Everything you need to know about nylon satin fabric, from manufacturing and uses to environmental impact and care instructions

Table of Contents

What is Nylon Satin Fabric?

Let’s clear up a common confusion right away: satin is not a type of fiber. Instead, it’s a specific weaving technique that creates that smooth, glossy finish we all recognize. When you combine nylon fibers with the satin weave, you get nylon satin fabric.

Think of it this way: nylon is the ingredient (the fiber), and satin is the recipe (the weave pattern). Just like you can make cookies with different flours, you can create satin fabric with different fibers including silk, polyester, or nylon.

Luxurious pink nylon satin fabric showcasing its high shine and fluid drape

Quick Definition

Nylon satin is a synthetic fabric that combines nylon polymer fibers woven in a satin weave pattern. This creates a material with a shiny front surface, dull back, smooth texture, and enhanced durability compared to traditional silk satin.

Is Satin Nylon or Silk?

This is another question that trips people up. Satin can be made from either nylon or silk (or several other fibers). The confusion happens because:

- Traditional satin was originally made only from silk

- Today, most affordable satin is made from synthetic fibers like nylon or polyester

- The label “satin” only tells you about the weave, not the fiber content

Always check the care label to see what fiber your satin is made from. This matters because silk satin and nylon satin require different care methods and have different properties.

Is Nylon Satin Fabric the Same as Nylon Fabric?

No, they’re different. Regular nylon fabric can be woven in many ways (plain weave, twill, ripstop), while nylon satin specifically uses the satin weave. This gives nylon satin its signature shine and drape that regular nylon fabrics don’t have.

Regular nylon fabric might be matte and sturdy (like taffeta), while nylon satin is glossy and flows beautifully. They’re both made from nylon fibers, but the weaving technique makes them look and feel completely different.

History and Evolution

Soft pink nylon satin fabric highlighting the luxurious texture that has shaped its evolution in fashion history

To understand nylon satin, we need to look at two separate histories that eventually merged together.

The Ancient Art of Satin Weaving

The satin weave originated in Quanzhou, China, over 2,000 years ago. Arab traders called this port city “Zaitun,” which is where we get the word “satin.” For centuries, satin was made exclusively from silk and was so expensive that only royalty and the wealthy could afford it.

Italy becomes the first Western country to produce satin fabric

Satin spreads throughout Europe, used in royal garments and furniture like those in the Palace of Versailles

Wallace Carothers at DuPont invents nylon, the world’s first fully synthetic fiber

After World War II, nylon production shifts from military use to consumer products

Manufacturers begin weaving nylon in satin patterns, making luxury-look fabric affordable

Recycled nylon satin emerges as sustainable alternative, with major fashion brands adopting eco-friendly options

The Nylon Revolution

When DuPont chemist Wallace Carothers invented nylon in 1935, he changed the textile world forever. Nylon was the first fiber made entirely in a laboratory from petroleum-based chemicals. During World War II, all nylon production went to military supplies like parachutes and rope.

After the war, manufacturers started experimenting with weaving nylon in different patterns, including the satin weave. This was a game-changer. Suddenly, people could buy fabric that looked and felt like silk satin but cost much less and lasted longer.

How Nylon Satin is Made

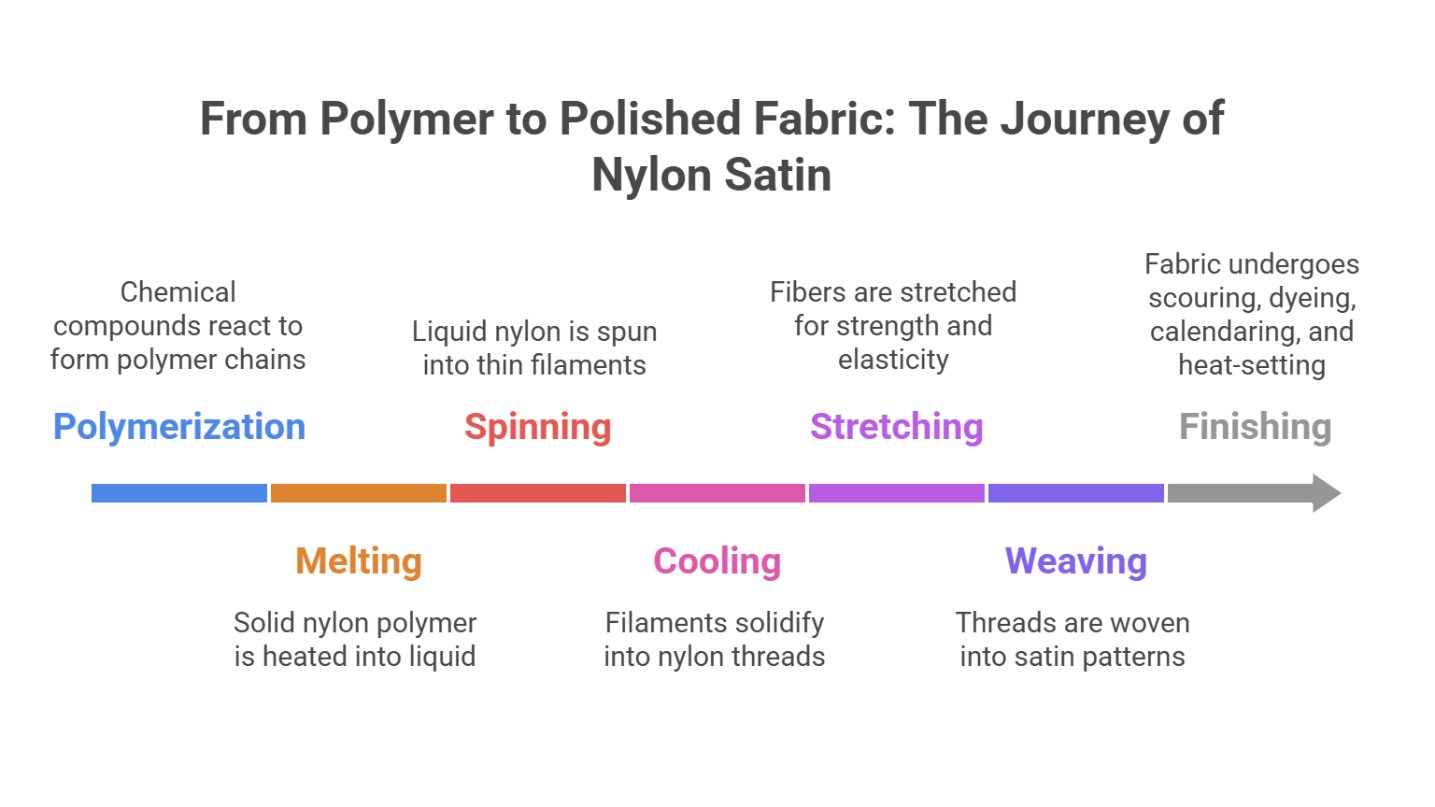

A step by step infographic illustrating the full production process of nylon satin fabric

Creating Nylon Fibers

The manufacturing process starts with chemistry. Here’s how nylon fibers are created:

- Polymerization: Chemical compounds from petroleum undergo a reaction that creates long polymer chains

- Melting: The solid nylon polymer is heated until it becomes liquid

- Spinning: The melted nylon is pushed through a spinneret (like a showerhead) to create thin filaments

- Cooling: Cool air solidifies the filaments into strong nylon threads

- Stretching: The fibers are stretched to increase their strength and elasticity

Satin Weave Pattern

In a satin weave, warp (lengthwise) threads float over multiple weft (crosswise) threads before going under one. This creates long, smooth surfaces that reflect light beautifully.

Weaving the Satin Pattern

Once the nylon threads are ready, they’re woven using specialized looms. The most common satin weaves are:

- 4-harness satin: Warp floats over 3, under 1 (more elastic, softer)

- 5-harness satin: Warp floats over 4, under 1 (balanced shine and durability)

- 8-harness satin: Warp floats over 7, under 1 (highest shine, most delicate)

Finishing Touches

After weaving, the fabric goes through finishing processes:

- Scouring: Removes any oils or impurities

- Dyeing: Nylon takes dye exceptionally well, resulting in rich, vibrant colors

- Calendaring: The fabric passes through heated rollers that flatten and polish the surface for extra shine

- Heat-setting: Locks in the shape and prevents shrinkage

Properties and Characteristics

Nylon satin has a unique combination of properties that make it stand out from other fabrics.

Advantages

- Durability: Nylon is one of the strongest synthetic fibers, resistant to tears and abrasion

- Wrinkle resistance: Bounces back without extensive ironing

- Shine and smoothness: Glossy finish rivals silk satin

- Color retention: Holds dye well, colors stay vibrant after multiple washes

- Quick drying: Doesn’t absorb much water, dries faster than natural fibers

- Affordable: Much cheaper than silk satin while delivering similar aesthetic

- Easy care: Less finicky than silk, can often be machine washed

Disadvantages

- Less breathable: Doesn’t allow air flow like natural fibers

- Can feel warm: Traps heat, especially in humid conditions

- Static electricity: Tends to cling and generate static

- Snags easily: The smooth surface catches on rough objects

- Not biodegradable: Takes hundreds of years to break down

- Can feel synthetic: Lacks the natural softness of silk

- Melts with heat: High temperatures can damage or melt the fibers

Is Nylon Satin Waterproof?

Nylon satin is water-resistant but not waterproof. Here’s what that means:

- Nylon fibers naturally repel water better than cotton or silk

- Water beads up on the surface initially but will eventually soak through

- The tight satin weave provides some protection against light rain or spills

- Without additional waterproof coating, it’s not suitable for heavy rain protection

Some manufacturers add DWR (durable water repellent) coating to nylon satin for enhanced water resistance. This is common in raincoats, bags, and outdoor gear. The treated fabric can handle more moisture but still isn’t fully waterproof like rubber or PVC-coated materials.

Sustainability and Environmental Impact

This is where things get real. If you care about the environment (and you should), it’s important to understand nylon satin’s impact.

The Environmental Concerns

Virgin Nylon’s Impact

Traditional nylon production has serious environmental costs:

- Fossil fuel dependency: Made from petroleum, a non-renewable resource

- Greenhouse gas emissions: Production releases nitrous oxide (N₂O), which is 300 times more potent than carbon dioxide as a greenhouse gas

- Energy intensive: Manufacturing requires massive amounts of energy

- Water pollution: Large volumes of water used for cooling can become contaminated

- Microplastic shedding: Releases tiny plastic particles when washed

- Non-biodegradable: Can take 30-40 years to decompose in landfills

The Good News: Recycled Nylon

The textile industry is making real progress with recycled nylon satin. Here’s why it matters:

Recycled Nylon Benefits

Choosing recycled nylon over virgin nylon dramatically reduces environmental impact:

- 71-80% energy savings compared to virgin nylon production

- 69-76% reduction in CO₂ emissions

- Diverts waste: Uses discarded fishing nets, fabric scraps, and old carpets

- Same quality: Performs identically to virgin nylon

- Multiple recycling cycles: Can be recycled again and again

How to Choose More Sustainable Options

When shopping for nylon satin fabric or garments, look for:

Major fashion brands like Gucci, Stella McCartney, and Patagonia now use recycled nylon in their collections. This shows that sustainable luxury is possible.

Bio-Based Alternatives

Researchers are developing plant-based nylon from renewable resources like castor oil. While still in development, these bio-nylons could offer:

- Lower carbon footprint

- Renewable resource base

- Potential for biodegradability

What You Can Do

As a consumer, you have power to reduce nylon satin’s environmental impact:

- Buy less, choose well: Invest in quality pieces that last

- Prioritize recycled: Choose recycled nylon when available

- Wash wisely: Use a microfiber-catching laundry bag to trap plastic particles

- Extend life: Repair instead of replacing

- Donate or recycle: Keep items out of landfills

Uses and Applications

Nylon satin’s unique combination of beauty and strength makes it incredibly versatile.

Fashion and Apparel

Evening and Formal Wear

The glossy finish makes nylon satin perfect for special occasions. You’ll find it in:

- Evening gowns and cocktail dresses

- Bridal party dresses (bridesmaid and flower girl dresses)

- Men’s ties, bow ties, and cummerbunds

- Dress shirts and blouses

Lingerie and Sleepwear

The smooth, soft surface feels comfortable against skin:

Nylon satin lingerie showing the smooth drape and glossy finish that make the fabric ideal for intimate apparel

- Slips and chemises

- Bras and panties

- Nightgowns and pajamas

- Robes

Athletic and Performance Wear

Nylon satin’s durability and quick-dry properties work well for:

- Gym shorts and track pants

- Boxing robes and sports jerseys

- Yoga and dance wear

- Swimsuit linings

Outerwear

Water resistance and wind protection make it suitable for:

- Windbreakers and rain jackets

- Bomber jackets and varsity jackets

- Coat and jacket linings

Home Textiles

Bedding

- Bed sheets and pillowcases

- Duvet covers

- Bed skirts and shams

Many people use our Satin Fabric Care Calculator to get personalized washing instructions for their bedding.

Upholstery and Decor

- Decorative pillows and cushion covers

- Curtains and drapes

- Table runners and placemats

- Chair covers and accent furniture

Accessories

- Handbags and evening clutches

- Scarves and hair accessories

- Ballet shoes and dance slippers

- Ribbons and decorative trim

Industrial Applications

Beyond fashion, nylon satin’s strength makes it useful for:

- Parachute fabric

- Flag material

- Tent linings

- Banner printing

Nylon Satin vs Other Fabrics

Nylon Satin vs Silk Satin

Nylon satin and silk satin displayed together to compare their natural feel, shine level, and draping qualities

| Feature | Nylon Satin | Silk Satin |

|---|---|---|

| Fiber Source | Synthetic (petroleum-based) | Natural (silkworm cocoons) |

| Cost | $5-15 per yard | $20-100+ per yard |

| Durability | Very strong, resists tears | Delicate, can snag easily |

| Breathability | Low, can trap heat | Excellent, naturally temperature-regulating |

| Care | Machine washable (delicate cycle) | Hand wash or dry clean only |

| Wrinkle Resistance | High | Moderate to low |

| Environmental Impact | High (virgin), lower (recycled) | Moderate (resource-intensive farming) |

| Texture | Smooth but slightly synthetic feel | Incredibly soft, natural luxury |

For more detailed information about silk varieties, check out our comparison of Charmeuse satin and Duchess satin.

Nylon Satin vs Polyester Satin

Visual comparison of nylon satin and polyester satin highlighting variations in shine, texture, and fabric character

| Feature | Nylon Satin | Polyester Satin |

|---|---|---|

| Strength | Stronger, more elastic | Strong but less flexible |

| Moisture Absorption | Very low (dries faster) | Even lower |

| Cost | Slightly more expensive | Most affordable option |

| Feel | Softer, more fabric-like | Can feel stiffer, more plastic-like |

| Color Brilliance | Excellent | Very good |

| UV Resistance | Good (can yellow over time) | Better (more stable) |

Other Satin Varieties

Satin comes in many forms beyond nylon. Here are some you might encounter:

- Messaline satin: Lightweight and highly lustrous

- Baronet satin: Rayon warp with cotton weft for maximum shine

- Crepe-back satin: Reversible with satin on one side, crepe texture on the other

- Antique satin: Made with irregularly spun yarns for vintage look

- Slipper satin: Medium-weight with matte finish

Care Instructions and Maintenance

Complete care guide for maintaining your nylon satin fabric items

Taking proper care of nylon satin will keep it looking beautiful for years. The good news? It’s much easier to care for than silk satin.

Hand Washing (Recommended Method)

- Prepare the water: Fill a basin with lukewarm water (never hot)

- Add detergent: Use a small amount of mild, liquid detergent designed for delicates

- Soak: Submerge the fabric and let it soak for 3-5 minutes

- Gentle agitation: Swish the fabric gently through the water (don’t scrub or twist)

- Rinse thoroughly: Run cool water over the fabric until all soap is gone

- Remove excess water: Lay the item on a clean, dry towel and roll it up to absorb water (never wring)

Machine Washing

Many nylon satin items can be machine washed if you’re careful:

- Always check the label first

- Turn garments inside out to protect the glossy surface

- Place items in a mesh laundry bag

- Use the delicate or gentle cycle

- Choose cold water only

- Use mild detergent (avoid fabric softeners)

- Skip the spin cycle if possible (high-speed spinning can damage the fabric)

For detailed care recommendations, try our Satin Fabric Care Calculator for personalized instructions.

Drying

Never Put Nylon Satin in the Dryer

Heat is nylon satin’s enemy. High dryer temperatures can:

- Melt or damage fibers

- Cause permanent wrinkles

- Shrink the fabric

- Dull the shine

Best drying method:

- Lay the item flat on a clean, dry towel

- Keep it away from direct sunlight (can fade colors)

- Allow to air dry completely in a shaded area

- Avoid hanging heavy items (can stretch out of shape)

Ironing and Steaming

If your nylon satin gets wrinkled:

- Set iron to lowest heat setting (synthetic/nylon setting)

- Turn garment inside out

- Use a pressing cloth between the iron and fabric

- Move quickly don’t let the iron sit in one spot

- Better option: Use a garment steamer on low heat

Stain Removal Guide

Act fast when spills happen:

For Oil Stains

- Blot (don’t rub) with a paper towel to absorb excess oil

- Sprinkle cornstarch or talcum powder on the stain

- Let it sit for 30-60 minutes to absorb the oil

- Brush off the powder gently

- Apply a small amount of dish soap directly to the stain

- Let it sit for 5 minutes

- Rinse with cool water

- Wash as normal

For Blood Stains

- Soak in cold water immediately (hot water sets blood stains)

- Let soak for 30 minutes to an hour

- Apply a small amount of hydrogen peroxide to the stain

- Blot gently

- Rinse with cold water

- Wash as normal

For more detailed guidance on caring for synthetic fabrics, visit our comprehensive care guide or check out this helpful resource on satin clothing care.

Storage Tips

- Store in a cool, dry place away from direct sunlight

- Fold neatly or hang on padded hangers (wire hangers can leave marks)

- Avoid plastic bags (can trap moisture and cause mildew)

- Use breathable fabric garment bags for long-term storage

- Keep away from rough surfaces that could cause snags

Buying Guide

What to Look For

Quality Indicators

- Weight: Measured in GSM (grams per square meter). Higher GSM usually means better quality and durability

- Thread count: Higher thread count generally indicates smoother, more durable fabric

- Even sheen: Quality nylon satin has consistent shine across the surface

- Color vibrancy: Should be rich and even, without streaks or fading

- Smooth texture: Run your hand across it should feel silky without rough patches

Check the Label

Look for:

- Fiber content (should say “100% nylon” or percentage blend)

- Weave type (confirm it’s satin weave)

- Care instructions

- Country of origin

- Certifications (OEKO-TEX, GRS, etc.)

Price Guide

| Quality Level | Price per Yard | Best For |

|---|---|---|

| Budget | $3-8 | Craft projects, costumes, practice garments |

| Mid-Range | $8-15 | Everyday clothing, home decor, accessories |

| Premium | $15-25 | Special occasion wear, professional garments |

| Luxury/Recycled | $25-40+ | High-end fashion, sustainable choice, designer pieces |

Where to Buy

Fabric Stores

- Jo-Ann Fabrics and Crafts

- Mood Fabrics

- Fabric.com

- Local fabric shops (support small businesses!)

Online Retailers

- Etsy (for unique colors and small quantities)

- Amazon (wide variety, read reviews carefully)

- Fabricwholesaledirect.com (bulk orders)

Sustainable Options

- Recycled fabric specialists

- Deadstock fabric suppliers

- Brands with GRS certification

How Much to Buy

Calculate your needs based on the project:

- Simple blouse: 2-3 yards

- Dress: 3-5 yards (depending on style and size)

- Pillowcase (standard): 1 yard

- Queen bed sheet set: 8-10 yards

- Table runner: 1-2 yards

Always buy 10-15% extra for mistakes, shrinkage, or pattern matching.

Future Trends and Innovations

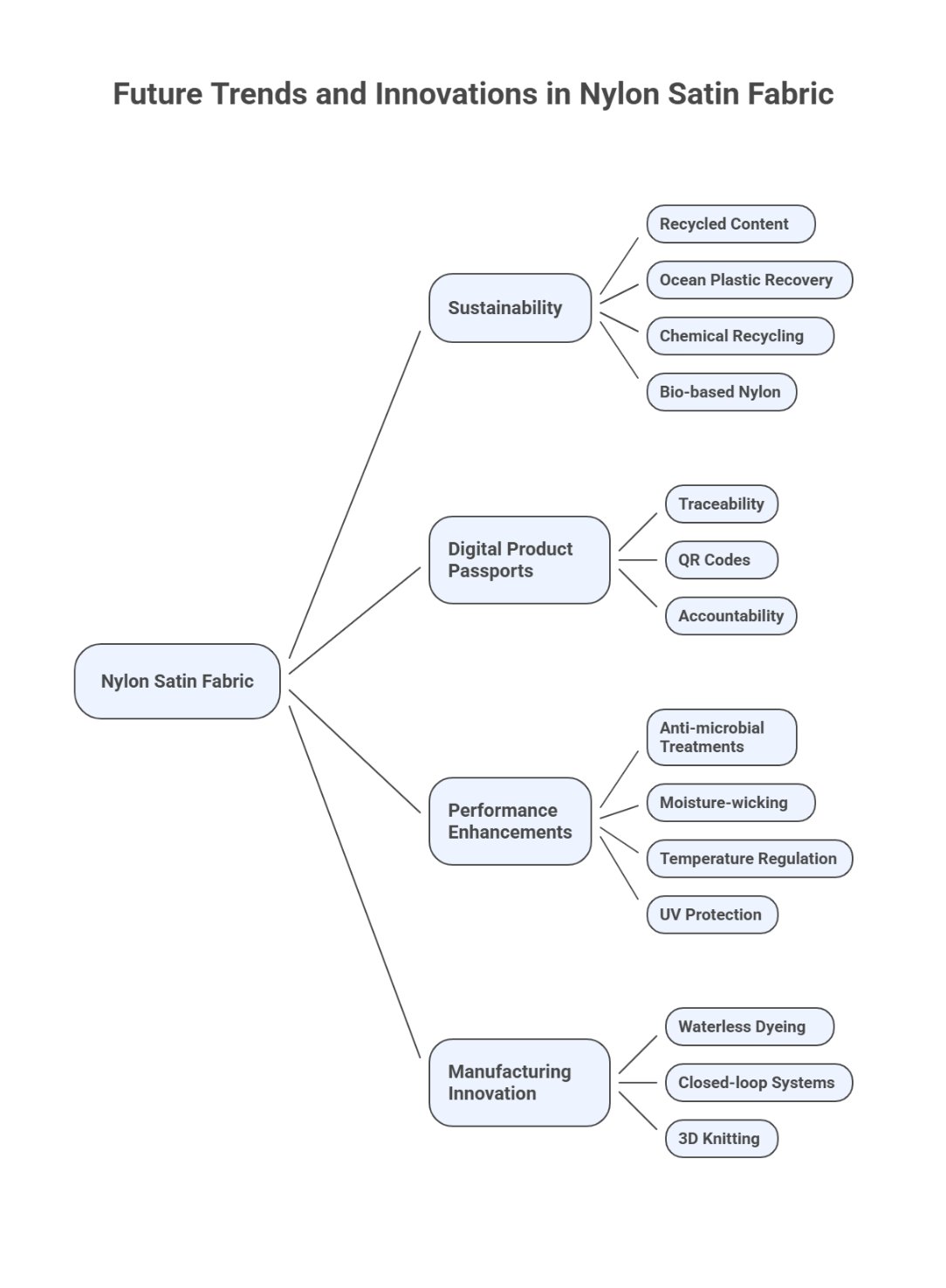

A visual mind map showing key future trends in nylon satin fabric such as sustainability efforts, digital traceability, performance upgrades, and modern manufacturing solutions

Sustainability is Taking Center Stage

The biggest trend in nylon satin is the shift toward sustainability:

- Recycled content is becoming standard: By 2030, industry experts predict recycled nylon will make up over 40% of global nylon production

- Ocean plastic recovery: More brands are creating nylon from recovered fishing nets and ocean waste

- Chemical recycling advances: New technology can break nylon back down to its base molecules for infinite recycling

- Bio-based nylon development: Plant-derived nylon alternatives are moving from labs to production

Digital Product Passports

By 2030, the European Union will require Digital Product Passports for all textile imports. This means:

- Complete traceability from fiber to finished garment

- QR codes you can scan to see a product’s full history

- Information about recycled content, carbon footprint, and manufacturing location

- Greater accountability across the supply chain

Performance Enhancements

Technology is making nylon satin smarter:

- Anti-microbial treatments: Built-in protection against bacteria and odors

- Moisture-wicking improvements: Better breathability without losing the satin sheen

- Temperature regulation: Phase-change materials integrated into fibers

- UV protection: Enhanced sun protection for outdoor applications

Manufacturing Innovation

- Waterless dyeing: New dyeing techniques that use 70% less water

- Closed-loop systems: Factories that recycle all waste materials

- 3D knitting: Creating seamless garments with zero waste

Frequently Asked Questions

Yes, but it requires acid dyes specifically formulated for synthetic fibers. Regular fabric dyes won’t work on nylon. The process involves heating the dye bath to near-boiling temperatures, which can be tricky. For best results, especially with larger items, professional dyeing is recommended.

Not ideal for hot weather. Nylon satin doesn’t breathe well and can trap heat against your skin. It works better for air-conditioned spaces or cooler climates. For summer wear, consider silk satin or cotton alternatives instead.

Nylon satin is resistant to shrinking if washed properly in cold water. However, hot water or high dryer heat can cause some shrinkage and may permanently damage the fabric. Always stick to cold water and air drying to maintain the original size and shape.

Check the care label first that’s the most reliable method. If there’s no label, here’s a simple test: touch the fabric. Nylon satin feels softer and more fabric-like, while polyester satin can feel stiffer or more plastic-like. Nylon also has slightly more stretch than polyester.

Generally yes, especially if certified by OEKO-TEX or similar safety standards. However, natural fibers like cotton are usually better for baby clothing because they breathe better and reduce overheating risk. If using nylon satin for children, choose looser-fitting garments and avoid it for sleep clothing.

Nylon satin is resistant to pilling compared to many other fabrics. The smooth, tightly woven surface doesn’t create the friction that causes pills. However, areas of high wear (like underarms or seat areas) may show some surface wear over time.

Yes, but it can be challenging because it’s slippery. Use a sharp needle (size 70/10 or 80/12), pins to hold fabric in place, and sew slowly. A walking foot attachment helps feed the fabric evenly. Practice on scraps first, and consider using tissue paper under the fabric to prevent slipping.

With proper care, nylon satin can last 5-10 years or longer. It’s more durable than silk satin and resists wear better than many fabrics. The main enemies are heat damage, snags, and exposure to direct sunlight, which can cause fading.

Yes! Recycled nylon performs identically to virgin nylon. The recycling process breaks the material down to its molecular level and rebuilds it, so you get the same strength, shine, and durability. The only difference is the much lower environmental impact.

Small snags can sometimes be fixed. Use a snag repair tool or a needle to gently pull the caught thread back to the wrong side of the fabric. For larger snags or tears, a professional tailor may be able to reweave the area, but it’s difficult. Prevention is the best approach avoid jewelry, rough surfaces, and Velcro.

Conclusion

Nylon satin represents an interesting point where luxury meets practicality. It’s a fabric born from scientific innovation that democratized the glossy elegance once reserved for the wealthy. Today, it sits at another turning point where environmental responsibility is reshaping how we think about synthetic materials.

The fabric’s journey from World War II parachutes to high-fashion runways shows its remarkable versatility. Whether you’re choosing it for a special occasion dress, comfortable bedding, or durable outerwear, nylon satin delivers a unique combination of beauty, strength, and affordability that few other fabrics can match.

But as we’ve discussed, this convenience comes with environmental costs. The traditional production of virgin nylon contributes to climate change through greenhouse gas emissions and depends on non-renewable petroleum resources. The good news? The textile industry is responding with recycled nylon options that deliver the same performance with dramatically less environmental impact.

Key Takeaways

- Satin is a weave, not a fiber: Remember that “satin” describes how the fabric is woven, while “nylon” tells you what it’s made from. This distinction matters for care, performance, and cost.

- Durability over delicacy: Choose nylon satin when you need something that looks elegant but can handle regular use. It’s far more practical than silk for everyday items.

- Care is straightforward: Unlike silk, you can usually machine wash nylon satin on delicate cycle with cold water. The main rules: avoid heat, never wring it, and air dry flat.

- Prioritize recycled options: When shopping, look for recycled nylon satin with GRS or Bluesign® certification. You’ll get identical quality with 70-80% less environmental impact.

- Not ideal for hot weather: Because nylon doesn’t breathe well, save it for air-conditioned spaces or cooler seasons. Natural fibers work better when breathability matters.

- Investment in quality pays off: Higher GSM and thread count usually mean better durability and appearance. A quality piece will last years with proper care.

- Consider the full lifecycle: Buy items you’ll actually use and wear them for years. When you’re done, donate or recycle rather than sending to landfill.

Final Recommendations

For fashion enthusiasts: Nylon satin gives you the luxe look without the luxury price tag or high-maintenance care routine. It’s perfect for building a versatile wardrobe of special-occasion pieces that you can actually afford to wear multiple times.

For eco-conscious consumers: Don’t write off nylon satin entirely choose recycled versions and care for them properly to extend their life. The environmental equation shifts dramatically when you’re keeping items out of landfills and choosing recycled materials.

For textile professionals: As consumer awareness grows, expect increased demand for transparency about fiber sources and recycled content. Getting ahead of this trend positions you well for future market demands.

For manufacturers: The shift toward recycled nylon and closed-loop systems isn’t just good PR it’s becoming a business necessity as regulations tighten and consumers demand sustainability.

For general readers: Understanding what you’re buying, how to care for it, and what its impact is gives you power as a consumer. Your choices, multiplied across millions of people, can drive real change in the textile industry.

The future of nylon satin looks promising. With advances in recycling technology, bio-based alternatives in development, and increased industry transparency on the horizon, we’re moving toward a more sustainable version of this versatile fabric. Your job as a consumer is to ask questions, read labels, choose quality over quantity, and care for what you buy so it lasts.

Whether you’re sewing your first nylon satin dress, shopping for bedding, or just curious about fabrics, we hope this guide has given you the knowledge to make informed decisions. The glossy surface may catch your eye, but now you know what lies beneath that shine.

Additional Resources

- Textile Exchange – Global non-profit driving sustainable fiber and materials

- OEKO-TEX® – Independent certification system for textiles tested for harmful substances

- Bluesign® – System for sustainable textile production