Everything You Need to Know About This Legendary Cold-Weather Fabric

Picture yourself standing on the deck of a ship in the North Atlantic, icy wind whipping across the waves. The only thing between you and hypothermia is your coat. For over 200 years, sailors have trusted one fabric to keep them warm and dry in these conditions: Melton wool.

But here’s what makes this fabric really interesting. The same material that protected working-class sailors and dockworkers also graced the backs of British aristocracy during fox hunts. Today, it’s having a moment again as people rediscover the value of clothes that last decades instead of seasons.

If you’re thinking about making a winter coat, buying a peacoat, or just want to understand what makes this wool fabric special, you’re in the right place. This guide covers everything from how Melton wool is made to how to sew with it, care for it, and why it costs more than regular wool coating.

Table of Contents

What is Melton Wool Fabric?

Melton wool is a thick, tightly woven wool fabric that goes through a special finishing process called fulling. Think of it as regular wool’s tougher, more weather-resistant cousin. The fabric has a smooth, almost felt-like surface, but it’s actually woven in a twill pattern before being processed. According to Wikipedia’s detailed documentation, Melton cloth is known for its solid construction and weatherproof qualities.

What Makes Melton Wool Special?

Here’s what sets Melton apart from regular wool:

- Dense structure: The fulling process creates an incredibly tight weave that completely hides the original twill pattern

- Wind resistance: That dense weave blocks wind better than almost any other wool fabric

- No fraying: Cut edges stay clean without finishing, which is rare for woven fabrics

- Water resistance: Not waterproof, but it sheds light rain and snow effectively

- Warmth when wet: Unlike cotton, wool retains insulation even when damp

- Durability: Properly cared for, Melton wool garments can last 20-30 years or more

Is Melton Wool the Same as Melton Fabric?

Yes, “Melton wool” and “Melton fabric” refer to the same thing. The terms are used interchangeably, though “Melton cloth” is also common. While traditionally made from 100% wool, modern Melton often includes 10-25% synthetic fibers like nylon or polyester to increase durability and reduce cost. The quality depends more on the fulling process and fiber quality than the exact composition.

Quick Facts About Melton Wool

- Typical weight: 14-32 oz per square yard

- Common fiber content: 75-100% wool

- Width: Usually 54-60 inches

- Price range: $15-$40 per yard

- Main use: Winter outerwear and coats

The Rich History of Melton Wool

Melton wool fabric representing its long history and traditional production.

Origins in Melton Mowbray

The story begins in a small town in Leicestershire, England. Melton Mowbray, famous today for its pork pies, was once the center of British fox-hunting culture. In the 18th century, local wool producers developed a fabric that could withstand the harsh weather conditions riders faced during hunts.

The town’s location in the East Midlands made it perfect for wool production. Local sheep provided the raw material, and the area’s water quality was ideal for the fulling process. As the fabric’s reputation grew, “Melton” became the standard name for this type of heavy, fulled wool throughout the British Isles.

A Fabric for All Classes

Here’s where the story gets interesting. Melton wool served two completely different social groups in the 18th and 19th centuries.

The Elite: Scarlet Hunting Coats

British aristocracy wore tailored hunting coats made from Melton wool, dyed a bright scarlet red. These coats were expensive, requiring high-quality wool and costly dye processes. The hunt leaders wore these vivid red jackets so they could be spotted easily across the countryside. The fitted design looked sharp and moved well on horseback.

The Workers: Donkey Jackets

At the same time, working-class laborers depended on Melton wool for protection during outdoor work. The donkey jacket, made from black or navy Melton with leather shoulder patches, became standard wear for dockworkers, builders, and miners. The leather patches protected the fabric (and the wearer) when carrying materials on their shoulders.

Both groups chose Melton for the same reason: it worked. Whether you were riding through the rain or working on a construction site, you needed fabric that blocked wind, shed water, and lasted years of hard use.

Military Adoption and the Peacoat

Navies across Europe recognized Melton’s weatherproof qualities and adopted it for sailor uniforms. The most famous garment is the peacoat (or pea coat), which has an interesting origin story.

The name likely comes from the Dutch word “pij” (pronounced “pay”), referring to coarse wool fabric. Dutch sailors wore these coats in the 1700s, and the design spread to the British Royal Navy, then to the U.S. Navy in the early 1900s.

The Evolution of the Navy Peacoat

Original peacoats from World War I and II were made from heavy Kersey wool, which is similar to Melton but has a slightly different finish. In 1980, the U.S. Navy switched to Melton wool for their peacoats. This change sparked ongoing debates among military surplus collectors about which fabric is better. The new Melton version was lighter (around 24-29 oz) and included a quilted lining for warmth.

The design features of the peacoat all served practical purposes. The double-breasted front protected against wind and moved buttons away from ropes (reducing snagging). The large collar could be turned up to protect the face and neck. The peacoat was cut short at the hip for easy movement through ship rigging.

Even though the U.S. Navy officially discontinued the peacoat in 2018, the style remains popular in civilian fashion. Companies like Schott NYC and Sterlingwear of Boston continue making peacoats to military specifications using 32 oz Melton wool.

The “Tenterhooks” Story

Here’s a fun bit of language history connected to Melton wool production. After the fulling process, wet wool fabric had to be dried without shrinking. Workers stretched the cloth on large wooden frames called tenters, securing it with hooks (tenterhooks) to keep it taut while drying.

This is where we get the phrase “on tenterhooks,” meaning to be in suspense or anxiety. Just like the fabric was stretched tight and held in place, waiting to be released, we use the phrase today when we’re nervously waiting for something.

From Windsor Castle to Tennis Courts

Melton wool found some unexpected uses beyond clothing. Queen Victoria commissioned curtains made from Melton cloth for Windsor Castle in the Victorian era. The fabric’s weight and insulation properties made it ideal for keeping drafts out of large castle rooms.

Today, Melton wool is still used as the covering for real tennis balls (as opposed to lawn tennis). The dense, durable fabric withstands the impact of the game better than lighter materials.

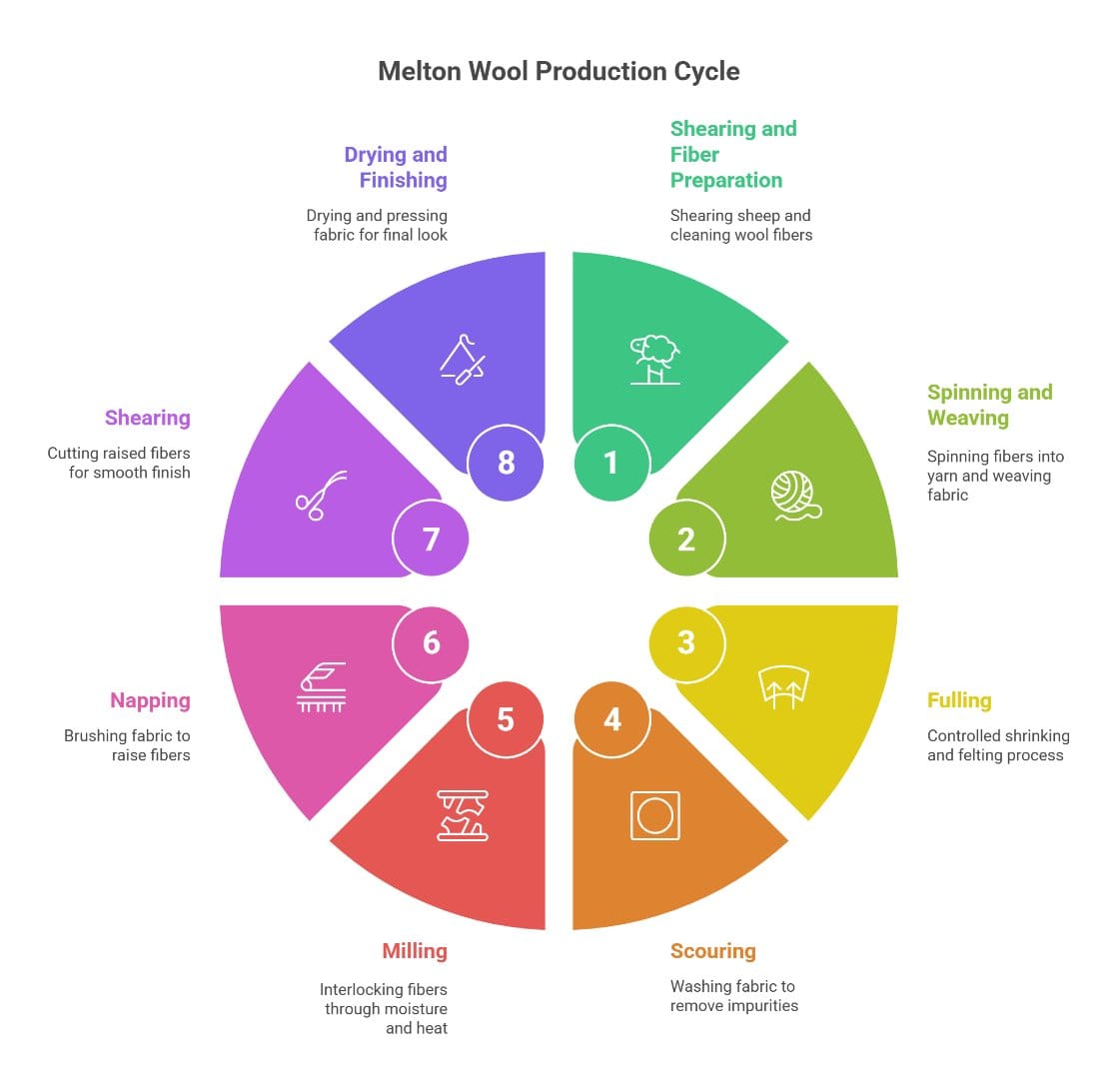

How Melton Wool is Made

Understanding how Melton wool is made helps explain why it costs more than regular wool fabric and why it performs so well. The process is labor-intensive and takes skill to get right.

Step by step visual guide explaining how melton wool fabric is made.

Shearing and Fiber Preparation

It starts with sheep shearing. The raw fleece is cleaned and prepared. Most Melton wool uses medium-quality sheep wool, typically from breeds like Merino or other common sheep varieties.

Spinning and Weaving

The cleaned wool fibers are spun into strong yarn. This yarn is then woven into fabric using a twill weave pattern. At this stage, it looks like regular woven wool, nothing special yet.

Fulling: The Magic Step

This is where Melton becomes Melton. Fulling is a controlled shrinking and felting process that transforms the fabric. The woven wool goes through two sub-processes: scouring and milling.

Scouring

The fabric is washed with soap or detergent in hot water to remove oils, dirt, and other impurities from the wool fibers. This cleaning prepares the fabric for the next step.

Milling (Thickening)

This is the key process. The cleaned fabric is subjected to moisture, heat, and physical agitation. The combination makes the wool fibers interlock and mat together. The fabric shrinks significantly (often by 30-50%) and becomes much thicker and denser. The original twill weave pattern becomes completely hidden.

Napping

After fulling, the fabric surface is brushed to raise the fibers slightly. This creates a soft, fuzzy nap on the surface.

Shearing

The raised fibers are then sheared (cut) very close to the fabric surface. This creates the smooth, uniform finish that Melton wool is known for. Multiple rounds of napping and shearing may be done to achieve the desired surface quality.

Drying and Finishing

The finished fabric is dried carefully (historically on tenters) and may receive additional treatments like steam pressing for a final smooth finish.

Historical vs. Modern Methods

In the past, fulling was done by hand. Workers literally stomped on the wet wool fabric with their feet, or beat it with clubs. This was exhausting work that took hours.

Today, industrial fulling mills use machines that automate the process, but the basic principles remain the same. Some high-end producers still use traditional methods for premium Melton wool. Mills in Yorkshire, England, for example, have been making Melton on the same premises for over a century, maintaining traditional quality standards. Marton Mills, a traditional British family-owned textile mill, continues this heritage by producing authentic Melton wool using time-honored techniques.

Properties and Performance

Let’s break down what makes Melton wool perform the way it does. Understanding these properties will help you decide if it’s the right fabric for your project.

Visual overview of melton wool fabric properties and performance features.

How Warm is Melton Wool?

Melton wool is one of the warmest wool fabrics available. The density of the fabric creates thousands of tiny air pockets that trap body heat. A well-made Melton coat can keep you comfortable in temperatures well below freezing.

The warmth also depends on the weight of the fabric. Here’s how different weights perform:

Light Weight (14-18 oz)

Temperature Range: 40-60°F

Best For: Fall jackets, lighter coats, indoor work clothing

Warmth Level: Moderate

Medium Weight (20-26 oz)

Temperature Range: 20-50°F

Best For: Winter coats, peacoats, everyday cold-weather wear

Warmth Level: High

Heavy Weight (28-32 oz)

Temperature Range: Below 20°F

Best For: Extreme cold, military peacoats, outdoor work gear

Warmth Level: Maximum

Is Melton Wool Heavy?

Yes, Melton wool is considered a heavyweight fabric. That’s actually part of why it works so well for winter wear. A typical Melton coat weighs several pounds. Some people find this reassuring (it feels substantial and protective), while others may find it cumbersome for long wear. The weight also limits the range of motion compared to lighter fabrics.

Can Melton Wool Get Wet? How Waterproof is It?

Here’s where we need to be clear: Melton wool is water-resistant, not waterproof. There’s an important difference.

The dense, tightly fulled structure makes water bead up and roll off the surface rather than soaking in immediately. Wool fibers naturally contain lanolin, a waxy substance that repels water. Combined with the tight weave, this means Melton wool can handle:

- Light rain and drizzle

- Snow

- Brief exposure to wet conditions

- Humid environments

What it can’t handle:

- Heavy, sustained rainfall

- Submersion in water

- Hours of wet weather without protection

If you’re caught in a downpour for 10-15 minutes, a Melton coat will keep you mostly dry. After 30+ minutes, water will start to penetrate. The good news is that wool continues to insulate even when damp, unlike cotton which loses all warmth when wet. For more information on water resistance, check out this guide to water-resistant fabrics.

Is Melton Wool Breathable?

This is one area where Melton wool has limitations. The same dense structure that makes it wind and water-resistant also limits breathability. Compared to looser wool knits or lighter woven wools, Melton doesn’t breathe as well.

This means:

- You might overheat if you’re active while wearing it

- Indoor wear can feel stuffy

- It’s best for outdoor use in cold weather

- Layering underneath should be moderate

The breathability is adequate for walking or standing in cold weather but not ideal for vigorous activity like hiking or sports.

Wind Resistance

This is where Melton wool really shines. The fulling process creates such a dense fabric that wind simply can’t penetrate it effectively. Sailors have relied on this property for centuries because ocean winds can make cold temperatures feel much colder (wind chill).

In practical terms, a Melton coat cuts wind better than most fleece or lighter wool tweed fabrics. This makes it excellent for windy conditions like coastal areas, open plains, or urban wind tunnels between buildings.

Durability and Longevity

Properly cared for, a Melton wool garment can last 20-30 years or longer. There are military surplus peacoats from the 1940s-1960s that are still wearable today. The fabric resists wear and tear better than most textiles because:

- The dense structure prevents threads from breaking easily

- Wool fibers are naturally elastic and resilient

- The non-fraying edges mean stress points don’t unravel

- The fulled structure is essentially partially felted, making it more cohesive

Moths are the main threat to Melton wool’s longevity (more on prevention in the care section).

The Fraying Question

One of Melton wool’s most practical features is that cut edges don’t fray. When you cut regular woven fabric, threads start to unravel at the edges. With Melton, the fulling process has made the fibers interlock so tightly that they stay in place even when cut.

This is huge for practical use:

- Seam allowances don’t need finishing

- You can create raw-edge designs

- Repairs are easier

- Construction is faster for sewers

How Does Melton Wool Compare to Other Fabrics?

Let’s compare Melton wool to other similar fabrics. This is where people often get confused because there are several heavy wool fabrics with overlapping characteristics.

Melton Wool vs Boiled Wool

This is the most common comparison question, and it’s important because the names sound similar.

Comparison of melton wool and boiled wool fabrics for warmth and structure.

| Feature | Melton Wool | Boiled Wool |

|---|---|---|

| Base Structure | Woven fabric (usually twill) | Knitted fabric |

| Processing Method | Fulled (scoured and milled) | Boiled and felted |

| Texture | Smooth, dense, slightly fuzzy surface | Thicker, spongy, more textured |

| Drape | Structured, holds shape well | More supple, better drape |

| Weight | 14-32 oz per yard | Usually lighter (10-20 oz) |

| Wind Resistance | Excellent | Good to very good |

| Best For | Structured coats, peacoats, military wear | Jackets, cardigans, hats, indoor wear |

| Temperature Range | Below freezing to 50°F | 30-60°F (generally warmer weather) |

The key difference is that boiled wool starts as a knit, while Melton starts as a woven fabric. This gives them different performance characteristics. Boiled wool is more flexible and comfortable for indoor wear or milder weather. Melton is more rigid and protective for harsh outdoor conditions.

Melton Wool vs Loden Wool

Loden wool originated in the Tyrolean Alps in the 16th century and is still popular for outdoor sportswear. Here’s how it compares:

Melton wool vs loden wool differences in density and surface feel.

Loden Characteristics

- Loose initial weave that’s heavily fulled

- Slightly “greasy” feel from retained lanolin

- Nap combed downward (like roof shingles)

- Excellent water shedding

- Traditional green color (though other colors exist)

- Supple hand despite density

Melton Characteristics

- Twill weave that’s heavily fulled

- Smooth, clean finish

- Nap sheared very short and even

- Good water resistance

- Navy and black most common

- More rigid structure

Both fabrics are excellent for outerwear, but Loden is traditionally preferred for hunting and outdoor sports, while Melton has stronger associations with military and naval use. Loden tends to shed water slightly better due to the directional nap and higher lanolin content.

Melton Wool vs Kersey Wool

Kersey wool is another heavy coating fabric, and this comparison matters particularly for military coat enthusiasts. Pre-1980 U.S. Navy peacoats used Kersey wool instead of Melton.

Melton wool vs kersey wool showing contrast in finish and fabric structure.

Kersey wool has a raised nap that gives it a slightly fuzzy surface, similar to a very fine velvet. The nap goes in one direction. It’s typically midnight blue (so dark it almost looks black) and has a distinctive hand feel.

Melton wool (post-1980 Navy coats) is black or very dark navy with a smoother surface. The nap is cut very short. It’s typically lighter in weight than traditional Kersey.

The debate among collectors: Kersey advocates argue it’s more water-resistant and wind-proof. Melton supporters say it’s lighter and easier to work with while providing adequate protection. Both groups agree that either fabric will last decades.

What is the Difference Between Merino and Melton Wool?

This is comparing apples to oranges a bit, because Merino refers to the sheep breed while Melton refers to the fabric processing. However, people often wonder about this, so let’s clarify:

Merino wool vs melton wool showing differences in softness, structure, and use.

Merino wool comes from Merino sheep and is prized for its fineness and softness. Merino fibers are typically 15-24 microns in diameter (very fine). Merino wool is used in base layers, dress shirts, suits, and premium knitwear. It’s soft against the skin, breathable, and has excellent temperature regulation. It’s also expensive due to the quality of the fiber.

Melton wool can be made from Merino sheep or other sheep breeds. What makes it Melton is the fulling process, not the sheep breed. Most Melton uses medium-grade wool (not the finest Merino) because the fulling process would be wasteful with expensive superfine wool.

You can have Melton wool made from Merino sheep, but it would be unusually expensive. Most Melton uses wool from breeds like Romney, Leicester, or crossbred sheep that produce good-quality but less fine fibers suitable for heavy coatings.

What is the Difference Between Felt and Melton?

Both felt and Melton undergo felting processes, but they’re quite different materials:

Felt vs melton wool fabric comparison highlighting structure, thickness, and finish.

Felt is made by matting loose wool fibers together without any weaving or knitting. The fibers are subjected to heat, moisture, and agitation until they interlock completely. True felt has no woven structure at all. It’s uniform throughout, doesn’t have grain direction, and can be quite thick. Felt is used for hats, craft projects, industrial applications, and some clothing.

Melton starts as a woven fabric and is then partially felted through fulling. It retains some woven structure underneath the felted surface. It’s stronger and more durable than felt because of the woven base. The surface looks smooth and uniform, but if you look very closely (or at the back), you can sometimes see traces of the original weave.

Think of it this way: felt is fully felted, Melton is heavily fulled woven fabric. Melton is more suitable for clothing that needs to withstand stress and wear.

What is the Difference Between Melton Wool and Mackinaw Wool?

Mackinaw cloth is very similar to Melton, and in fact, some sources consider them nearly identical. Both are heavy, fulled wool fabrics. The main differences are regional and historical:

Melton wool vs Mackinaw wool differences in texture, weight, and performance.

- Origin: Melton comes from England, Mackinaw from North America (named after Mackinaw City, Michigan)

- Traditional use: Melton for military and naval wear, Mackinaw for lumberjacks and outdoor workers

- Pattern: Mackinaw is traditionally made in plaid patterns, particularly red-and-black buffalo check. Melton is usually solid colors

- Weight: Both are heavy, though Mackinaw can be slightly heavier in some versions

The structural difference is minimal. If you see “Mackinaw cloth” listed as a fabric option, expect similar properties to Melton wool.

Quick Comparisons with Other Wool Types

Quick visual comparison of melton wool with other common wool fabrics.

Melton vs Wool Gabardine: Gabardine is a tightly woven twill that’s much lighter and more breathable than Melton. It’s used for suits and dress trousers. Melton is much heavier and more weather-resistant.

Melton vs Wool Flannel: Flannel has a brushed surface but is much lighter and softer than Melton. It’s used for shirts, lighter trousers, and suiting. Melton is several times heavier.

Melton vs Wool Coating: “Wool coating” is a general term that includes Melton but also other heavy wools like Duffle, Boucle, or thick tweeds. Melton is one specific type of wool coating.

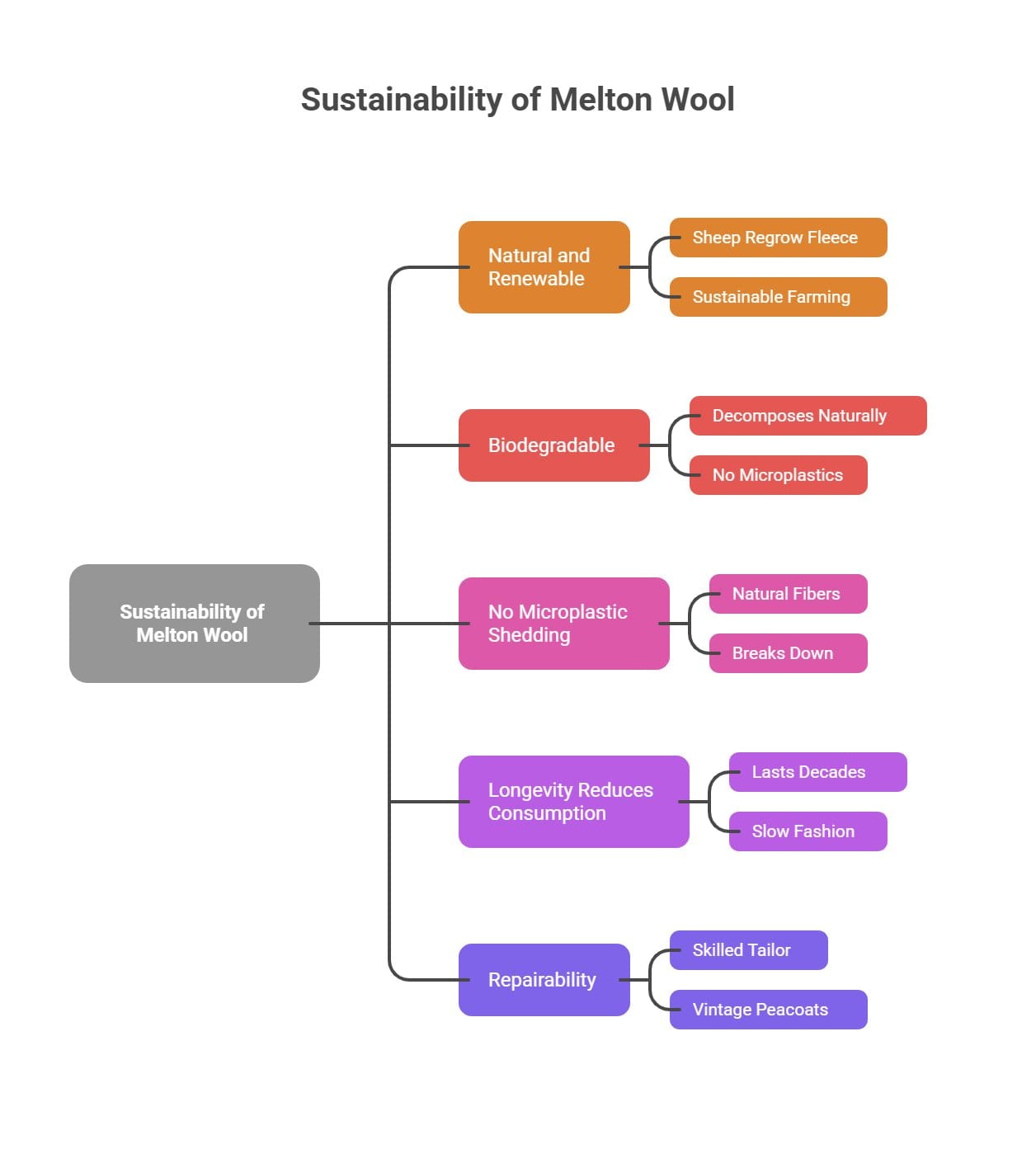

Sustainability and Quality: An Investment Piece

Let’s talk about why Melton wool costs more and why it’s actually a good deal in the long run.

Visual overview of melton wool sustainability and environmental benefits.

The True Cost of Quality

Melton wool fabric typically runs $15-$40 per yard. A winter coat might need 3-4 yards, putting fabric cost alone at $45-$160. That’s before labor, lining, buttons, and time. Why so expensive?

- Natural material: Wool is more expensive than synthetic fibers

- Processing time: The fulling process requires time, energy, and skilled operators

- Shrinkage: The fabric shrinks 30-50% during fulling, so you need more raw material to end up with a yard of finished Melton

- Quality control: Getting consistent results requires experience and attention

Cost-Per-Wear: The Real Value

Here’s how to think about the investment. Compare a $200 Melton peacoat that lasts 20 years to a $60 synthetic coat that lasts 3 years:

Melton peacoat: $200 ÷ 20 years = $10 per year, or about 17 cents per wear if worn 60 times per year

Synthetic coat: $60 ÷ 3 years = $20 per year, or about 33 cents per wear

Over 20 years, you’d buy 6-7 synthetic coats at $60 each, spending $360-$420 total. The single Melton coat costs half as much over the same period.

Sustainability and Environmental Impact

Melton wool aligns well with sustainable fashion principles:

Natural and Renewable

Wool is a renewable resource. Sheep regrow their fleece every year. When managed responsibly, sheep farming can be sustainable. Unlike synthetic fabrics made from petroleum, wool comes from a biological source that doesn’t deplete finite resources.

Biodegradable

At the end of its life (which could be 30+ years away), wool is biodegradable. It will decompose naturally without leaving microplastics in the environment. Compare this to polyester or nylon, which will persist for hundreds of years in landfills.

No Microplastic Shedding

Synthetic fabrics shed tiny plastic fibers every time they’re washed. These microplastics enter waterways and oceans, where they’re consumed by fish and other marine life. Wool doesn’t have this problem. Any fibers that shed are natural and will break down.

Longevity Reduces Consumption

The biggest sustainability factor is simple: buy once, use for decades. A coat that lasts 25 years doesn’t need to be replaced every few years, which means less manufacturing, less shipping, less packaging, and less waste. This is the core principle of slow fashion.

Repairability

Melton wool can be repaired relatively easily. A skilled tailor can patch tears, replace buttons, refinish collars, or even recut a coat to update the style. Many vintage peacoats have been repaired and are still in use 50+ years after manufacture.

Is Melton Wool Good Quality?

Yes, but quality varies. Here’s what to look for in good-quality Melton:

- Fiber content: 75-100% wool is best. Higher wool content generally means better quality

- Weight consistency: The fabric should feel uniformly heavy throughout

- Smooth surface: Good Melton has a very smooth, even surface with no slubs or thick spots

- No pilling: Quality Melton shouldn’t pill easily (form little fiber balls on the surface)

- Rich color: Dyes should be deep and even, not streaky

- Hand feel: It should feel dense and slightly soft, not scratchy or stiff

Lower-quality Melton might have higher synthetic content, uneven fulling, or use inferior wool grades. It will still function as winter wear but won’t last as long or perform as well.

Uses and Applications

What can you actually make with Melton wool? Here are the main applications:

Melton wool winter coat showcasing durability, warmth, and tailored structure.

Outerwear and Coats

This is Melton’s primary use:

- Peacoats: The classic application. Whether you’re making an authentic military-style coat or a modern fashion peacoat

- Winter coats: Long coats, car coats, trench coats in Melton provide maximum warmth

- Duffle coats: Another traditional style that works beautifully in Melton

- Capes and ponchos: The non-fraying edges make these easy to construct

- Hunting jackets: Following the traditional use

Accessories

Lighter weights of Melton work for:

- Hats and berets

- Scarves (though they’ll be quite thick)

- Mittens and gloves

- Boot liners

Home Goods

Melton’s durability makes it suitable for:

Melton wool throw blanket used for warmth and home decor.

- Blankets: Heavy, warm, and long-lasting

- Upholstery: For chairs or benches that need durable, warm covering

- Curtains: Following Queen Victoria’s example, for insulation and draft-blocking

- Door draft stoppers: The weight and density make these effective

Historical Costumes

If you’re into historical reenactment or costume work, Melton is period-appropriate for:

- 18th and 19th century workwear

- Victorian-era coats

- Military uniforms from multiple eras

- 1940s-1960s civilian coats

Unusual Applications

Real tennis ball covers (as mentioned earlier) and some industrial uses where a thick, durable fabric is needed.

Sewing with Melton Wool: A Complete Guide

Melton wool is actually easier to sew than many sewers expect. The non-fraying edges and forgiving nature make it good for beginners attempting their first coat. Here’s everything you need to know.

Pre-Treatment: A Crucial First Step

Does Melton Wool Shrink?

Yes, Melton can still shrink if exposed to heat, moisture, and agitation. Even though it’s already been fulled, it hasn’t been completely stabilized. You must pre-treat your fabric before cutting.

Pre-Treatment Options:

Option 1: Professional Dry Cleaning (Recommended)

Take your fabric to a dry cleaner and ask them to clean it with extra steam. This is the safest method and ensures any potential shrinkage happens before you cut. Cost is usually $10-20 depending on yardage.

Option 2: At-Home Steaming

Use your iron’s steam function (or a garment steamer) to thoroughly steam the entire piece of fabric on both sides. Work in sections, holding the iron close but not touching the fabric. Let it dry flat for 24 hours.

Option 3: Hand Washing (Use with Caution)

If you must wash it at home, use cool water and a wool-safe detergent. Gently squeeze (don’t wring or agitate). Lay flat to dry. This is risky because you might cause uneven shrinking.

Pro Tip: Always Pre-Treat

Never skip pre-treatment, even if you’re in a hurry. Spending 20+ hours making a coat only to have it shrink the first time it gets caught in rain is heartbreaking. Pre-treating takes 30 minutes to a day, depending on your method.

Pattern Selection

Melton wool works best with coat patterns that have:

- Simple, clean lines

- Moderate ease (not skin-tight)

- Gentle curves rather than tight corners

- Minimal seaming and details

The bulk of the fabric makes complex designs harder to execute. Stick to classic coat silhouettes for best results.

Cutting

Good news: Melton cuts beautifully.

- Shears: Sharp fabric shears work great. The fabric doesn’t slip much

- Rotary cutter: Also excellent. Use a cutting mat

- Marking: Use tailor’s chalk or a fade-away marker. Regular pen or pencil won’t show well on dark fabric

- Notches: Cut outward notches (not inward) since the fabric is thick

- Edges: Don’t worry about fraying. Cut edges will stay clean

Sewing Machine Setup

Sewing melton wool fabric for coats and structured garments.

Melton is thick but not particularly difficult for a standard home sewing machine.

Needle:

Use a Universal or Sharp needle, size 80/12 to 90/14. Some sewers prefer 100/16 for very heavy Melton. Start with 90/14, which works for most Melton weights.

Thread:

All-purpose polyester thread works fine. Some sewers prefer upholstery thread for heavy-duty seams like shoulder seams or button attachment. Match the color to your fabric or go slightly darker.

Stitch Length:

Use a slightly longer stitch than normal: 3.0-3.5mm works well. This allows the fabric to sit properly between stitches without puckering.

Presser Foot:

A walking foot is extremely helpful for long seams. It feeds the top and bottom layers evenly, preventing shifting. If you don’t have one, standard presser foot works, but pin carefully.

Construction Techniques

Seam Allowances

Standard 5/8″ seam allowances are fine. Because edges don’t fray, you don’t need to finish them. Many sewers leave them raw.

Reducing Bulk

This is critical with thick fabric:

- Grade seams: Trim seam allowances to different widths (the one facing the body can be narrower). This reduces the ridge that forms at seams

- Trim corners: Cut diagonally across corner seam allowances before turning

- Notch curves: Cut small triangular notches out of curved seam allowances to help them lie flat

Pressing

Proper pressing makes a huge difference with Melton wool:

- Use a press cloth (a piece of cotton fabric) between iron and wool

- Set iron to wool setting with plenty of steam

- Press from the wrong side when possible

- Use a wooden clapper (a smooth wooden paddle) to press seams flat. Press with iron and steam, then immediately pound the seam with the clapper while it’s still hot and damp. This sets the seam beautifully flat

- Let pressed areas cool completely before moving the fabric

Interfacing: To Use or Not?

This depends on the pattern and fabric weight.

Heavy Melton (24+ oz): Often needs no interfacing at all. The fabric has enough body on its own. You might interface just the collar and buttonholes.

Medium Melton (18-22 oz): Interface areas that need structure: collar, buttonholes, front facings, pockets.

Use a fusible knit interfacing or woven interfacing suitable for wool. Test on a scrap first to make sure your iron temperature won’t damage the fabric.

Buttonholes

Buttonholes in Melton are straightforward because the fabric doesn’t fray. Your machine’s regular buttonhole setting should work. Some tips:

- Test on a scrap piece first

- Use a buttonhole cutter or small sharp scissors to open the buttonhole after stitching

- For extra durability, you can hand-stitch around machine buttonholes

Lining Your Coat

Most Melton coats are lined. The lining:

- Hides interior seams for a professional look

- Makes the coat easier to put on and take off

- Adds a bit of warmth

- Protects the Melton from body oils and sweat

Common lining fabrics: Rayon or polyester satin (slippery and durable), cotton sateen (more breathable), or quilted lining (adds warmth).

Common Sewing Mistakes to Avoid

- Skipping pre-treatment: Results in a shrunken garment

- Using tiny stitches: Makes seams stiff and hard to work with

- Not grading seams: Creates bulky ridges

- Over-interfacing: Makes the coat too stiff

- Forcing the fabric: If your machine struggles, you might need a heavier-duty machine or to take seams slower

Care and Maintenance: Making It Last Decades

Proper care is what separates a coat that lasts 5 years from one that lasts 30 years. The good news is that Melton wool needs relatively little care.

How Do You Clean Melton Wool?

The golden rule: clean as little as possible. Overwashing or overcleaning shortens the life of wool garments. Melton coats worn as outerwear typically need cleaning only once or twice per season.

Method 1: Spot Cleaning (First Line of Defense)

For small stains or dirty spots:

- Let mud or dirt dry completely, then brush off with a stiff brush

- For wet stains, blot (don’t rub) with a clean cloth to absorb excess liquid

- Mix a tiny amount of wool-safe detergent with cool water

- Dip a clean cloth in the solution and gently dab the stain

- Rinse the area with a cloth dampened in plain water

- Blot dry and let air dry completely

Method 2: Dry Cleaning (Recommended for Full Cleaning)

Professional dry cleaning is the safest way to clean a Melton wool garment. Find a reputable cleaner and tell them it’s wool. Dry clean only when necessary, not after every wear.

Method 3: Hand Washing (Use with Extreme Caution)

This is risky and not generally recommended, but if you must:

- Fill a tub with cool or lukewarm water (never hot)

- Add a small amount of wool-safe detergent (like Woolite or Eucalan)

- Submerge the garment and gently squeeze the water through (don’t agitate, twist, or wring)

- Let soak for 10-15 minutes

- Drain and refill with clean water to rinse

- Gently squeeze out water (again, no wringing or twisting)

- Roll in towels to absorb excess water

- Lay flat on a clean surface to dry, reshaping as needed

- Drying can take 24-48 hours

Method 4: Never Machine Wash

Do not put Melton wool in a washing machine, even on gentle cycle. The agitation will cause uneven shrinking and felting. Your coat will not recover from this.

How Do You Care for Wool Melton?

Regular Maintenance

After Each Wear:

- Hang on a sturdy wooden or padded hanger

- Brush with a clothes brush to remove surface dirt, lint, and pet hair

- Let air out before putting in a closet

- Check for spots and treat immediately if found

Every 10-15 Wears:

- Steam the garment with a handheld steamer or iron steam function

- This refreshes the fabric, removes mild creases, kills bacteria, and eliminates any moth eggs

- Let dry completely before wearing or storing

Dealing with Wrinkles

Melton wool doesn’t wrinkle as easily as lighter fabrics, but it can crease from extended storage or sitting.

- Hang in a steamy bathroom while you shower

- Use a steamer

- Press with an iron (wool setting, press cloth, steam) but be very careful not to flatten the nap

Storage: The Moth Problem

Moths are the biggest threat to Melton wool during storage. These insects eat wool fibers and can cause irreparable damage.

Short-Term Storage (During Wearing Season)

- Hang on a sturdy wooden hanger

- Give the coat room to breathe (don’t pack closets too tight)

- Keep the area clean, moths are attracted to food particles and body oils

Long-Term Storage (Off-Season)

- Clean first: Never store dirty clothing. Moths are attracted to oils and stains

- Use a breathable garment bag: Cotton or muslin bags let air circulate while protecting from dust and pests

- Add moth deterrents:

- Cedar blocks, balls, or hangers (renew the cedar scent by sanding lightly each year)

- Lavender sachets

- Commercial moth repellent strips

- Never use mothballs, they’re toxic and the smell is hard to remove

- Store in a cool, dry place: Avoid damp basements or hot attics

- Check periodically: Once a month, inspect for signs of moths and air out the garment

Repair and Restoration

Minor damage can often be repaired:

- Small holes or tears: Can be darned or patched by a skilled tailor

- Worn collars or cuffs: Can be refinished or replaced

- Loose buttons: Easy to reattach

- Lining replacement: Old linings can be removed and replaced without affecting the Melton shell

A good tailor who works with wool can perform miracles on vintage or damaged Melton coats.

Buying Guide: What to Look For

Whether you’re buying fabric to sew or a finished garment, here’s how to make smart choices.

Melton wool buying guide showing how to evaluate fabric quality and structure.

Buying Melton Wool Fabric

Fabric Content

Look for at least 75% wool content. Higher is better for traditional Melton qualities. Blends with 10-25% nylon or polyester can actually increase durability while maintaining warmth. Avoid anything less than 70% wool, as it won’t perform like true Melton.

Weight

Consider your project and climate:

- 14-18 oz: Lighter coats, fall wear, indoor work

- 20-26 oz: General winter coats, most projects

- 28-32 oz: Extreme cold, military peacoats, outdoor work gear

Most sewers find 24 oz to be a good all-purpose weight.

Colors

What colors does Melton wool come in? Traditional colors are navy blue, black, camel, gray, and brown. These are the most widely available and have the strongest association with Melton’s heritage. You can find Melton in other colors, including plaids, burgundy, forest green, and even bright colors, though availability varies by supplier.

Solid colors are more traditional and easier to work with for classic coat styles.

Where to Buy

Online fabric retailers: Offer good selection but you can’t feel the fabric before buying. Look for detailed descriptions including fiber content, weight, and width.

Local fabric stores: Let you examine and feel the fabric. Staff can often provide advice. Selection may be limited.

Wholesale/mill-direct: Best prices if buying 5+ yards. Some mills will sell direct to consumers.

Price Expectations

- $15-$25/yard: Budget Melton, likely lower wool content or lighter weight

- $25-$35/yard: Mid-range, good quality for most projects

- $35-$50/yard: Premium Melton, high wool content, excellent quality

For a coat, expect to need 3-4 yards depending on size and style.

Buying Ready-Made Melton Garments

New Peacoats and Coats

If buying new:

- Check fiber content: Should specify wool percentage

- Feel the fabric: Should be dense and smooth, not scratchy or thin

- Check stitching: Seams should be straight and strong

- Test buttons: Should be securely attached

- Try it on over layers: You’ll wear it over sweaters

Quality brands for Melton peacoats: Schott NYC, Sterlingwear of Boston, Buzz Rickson’s (Japanese reproduction), and various military surplus suppliers.

Vintage and Surplus

Military surplus stores and vintage shops can be goldmines for Melton coats:

What to check:

- Moth damage (tiny holes)

- Worn areas (elbows, collar, cuffs)

- Seam integrity

- Lining condition

- Smell (musty odors are hard to remove from wool)

- Buttons (original military buttons add value to collectors)

Vintage peacoats from the 1950s-1970s are often excellent quality and can last another 30+ years if in good condition.

Red Flags to Avoid

- Price too good to be true (under $10/yard for fabric)

- “Melton-style” or “Melton-like” (probably not real Melton)

- Less than 70% wool content

- Uneven color or surface texture

- Excessive pilling on display samples

- Very thin hand (feel)

Frequently Asked Questions

Melton wool is generally not itchy when worn as outerwear because you wear layers underneath. The smooth, fulled surface is less prickly than rough wool. However, it’s not as soft as fine Merino or cashmere. If you’re sensitive to wool, wear a shirt or sweater underneath and avoid direct skin contact.

Yes, Melton wool can be tailored by a skilled tailor. The non-fraying edges actually make some alterations easier. Common alterations include hemming, taking in or letting out seams, shortening sleeves, and adjusting shoulder width. Complex alterations may cost more due to the fabric thickness.

No, Melton wool is fulled, not boiled. While both processes involve heat and moisture, they’re different. Fulling uses milling (physical agitation) to shrink and compact woven fabric. Boiling typically refers to felting knitted wool fabric in hot water. The end results are similar but the processes and starting materials differ.

Yes, Melton coats are very warm. The dense fabric traps body heat effectively. A heavy Melton peacoat can keep you comfortable in temperatures well below freezing. The warmth level depends on the fabric weight, with 28-32 oz Melton being suitable for extreme cold.

Quality Melton wool pills minimally compared to other wool fabrics. The fulling process creates such a tight structure that fibers don’t work loose easily. Some pilling may occur in high-friction areas (underarms, where a bag strap rubs) but much less than with regular wool. Poor-quality Melton or blends with high synthetic content may pill more.

The name comes from Melton Mowbray, a town in Leicestershire, England, where the fabric was first produced in the 18th century. The town was the center of British fox-hunting culture, and local wool producers developed this weather-resistant fabric for hunting coats. The name stuck even as production spread throughout Britain.

Never machine dry Melton wool. The heat and tumbling will cause severe shrinkage and potential felting damage. Always air dry flat or hanging, away from direct heat or sunlight. Drying can take 24-48 hours.

Yes, Melton fabric is one of the warmest wool fabrics available. Its dense structure creates excellent insulation, and wool continues to provide warmth even when slightly damp. It’s particularly effective at blocking wind, which makes cold weather feel much colder when unchecked.

Melton wool has minimal stretch and maintains its shape well over time. Some areas may relax slightly with wear (like elbows or shoulders from body movement), but significant stretching is uncommon. This is why proper fitting is important when buying a coat, as it won’t stretch to accommodate like knitted fabrics do.

While technically possible, dying Melton wool at home is not recommended. The fabric’s dense structure makes even dye penetration difficult, and the high heat required for wool dyes could cause shrinkage. If you want a specific color, buy it pre-dyed. Professional textile dyers may be able to dye Melton, but it’s expensive.

Yes, Melton wool aligns well with sustainable fashion principles. It’s made from renewable, biodegradable natural fibers. The longevity of Melton garments (20-30+ years) means fewer resources spent on replacement clothing. It doesn’t shed microplastics like synthetic fabrics. However, the environmental impact depends on farming practices and processing methods.

Yes, lighter weights of Melton (14-18 oz) work well for hats and berets. The non-fraying edges make construction easier, and the fabric provides good structure. Heavier weights are too stiff for comfortable headwear.

If Melton wool gets thoroughly soaked, it will eventually dry without damage as long as you dry it properly. Lay it flat or hang it to air dry at room temperature. Don’t use heat (no hair dryers, radiators, or dryers). The coat will be heavy while wet. Wool continues to insulate when damp, which is one of its advantages over cotton or down.

Vintage Melton (particularly military surplus from 1940s-1970s) was often made to higher specifications than modern mass-market versions. However, modern premium brands can match or exceed vintage quality. The advantage of vintage is proven longevity (it’s already lasted 50+ years) and often lower price. New offers perfect condition and exact sizing.

Conclusion

After 200+ years, Melton wool continues to be one of the most practical cold-weather fabrics ever developed. It’s a rare case where tradition and performance meet perfectly. The same fabric that kept 18th-century fox hunters warm and protected WWII sailors in the North Atlantic works just as well today for urban winters or outdoor activities.

Key Takeaways

What makes Melton wool special: It’s the fulling process that sets it apart. This controlled shrinking and matting creates a dense, wind-resistant, water-shedding fabric that doesn’t fray. No other wool fabric offers quite the same combination of protection and durability.

The investment is worth it: Yes, quality Melton fabric or garments cost more upfront. But when you calculate cost-per-wear over 20-30 years, it’s actually more economical than buying cheap coats every few years. You’re also avoiding the environmental impact of frequent replacement.

It’s easier to work with than you think: If you sew, don’t be intimidated by Melton wool. The non-fraying edges and forgiving nature make it suitable even for beginners attempting their first coat. Just remember to pre-treat the fabric and use proper techniques for managing bulk.

Care is simpler than expected: Melton wool needs minimal care. Brush after wearing, steam occasionally, spot clean as needed, and dry clean once or twice per season. The main requirement is protecting from moths during storage. That’s it.

Know what you’re buying: Not all Melton is created equal. Look for at least 75% wool content, appropriate weight for your needs, and smooth even texture. Whether buying fabric or finished garments, understanding quality indicators helps you make smart choices.

Who Should Choose Melton Wool?

Melton wool is perfect for:

- Slow fashion advocates: Who want clothes that last decades

- Cold climate dwellers: Who need serious winter protection

- Sewers looking for an ambitious project: That will create a family heirloom

- People who value quality over quantity: And are willing to invest in pieces that perform

- Anyone tired of replacing coats: Every few years

- Historical costume makers: Who need period-appropriate fabric

- Minimalists: Who want one excellent coat instead of several mediocre ones

It’s Not Right for Everyone

Melton wool may not suit you if:

- You need something machine washable

- You live in a warm climate year-round

- You want lightweight, packable outerwear

- You need maximum breathability for active wear

- You’re looking for budget-friendly options

- You prefer the softest fabrics against your skin

Final Recommendations

If you’re buying fabric to sew: Start with a quality 24 oz Melton in a classic color like navy or black. This weight is versatile and manageable for most sewers. Choose a reputable pattern designed for coating fabric. Pre-treat before cutting. Take your time with construction, and the result will be something you’ll wear for decades.

If you’re buying a ready-made coat: Consider military surplus or vintage options for best value. Look for quality wool and cashmere pieces that have proven their durability. Check the fiber content (aim for 75%+ wool) and inspect for damage. A good Melton peacoat should feel substantial and dense.

If you’re on the fence: Consider that your grandchildren might wear the coat you make or buy today. Few modern garments can make that claim. Melton wool represents a time when clothes were built to last, and choosing it is a small rebellion against disposable fashion.

Looking Forward

As more people become interested in sustainable, long-lasting clothing, Melton wool is experiencing a revival. Small mills and artisan producers are keeping traditional methods alive, while modern manufacturers continue to refine the process. The fabric that served sailors, soldiers, aristocrats, and workers for two centuries isn’t going anywhere.

Whether you’re drawn to Melton wool for its history, its performance, or its sustainability credentials, you’re participating in a textile tradition that has stood the test of time. In a world of fast fashion and disposable clothing, choosing Melton wool is choosing something different, something better, something that will outlast trends and seasons and maybe even outlast you.

Now you have all the information you need to work with, buy, or care for this remarkable fabric. The rest is up to you.

Ready to Start Your Melton Wool Project?

For more information on working with wool fabrics, check out our comprehensive wool care guide. If you’re interested in other coating fabrics, see our guides on wool coating and cashmere wool.