Everything you need to know about spider silk, from ancient uses to modern biotech breakthroughs and sustainable fashion

Table of Contents

- What Is Spider Silk?

- Amazing Properties of Spider Silk

- Spider Silk vs Other Fabrics

- The History of Spider Silk

- How Spider Silk Is Made

- Sustainability and Environmental Benefits

- Spider Silk in Fashion and Luxury

- Uses Beyond Fashion

- How to Care for Spider Silk

- Current Market and Future Outlook

- Buying Spider Silk Fabric

- Frequently Asked Questions

What Is Spider Silk?

Traditional weaving of golden spider silk fabric showcasing its precision, rarity, and intricate pattern design. Credit: Victoria and Albert Museum

Spider silk is a natural protein fiber produced by spiders from their spinnerets. It’s one of the most amazing materials found in nature, combining strength, elasticity, and biodegradability in ways that scientists have been trying to copy for centuries.

Unlike regular silk fabric from silkworms, spider silk comes in different types, each designed for a specific purpose. Spiders can produce up to seven different kinds of silk, including dragline silk (used for the main frame of webs), capture spiral silk (the sticky parts that trap prey), and egg sac silk (for protecting their babies).

Is Spider Silk a Fiber or Fabric?

Spider silk is technically a fiber, not a fabric. A fiber is the raw material, while fabric is what you get when fibers are woven, knitted, or bonded together. Think of it like cotton: cotton fibers can be made into cotton fabric, and spider silk fibers can be made into spider silk fabric.

The natural silk fiber is incredibly thin (2-4 micrometers in diameter) but packed with protein molecules arranged in a special structure that gives it super strength and stretch.

What Is Spider Silk Called?

Spider silk goes by several names depending on the context:

- Spidroin: The scientific name for spider silk proteins

- Dragline silk: The strongest type, used for web frames and spider safety lines

- Gossamer: An old poetic name for spider silk, especially the fine strands that float in the air

- Synthetic spider silk: Lab-made versions with brand names like Microsilk™, Biosteel®, and Dragon Silk®

Is Spider Silk Keratin?

No, spider silk is not made of keratin. It’s made of proteins called spidroins, which are different from keratin (the protein in hair and nails). Spidroins have a unique structure with crystalline regions (giving strength) and amorphous regions (giving flexibility), which is why spider silk can be both super strong and stretchy at the same time.

Amazing Properties of Spider Silk

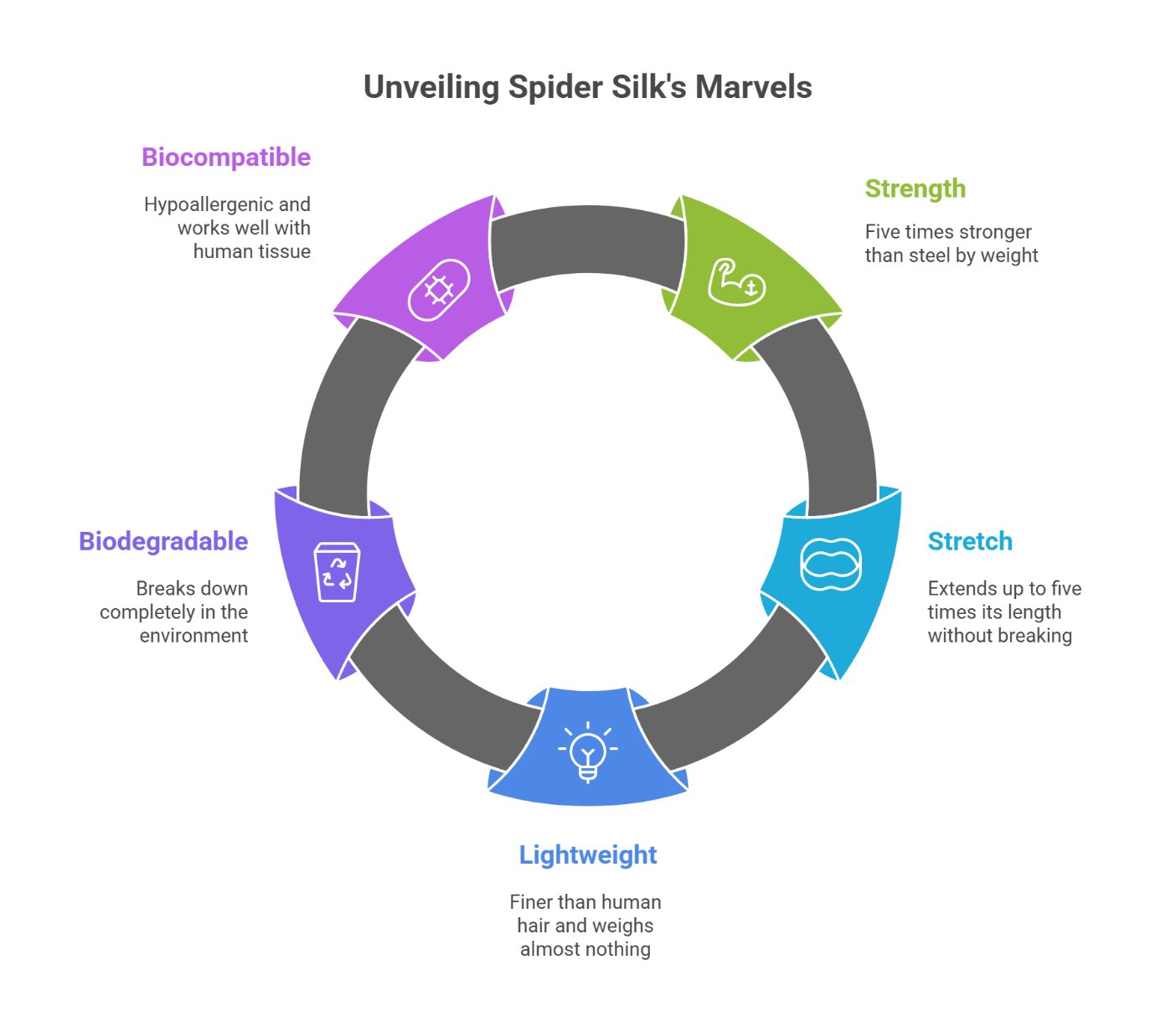

Spider silk properties illustrated through a circular infographic highlighting its strength, flexibility, biocompatibility, and environmental benefits.

What makes spider silk so special? Let’s break down its amazing properties that have scientists and fashion designers equally excited.

Strength That Beats Steel

Spider silk is five times stronger than steel by weight. If you had a spider silk thread and a steel wire of the same thickness, the spider silk could hold more weight before breaking. The tensile strength reaches up to 1.75 gigapascals (GPa), which is impressive for something produced naturally at room temperature.

Stretch Like Rubber

Unlike steel, which snaps when you try to stretch it, spider silk can extend up to five times its original length without breaking. This 30% or more elongation before failure means the material can absorb huge amounts of energy, making it tougher than Kevlar or any other synthetic fiber.

Lighter Than Air (Almost)

Spider silk is incredibly lightweight. It’s finer than human hair and weighs almost nothing, yet maintains all that strength and elasticity. This combination of being super light and super strong is rare in nature and almost impossible to achieve with man-made materials.

Completely Biodegradable

Being a natural protein, spider silk breaks down completely in the environment. Unlike polyester fabric or other synthetics that can take hundreds of years to decompose and shed microplastics, spider silk returns to nature without leaving any harmful residue.

Biocompatible and Safe

Spider silk is hypoallergenic and works well with human tissue. It doesn’t cause allergic reactions or immune responses, which makes it perfect for medical uses like sutures and tissue scaffolds. It’s also antimicrobial, helping prevent infections.

Quick Fact: Darwin’s bark spider produces the toughest known spider silk, with a toughness averaging 350 megajoules per cubic meter (MJ/m³). That’s more than twice as tough as any previously measured silk and over 10 times tougher than Kevlar.

Spider Silk vs Other Fabrics

How does spider silk stack up against other materials? Let’s compare it to common fabrics and high-performance fibers.

| Material | Strength | Elasticity | Weight | Biodegradable | Best For |

|---|---|---|---|---|---|

| Spider Silk | 1.75 GPa | Stretches 5x | Very light | Yes | High-performance textiles, medical uses |

| Steel | 0.4-2 GPa | Minimal | Heavy | No | Construction, tools |

| Kevlar | 3.0 GPa | Limited (4%) | Light | No | Body armor, protective gear |

| Silkworm Silk | 0.5 GPa | Moderate | Very light | Yes | Luxury clothing, bedding |

| Nylon | 0.08 GPa | Good | Light | No | Activewear, hosiery |

| Carbon Fiber | 4+ GPa | Very low (1%) | Light | No | Aerospace, automotive |

What Is the Difference Between Silk and Spider Silk?

Regular mulberry silk and spider silk are both natural protein fibers, but they have key differences:

- Source: Regular silk comes from silkworm cocoons; spider silk comes from spider spinnerets

- Strength: Spider silk is about 3-5 times stronger than silkworm silk

- Elasticity: Spider silk can stretch much more (up to 5x vs. about 2x for silkworm silk)

- Water resistance: Spider silk is more waterproof and can absorb three times the impact force without breaking

- Production: Silkworm silk is commercially farmed; spider silk is nearly impossible to farm naturally

- Proteins: Silkworm silk contains sericin proteins; spider silk doesn’t

Is Caterpillar Silk the Same as Spider Silk?

No, caterpillar silk (silkworm silk) and spider silk are different. While both are natural protein fibers, they come from different creatures with different protein structures. Silkworm silk has been farmed for over 5,000 years and is commercially available. Spider silk, on the other hand, has been almost impossible to produce in large quantities until recent biotech advances.

Can Spider Silk Replace Kevlar?

Spider silk could potentially replace Kevlar in some applications, but each has advantages. Kevlar is stronger in pure tensile strength (3.0 GPa vs. 1.75 GPa for spider silk), but spider silk is tougher overall because it can absorb more energy before breaking. Spider silk’s flexibility and biodegradability make it better for medical and sustainable applications, while Kevlar’s current availability and proven track record keep it in use for body armor.

Could Spider Silk Stop a Bullet?

Theoretically, yes, but you’d need a lot of it. Research shows that a bulletproof vest would need to be made of many layers of spider silk to stop a bullet. While spider silk’s toughness is impressive, its thinner diameter compared to Kevlar means you’d need more material. Scientists are working on this, and companies like Kraig Biocraft Labs are developing spider silk specifically for military-grade protective gear.

Is Spider Silk Better Than Kevlar?

It depends on what you mean by “better.” Spider silk wins in toughness (energy absorption), flexibility, biodegradability, and biocompatibility. Kevlar wins in pure tensile strength and current commercial availability. For protective clothing that needs to move with the body and eventually break down, spider silk would be better. For rigid protective panels, Kevlar still has the edge.

Is Spider Silk the Strongest Material?

Spider silk isn’t the absolute strongest material in terms of tensile strength (graphene and carbon nanotubes are stronger), but it’s the strongest natural fiber and has the best combination of strength and toughness. Its ability to absorb energy while staying flexible makes it functionally stronger for many real-world applications.

Is Spider Silk Stronger Than Carbon Fiber?

Carbon fiber has higher tensile strength (4+ GPa), but it’s rigid and brittle. Spider silk (1.75 GPa) is more flexible and tough. Carbon fiber will snap if bent too far, while spider silk can stretch and bounce back. For applications needing both strength and flexibility, spider silk wins.

Why Don’t We Use Spider Silk Instead of Steel?

Three main reasons:

- Scale: We can’t produce spider silk in the massive quantities needed to replace steel in construction

- Properties: Steel is stiff and rigid, which is what you want for buildings and bridges; spider silk is flexible

- Cost: Spider silk currently costs about 10 times more than high-performance synthetic fibers, while steel is cheap and abundant

Steel and spider silk are simply suited for different purposes. Spider silk shines in applications where you need something lightweight, flexible, and strong, not in situations requiring rigid structural support.

The History of Spider Silk

Humans have been fascinated by spider silk for thousands of years. Let’s walk through some key moments in spider silk history.

Ancient Times

The ancient Greeks and Romans used spider webs as wound dressings. They discovered that webs helped stop bleeding and seemed to protect wounds from infection. Indigenous people in the Solomon Islands used spider silk to make fishing lures for catching needlefish.

1621

First written reference to spider silk thread appears in Italy. Dr. Epifanio Ferdinando spun tarantula egg sacs into yarn, producing about 450 grams of material.

1709

François-Xavier Bon de Saint-Hilaire creates the first recorded spider silk garments: stockings and gloves. He made them by collecting spider egg cocoons and spinning the fibers. He presented them to the French Academy, convincing himself that spider silk would soon replace silkworm silk. When Louis XIV tried on a spider silk garment, however, it tore easily, causing a royal fashion disaster.

1796

Spanish Jesuit priest Raimondo Maria de Termeyer invents a reeling device for harvesting spider silk directly from living spiders. He establishes a spider farm and produces over 2,000 cocoons.

1800s

French missionary Paul Camboué, working in Madagascar, becomes fascinated with Golden Orb Weaver spiders. He develops a system for collecting spiders and harvesting their silk, realizing the long, strong, golden fibers could improve textile production.

1900

French colonial authorities produce a spider silk bed canopy for the Paris Exposition Universelle. Unfortunately, this piece is now lost to history.

2005-2009

Nicholas Godley and Simon Peers begin collecting spider silk in Madagascar to revive the art of spider silk textiles. After four years of work involving 82 people and more than 1.2 million golden orb spiders, they complete the Golden Spider Silk Cape. It takes 23,000 spiders to produce just one ounce of thread. The finished piece measures 11 by 4 feet and is the largest piece of spider silk cloth ever made.

Discover how the largest pieces of golden spider silk cloth were made, from collecting the silk from the spiders, spinning the threads and weaving, to embroidering the finished garments.

2012

The Golden Spider Silk Cape is displayed at London’s Victoria and Albert Museum, attracting worldwide attention to spider silk’s potential.

2017

Stella McCartney partners with biotech company Bolt Threads to create a dress made from Microsilk™ (synthetic spider silk). The piece debuts at the Museum of Modern Art (MoMA) in New York, marking spider silk’s entry into high fashion.

2024-2025

Multiple companies (Bolt Threads, Spiber, AMSilk, Kraig Biocraft Labs) scale up synthetic spider silk production. First commercial products expected in late 2025. The spider silk market reaches $160.1 million with projections to hit $610.3 million by 2035.

How Spider Silk Is Made

There are two ways to get spider silk: natural harvesting and synthetic production. Let’s look at both.

Natural Harvesting (The Traditional Way)

Natural spider silk harvesting is labor-intensive and rare. Here’s how the Golden Spider Silk Cape team did it in Madagascar:

- Collect golden orb weaver spiders (only females produce the strong silk needed for textiles)

- Secure each spider carefully without harming it

- Gently pull silk from the spider’s spinnerets using a hand-cranked device

- Each spider produces about 100 feet (30 meters) of silk in a 5-minute session

- Release the spider back into the wild to continue its normal life

- Collect silk from multiple spiders (24 strands twisted together make one basic thread)

Why We Can’t Farm Spiders Like Silkworms: Spiders are solitary and territorial. Put too many together, and they’ll eat each other. Unlike silkworms, which happily live in crowded conditions, spiders need their space. This makes large-scale natural production almost impossible.

Synthetic Spider Silk (The Modern Approach)

Scientists have found a way to make spider silk without using spiders at all. This is where biotechnology becomes exciting.

How Synthetic Spider Silk Is Made

The process uses genetic engineering and fermentation:

- Study spider DNA: Scientists analyze spider genes to understand which DNA sequences create silk proteins

- Insert genes into microbes: The spider silk genes are inserted into bacteria, yeast, or other microorganisms

- Fermentation: The modified microbes are grown in large fermentation tanks with sugar and water (similar to brewing beer)

- Protein production: The microbes produce spider silk proteins as they grow

- Protein extraction: The silk proteins are separated and purified from the microbes

- Spinning into fiber: The liquid proteins are spun into solid fibers using a process similar to making rayon or acrylic

- Weaving or knitting: The fibers are processed into fabrics and garments

The beauty of this method? It happens at room temperature (unlike silkworm silk production, which requires boiling cocoons), uses renewable resources (plant sugars), and doesn’t harm any animals.

Leading Companies Making Synthetic Spider Silk

- Bolt Threads (California, USA): Makes Microsilk™ using engineered yeast. Partners with fashion brands like Stella McCartney. Revenue: about $65 million in 2024.

- Spiber (Japan): Produces Brewed Protein™ fibers using fermentation. Partners with The North Face, Adidas, and Airbus. Has a production facility in Thailand making 100 tons of protein per year. Revenue: $72 million in 2024.

- AMSilk (Germany): Creates Biosteel® fibers using bacteria. Works with Adidas and Airbus on automotive interiors and sportswear. Building new production facility to double capacity by 2026.

- Kraig Biocraft Labs (USA): Takes a different approach by genetically modifying silkworms to produce spider silk proteins. Produces Dragon Silk® and Monster Silk™. Has facilities in Vietnam. Revenue: $32 million in 2024, with breakthrough expected in 2025.

- Spintex Engineering (UK): Focuses on replicating the natural spider spinning process at room temperature. Spun out from Oxford University’s Silk Group.

- Seevix Material Sciences (Israel): Makes 100% spider silk protein materials for aerospace, automotive, textiles, and defense applications.

Sustainability and Environmental Benefits

Spider silk sustainability infographic outlining its eco friendly production and environmental advantages.

Fashion has a serious environmental problem. The industry produces about 100 billion new garments every year, with 60% made from synthetic materials. Fashion contributes around 10% of global carbon dioxide emissions. Synthetic fabrics release an estimated 35% of the microplastic pollution in the ocean and make up most of the waste in landfills.

Spider silk offers a sustainable alternative. Here’s why it’s better for the planet:

100% Biodegradable

Spider silk is pure protein. When you’re done with a spider silk garment, it will break down completely in the environment, just like wool or cotton. No microplastics, no forever chemicals, no landfill waste lasting hundreds of years.

No Microplastic Pollution

Every time you wash synthetic clothes, tiny plastic fibers wash down the drain and end up in rivers and oceans. Spider silk doesn’t shed microplastics. Being a natural protein, any fibers that come off will simply biodegrade.

Low-Energy Production

Spider silk (both natural and synthetic) is produced at room temperature using water-based processes. Compare this to traditional silk production, which requires boiling thousands of liters of water every day to process cocoons, or synthetic fiber production, which uses petroleum and high temperatures.

Renewable Resources

Synthetic spider silk uses plant sugars (usually from corn) and microbes that can be grown indefinitely. Unlike petroleum-based synthetics like polyester or nylon, the raw materials are renewable and don’t deplete fossil fuel reserves.

Potential for Closed-Loop Manufacturing

Because spider silk production uses fermentation (similar to brewing), companies can design closed-loop systems where byproducts from one stage feed into another. Some companies are even exploring using the leftover yeast or bacteria as food or fertilizer.

Real Impact Numbers

If spider silk could replace just 10% of synthetic fabrics in fashion:

- It would eliminate about 3.5% of ocean microplastic pollution

- Save energy equivalent to millions of barrels of oil per year

- Reduce fashion industry carbon emissions by approximately 1%

- Divert millions of tons of waste from landfills

Spider Silk in Fashion and Luxury

Model Bianca Gavrilas wears a hand-embroidered cape made from the silk of the Golden Orb Spider in the V&A Museum’s Medieval and Renaissance Gallery. Credit: Getty Images

Spider silk is making its way into high-end fashion, and designers are excited about its potential for luxury sustainable clothing.

Why Fashion Designers Love Spider Silk

- Luxury feel: Soft and smooth like traditional silk, with a natural golden shimmer

- Performance: Strong and durable, perfect for garments that need to last

- Versatility: Can be made into different weights and textures

- Sustainability story: Appeals to eco-conscious consumers

- Innovation factor: Cutting-edge technology meets timeless elegance

Current Fashion Applications

While large-scale spider silk fashion is still emerging, some pieces have already made waves:

- Stella McCartney x Bolt Threads dress: A golden dress unveiled at MoMA in 2017, made entirely from Microsilk™

- Bolt Threads necktie: Limited edition ties released as one of the first commercial spider silk fashion items

- Activewear prototypes: Adidas and other sportswear brands testing spider silk for high-performance athletic clothing

- Luxury scarves and shawls: Small batches from companies experimenting with spider silk textiles

Spider Silk for Performance Wear

Spider silk’s combination of strength, stretch, and breathability makes it perfect for activewear and sportswear. Companies are developing:

- Running shoes with spider silk uppers (lightweight and breathable)

- Yoga pants that move with you and last longer

- Outdoor gear that’s tough but packs light

- Compression garments that support without restricting

Kraig Biocraft Labs is specifically targeting the sports apparel market, with prototypes expected to ship to interested brands by late 2025. The global sports apparel market is projected to reach $400 billion by 2030, and spider silk could capture a niche in the $50-70 billion premium performance category.

The Golden Color

Natural spider silk, particularly from golden orb weavers, has a beautiful golden hue. This color isn’t from dye; it comes from light refraction through the silk’s protein structure. This natural shimmer gives spider silk fabrics a luxurious appearance without any chemical treatments.

Uses Beyond Fashion

Spider silk isn’t just for clothes. Its amazing properties make it useful in many other industries.

Is Spider Silk Used in Medicine?

Yes, and this might be where spider silk has the biggest impact. Its biocompatibility and biodegradability make it perfect for medical applications.

Medical Uses of Spider Silk

- Surgical sutures: Strong, flexible, and cause minimal scarring. Particularly good for delicate surgeries like nerve repair or eye operations

- Wound dressings: Natural antimicrobial properties help prevent infections while promoting faster healing

- Tissue scaffolds: Used in tissue engineering to grow new organs and tissues. The silk provides structure for cells to grow on, then biodegrades as the new tissue develops

- Artificial ligaments and tendons: The combination of strength and elasticity mimics natural connective tissue

- Drug delivery systems: Spider silk can be formed into capsules that release medication slowly over time

- Nerve regeneration: Research shows spider silk can help guide nerve cells as they regrow after injury

Is Spider Silk Used for Bulletproof Vests?

Not yet in commercial products, but research is ongoing. Spider silk’s toughness and energy absorption make it promising for body armor, and companies like Kraig Biocraft Labs are developing military-grade spider silk specifically for defense applications. The challenge is producing enough material at the right specifications.

Other Industrial Applications

- Aerospace: Lightweight composites for aircraft parts, parachutes, and flexible electronics

- Automotive: Rust-proof panels, interior fabrics, and safety components

- Electronics: Biodegradable sensors and circuits

- Packaging: Biodegradable alternatives to plastic packaging

- Cosmetics: Hair care products (strengthening) and skin care (moisture retention)

- Ropes and cables: Strong, lightweight alternatives to synthetic ropes

Can Spider Silk Be Used as a Rope?

Absolutely. Spider silk’s strength-to-weight ratio makes it ideal for ropes and cables. A rope made from spider silk would be much lighter than traditional rope while being just as strong. This is particularly useful in applications where weight matters, like mountain climbing gear or aerospace applications.

How to Care for Spider Silk

Spider silk fabric requires gentle care, similar to traditional silk fabric care. Since commercial spider silk garments are still rare, most care instructions are adapted from traditional silk and early synthetic spider silk products.

Washing Spider Silk

- Check the label first: Always follow the manufacturer’s specific care instructions

- Hand washing is safest: Fill a basin with cool or lukewarm water (never above 30°C/86°F)

- Use gentle detergent: Choose a pH-neutral detergent designed for delicate fabrics. No enzymes, bleach, or harsh chemicals

- Soak briefly: Let the garment soak for 3-5 minutes, gently swishing the water

- Don’t agitate: No rubbing, twisting, or wringing. Protein fibers lose strength when wet

- Rinse thoroughly: Use cool water until all detergent is removed

- Remove excess water gently: Press the garment between clean towels. Never wring or twist

Machine Washing (If Permitted)

Some synthetic spider silk items may be machine washable. If so:

- Use a mesh laundry bag to protect the fabric

- Select the most delicate cycle available

- Use cool water (30°C/86°F maximum)

- Use the lowest spin speed

- Remove immediately when cycle finishes

Drying Spider Silk

- Air dry only: Never use a tumble dryer. High heat can damage protein fibers

- Dry flat: Lay the garment on a clean, dry towel away from direct sunlight

- Avoid hanging wet silk: The weight of water can stretch the fabric

- Keep out of direct sun: UV rays can fade colors and weaken fibers

Ironing and Pressing

- Iron while slightly damp for best results

- Use the lowest heat setting (silk setting if available)

- Turn garment inside out

- Place a clean cloth between iron and fabric

- Never leave the iron in one spot

Storage

- Store in a cool, dry place

- Use breathable garment bags, not plastic

- Avoid mothballs (use cedar instead)

- Don’t overcrowd the closet

- Keep away from direct sunlight

Important Note: Spider silk maintains about 70% of its strength when wet, similar to regular silk. This means you need to be extra gentle during washing and never wring or twist wet spider silk items.

For more detailed fabric care guidance, check out our comprehensive silk care guide and guide to washing different fabrics.

Current Market and Future Outlook

The spider silk market is growing fast as production technology improves and costs come down.

Market Size and Growth

- 2024 market value: $160.1 million for natural and synthetic spider silk combined

- Synthetic spider silk alone: $31.6 million in 2024

- 2033 projection: $387.97 million for synthetic spider silk (32.5% annual growth)

- 2035 projection: $610.3 million for the overall spider silk market (13% annual growth)

What’s Driving Growth?

- Government funding for biotechnology research (US Department of Energy: $945 million for biological research in FY 2025)

- Demand for sustainable alternatives to synthetic fabrics

- Advances in fermentation technology (production time cut by 25% in recent years)

- Fashion industry push for eco-friendly materials

- Military and aerospace interest in high-performance materials

- Medical applications for biocompatible materials

Regional Leaders

- Asia-Pacific: Dominates with 45% market share. Japan, China, and South Korea are investing heavily in biotech textile manufacturing

- North America: About 45% of synthetic spider silk market. Strong biotech ecosystem in California, Massachusetts, and North Carolina

- Europe: Growing market, particularly in Germany and UK. Strict sustainability policies drive demand for biodegradable fabrics

Challenges Holding Back Growth

- Cost: Production costs are still about 10 times higher than traditional synthetic fibers

- Scale: Companies are still working on scaling from pilot production to industrial quantities

- Technical challenges: Replicating all of natural spider silk’s properties in synthetic versions is difficult

- Consumer awareness: Most people have never heard of spider silk fabric

- Supply chain: Infrastructure for spider silk production and processing is still developing

What to Expect by 2030

Industry experts predict that by 2030, spider silk will:

- Be commercially available in premium fashion and sportswear

- Cost less as production scales up

- Have multiple medical products on the market

- Be used in military and aerospace applications

- Start appearing in mainstream consumer products

Buying Spider Silk Fabric

Can You Buy Spider Silk Fabric?

Yes, but availability is extremely limited. As of 2025, spider silk fabric and products are not widely available to regular consumers. You’re most likely to find:

- Limited edition fashion pieces from luxury brands

- Prototype products from biotech companies

- Small-batch items from specialty retailers

- Professional/industrial applications (medical, aerospace)

Why Is Spider Silk So Expensive?

Several factors make spider silk pricey:

- Production costs: Synthetic production requires expensive fermentation equipment and genetic engineering technology

- Low volume: Companies are still scaling up. Small production runs mean higher per-unit costs

- Natural harvesting is labor-intensive: Remember, it took 1.2 million spiders and four years to make one cape

- Research and development: Companies have invested heavily in developing production methods

- Luxury positioning: Early products target high-end markets willing to pay premium prices

As production scales up and technology improves, prices are expected to drop significantly over the next 5-10 years.

What to Look for When Buying

If you find spider silk products for sale:

- Verify authenticity: Look for products from known companies (Bolt Threads, Spiber, AMSilk, etc.)

- Check if it’s natural or synthetic: Natural harvested spider silk is extremely rare; most products use synthetic spider silk

- Read care instructions carefully: Follow them exactly to protect your investment

- Understand the price reflects innovation: You’re paying for cutting-edge biotechnology and sustainability

- Ask about certifications: Look for sustainability certifications or biocompatibility testing if relevant

Alternatives While You Wait

If you’re interested in sustainable, high-performance fabrics but spider silk isn’t available yet, consider:

- Mulberry silk (look for peace silk/ahimsa silk for ethical options)

- Other silk types like dupioni or charmeuse

- Organic cotton

- Linen (also biodegradable and sustainable)

- Recycled synthetic fabrics as a more sustainable option than virgin synthetics

Frequently Asked Questions

Why can’t we use spider silk?

We can use spider silk, but mass production has been challenging. Natural harvesting is almost impossible because spiders are territorial and cannibalistic (they can’t be farmed like silkworms). However, companies have now developed synthetic spider silk using biotechnology, making it possible to produce spider silk without using any spiders. The remaining challenge is scaling up production to meet demand and bringing costs down.

Can humans use spider silk?

Yes, humans can safely use spider silk. It’s biocompatible (works well with human tissue), hypoallergenic (doesn’t cause allergic reactions), and antimicrobial. People have been using spider webs for wound care since ancient times. Modern applications include surgical sutures, tissue engineering scaffolds, and clothing. Spider silk is one of the safest natural fibers for human contact.

Is spider silk poo?

No, spider silk is not waste material. It’s a protein fiber produced by special glands in the spider’s abdomen. The spider creates liquid silk proteins inside its body, then pushes them through tiny tubes called spinnerets. As the liquid passes through the spinnerets, it transforms into solid silk thread. Think of it more like how your body produces hair or nails (proteins), not waste.

What are the downsides to using artificial spider silk?

Current challenges with synthetic spider silk include: higher production costs (about 10 times more expensive than traditional synthetic fibers), difficulty replicating all of natural spider silk’s properties simultaneously, limited production capacity (companies are still scaling up), requirement for specialized production facilities, and some versions may not match the exact performance of natural spider silk. However, these downsides are being addressed as technology improves.

How strong is spider silk fabric?

Spider silk has a tensile strength of up to 1.75 gigapascals (GPa), making it about five times stronger than steel by weight. It can stretch up to five times its original length and is two to three times tougher than Kevlar. Darwin’s bark spider produces the toughest spider silk ever measured, with toughness averaging 350 megajoules per cubic meter (over 10 times tougher than Kevlar).

Can you make fabric from spider silk?

Yes, you can make fabric from spider silk, but it’s extremely difficult and time-consuming. The largest spider silk fabric ever made (the Golden Spider Silk Cape in 2009) required 1.2 million spiders and four years of work. Modern synthetic spider silk makes fabric production more practical by using biotechnology to produce silk proteins without spiders, then spinning those proteins into fibers that can be woven or knitted into fabric.

Is spider silk good for clothes?

Spider silk is excellent for clothes. It combines softness and luxury feel with impressive strength and durability. It’s breathable, moisture-wicking, lightweight, and completely biodegradable. The natural golden shimmer adds a luxurious appearance. Spider silk clothing would last longer than most fabrics while being comfortable to wear and better for the environment. The main limitation is current availability and cost.

What is the future of spider silk technology?

The future of spider silk looks bright. By 2030, experts predict wider availability in premium fashion and sportswear, medical products on the market, military and aerospace applications, lower costs as production scales up, and possible mainstream consumer products. Companies are working on producing tens to hundreds of metric tons per year. The market is projected to reach over $600 million by 2035, with new applications constantly being discovered.

Is spider silk stronger than silk?

Yes, spider silk is significantly stronger than silkworm silk. Spider silk is about 3-5 times stronger, can stretch more (up to 5x its length vs. about 2x for silkworm silk), is more waterproof, and can absorb three times the impact force without breaking. While both are natural protein fibers, spider silk has a superior protein structure that gives it better mechanical properties.

Which insect is silk fiber made from?

Traditional silk fiber comes from silkworms (the caterpillar of the Bombyx mori moth), not spiders. Spiders are arachnids, not insects. Silkworms have been farmed for over 5,000 years to produce commercial silk. Spider silk, while also a natural fiber, comes from spiders and has different properties. Some biotech companies are now genetically modifying silkworms to produce spider silk proteins, combining the ease of silkworm farming with spider silk’s superior properties.

Conclusion

Spider silk represents one of the most exciting developments in sustainable textiles and high-performance materials. What ancient Greeks used for wound healing and what spiders have perfected over millions of years is finally becoming accessible through modern biotechnology.

The journey from rare curiosity to commercial reality has been long. From Louis XIV’s torn spider silk stockings in 1709 to the stunning Golden Spider Silk Cape displayed at the V&A Museum to Stella McCartney’s Microsilk™ dress at MoMA, spider silk has captured human imagination for centuries. Now, companies like Bolt Threads, Spiber, AMSilk, Kraig Biocraft Labs, and others are turning that imagination into reality.

Key Takeaways

- Spider silk is nature’s super fiber: Five times stronger than steel by weight, stretches like rubber, lighter than air, and completely biodegradable

- It’s not just for fashion: Medical applications (sutures, tissue scaffolds), military gear, aerospace components, and more

- Sustainability champion: No microplastics, biodegradable, renewable resources, low-energy production

- Biotechnology makes it possible: Synthetic spider silk uses fermentation to produce silk proteins without any spiders

- The market is growing fast: Expected to reach over $600 million by 2035 as production scales and costs drop

- Limited availability now, but expanding: First commercial products expected in late 2025, with wider availability by 2030

What This Means for You

If you’re a fashion lover, spider silk offers the chance to wear cutting-edge sustainable luxury. The fabric combines the best of natural and high-performance materials without the environmental guilt of synthetics.

For eco-conscious consumers, spider silk represents what the future of textiles should look like: strong, durable, biodegradable, and produced without depleting resources or harming animals.

Textile professionals should watch this space closely. As production costs come down and availability increases, spider silk will likely disrupt multiple market segments from luxury fashion to technical textiles.

Science enthusiasts can appreciate the amazing intersection of biology, materials science, and genetic engineering that makes synthetic spider silk possible. We’re literally programming microbes to produce one of nature’s most amazing materials.

Looking Ahead

The next five years will be transformative for spider silk. As production facilities scale up, costs come down, and more companies enter the market, we’ll see spider silk move from rare luxury items to more accessible products. The fashion industry’s demand for sustainable alternatives, combined with government support for biotechnology, creates perfect conditions for spider silk’s growth.

Major fashion collaborations announced for 2025 and 2026 will bring spider silk into the spotlight. Military contracts for protective gear will drive production volumes up. Medical applications will save lives while proving spider silk’s biocompatibility. And all of this happens while reducing fashion’s environmental footprint.

Spider silk won’t replace all textiles, nor should it. But it will claim an important place in the fabric world, particularly for applications where strength, performance, and sustainability matter most. From the web to the wardrobe, spider silk’s journey continues, and we’re fortunate to witness this transformation.

Want to explore more sustainable and innovative fabrics? Check out our guide to natural vs synthetic fabrics and discover which materials work best for your needs.