Everything you need to know about panne satin, from its history and properties to care instructions and sustainable alternatives

Table of Contents

- What is Panne Satin Fabric?

- Understanding the Terminology: Panne Satin vs Panne Velvet

- The Rich History of Satin Fabric

- How Panne Satin is Made

- Types of Satin Fabrics

- Properties and Characteristics

- Uses and Applications

- Sustainability and Eco-Friendly Alternatives

- How to Care for Panne Satin

- Fabric Comparisons

- Buying Guide: What to Look For

- Frequently Asked Questions

- Conclusion

What is Panne Satin Fabric?

Panne satin is a special type of satin fabric that has been treated through a process called calendaring to create an exceptionally high luster finish. The word “panne” comes from French, meaning “flattened” or “pressed,” which perfectly describes how this fabric achieves its mirror-like shine.

Unlike regular satin, which already has a natural glossy appearance due to its weaving technique, panne satin takes shine to the next level. The fabric is passed through heavy heated rollers under pressure, which flattens the surface fibers and creates an intense, almost wet-looking sheen. This treatment makes panne satin one of the most reflective and glamorous fabrics available.

A detailed look at the shine and fluid drape of panne satin fabric.

Quick Definition

Panne satin is satin fabric that has undergone calendaring (a finishing process using heated rollers) to create an ultra-glossy, reflective surface. It can be made from silk, polyester, or other fibers.

Understanding the Terminology: Panne Satin vs Panne Velvet

Is Panne Satin the Same as Panne Fabric?

This is where things get confusing, and it’s important to clear this up right away. In today’s fabric market, when people say “panne,” they’re usually talking about two completely different materials:

Traditional Panne Satin

This is the original meaning: a satin fabric with a calendared finish that creates extreme shine. It’s stiff, very glossy, and has a distinctive reflective quality. You’ll find this in high-end evening wear and bridal gowns.

Modern “Panne” (Usually Panne Velvet)

More commonly today, “panne” refers to crushed velvet or velour fabric. When you search online for “panne fabric,” you’ll mostly find soft, stretchy velvet with pile pressed in one direction. This creates a shimmering effect, but it’s completely different from panne satin. This type is popular for costumes, dancewear, and drapery.

Comparing panne satin’s smooth shine with the crushed, plush texture of panne velvet.

Important Note: When shopping for fabric, always specify whether you want panne satin (the glossy, stiff satin) or panne velvet (the soft, crushed velvet). These are entirely different materials with different properties, uses, and care requirements. Many sellers use “panne” interchangeably, which creates confusion.

For the rest of this article, we’ll focus on traditional panne satin: the calendared satin fabric with exceptional luster.

The Rich History of Satin Fabric

Luxury satin fabric showcasing the timeless shine and fluid drape that shaped its historic popularity.

To understand panne satin, we need to look at the history of satin itself. The story begins over 1,300 years ago in China. According to historical textile records, satin weaving techniques represent one of the most important developments in textile manufacturing.

Satin weaving techniques were developed in China during the Tang Dynasty. The Chinese city of Quanzhou (called “Zaitun” by Arab traders) became the center of satin production. The name “satin” actually comes from this Arabic name. “Zaitun” eventually evolved into “satin” in European languages.

Arab merchants transported satin along the Silk Road trade routes, introducing this fabric to the Middle East. Satin was made exclusively from silk threads and was incredibly expensive. Only the wealthiest merchants, religious leaders, and royalty could afford it.

Italy became the first Western country to produce satin. Italian weavers mastered the complex satin weave, and the fabric began spreading throughout Europe. It remained a luxury item reserved for the upper classes.

By the 1300s, satin production had spread across Europe. France, England, and Spain developed their own satin-weaving industries. Satin became the fabric of choice for royal garments and ceremonial dress.

The Palace of Versailles in France showcased satin extensively in both clothing and furniture. Marie Antoinette’s extravagant satin gowns became symbols of royal luxury. This period saw the development of various satin finishing techniques, including early forms of calendaring.

New weaving technologies made satin production faster and more affordable. The development of calendaring machines allowed manufacturers to create the ultra-glossy panne finish. However, satin was still primarily made from expensive silk.

The invention of synthetic fibers like polyester, nylon, and rayon changed everything. Manufacturers could now create satin from affordable materials, making it accessible to everyone. Panne satin production became more common, especially for theatrical and formal wear.

Today, we have access to both traditional silk panne satin and modern synthetic versions. Sustainable options are emerging, including recycled polyester satin and organic silk. The calendaring process has been refined to create even more spectacular finishes.

How Panne Satin is Made

The Satin Weave

Before we get to the calendaring process, let’s understand what makes fabric “satin” in the first place. Satin isn’t actually a type of fiber. It’s a weaving technique.

In satin weave, the threads are arranged so that most of the warp threads (the threads running lengthwise) “float” over multiple weft threads (the threads running crosswise) before going under one. This creates long stretches of unbroken threads on the fabric surface, which reflect light beautifully instead of scattering it like other weaves do.

Types of Satin Weaves:

- 4-Harness Satin Weave: The weft thread goes over 3 warp threads, then under 1. This creates a smooth surface with good elasticity.

- 5-Harness Satin Weave: The weft goes over 4 warp threads, then under 1. This is slightly more flexible than 4-harness.

- 8-Harness Satin Weave: The weft goes over 7 warp threads, then under 1. This produces the smoothest, glossiest surface and is used for high-end satin.

The result is a fabric with one shiny side (where the long thread floats are) and one duller side (where the thread intersections are visible).

The Calendaring Process

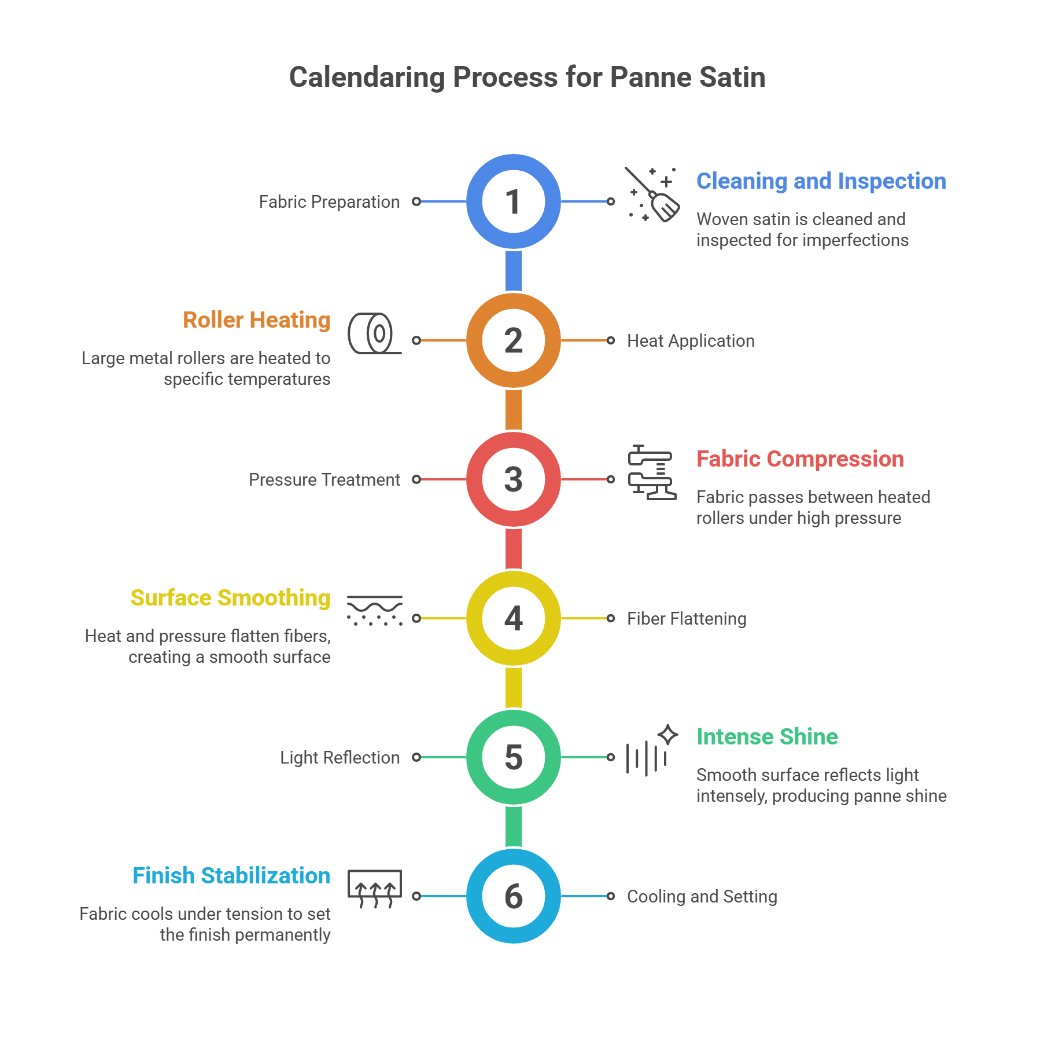

To transform regular satin into panne satin, manufacturers use a finishing process called calendaring. Here’s how it works:

A visual breakdown of how panne satin is produced through cleaning, heating, compression, smoothing, shining, and finish setting.

Calendaring Steps:

- Fabric Preparation: The woven satin fabric is cleaned and prepared to ensure there are no imperfections.

- Heat Application: Large metal rollers are heated to specific temperatures (the exact temperature depends on the fiber type).

- Pressure Treatment: The fabric passes between these heated rollers under tremendous pressure. For panne satin, the pressure is much higher than for regular finishing.

- Fiber Flattening: The heat and pressure flatten the surface fibers, pressing them in one direction and compressing them tightly together.

- Light Reflection: This flattening creates an extremely smooth, almost glass-like surface that reflects light intensely, producing the characteristic panne shine.

- Cooling and Setting: The fabric is allowed to cool while maintaining tension, which helps set the finish permanently.

Why Panne Satin is Different

Regular satin gets its shine from the weave structure. Panne satin has this weave-based shine PLUS the mirror-like finish from calendaring. This double shine effect is what makes panne satin so distinctive.

Fiber Selection for Panne Satin

Panne satin can be made from various fibers, each creating different results:

- Silk: Creates the most luxurious panne satin with natural luster and excellent drape. Very expensive.

- Polyester: The most common choice for panne satin. Affordable, durable, and takes calendaring very well. Creates brilliant shine.

- Nylon: Similar to polyester but slightly softer. Good for garments that need some stretch.

- Acetate: Economical option with decent shine. Less durable than polyester.

- Rayon: Semi-synthetic fiber with a silk-like feel. More affordable than silk but requires careful handling.

Types of Satin Fabrics

While we’re focusing on panne satin, it’s helpful to understand how it compares to other satin types. Here’s a comprehensive look at the satin family:

A visual comparison of different satin fabric types and their unique characteristics.

| Satin Type | Description | Best Uses | Price Range |

|---|---|---|---|

| Panne Satin | Ultra-glossy calendared finish, very stiff, mirror-like shine | Evening gowns, bridal wear, theatrical costumes | $$-$$$ |

| Charmeuse | Lightweight, drapey, shiny front with dull back | Lingerie, blouses, flowing dresses | $$-$$$$ |

| Duchess Satin | Heavy, stiff, holds shape well, moderate shine | Wedding gowns, formal wear, structured garments | $$$-$$$$ |

| Crepe Back Satin | Reversible: shiny satin one side, textured crepe other side | Versatile garments, bridal wear, evening wear | $$-$$$ |

| Baronet Satin | Rayon warp, cotton weft, very lustrous | Dresses, linings, formal wear | $$ |

| Messaline | Lightweight, high shine, loose weave | Linings, lightweight dresses, scarves | $-$$ |

| Antique Satin | Dull luster, textured with slubbed yarns, reversible | Upholstery, drapery, vintage-style garments | $$-$$$ |

| Slipper Satin | Medium weight, tightly woven, cotton backing | Ballet shoes, accessories, bridal wear | $$ |

| Acetate Satin | Affordable, medium weight, good shine | Linings, costume garments, budget formal wear | $ |

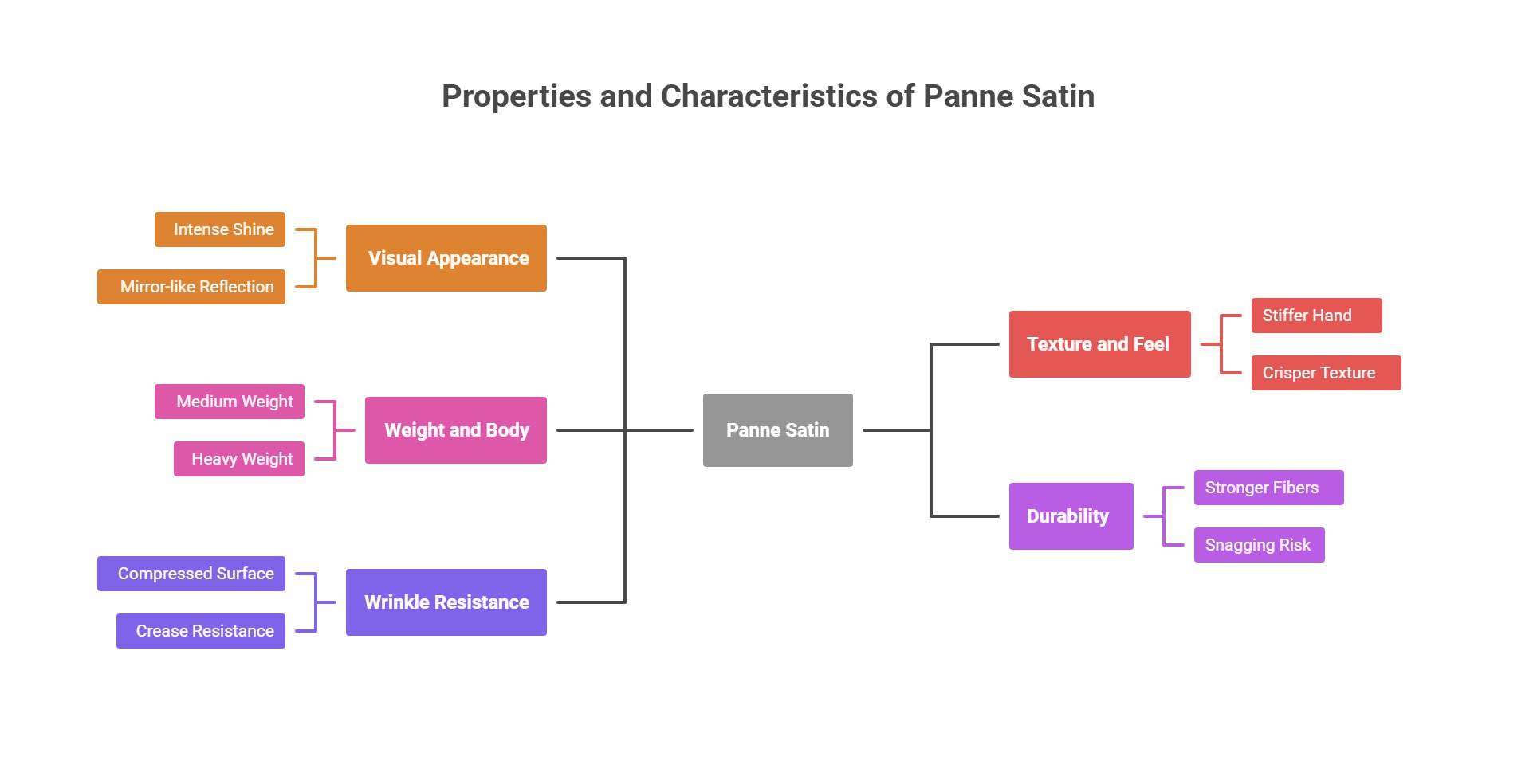

Properties and Characteristics of Panne Satin

A visual guide explaining the key performance traits that define panne satin fabric.

Visual Appearance

Panne satin is immediately recognizable by its intense, almost metallic shine. When light hits the surface, it creates a mirror-like reflection that’s far more dramatic than regular satin. The fabric often appears to glow, and it can look different from various angles as the light catches the flattened fibers.

Texture and Feel

Unlike the soft, flowing feel of charmeuse or regular satin, panne satin has a stiffer, crisper hand. The calendaring process compresses the fibers, creating a firmer texture. It’s smooth to the touch but doesn’t drape as easily as other satins. This stiffness is actually an advantage in garments that need to hold their shape.

Weight and Body

Panne satin typically falls into the medium to heavy weight category, depending on the fiber content and thread count. The calendaring process adds some weight and body to the fabric, making it more substantial than un-calendared satin of the same thread count.

Advantages of Panne Satin

- Spectacular Shine: The most reflective satin finish available

- Shape Retention: Holds structure better than flowing satins

- Wrinkle Resistance: The calendared finish resists wrinkling

- Dramatic Effect: Perfect for making a statement

- Professional Appearance: Looks expensive and formal

- Color Vibrancy: Colors appear deeper and more saturated

- Durability: The compressed fibers are more resistant to wear

Disadvantages of Panne Satin

- Less Drape: Doesn’t flow as beautifully as softer satins

- Stiff Feel: Not as comfortable for all-day wear

- Shine Can Be Too Much: Not suitable for daytime or casual wear

- Shows Fingerprints: The smooth surface shows handling marks

- Limited Breathability: Especially in synthetic versions

- Care Requirements: Needs special handling to maintain finish

- Snagging Risk: Smooth surface can catch on rough items

Durability

Panne satin is generally more durable than lighter satins because the calendaring process compresses and strengthens the fibers. However, like all satins, it can snag if caught on rough surfaces. The shine can diminish over time with repeated washing, though the fabric itself remains strong.

Wrinkle Resistance

One major advantage of panne satin is its resistance to wrinkles. The compressed, flattened surface doesn’t crease as easily as other fabrics. This makes it excellent for garments that need to look crisp throughout an event.

Uses and Applications of Panne Satin

A stylish example of panne satin used in modern fashion, showcasing its drape and luxurious shine.

Fashion and Apparel

Evening Wear and Formal Occasions

Panne satin’s spectacular shine makes it a top choice for evening gowns and formal dresses. The fabric catches the light beautifully under ballroom or stage lighting, creating a truly glamorous effect. It’s perfect for:

- Prom dresses

- Evening gowns

- Cocktail dresses

- Red carpet outfits

- Awards ceremony attire

Bridal Fashion

Some brides choose panne satin for its dramatic, formal appearance. It works especially well for structured wedding gown designs, bodices, and formal wedding accessories. However, many brides prefer softer satins like duchess satin for a more traditional bridal look.

Theatrical and Performance Costumes

The theater industry loves panne satin because it shows up brilliantly under stage lights. Dance costumes, theatrical productions, and performance wear often feature this fabric because it creates visual impact from a distance.

Formal Accessories

Panne satin appears in:

- Evening bags and clutches

- Dress shoes

- Hair accessories for formal events

- Formal belts and sashes

- Bow ties and cummerbunds

Home Décor

Special Occasion Decorations

Event planners and decorators use panne satin for:

- Luxury table linens for galas

- Decorative pillow covers for formal spaces

- Ceremonial draping

- Chair sashes for weddings

- Backdrop fabrics for photo booths

Not Recommended For: Panne satin is NOT suitable for everyday upholstery or curtains in living spaces. The shine is too formal, and the fabric will show wear quickly in high-traffic areas. For home use, consider antique satin or other durable upholstery fabrics instead.

Special Projects

- Costume Making: Historical costumes, cosplay, and fantasy garments

- Dance Recitals: Stage costumes for ballet, ballroom, and performance dance

- Pageant Wear: Beauty pageant gowns and competition outfits

- Religious Ceremonies: Choir robes, ceremonial vestments

Sustainability and Eco-Friendly Alternatives

Like most synthetic fabrics, traditional polyester panne satin has some environmental concerns. However, the industry is making progress toward more sustainable options.

Environmental Impact of Conventional Panne Satin

Polyester Production

Most panne satin today is made from polyester, which comes from petroleum. The production process:

- Uses significant energy

- Creates greenhouse gas emissions

- Relies on non-renewable resources

- Takes hundreds of years to biodegrade

- Can shed microplastics when washed

The Calendaring Process

The heat and pressure required for calendaring uses additional energy, though this is a relatively small part of the overall environmental footprint.

Sustainable Alternatives

Recycled Polyester Satin

Several manufacturers now produce satin from recycled polyester (rPET), made from post-consumer plastic bottles. This option:

- Reduces landfill waste

- Uses 50-60% less energy than virgin polyester

- Produces fewer emissions

- Maintains the same quality and shine as virgin polyester satin

- Can be calendared just like regular polyester

Organic Silk Satin

For those who can afford it, organic silk offers a more natural option:

- Made from silkworms raised without pesticides

- Biodegradable at end of life

- Uses natural dyes in some production methods

- Lower chemical usage in processing

However, traditional silk production involves killing the silkworm pupae. For a more ethical option, look for “peace silk” or “Ahimsa silk,” where the moths are allowed to emerge before the cocoons are processed.

Tencel™ or Lyocell Satin

While you won’t often find Tencel in panne satin specifically, it’s worth mentioning as a sustainable option for regular satin:

- Made from sustainably sourced wood pulp

- Closed-loop production process (99% of solvents are recovered and reused)

- Biodegradable

- Soft and luxurious

- OEKO-TEX and EU Ecolabel certified

Certifications to Look For

Eco-Friendly Certifications

- GOTS (Global Organic Textile Standard): For organic silk satin – Learn more about GOTS certification

- OEKO-TEX Standard 100: Ensures fabric is free from harmful chemicals – Official OEKO-TEX information

- GRS (Global Recycled Standard): Verifies recycled content in polyester satin

- EU Ecolabel: Indicates reduced environmental impact

- Bluesign: Certifies sustainable textile production

Making Sustainable Choices

If you’re shopping for panne satin and want to be more environmentally conscious:

- Choose Recycled: Look for rPET panne satin when possible

- Buy Quality: Higher quality fabrics last longer, reducing waste

- Buy What You Need: Purchase only the yardage you’ll actually use

- Proper Care: Maintain your garments well to extend their life

- Reuse and Repurpose: Find new uses for scraps and old garments

- Support Ethical Brands: Choose manufacturers committed to sustainability

- Consider Resale: Buy secondhand formal wear when possible

How to Care for Panne Satin

Proper care is essential to maintain panne satin’s beautiful shine and prevent damage. The stiff, calendared finish requires special attention.

Hand washing panne satin with mild detergent to maintain softness and shine.

Most Important Rule: Always check the care label first. Different fiber contents require different care methods. What works for polyester panne satin might ruin silk panne satin.

Before You Wear

Pre-Treatment

New panne satin garments sometimes have excess sizing or manufacturing residue. For synthetic panne satin, you can gently wipe the surface with a slightly damp cloth. For silk panne satin, skip this step and proceed directly to professional cleaning if needed.

General Washing Guidelines

Silk Panne Satin

- Dry Clean Only: Silk panne satin should always go to a professional cleaner. The calendared finish is delicate, and water can ruin the shine permanently.

- Choose a Specialist: Tell the cleaner that the fabric has a calendared finish and should be handled with extra care.

- Frequency: Dry clean only when necessary. Excessive cleaning can wear down the finish over time.

Polyester, Nylon, or Acetate Panne Satin

These synthetic versions can sometimes be hand-washed, but it’s risky. For best results:

Hand Washing Method (Use Cautiously):

- Test First: Test on a small, hidden area to ensure the finish won’t be damaged.

- Use Cold Water: Fill a clean basin with cold water (never warm or hot).

- Gentle Detergent: Add a small amount of detergent specifically designed for delicate fabrics. Avoid harsh chemicals.

- No Agitation: Gently swish the fabric in the water. Don’t scrub, wring, or twist.

- Minimal Soaking: Soak for no more than 3-5 minutes.

- Rinse Thoroughly: Rinse in cold water until all detergent is gone.

- Remove Water: Lay flat on a clean towel, roll gently to absorb water. Never wring.

- Air Dry Flat: Lay flat on a dry towel away from direct sunlight and heat.

Warning: Even hand washing can dull the panne finish over time. For garments you want to keep pristine, stick with dry cleaning.

Machine Washing (Not Recommended)

Machine washing panne satin is risky, even on delicate cycles. The agitation can permanently damage the calendared finish. If you absolutely must machine wash:

- Turn the garment inside out

- Place in a mesh laundry bag

- Use the most delicate cycle available

- Cold water only

- Minimal spin cycle

- Remove immediately when finished

Drying

Never Use a Dryer: The heat will ruin the calendared finish and can melt synthetic fibers. There are no exceptions to this rule.

Proper Drying Method:

- Lay the garment flat on a clean, dry towel

- Keep it away from direct sunlight (which can fade colors)

- Keep it away from heat sources (radiators, heating vents)

- Allow to air dry completely

- Reshape the garment while damp if needed

Ironing and Steaming

Pressing panne satin lightly with a low temperature iron to protect its reflective surface.

Ironing

If you must iron panne satin:

- Use the lowest heat setting (silk or synthetic setting)

- Always use a pressing cloth between the iron and fabric

- Iron on the wrong (dull) side only

- Never iron directly on the shiny side (it will damage the finish)

- Don’t use steam on the calendared side

- Use very light pressure

Steaming

Steaming is generally safer than ironing for panne satin:

- Hold the steamer at least 6 inches away from the fabric

- Use gentle steam (not high pressure)

- Steam from the wrong side when possible

- Allow the garment to cool and dry completely before wearing

For detailed care instructions that apply to all satin types, check out this guide on how to care for satin clothing.

Stain Removal

Stains on panne satin are tricky because rubbing can damage the finish.

Emergency Stain Treatment:

- Act Quickly: The faster you treat a stain, the better chance of removal.

- Blot, Don’t Rub: Gently blot with a clean, white cloth. Never rub or scrub.

- Cold Water: Dab with cold water to dilute water-based stains.

- No Harsh Chemicals: Avoid bleach, strong stain removers, or anything with alcohol.

- Professional Help: For serious stains, take the garment to a professional cleaner immediately.

Storage

Proper storage helps maintain panne satin’s appearance:

- Clean Before Storing: Always clean garments before long-term storage

- Use Padded Hangers: For hanging garments, use padded hangers to prevent shoulder marks

- Garment Bags: Store in breathable garment bags (not plastic, which can trap moisture)

- Fold Carefully: If folding, place acid-free tissue paper between folds

- Cool, Dry Place: Store in a cool, dry location away from direct sunlight

- Avoid Compression: Don’t stack heavy items on top of panne satin garments

- Check Periodically: Inspect stored items occasionally for signs of damage or pests

Fabric Comparisons

Panne Satin vs Regular Satin

Panne satin offers a more intense reflective shine compared to classic satin fabric.

| Feature | Panne Satin | Regular Satin |

|---|---|---|

| Shine Level | Extremely high, mirror-like | Moderate to high, natural sheen |

| Stiffness | Stiff, holds shape | Soft to medium, depends on type |

| Drape | Limited drape | Usually flows well |

| Best For | Formal events, theatrical use | Various uses from casual to formal |

| Price | Usually higher | Varies widely |

| Care | More delicate, dry clean recommended | Varies by fiber type |

Panne Satin vs Silk

A visual comparison of panne satin’s intense shine and silk’s natural, elegant glow.

People often confuse these terms. Remember: silk is a fiber (the material), while satin is a weave (how it’s made). You can have silk satin (silk fiber woven in satin weave) or silk woven in other patterns like taffeta or chiffon.

Quick Clarification

- Silk: A natural fiber from silkworm cocoons

- Satin: A weaving technique that creates a glossy surface

- Silk Satin: Silk fiber woven using satin weave

- Polyester Satin: Polyester fiber woven using satin weave

- Panne Satin: Any satin (silk or synthetic) that’s been calendared

Panne Satin vs Sateen

Comparing the high sheen of panne satin with the smooth but matte finish of sateen.

Sateen uses the satin weave technique but with short-staple fibers (usually cotton) instead of long filament fibers. The result:

- Sateen: Softer shine, cotton-based, more matte, breathable, commonly used for bedding

- Panne Satin: High shine, usually synthetic or silk, less breathable, used for formal wear

Panne Satin vs Velvet

A comparison showing the smooth reflective surface of panne satin next to the plush depth of velvet.

These are completely different fabric structures:

- Velvet: Has a soft, raised pile surface created by cut loops. Absorbs light, creating depth.

- Panne Satin: Smooth, flat surface with no pile. Reflects light intensely.

- Panne Velvet (Crushed Velvet): Velvet with the pile pressed down, creating shine. This is what causes the confusion with “panne” terminology.

Panne Satin vs Taffeta

Comparing panne satin’s fluid shine with the structured, slightly stiff texture of taffeta.

Taffeta is another formal fabric, but very different:

| Feature | Panne Satin | Taffeta |

|---|---|---|

| Weave | Satin weave | Plain weave |

| Surface | Very smooth, glossy | Slightly crisp, subtle sheen |

| Sound | Quiet | Rustles when moving |

| Body | Stiff but smooth | Crisp, paper-like |

| Best For | High-shine evening wear | Structured gowns, full skirts |

Buying Guide: What to Look For

Evaluating panne satin by checking drape, sheen, and fiber smoothness during purchase.

Identifying Quality Panne Satin

Visual Inspection

- Even Shine: The shine should be consistent across the entire fabric surface

- No Streaks: Look for uneven areas or streaking, which indicate poor calendaring

- Color Depth: High-quality panne satin shows rich, vibrant colors

- No Pulls or Snags: Inspect carefully for any surface damage

Touch Test

- Smooth Surface: Should feel slippery-smooth, not rough or uneven

- Consistent Stiffness: The fabric should have even body throughout

- Weight: Should feel substantial, not flimsy or cheap

Drape Test

While panne satin doesn’t drape as much as other satins, quality fabric should still move somewhat gracefully. If it’s completely rigid or crackly, it’s low quality.

Understanding Pricing

Fiber Content Impact

- Polyester Panne Satin: $8-$20 per yard

- Silk Panne Satin: $30-$100+ per yard

- Nylon or Acetate Panne Satin: $6-$15 per yard

Price vs Quality

Higher price doesn’t always mean better quality, but extremely cheap panne satin often has problems: uneven calendaring, poor color fastness, or weak construction. For special occasion garments, it’s worth investing in mid-range to higher-end fabric.

Where to Buy

Physical Fabric Stores

Pros: Can see and touch the fabric, get expert advice, no shipping costs for local shops

Cons: Limited selection, often higher prices, may not have panne satin in stock

Online Fabric Retailers

Pros: Wider selection, competitive pricing, convenient shopping, customer reviews

Cons: Can’t feel the fabric before buying, colors may look different on screen, shipping costs

Specialty Bridal or Formal Fabric Suppliers

Pros: High-quality options, knowledgeable staff, fabric specifically for formal wear

Cons: Usually more expensive, may have minimum purchase requirements

Smart Shopping Tip: Order swatches before committing to yardage, especially when buying online. Most reputable fabric sellers offer swatches for a small fee. This lets you see the actual color, feel the texture, and test the quality before investing in your full yardage.

How Much to Buy

When purchasing fabric for a garment project:

- Check Pattern Requirements: Your sewing pattern will specify yardage needed

- Add Extra for Mistakes: Purchase 10-20% more than the pattern requires

- Consider Nap Direction: Panne satin can look different depending on direction due to the calendared finish

- Account for Matching: If your fabric has a pattern or print, you’ll need extra for pattern matching

- Plan for Testing: Buy extra for making test muslins or practice seams

Red Flags to Avoid

- Bargain Bin Prices: Extremely cheap panne satin often disappoints

- Inconsistent Reviews: Mixed reviews about shine quality or durability are warning signs

- Vague Fiber Content: “Satin-like” or “satin finish” without listing actual fibers

- No Care Instructions: Reputable sellers provide care information

- Excessive Shedding: Some low-quality polyester satin sheds fibers noticeably

Frequently Asked Questions

Conclusion

Panne satin stands out as one of the most glamorous and eye-catching fabrics available. Its intense, mirror-like shine comes from a special calendaring process that flattens and compresses the surface fibers, creating a finish that surpasses regular satin in drama and visual impact.

Key Takeaways

What to Remember About Panne Satin

- Terminology Matters: True panne satin is calendared satin fabric, not crushed velvet. Always clarify which type you’re looking for when shopping.

- Perfect for Formal Occasions: The spectacular shine makes panne satin ideal for evening wear, bridal fashion, theatrical costumes, and special events.

- Different from Regular Satin: Panne satin is stiffer, shinier, and less drapey than other satin types. It holds its shape well but sacrifices softness.

- Care is Critical: The calendared finish requires special handling. Dry cleaning is usually best, especially for silk versions. Never use a dryer or iron directly on the shiny side.

- Sustainable Options Exist: Look for recycled polyester satin or organic silk options to reduce environmental impact.

- Quality Varies: Invest in good-quality fabric for special garments. Check for even shine, consistent color, and smooth texture.

Making the Right Choice

Panne satin isn’t right for every project. Its intense shine and stiff character work best when you want maximum glamour and formality. Consider choosing a different satin type if you need:

- Soft drape and flow (choose charmeuse instead)

- All-day comfort (consider lighter satins or silk alternatives)

- Subtle elegance (try duchess satin or crepe-back satin)

- Easy care (synthetic satins without calendaring are more forgiving)

Your Next Steps

If you’re ready to work with panne satin:

- Order Swatches: Always test the fabric before buying full yardage, especially when ordering online.

- Review Care Requirements: Make sure you’re comfortable with the maintenance needs before committing.

- Consider the Occasion: Think carefully about where and when the garment will be worn.

- Plan for Professional Help: For expensive projects or if you’re new to sewing with slippery fabrics, consider having a professional seamstress handle construction.

- Invest in Proper Storage: Purchase padded hangers and breathable garment bags to protect your finished pieces.

Final Thoughts

Panne satin represents centuries of textile innovation, from ancient Chinese weaving techniques to modern calendaring processes. While it may not be the easiest fabric to work with or care for, its unmatched shine and formal elegance make it worthwhile for special occasions that deserve a touch of true glamour.

Whether you’re planning a show-stopping evening gown, a dramatic wedding dress, or theatrical costumes that need to shine under stage lights, panne satin delivers visual impact like no other fabric. Just remember to handle it with care, follow proper cleaning methods, and store it correctly between wears.

With the right knowledge and preparation, panne satin can help you create garments and projects that truly stand out and literally catch every eye in the room.