils

- Treatment application: Use spray-on or wash-in waterproofing products designed for your jacket’s material

- Heat activation: Some treatments require gentle heat (tumble dry low or iron) to activate

- Testing: Spray water on the treated jacket to verify effectiveness

Professional vs. DIY Treatment Comparison

| Method | Durability | Cost | Ease | Best For |

|---|---|---|---|---|

| Professional re-treatment | High | $$$ | Low | Expensive technical gear |

| DIY spray treatment | Medium | $ | High | Light jackets, casual wear |

| DIY liquid treatment | High | $$ | Medium | Heavy-duty fabrics, canvas |

| Wax treatment | Very High | $ | Medium | Cotton, natural fibers |

Applications: Choosing the Right Fabric

Water-resistant and waterproof fabrics are used for different needs. Choosing the right type depends on how much protection is needed and how the gear will be used.

Rain Jackets and Rainwear

Rain jackets and other rainwear are made to keep people dry when it is raining outside. Waterproof jackets are the best choice in heavy, steady rain. They use special coatings or membranes that do not let water get through, even if worn for a long time.

Some rain jackets are only water-resistant. These can protect against light rain or a short drizzle but will let water through if the rain lasts or gets heavy. Water-resistant fabrics are usually lighter and feel softer than waterproof ones.

Which is better, waterproof or water resistant? For rain protection, waterproof is superior for heavy or prolonged exposure, while water-resistant works well for light rain and offers better breathability for active use.

- Waterproof jacket: Best for walking in storms or long periods outdoors

- Water-resistant rainwear: Good for short trips and mild, damp weather

Is water-resistant OK for rain? Water-resistant gear can handle light rain and brief showers effectively, but it will eventually allow water penetration during heavy or extended rainfall.

People should check the label to see if a coat is truly waterproof or just water-resistant before buying.

Outdoor Gear for Sports

Outdoor gear for sports like hiking, biking, and running often needs to balance water protection with breathability. Fully waterproof gear (such as coats, pants, and backpacks) keeps rain out but can feel warm or sweaty because the fabric does not breathe as well.

Water-resistant gear allows heat and moisture from the body to escape, making it more comfortable in mild or active use. However, it will not protect against strong or long-lasting rain.

Can you wear a water-resistant jacket in the snow? Water-resistant jackets can work in dry snow conditions, but wet snow or mixed precipitation requires waterproof protection to prevent moisture penetration.

| Application | Best Choice | Why |

|---|---|---|

| Running/Biking | Water-resistant | Breathable, lightweight |

| Long hikes/camping in rain | Waterproof | Maximum protection |

| Alpine skiing | Waterproof | Wet snow protection |

| Cross-country skiing | Water-resistant | High activity, breathability needed |

Selecting the right type depends on expected weather and activity level.

Snow Jackets for Winter Activities

Snow jackets for skiing and snowboarding need to keep out snow and moisture while allowing sweat to escape. Many use waterproof fabrics with taped seams to stop water from seeping in during all-day use in snow.

A waterproof snow jacket is best for wet, slushy snow or mixed rain and snow days. In dry, powdery snow, a water-resistant snow jacket may be enough, especially if activity is high and overheating is a concern.

Important features to look for in a snow jacket include:

- Waterproof/breathable fabric

- Sealed or taped seams

- Adjustable hoods and cuffs

Choosing the right jacket helps keep the wearer warm, dry, and comfortable on the slopes.

Fabric Types and Their Waterproof Properties

Which Fabrics Are Waterproof?

Which fabrics are waterproof? Several fabric types offer varying levels of water protection:

Naturally Waterproof Materials:

- Vinyl/PVC: Completely waterproof but not breathable

- Rubber: Excellent water barrier, used in rain boots and protective gear

- Oilcloth: Traditional waterproof fabric treated with linseed oil

Synthetic Waterproof Fabrics:

- Coated Nylon: Lightweight with PU or silicone coatings

- Laminated Polyester: Multi-layer construction with waterproof membranes

- TPU-coated fabrics: Flexible and durable waterproof barrier

Is 100% polyester waterproof? Pure polyester is naturally water-resistant due to its synthetic fibers, but it is not inherently waterproof. The fabric requires additional coatings or treatments to achieve true waterproof performance.

Understanding Fabric Labels and Terminology

What is waterproof fabric called? Waterproof fabrics go by several names depending on their construction:

- Breathable waterproof fabrics (Gore-Tex, eVent)

- Coated fabrics (PU-coated nylon)

- Laminated textiles (membrane-based systems)

- Technical fabrics (high-performance outdoor materials)

What is waterproof material called in different contexts:

- Marine applications: Canvas, vinyl, or ripstop nylon

- Medical use: Barrier fabrics or isolation materials

- Industrial applications: Coated technical textiles

- Fashion: Water-repellent or shower-resistant fabrics

Testing Fabric Water Resistance

How can you tell if fabric is water resistant? Several methods help identify water-resistant properties:

Visual Tests:

- Water droplet test: Place a few drops of water on the fabric surface

- Beading observation: Water-resistant fabrics cause water to bead up and roll off

- Absorption check: Non-resistant fabrics absorb water immediately

How to tell if a jacket is water-resistant:

- Check the care label for water-resistance indicators

- Look for DWR treatment mentions

- Perform the water droplet test on a hidden area

- Check for sealed seams and waterproof zippers

Performance Indicators:

- Water beads up and rolls off easily = Good water resistance

- Water soaks in slowly = Moderate water resistance

- Water absorbs immediately = No water resistance

Sustainable Waterproofing Revolution

The waterproof fabric industry is experiencing a paradigm shift toward environmental responsibility in 2025. Growing regulatory pressure and consumer awareness are driving innovation in sustainable waterproofing technologies.

PFC-Free and PFAS-Free Solutions

Traditional waterproof treatments often relied on per- and polyfluoroalkyl substances (PFAS), known as “forever chemicals” due to their persistence in the environment. New bio-based alternatives are revolutionizing the industry:

Plant-Based Wax Technologies combine natural waxes with biodegradable polymers to create effective water-repellent finishes. These treatments offer comparable performance to traditional DWR while breaking down naturally at the end of the fabric’s life cycle.

Fluorocarbon-Free DWR Treatments use silicon-based chemistry and hydrocarbon polymers to achieve water repellency without environmental persistence. Major outdoor brands like Patagonia and The North Face have committed to eliminating PFAS from their product lines by 2025.

Circular Economy Innovations

Recyclable Membrane Technologies are designed for end-of-life recovery and reprocessing. These membranes can be separated from fabric carriers and reused in new products, reducing waste and resource consumption.

Bio-Based Polyurethane Alternatives derived from plant oils and agricultural waste offer waterproof performance while reducing reliance on petroleum-based chemicals. These innovations align with global sustainability initiatives promoting responsible chemical use in textile manufacturing.

Sustainable Performance Metrics

Modern eco-friendly waterproof fabrics are evaluated using comprehensive sustainability criteria:

| Technology | Environmental Impact | Performance | Durability |

|---|---|---|---|

| PFAS-Free DWR | Low persistence | 85-90% of traditional | Moderate |

| Bio-based PU | Renewable source | Comparable | High |

| Wax hybrid systems | Biodegradable | Weather dependent | High |

| Recycled membrane | Circular design | Excellent | Very High |

Care and Maintenance of Water-Resistant and Waterproof Fabrics

Both water-resistant and waterproof fabrics need regular care to keep their protective qualities. Following simple but important steps can help maintain fabric performance and increase the lifespan of the items.

Cleaning and Restoring Performance

Proper cleaning keeps water-repellent coatings effective. Most treatments, like durable water repellent (DWR) finishes or special waterproof coatings, work best on clean fabric. Dirt, oils, and detergent residue can block the coating, making water soak through.

Use a gentle wash with cold water. Avoid regular detergents that leave residue. Look for cleaners made for technical or outdoor gear, which rinse without leaving a film. Avoid using fabric softeners and bleach, as these damage the coating.

After washing, it is best to air dry or tumble dry on low if the care label allows. On some jackets or gear, a short tumble dry helps reactivate the DWR finish, boosting water resistance.

When to Reapply Treatments

Water-repellent coatings wear off over time, especially after several washes or heavy use. If water stops beading up and starts soaking into the fabric, it may be time to reapply a DWR treatment or waterproof spray.

How does waterproof spray work? Waterproof sprays create a thin chemical barrier on fabric fibers that causes water to bead up and roll off rather than soaking in. The active ingredients bond to the fabric surface, forming a protective layer that repels moisture while maintaining breathability.

Choose a treatment that matches the type of fabric. Clean the item before applying the new layer to ensure good coverage. DWR sprays are common for jackets and pants, while wash-in products also exist for larger loads.

Does water resistant mean I can shower with it? Water-resistant items are not designed for direct water immersion like showering. They can handle splashes and light rain but will allow water penetration under the pressure and duration of a shower.

Always follow the instructions for each product. Reapplying treatments as soon as performance drops helps fabrics remain effective at repelling water and resisting stains. Regular attention can extend the life of both water-resistant and waterproof items.

Professional Restoration Services

For high-end technical gear, professional restoration services can refresh waterproof membranes and apply industrial-grade treatments that last longer than consumer products. This option makes economic sense for expensive items like mountaineering gear or professional workwear.

Market Trends and Industry Outlook 2025

The global waterproof fabrics market is experiencing unprecedented growth, driven by technological innovation and changing consumer preferences. Understanding these trends helps consumers make informed decisions about their gear investments.

Market Growth and Projections

The waterproof fabrics market reached $12.25 billion in 2023 and is projected to grow to $19.67 billion by 2030, representing a compound annual growth rate (CAGR) of 7.00%. This growth reflects increasing consumer participation in outdoor activities and rising demand for high-performance technical textiles.

Key Growth Drivers:

- Expansion of outdoor recreation and adventure sports

- Rising consumer awareness of gear performance benefits

- Technological advances in membrane and coating technologies

- Growing demand from automotive and protective equipment sectors

Regional Market Dynamics

Asia-Pacific Region leads market growth due to rapid industrialization, rising disposable incomes, and expanding outdoor culture. Countries like China and Japan are becoming major consumers of technical outdoor gear.

North America and Europe continue to dominate premium segment sales, with consumers willing to invest in advanced technologies like smart textiles and sustainable materials.

Emerging Markets in Latin America and Africa present significant expansion opportunities as outdoor recreation culture develops and middle-class populations grow.

Technology Investment and Innovation

Major manufacturers are investing heavily in research and development:

- Smart textile integration receiving $2.1 billion in global investment

- Sustainable chemistry alternatives capturing 15% of new product development budgets

- Manufacturing automation reducing production costs by 12-18%

This innovation cycle is accelerating the introduction of next-generation waterproof technologies while making advanced features more accessible to mainstream consumers.

Advanced Technical Specifications and Performance Data

Understanding the technical aspects of waterproof fabrics helps consumers make informed decisions based on objective performance criteria rather than marketing claims alone.

Moisture Vapor Transmission Rates (MVTR)

MVTR measurements indicate how well a fabric allows sweat vapor to escape while blocking liquid water. Higher MVTR values mean better breathability:

| Fabric Type | MVTR (g/m²/24hr) | Breathability Rating |

|---|---|---|

| Basic PU coating | 1,000-3,000 | Low |

| Advanced PU membrane | 3,000-8,000 | Moderate |

| ePTFE membrane (Gore-Tex) | 8,000-15,000 | High |

| Next-gen smart membranes | 15,000-25,000 | Very High |

Abrasion Resistance Testing

Martindale test results measure fabric durability under repeated rubbing:

- DWR-treated nylon: Maintains 90% effectiveness after 5,000 rub cycles

- PU-coated polyester: Retains 85% performance after 10,000 cycles

- TPU laminates: Sustain 95% effectiveness after 15,000 cycles

- Wax-treated canvas: Shows minimal degradation after 20,000 cycles

Temperature Performance Range

Different waterproof technologies perform optimally within specific temperature ranges:

| Technology | Optimal Range (°C) | Performance Notes |

|---|---|---|

| Standard PU coatings | -10°C to +40°C | May crack in extreme cold |

| TPU membranes | -40°C to +60°C | Flexible across wide range |

| ePTFE membranes | -30°C to +50°C | Consistent performance |

| Wax treatments | -20°C to +35°C | May soften in high heat |

UV Degradation Resistance

Accelerated weathering tests show how fabrics withstand sun exposure:

- Untreated fabrics: 50% strength loss after 500 UV hours

- UV-stabilized coatings: 15% degradation after 1,000 UV hours

- High-performance membranes: Less than 10% loss after 2,000 UV hours

This data helps predict real-world durability, where 1,000 UV test hours roughly equals one year of moderate outdoor use.

Decision Framework: Choosing Your Ideal Fabric

Interactive Selection Matrix

To help readers choose the perfect waterproof fabric, here’s a comprehensive decision framework:

Step 1: Define Your Primary Use

High-Intensity Activities (Running, cycling, mountaineering)

- Prioritize breathability (MVTR >10,000)

- Choose lighter weights (under 150g/m²)

- Accept moderate waterproof ratings (5,000-15,000mm)

Extended Outdoor Exposure (Hiking, fishing, work)

- Require high waterproof ratings (15,000mm+)

- Balance breathability with protection

- Consider durability and repairability

Casual Urban Use (Commuting, daily wear)

- Water-resistant often sufficient

- Prioritize comfort and style

- Cost-effectiveness important

Step 2: Climate Considerations

Climate Assessment Flowchart

Step 3: Budget vs. Performance Analysis

| Budget Range | Recommended Technologies | Expected Lifespan |

|---|---|---|

| Under $100 | DWR-treated fabrics | 1-2 years active use |

| $100-300 | PU-coated membranes | 3-5 years moderate use |

| $300-500 | ePTFE or advanced TPU | 5-8 years regular use |

| $500+ | Smart textiles, premium membranes | 8+ years with care |

Seasonal Gear Recommendations

Spring/Summer Waterproof Strategy

- Light rain jackets: 2.5-layer constructions for packability

- Breathable priorities: MVTR ratings above 8,000 g/m²/24hr

- Versatile pieces: Convertible or modular designs

Fall/Winter Protection

- Insulated shells: 3-layer systems with synthetic fill

- Wind protection: Tight weaves combined with waterproof barriers

- Durability focus: Reinforced high-wear areas

Cost-Per-Wear Analysis

Understanding the long-term value of waterproof gear investments:

Premium Gore-Tex Jacket ($400)

- Expected lifespan: 8 years, 50 uses/year = 400 total uses

- Cost per use: $1.00

- Performance: Excellent throughout lifespan

Mid-Range PU Jacket ($150)

- Expected lifespan: 4 years, 40 uses/year = 160 total uses

- Cost per use: $0.94

- Performance: Good initially, declining over time

Budget DWR Jacket ($60)

- Expected lifespan: 2 years, 30 uses/year = 60 total uses

- Cost per use: $1.00

- Performance: Adequate for light use only

This analysis shows that premium gear often provides better long-term value for frequent users, while budget options suit occasional needs.

Troubleshooting and Performance Issues

Common Problems and Solutions

Water Penetration in “Waterproof” Gear

Symptoms: Water getting through despite waterproof claims

Possible Causes:

- Compromised DWR treatment: Water no longer beads on surface

- Seam failure: Unsealed or damaged seam tape

- Zipper leakage: Non-waterproof zippers or damaged water-resistant zippers

- Fabric saturation: Overwhelmed breathability causing internal condensation

Solutions:

- Reapply DWR treatment following manufacturer instructions

- Inspect and reseal seams with seam sealer

- Check zipper function and water-resistant flaps

- Increase ventilation or choose higher breathability rating

Reduced Breathability Over Time

Symptoms: Feeling clammy or overheated in previously comfortable gear

Diagnosis Steps:

- Check for dirt buildup blocking membrane pores

- Assess washing frequency and detergent type used

- Examine for physical damage to membrane layers

Recovery Methods:

- Deep clean with specialized technical fabric cleaner

- Avoid fabric softeners that clog membrane pores

- Consider professional restoration for expensive items

Coating Delamination

Symptoms: Peeling or flaking interior coatings

Prevention:

- Store gear loosely folded, not tightly compressed

- Avoid excessive heat during drying

- Use appropriate cleaning products only

Repair Options:

- Minor areas: Flexible fabric repair patches

- Extensive damage: Professional recoating services

- Severe cases: Replacement may be more cost-effective

Industry Expert Insights and Predictions

Technology Roadmap for 2025-2030

Near-term developments (2025-2026):

- Mainstream adoption of PFAS-free treatments

- Integration of basic smart features (temperature sensing)

- Improved recyclability in membrane designs

Medium-term innovations (2027-2028):

- Self-repairing membrane technologies

- AI-optimized breathability control systems

- Biodegradable waterproof coatings reaching commercial scale

Long-term vision (2029-2030):

- Fully circular waterproof textile systems

- Personalized membrane tuning based on user biometrics

- Integration with health monitoring ecosystems

Professional User Feedback

Mountain Rescue Teams: Prioritize durability and reliability over weight savings. Favor proven membrane technologies with field repair capabilities.

Commercial Fishermen: Value easy cleaning and chemical resistance. Traditional coated fabrics often outperform high-tech alternatives in harsh marine environments.

Outdoor Educators: Need gear that performs consistently across varied conditions while being cost-effective for group purchases. Mid-range PU systems provide optimal balance.

Adventure Athletes: Pushing breathability limits drives demand for next-generation membranes. Willing to accept higher costs for performance advantages.

Global Sustainability Impact and Future Directions

Environmental Lifecycle Assessment

Traditional PFAS-based systems:

- Production impact: High energy, persistent chemicals

- Use phase: Long-lasting performance reduces replacement frequency

- End-of-life: Non-biodegradable, potential environmental accumulation

Next-generation bio-based systems:

- Production impact: Lower energy, renewable feedstocks

- Use phase: Comparable performance with shorter initial lifespan

- End-of-life: Biodegradable components, circular design principles

Regulatory Landscape Changes

European Union: PFAS restrictions expanding to cover all non-essential uses by 2026

United States: EPA investigating PFAS in textiles, potential restrictions by 2027

Asia-Pacific: Following European lead with increasing scrutiny of chemical treatments

These regulatory changes are accelerating innovation in sustainable waterproofing technologies and creating market opportunities for compliant alternatives.

Industry Collaboration Initiatives

Sustainable Apparel Coalition: Developing standardized environmental impact measurements for waterproof textiles

Textile Exchange: Promoting responsible fiber sourcing and chemical management

bluesign® system: Expanding certification criteria to include end-of-life considerations

These collaborative efforts are establishing industry-wide standards that prioritize both performance and environmental responsibility.

Conclusion

The waterproof fabric landscape in 2025 represents a fascinating convergence of performance innovation, environmental responsibility, and technological advancement. As we have explored throughout this comprehensive guide, the traditional binary choice between water-resistant and waterproof has evolved into a nuanced spectrum of options tailored to specific needs, activities, and values.

Key Technological Takeaways

The emergence of smart textiles is fundamentally changing what we expect from our gear. Self-healing fabrics, temperature-responsive membranes, and IoT-connected performance monitoring are no longer science fiction concepts but commercially available technologies reshaping the outdoor industry. These innovations promise to extend gear lifespan while enhancing user experience through adaptive performance characteristics.

Simultaneously, the sustainability revolution is addressing the environmental costs of traditional waterproofing chemistry. The phase-out of PFAS chemicals and the rise of bio-based alternatives demonstrate that high performance and environmental responsibility are not mutually exclusive. Consumers can now choose gear that protects both themselves and the planet.

Performance vs. Sustainability Balance

Modern consumers face an encouraging reality: the traditional trade-off between performance and sustainability is diminishing. Bio-based DWR treatments now achieve 85-90% of traditional performance while offering complete biodegradability. Recycled membrane technologies provide excellent waterproofing while supporting circular economy principles. This convergence means that environmentally conscious choices no longer require significant performance compromises.

Strategic Recommendations for Consumers

- For Casual Users: Water-resistant fabrics with renewable DWR treatments offer optimal value. These provide adequate protection for everyday use while supporting sustainable manufacturing practices. Expect to reapply treatments annually, but enjoy better breathability and comfort.

- For Serious Outdoor Enthusiasts: Invest in premium membrane technologies from established manufacturers. Look for gear with proven field performance, repair services, and take-back programs. The higher initial cost provides better long-term value through extended lifespan and consistent performance.

- For Professional Applications: Prioritize durability and reliability over cutting-edge features. Choose systems with field repair capabilities and established supply chains. Consider multiple gear sets to ensure availability during critical periods.

- For Early Adopters: Smart textile features offer exciting possibilities but require careful evaluation of battery life, maintenance requirements, and integration with existing gear systems. Start with single pieces rather than complete system overhauls.

Economic Considerations

The cost analysis reveals that premium waterproof gear often provides superior value for frequent users. A $400 Gore-Tex jacket used regularly for eight years costs the same per use as a $60 budget jacket replaced every two years, while delivering far superior performance throughout its lifespan. However, infrequent users may find better value in mid-range options that balance cost with adequate performance.

Budget-conscious consumers should focus on versatile pieces that serve multiple purposes rather than specialized gear for specific conditions. A quality 2.5-layer jacket can handle most weather situations while weighing less and costing significantly less than separate lightweight and heavy-duty options.

Future-Proofing Your Gear Choices

As technology continues advancing rapidly, consider gear purchases as part of an evolving system rather than permanent solutions. Choose brands with strong innovation track records and customer service capabilities. Look for modular designs that allow component upgrades rather than complete replacement.

The trend toward subscription and service models in outdoor gear suggests that ownership patterns may shift dramatically over the next decade. Consider whether purchasing or accessing gear through rental, subscription, or take-back programs better suits your usage patterns and values.

Care and Maintenance Excellence

Proper care remains the most cost-effective way to maximize gear performance and lifespan. Regular cleaning with appropriate products, timely DWR reapplication, and proper storage significantly extend the life of waterproof treatments. Professional restoration services can refresh expensive gear at a fraction of replacement cost.

Understanding the specific care requirements of your gear prevents premature failure and maintains warranty coverage. Keep documentation and follow manufacturer guidelines precisely, especially for technical membrane systems.

Industry Outlook and Investment Implications

The $19.67 billion projected market size by 2030 indicates robust growth opportunities, but also increasing competition and rapid technological change. Consumers benefit from this competitive environment through better products, lower prices, and increased innovation pace.

Regional manufacturing trends suggest that high-quality technical fabrics will become more accessible globally as production capabilities expand beyond traditional centers. This geographic diversification may improve supply chain resilience while reducing costs.

Environmental Legacy and Responsibility

Perhaps most importantly, our fabric choices today influence the environmental legacy we leave for future generations. The transition away from persistent chemicals like PFAS represents a fundamental shift toward regenerative manufacturing practices. Supporting brands that prioritize environmental responsibility accelerates this transition while demonstrating market demand for sustainable alternatives.

The circular economy principles emerging in textile manufacturing promise to eliminate the concept of waste in waterproof fabric production. By choosing gear designed for end-of-life recovery and supporting take-back programs, consumers actively participate in creating sustainable industry practices.

Final Recommendations

- Assess your actual needs rather than worst-case scenarios when selecting waterproof fabrics

- Prioritize versatility over specialization unless you have specific professional requirements

- Invest in quality care products and maintenance routines to maximize gear lifespan

- Stay informed about emerging technologies but avoid constant upgrades for marginal improvements

- Support sustainable innovation through purchasing decisions and brand advocacy

- Consider the total system including layering, ventilation, and activity-specific requirements

- Plan for gear evolution rather than permanent solutions in this rapidly changing field

The future of waterproof fabrics promises continued innovation in performance, sustainability, and user experience. By understanding the principles outlined in this guide and staying informed about emerging developments, you can make confident decisions that serve your needs while supporting positive industry evolution.

Whether you are preparing for weekend adventures or professional challenges, the modern landscape of waterproof fabric technology offers unprecedented options for staying dry, comfortable, and environmentally responsible. The key lies in matching these technological capabilities with your specific requirements, values, and usage patterns to create the optimal gear system for your adventures ahead.

Frequently Asked Questions

General Understanding

What does waterproof mean?

Waterproof means a material completely prevents water from passing through it, even under pressure or extended exposure. This differs from water-resistant, which only provides temporary protection against light moisture.

What is the best waterproof material?

The best waterproof material depends on your specific needs. For breathable outdoor gear, Gore-Tex and similar membranes offer excellent performance. For maximum protection, laminated PVC or TPU provides complete water barriers. For budget-conscious applications, PU-coated fabrics offer good value.

What is the difference between waterproof and water repellent fabric?

Waterproof fabrics block all water penetration, while water repellent fabrics cause water to bead up and roll off the surface but may eventually allow penetration under pressure or extended exposure.

Fabric Performance

How can you tell if fabric is water resistant?

Perform a simple water droplet test: place a few drops of water on the fabric surface. If the water beads up and rolls off, the fabric has water resistance. If it soaks in immediately, the fabric lacks water-resistant treatment.

How do you make water resistant fabric waterproof?

You can upgrade water-resistant fabric to waterproof by applying additional treatments like liquid waterproofing solutions or adding a waterproof membrane backing. However, this may reduce breathability and flexibility.

Specific Applications

Can you wear a water-resistant jacket in the snow?

Water-resistant jackets work well in dry, powdery snow conditions. However, wet snow or mixed precipitation requires waterproof protection, as melting snow can penetrate water-resistant barriers over time.

Is water-resistant OK for rain?

Water-resistant gear handles light rain and brief showers effectively but will eventually allow water penetration during heavy or prolonged rainfall. For reliable rain protection, choose waterproof gear.

Product Comparisons

Which fabric is 100% waterproof?

Several fabrics achieve 100% waterproof performance:

• PVC and vinyl (completely impermeable)

• Rubber-coated fabrics

• Multi-layer laminates with sealed membranes

• TPU-coated technical fabrics

Is 100% polyester waterproof?

Pure polyester is naturally water-resistant due to its synthetic fiber structure, but it requires additional coatings or treatments to achieve true waterproof performance.