From Alpine Tradition to Modern Sustainable Fashion: Everything You Need to Know About This Remarkable Material

Imagine a fabric so smart it keeps you warm without weight, sheds water without chemicals, and gets better with age instead of falling apart. That’s boiled wool. This ancient textile, born in the harsh Alpine mountains centuries ago, has made a stunning comeback in today’s world of sustainable fashion. Whether you’re a sewer looking for the perfect outerwear fabric, a conscious consumer seeking eco-friendly materials, or simply curious about this unique textile, you’re about to discover why boiled wool deserves a place in your wardrobe and your projects.

Table of Contents

What Is Boiled Wool Fabric?

Boiled wool is a type of felted fabric created through a process called fulling, where knitted wool fabric is washed and agitated in hot water. This treatment causes the wool fibers to shrink and mat together, creating a dense, smooth material that’s stronger and more water-resistant than regular wool.

Unlike standard sheep wool fabric, which maintains its knitted or woven structure, boiled wool transforms into something entirely different. The fibers interlock so tightly that you can barely see the original knit pattern. What you get is a fabric that won’t fray when cut, resists pilling, and provides exceptional warmth without the bulk.

Quick Facts About Boiled Wool

- Other names: Walk fabric (German: “Walk”), felted wool, fulled wool

- Typical weight: 380-420 g/m² for outerwear, 260 g/m² for lighter garments

- Shrinkage during production: Up to 50-66% in all directions

- Base structure: Knitted fabric (unlike melton wool or loden, which are woven)

- Typical width: 142cm (56-58 inches)

Is Boiled Wool Good Quality?

Yes, boiled wool is considered a high-quality fabric. The fulling process actually improves the wool’s natural properties, making it more durable, water-resistant, and stable than untreated wool. Quality boiled wool can last decades with proper care, often outlasting synthetic alternatives by years.

The best boiled wool comes from premium sources like merino wool, which creates softer, finer fabric. Some manufacturers also blend in luxury fibers like cashmere or alpaca to create even more refined versions.

What Is 100% Boiled Wool?

The term “100% boiled wool” means the fabric is made entirely from wool fibers with no synthetic blends. After the fulling process, these pure wool fabrics offer the best breathability, temperature regulation, and biodegradability. However, you’ll also find blends that mix wool with rayon or viscose to add drape and reduce cost while maintaining many of boiled wool’s benefits.

The Rich History of Boiled Wool

Boiled wool fabric representing its long history and traditional use

Boiled wool’s story begins in the Alpine regions of Tyrol, Austria, where the fulling process dates back to at least the Middle Ages. This wasn’t fashion at first – it was survival. Mountain shepherds and farmers needed clothing that could withstand freezing temperatures, biting winds, and sudden snow or rain. The wool from their own sheep, processed through fulling, created the perfect solution.

The Imperial Decree and Class Distinctions

Here’s a fascinating historical detail: Austrian peasants were actually required by imperial decree to wear only loden (a woven and fulled wool), linen, or leather. The nobility and upper classes wore different fabrics, making boiled wool and loden a marker of working-class status. This fabric literally kept the people of the high Alps alive during brutal winters.

Archduke Johann’s Fashion Revolution

Everything changed in the early 19th century thanks to Archduke Johann, brother of Emperor Franz II. After a military defeat at Hohenlinden in 1800, Johann was posted to Tyrol to represent his brother. Unlike other royals, he embraced local culture and started wearing the traditional Styrian wool jacket made from boiled wool. When royalty adopts peasant clothing, fashion takes notice.

His choice transformed boiled wool from workwear into a symbol of Alpine authenticity and quality. Soon, the fabric gained popularity among the middle and upper classes throughout the Austrian Empire and neighboring Germany. What was once forbidden to the wealthy became a status symbol of refined taste and appreciation for traditional craftsmanship.

The Loden Connection

The story of boiled wool is closely tied to loden, another fulled wool fabric. While they share the same basic process, loden is woven before fulling, giving it a different character. Traditional loden production centered in regions like Tyrol and Bavaria, where mills developed their own specialized techniques passed down through generations.

By the mid-1800s, companies like Lodenfrey in Munich began producing water-repellent loden on an industrial scale. Their innovation, called Strichloden, featured a surface brushed with thistles to enhance water resistance – a technique still used today. These developments made fulled wool fabrics more accessible while maintaining their legendary quality.

Modern Revival

Today, only a handful of traditional Alpine mills continue producing authentic boiled wool and loden using time-honored methods. These mills, like Loden Steiner in Mandling, Austria, use mountain spring water and follow strict quality standards. The current revival of interest in boiled wool comes from growing awareness of sustainable fashion and natural materials. People are rediscovering what Alpine shepherds knew centuries ago: few materials match the performance, durability, and environmental benefits of properly fulled wool.

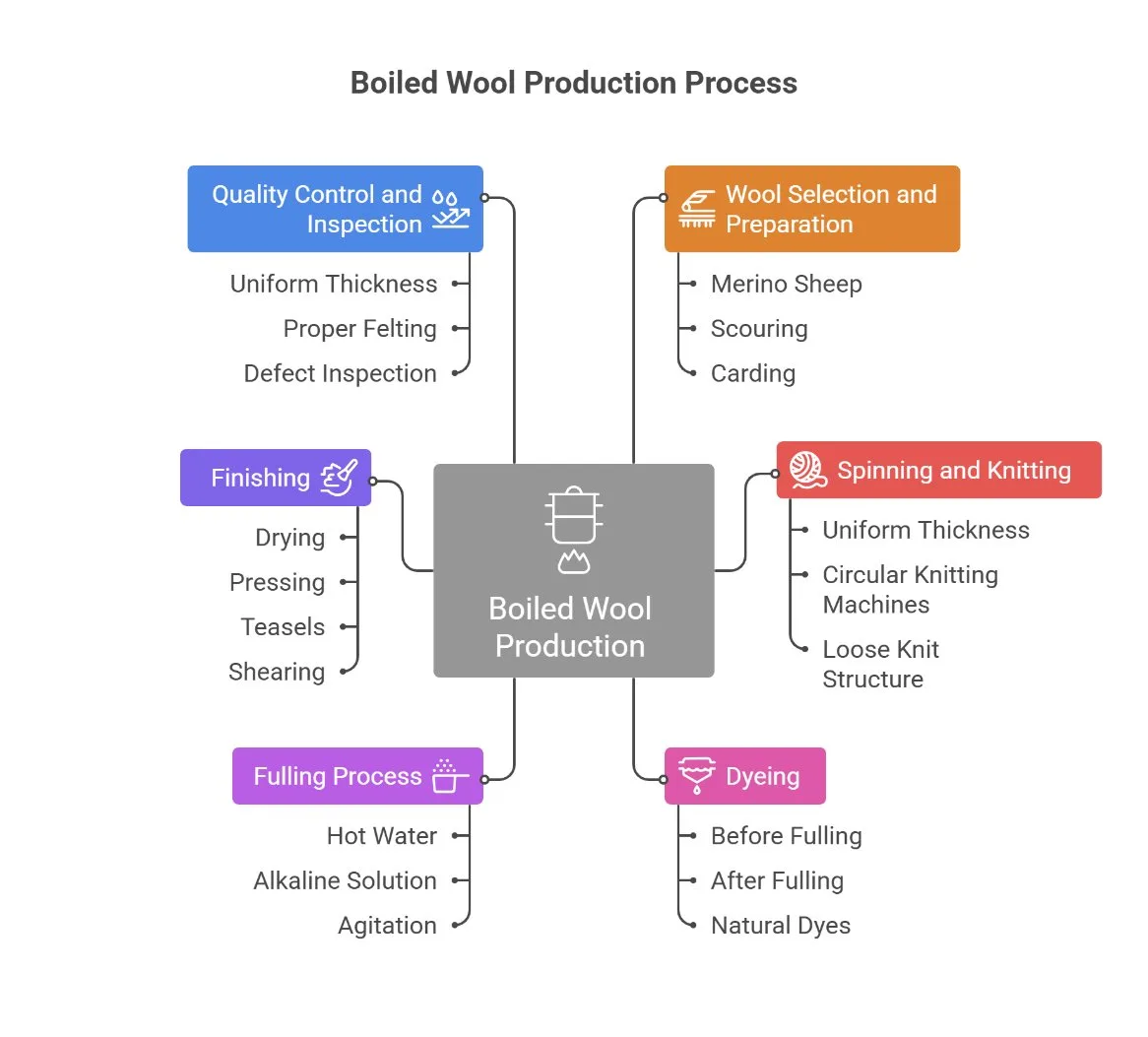

How Boiled Wool Is Made

Visual guide explaining how boiled wool fabric is made

The process of creating boiled wool is part science, part art, refined over centuries. Understanding how it’s made helps explain why this fabric has such unique properties.

Wool Selection and Preparation

It all starts with quality wool fibers, typically from merino sheep or other premium breeds. The raw wool is thoroughly cleaned (scoured) and carded to remove impurities and align the fibers. This creates a clean, organized starting material ready for spinning.

Spinning and Knitting

The carded wool is spun into yarn of uniform thickness. This yarn is then knitted (not woven) into fabric on circular knitting machines. This knitted base is what distinguishes boiled wool from loden, which uses woven fabric. The loose knit structure allows the fibers to move and interlock during the next step.

Dyeing

The fabric can be dyed either before or after fulling. Many producers prefer natural, undyed colors, but when color is desired, the dyeing happens at this stage. Modern eco-friendly mills are increasingly using natural dyes to reduce environmental impact.

The Fulling Process (Boiling)

This is where the magic happens. The knitted fabric is submerged in hot water (around 30°C in eco-friendly production, higher in traditional methods) with an alkaline solution like soap. The fabric is then vigorously agitated – either by machine or, in traditional mills, by physically pounding it with wooden hammers or stomping it with feet.

This combination of heat, moisture, alkaline solution, and mechanical action causes the microscopic scales on wool fibers to open and stick together. The fabric shrinks dramatically – up to 50-66% in all directions. What starts as a loose knit becomes a tight, dense, felt-like material.

The best eco-friendly producers use only pure mountain spring water without harsh chemicals, relying on temperature and mechanical action alone. This creates fabric that’s gentler on the environment while maintaining exceptional quality.

Finishing

After fulling, the fabric is carefully dried and pressed. Some producers brush the surface with teasels (metal combs or natural thistle heads) to raise the fibers slightly, creating extra softness or enhanced water repellency. The fabric may be sheared repeatedly to achieve the perfect balance of density, loft, and texture.

Quality Control and Inspection

Each piece is inspected for uniform thickness, proper felting, and any defects. The fabric is measured, rolled, and prepared for sale. Traditional mills take particular pride in this step, as their reputation depends on consistent quality.

Can You Make Your Own Boiled Wool?

Yes, you can make boiled wool at home, though results won’t match commercial production. Here’s the basic process:

- Start with 100% wool knitted fabric (not woven)

- Prepare a basin of very hot water (as hot as your hands can tolerate) with a small amount of gentle soap

- Submerge the fabric and agitate it vigorously – squeeze, rub, and knead it continuously

- Continue for 10-15 minutes, checking the fabric’s progress

- When it has shrunk and felted to your desired density, rinse in cold water to stop the process

- Roll in towels to remove excess water, then lay flat to dry

Keep in mind that home-boiled wool won’t achieve the same uniformity or quality as professionally produced fabric. The process is labor-intensive and results can be unpredictable. For sewing projects, buying properly fulled fabric from reputable suppliers gives much better results.

Properties and Benefits of Boiled Wool

Key properties and benefits of boiled wool fabric explained visually

Boiled wool isn’t just another fabric – it’s a performance material that happens to be completely natural. Here’s what makes it special:

Thermal Insulation and Warmth

Boiled wool is exceptionally warm for its weight. During fulling, countless tiny air pockets form between the matted fibers. These pockets trap warm air close to your body while allowing moisture vapor to escape. This is why a boiled wool jacket can keep you comfortable in temperatures down to -15°C (5°F) without feeling bulky or heavy.

Is Boiled Wool Warmer Than Regular Wool?

Yes, significantly. The fulling process creates a much denser fabric with more trapped air pockets per square inch than regular wool fabric. This increased density provides superior insulation. While a regular wool sweater might keep you comfortable to 5°C (41°F), boiled wool outerwear can handle much colder conditions.

How Warm Is Boiled Wool?

Boiled wool garments can handle cold weather exceptionally well. A quality boiled wool jacket with a density of 420 g/m² will keep you warm in temperatures ranging from 10°C to -15°C (50°F to 5°F), especially when layered appropriately. Lighter weight boiled wool at 260 g/m² works well for transitional weather from 15°C to 5°C (59°F to 41°F).

Natural Water Repellency

Here’s something amazing: boiled wool repels water without any chemical treatment. The dense, felted structure causes water droplets to bead up and roll off the surface rather than soaking in. This isn’t the same as waterproof – heavy rain will eventually penetrate – but it handles light rain, mist, and snow remarkably well.

Can Boiled Wool Get Wet?

Boiled wool can get wet, but it’s naturally water-resistant rather than waterproof. Light rain and snow will bead off, but prolonged exposure to heavy rain will eventually soak through. The good news is that even when damp, boiled wool continues to insulate because the fibers maintain their structure. Just dry it properly afterward to maintain its quality.

Breathability Despite Density

Despite being dense and wind-resistant, boiled wool breathes beautifully. The natural structure of wool fibers allows moisture vapor from your body to pass through the fabric while blocking cold air from penetrating. This prevents the clammy feeling you get with synthetic materials that trap perspiration.

Exceptional Durability

The fulling process strengthens wool fibers considerably. Boiled wool is highly resistant to wear, tear, and abrasion. Unlike regular knitted wool that can snag or develop holes, boiled wool’s matted structure distributes stress across many interlocked fibers. A well-made boiled wool coat can last 20-30 years or more with proper care.

No Fraying

One of boiled wool’s most beloved features for sewers: it doesn’t fray when cut. The felted structure holds together even at raw edges, meaning you can create garments with unfinished seams and edges. This opens up design possibilities and simplifies construction.

Does Boiled Wool Fabric Fray?

No, boiled wool does not fray. The fulling process causes the fibers to mat together so thoroughly that they hold firmly even when cut. This is one of its major advantages for sewing – you can leave edges raw for a modern look or skip time-consuming edge finishing.

Pilling Resistance

While regular wool can develop annoying pills (those little fiber balls that form with friction), boiled wool is much more resistant. The tightly interlocked fibers have less tendency to work free and form pills. If any do develop, they’re easily removed with a fabric shaver.

Shape Retention

Boiled wool holds its shape exceptionally well. The felted structure resists stretching and sagging, even in areas that experience stress like elbows and knees. This means garments maintain their silhouette for years, looking nearly as good as the day you made or bought them.

Wrinkle Resistance

The dense, springy nature of boiled wool makes it naturally wrinkle-resistant. Minor creases from packing or sitting simply disappear. For stubborn wrinkles, a quick steam does the trick – the fibers relax and return to their original shape.

Soft, Non-Itchy Feel

Regular wool can feel scratchy against skin, but boiled wool is surprisingly soft. The fulling process smooths the fiber surfaces, reducing the prickly sensation. Quality boiled wool, especially from fine merino, feels comfortable even directly against skin.

Is Boiled Merino Wool Soft?

Yes, boiled merino wool is exceptionally soft. Merino fibers are already finer than regular wool (measuring 15-19.5 microns versus 20-40 microns for standard wool). After boiling, the already-fine fibers create an even softer fabric that feels luxurious against skin without any itchiness.

Anti-Allergic Properties

Boiled wool is naturally hypoallergenic. The fulling process removes remaining lanolin and other potential irritants. Plus, wool naturally resists dust mites, mold, and mildew, making it a good choice for people with allergies.

Moth and Insect Resistance

While not completely moth-proof, boiled wool’s dense structure makes it harder for moths to access and damage fibers compared to regular wool. The tight felting provides some natural protection, though proper storage remains important for long-term preservation.

Quiet Movement

Unlike synthetic outerwear that rustles with every movement, boiled wool is remarkably quiet. This is why hunters traditionally preferred loden and boiled wool jackets – they could move through forests without making noise that alerts game. It’s also just more pleasant for everyday wear.

The Disadvantages of Boiled Wool

To be fair, boiled wool isn’t perfect for every situation:

- Cost: Quality boiled wool is expensive, typically $20-50 per yard, because the production process is labor-intensive and material-intensive (remember, the fabric shrinks 50% during production)

- Weight: While lighter than it looks, boiled wool is still heavier than many synthetic alternatives

- Care requirements: It needs more careful washing than synthetic fabrics and shouldn’t be machine dried

- Not waterproof: Water-resistant doesn’t mean waterproof – you’ll still get wet in heavy rain without additional protection

- Limited stretch: The felted structure means less give than regular knitted wool, which may feel restrictive in very fitted garments

- Risk of additional shrinkage: If washed incorrectly (hot water, agitation), boiled wool can shrink further and become distorted

Boiled Wool vs. Other Fabrics

Understanding how boiled wool compares to similar fabrics helps you make informed choices for your projects and purchases.

Boiled Wool vs. Regular Wool

Boiled wool vs regular wool fabric comparison highlighting structure and density

| Feature | Boiled Wool | Regular Wool |

|---|---|---|

| Texture | Dense, smooth, felt-like | Soft, fluffy, shows knit/weave pattern |

| Structure | Fibers matted and interlocked | Individual fibers visible and lofty |

| Water Resistance | Naturally water-repellent | Absorbs moisture more readily |

| Warmth | Superior insulation from trapped air pockets | Warm, but less dense insulation |

| Durability | Highly resistant to wear and pilling | Can pill and snag more easily |

| Fraying | No fraying when cut | Edges fray and need finishing |

| Stretch | Minimal stretch, holds shape | More elastic and flexible |

| Weight | Heavier (380-420 g/m²) | Varies, often lighter |

| Best Uses | Outerwear, jackets, slippers, structured garments | Sweaters, scarves, blankets, suits |

Boiled Wool vs. Felt

These two fabrics often get confused because they’re both felted, but they’re actually quite different.

Boiled wool vs felt fabric comparison highlighting structure and finish

| Feature | Boiled Wool | Felt |

|---|---|---|

| Starting Material | Knitted wool fabric | Raw, carded wool fibers (no knitting or weaving) |

| Production Method | Fulling process (washing and agitating knitted fabric) | Wet felting or needle felting of loose fibers |

| Visible Structure | Can still see faint knit pattern in some areas | Completely uniform, no visible pattern |

| Flexibility | More flexible and drapable | Stiffer, less drape |

| Softness | Softer, more comfortable for clothing | Can be rougher, more textured |

| Durability | Very durable, excellent for outerwear | Durable but can separate at stress points |

| Typical Uses | Jackets, coats, slippers, fashion garments | Crafts, decorative items, industrial applications, simple slippers |

| Price | Higher (more processing steps) | Lower to moderate |

The key difference is that boiled wool starts as a knitted fabric, while felt starts as loose fibers. This gives boiled wool more body, flexibility, and better clothing performance.

Boiled Wool vs. Loden

Loden and boiled wool are close cousins, both originating in the Alps and both using the fulling process. The main difference lies in what happens before fulling.

Boiled wool vs loden wool differences in surface texture and use

| Feature | Boiled Wool | Loden |

|---|---|---|

| Base Structure | Knitted wool | Woven wool |

| Production | Knit, then full/boil | Weave, then full/boil |

| Flexibility | More flexible and elastic | More structured and rigid |

| Drape | Better drape, more fluid | Stiffer drape, holds shape firmly |

| Density | Dense, but with slight give | Extremely dense and compact |

| Traditional Uses | Jackets, cardigans, sweaters | Heavy coats, hunting jackets, capes |

| Modern Applications | Fashion, outerwear, accessories | Traditional outerwear, heritage fashion |

| Typical Weight | 260-420 g/m² | 400-600 g/m² |

Think of loden as boiled wool’s tougher older sibling. Both are excellent, but loden’s woven base makes it more suitable for very heavy outerwear that needs maximum structure, while boiled wool’s knitted base makes it better for garments that need some flexibility and drape.

Boiled Wool vs. Wool Fleece

Wool fleece (also called walk fleece in Europe) is another felted wool option, but it has distinctly different characteristics.

Boiled wool vs wool fleece differences in warmth and fabric feel

| Feature | Boiled Wool | Wool Fleece |

|---|---|---|

| Production | Knitted, then fulled | Knitted, then brushed (not fulled as much) |

| Texture | Dense, smooth, firm | Soft, fluffy, brushed surface |

| Density | Very dense (420 g/m²) | Less dense (280 g/m²) |

| Wind Resistance | Excellent windproof qualities | Less wind-resistant |

| Water Resistance | Very water-resistant | Less water-resistant |

| Warmth | Very warm | Warm but less insulating |

| Weight | Heavier | Lighter, more breathable |

| Softness | Smooth and soft | Very soft and cozy |

| Best For | Active toddlers, outdoor play, cold weather | Babies, indoor wear, layering |

Wool fleece is popular for baby and toddler clothing in Europe. It’s softer and lighter than boiled wool, making it comfortable for little ones who are carried or in strollers. Boiled wool, being denser and more protective, is better for active toddlers who play outside in cold, wet weather.

What Is the Difference Between Melton Wool and Boiled Wool?

Melton wool is another dense wool fabric that’s sometimes confused with boiled wool, but they’re quite different:

Visual comparison of melton wool and boiled wool fabrics

| Feature | Boiled Wool | Melton Wool |

|---|---|---|

| Base Structure | Knitted fabric | Tightly woven fabric (twill weave) |

| Production Process | Knit + fulling/boiling | Weave + fulling + heavy napping (raising fibers) |

| Surface Texture | Smooth, slightly fuzzy | Very smooth, almost felt-like nap |

| Flexibility | More flexible and drapable | Very stiff and structured |

| Wind Resistance | Excellent | Superior (completely windproof) |

| Traditional Uses | Alpine outerwear, jackets | Military peacoats, duffle coats, stadium blankets |

| Appearance | Casual, textured | Formal, smooth |

| Typical Weight | 380-420 g/m² | 500-700 g/m² |

Melton wool is heavier and stiffer because it’s woven and then heavily napped to create an ultra-smooth surface. It’s the traditional fabric for naval peacoats and formal outerwear. Boiled wool is lighter and more casual, with better drape for everyday wear.

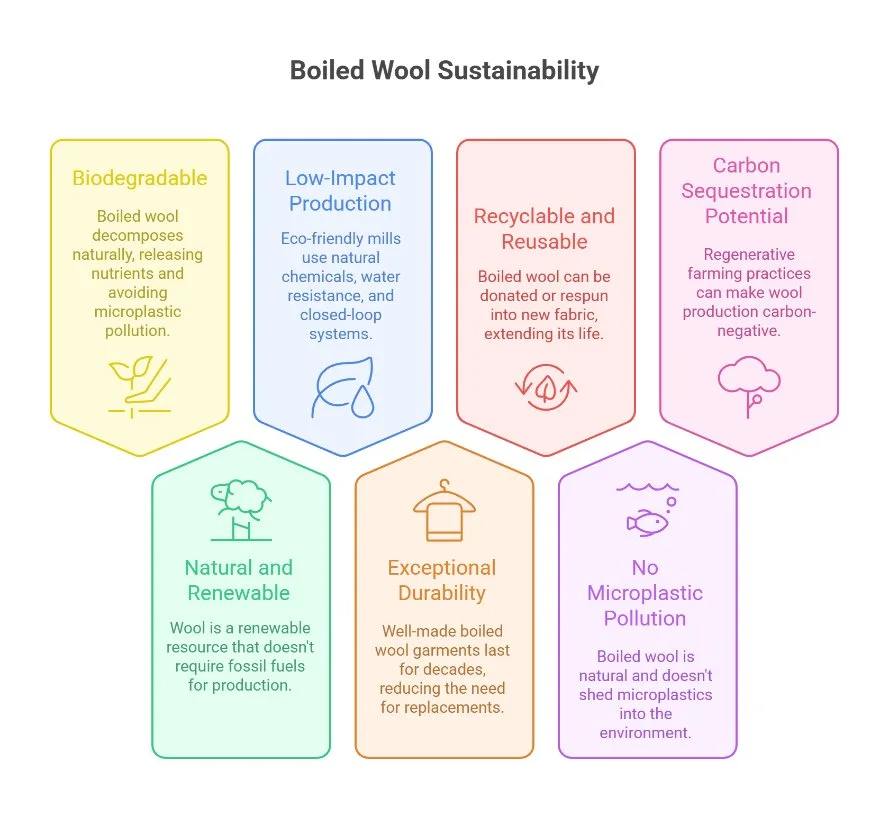

Sustainability and Environmental Impact

Visual overview of boiled wool sustainability and environmental benefits

In an era of fast fashion and synthetic materials, boiled wool stands out as one of the most sustainable fabric choices available. Here’s why conscious consumers are returning to this ancient material.

Is Boiled Wool Sustainable?

Yes, boiled wool is highly sustainable when sourced responsibly. It checks almost every box for environmentally friendly materials:

100% Biodegradable

Boiled wool completely biodegrades in natural environments. Research shows that wool products decompose almost entirely within six months in soil, and about 20% breaks down within 90 days even in marine environments. Compare this to synthetic fabrics that can persist for hundreds of years, and the advantage is clear.

As wool biodegrades, it releases nutrients back into the soil – nitrogen, sulfur, phosphorus, and potassium – acting as a natural fertilizer. It doesn’t contribute to the microplastic pollution crisis that’s affecting our oceans and food chain.

Natural and Renewable

Wool is a completely renewable resource. Sheep produce new fleece every year, making it infinitely renewable when managed responsibly. Unlike petroleum-based synthetics, no fossil fuels are required to create the raw material.

Low-Impact Production

The best boiled wool producers use eco-friendly methods that minimize environmental harm:

- No harsh chemicals: Traditional fulling uses only heat, water, and natural soap. Modern eco-friendly mills like those in Tyrol use pure mountain spring water at moderate temperatures (around 30°C) with no alkalis or chemical softeners.

- Natural water resistance: No chemical treatments are needed to make boiled wool water-repellent – it’s a natural result of the fulling process.

- Low energy use: Compared to synthetic fabric production, boiled wool requires relatively little energy. The main energy input is heating water, which can be done sustainably.

- Closed-loop water systems: Some mills recycle the water used in fulling, reducing overall water consumption.

Exceptional Durability Means Less Consumption

A well-made boiled wool garment can last 20-30 years or more. This longevity dramatically reduces the need for replacement and the environmental impact of constant manufacturing. One boiled wool coat might replace five or more synthetic jackets over its lifetime.

The fabric also requires less frequent washing than synthetic materials because wool naturally resists odors and dirt. Fewer washes mean less water use, less energy consumption, and less release of any microfibers.

Recyclable and Reusable

Boiled wool garments can be donated and worn by new owners, extending their useful life even further. When clothing is finally past wearable condition, the wool can be respun into new yarn and fabric, giving it a second life without downcycling into lower-quality products.

No Microplastic Pollution

Synthetic fabrics shed microplastic fibers every time they’re washed, worn, or dried. These microscopic particles end up in waterways and oceans, entering the food chain and causing environmental damage. Boiled wool, being 100% natural, produces no microplastics. Any fibers that do shed will biodegrade naturally.

Carbon Sequestration Potential

Wool is 50% pure organic carbon by weight. During a sheep’s life, it consumes organic carbon stored in plants and converts it to wool. When managed with regenerative farming practices – using rotational grazing, improving soil health, and planting trees – wool production can actually help sequester carbon from the atmosphere.

Responsible Sourcing Matters

To maximize sustainability benefits, look for boiled wool with these certifications:

- GOTS (Global Organic Textile Standard): Ensures organic farming practices, no chemical pesticides on pastures, and ethical treatment of sheep

- RWS (Responsible Wool Standard): Guarantees animal welfare and sustainable land management

- Mulesing-free: Confirms sheep aren’t subjected to the painful mulesing procedure

- Authentic Alpine origin: Wool from Austria, Bavaria, or Northern Italy often comes from traditional mills with high standards

Environmental Challenges to Consider

While boiled wool is generally sustainable, sheep farming does have environmental impacts:

- Methane emissions: Sheep produce methane, a potent greenhouse gas. However, researchers in Australia and New Zealand are developing feed supplements and farming practices to reduce these emissions.

- Land use: Sheep grazing requires significant land. When managed poorly, overgrazing can lead to soil degradation. Responsible farming with rotational grazing actually improves soil health and biodiversity.

- Water use in scouring: Cleaning raw wool (scouring) requires water. Progressive mills recycle this water and use natural cleaning methods to reduce environmental impact.

Despite these challenges, boiled wool’s overall environmental footprint remains significantly lower than synthetic alternatives when you factor in the full lifecycle from production through disposal.

Modern Applications and Uses

Boiled wool’s unique properties make it suitable for a wide range of applications, from high-end fashion to practical everyday items.

Fashion and Outerwear

Boiled wool jacket demonstrating comfort and everyday outerwear design

The fashion world has embraced boiled wool for its combination of performance and aesthetic appeal:

- Jackets and coats: The traditional Hubertus coat and Styrian jacket remain popular, but modern designers are creating sleek, minimalist outerwear that appeals to contemporary tastes

- Structured blazers: Boiled wool holds its shape beautifully, making it perfect for tailored blazers that don’t need constant steaming

- Cardigans and vests: Lighter weight boiled wool (260 g/m²) works wonderfully for layering pieces

- Dresses and skirts: The fabric’s body creates sophisticated silhouettes with excellent drape

Brands like Eileen Fisher, Giesswein, and Robert W. Stolz have built followings around quality boiled wool pieces that combine traditional craftsmanship with modern design sensibilities.

What to Sew with Boiled Wool

If you’re a sewer, boiled wool opens up exciting project possibilities:

- Outerwear: Jackets, coats, capes, and vests are natural choices. The fabric’s structure means you can create unlined garments with professional results

- Accessories: Hats, berets, scarves, bags, and mittens work beautifully. The no-fray property allows for creative edge treatments

- Slippers and boots: Boiled wool’s water resistance and warmth make it perfect for indoor and outdoor footwear

- Home décor: Pillows, blankets, wall hangings, and rugs benefit from boiled wool’s durability and acoustic properties

- Raw-edge designs: The fabric’s unique property of not fraying lets you create modern, architectural pieces with exposed seams and edges

- Stuffed items: Because it doesn’t fray, boiled wool works well for toys, decorative objects, and crafts

Children’s Clothing

Boiled wool clothing used for comfortable and warm childrens wear. Credit: Woollykins

Boiled wool is hugely popular for children’s outerwear in Europe, particularly in Germany, Austria, and Switzerland. Parents appreciate its practical benefits:

- Keeps kids warm in cold weather without bulk

- Resists light rain and snow

- Extremely durable for active play

- Natural and non-toxic

- Easy to clean spot stains

Brands like Disana, Engel, and SISKIN specialize in children’s boiled wool clothing, from overalls to jackets designed to grow with children.

Footwear

Boiled wool slippers have become increasingly popular for their comfort and performance:

- Exceptional warmth without sweaty feet (thanks to breathability)

- Natural moisture-wicking keeps feet dry

- Durable enough for both indoor and light outdoor use

- Molds to foot shape over time for custom comfort

Companies like Giesswein have built entire product lines around boiled wool footwear, from house slippers to outdoor-ready boots.

Home Textiles

Boiled wool throw used for warmth and interior decoration

Boiled wool’s properties translate beautifully to home applications:

- Acoustic insulation: The dense fabric absorbs sound exceptionally well, reducing noise in rooms

- Thermal insulation: Wool’s insulating properties make it useful in eco-building projects

- Blankets and throws: Warm, durable, and naturally fire-resistant

- Rugs: Resilient, dirt-resistant, and long-lasting

Sewing with Boiled Wool

Boiled wool is actually one of the more forgiving fabrics to sew with, especially for beginners tackling outerwear for the first time. Its stability and no-fray properties eliminate many common sewing headaches.

Is Boiled Wool Easy to Sew?

Yes, boiled wool is relatively easy to sew compared to other outerwear fabrics. The felted structure is stable and doesn’t shift or slide as you work with it. The edges don’t fray, eliminating the need for serging or edge finishing. However, its thickness does require some special considerations for best results.

Is Boiled Wool a Knit Fabric?

Boiled wool starts as a knit fabric, but after fulling, it behaves more like a woven. The original knit structure is locked in place by the felting process, so it doesn’t stretch or curl like a typical knit. You can treat it like a stable woven fabric for sewing purposes, though you’ll still see faint traces of the original knit pattern in some areas.

Does Boiled Wool Have a Right and Wrong Side?

Generally no, most boiled wool doesn’t have distinctly different sides. Both surfaces look and feel similar because the fulling process affects the entire fabric uniformly. This is actually an advantage – you can use either side, and if you make a cutting mistake, it won’t show. However, some specially finished boiled wool (like brushed surfaces) may have a preferred right side. Check your specific fabric before cutting.

Does Boiled Wool Have a Grain?

Technically yes, but it matters less than with woven fabrics. The original knit direction creates a subtle grain, but because the fabric is felted and stable, you have more flexibility in pattern layout. That said, for best results, you should still follow pattern grain lines, especially for garments where drape and hang matter.

Essential Sewing Tips

Tools and Supplies

- Needles: Use a sharp needle size 90/14 or 100/16 for thicker boiled wool. The sharp point penetrates the dense fabric cleanly. Similar to working with other wool coating fabrics, the right needle makes all the difference.

- Thread: Polyester or poly-cotton thread works well. It has the strength needed for the weight of boiled wool garments

- Scissors or rotary cutter: Sharp tools are essential. Boiled wool’s density will dull blades faster than lighter fabrics, so keep them sharp

- Pins or clips: Either works well. Wonder clips are handy for thick seams where pins might bend

- Walking foot: Helpful but not essential. A walking foot helps feed thick layers evenly through the machine

Cutting and Preparation

- Let fabric relax after unfolding. If it has storage creases, steam them out before cutting

- Use pattern weights instead of pins when laying out patterns to avoid marking the fabric

- Cut with confident, long strokes for clean edges. Short, choppy cuts create rough edges

- Mark with tailor’s chalk or soap slivers. Avoid pens or markers that might show through

Does Boiled Wool Fray When Cut?

No, boiled wool does not fray when cut. This is one of its biggest advantages for sewing. You can cut it, and the edges will stay clean and stable. This means you can:

- Skip edge finishing on seam allowances

- Create raw-edge details and decorative elements

- Make unlined garments that look professional inside and out

- Add appliqués and patches without worrying about fraying

Do You Have to Hem Boiled Wool?

No, you don’t have to hem boiled wool in the traditional sense. Because it doesn’t fray, you can simply cut the hem edge and leave it raw for a modern look. Many contemporary designs use this raw-edge aesthetic. However, if you prefer a traditional hem, you can certainly add one – just keep it simple since the fabric’s thickness makes complex hems bulky.

Seam Construction

- Seam allowance: Use standard 5/8″ (1.5cm) seam allowances. You don’t need to finish them since the fabric doesn’t fray

- Stitch length: Use a slightly longer stitch length (3.0-3.5mm) to accommodate the fabric’s thickness

- Pressing seams: Press seams open to reduce bulk. Use a pressing cloth and steam to avoid flattening the fabric’s texture

- Topstitching: Works beautifully on boiled wool. Use a longer stitch length (3.5-4.0mm) for visible topstitching

Does Boiled Wool Need Interfacing?

Rarely. Boiled wool has enough body and structure on its own for most applications. You generally don’t need interfacing unless you’re creating very structured areas like coat collars, button plackets, or pocket flaps where you want extra crispness. If you do use interfacing, choose a lightweight fusible interfacing and test on a scrap first to ensure it adheres well without stiffening the fabric too much.

Buttonholes and Closures

- Buttonholes: Work beautifully in boiled wool because the fabric is stable and won’t fray. The density provides excellent support for buttons

- Buttons: Choose sturdy buttons appropriate for the fabric weight. Large buttons work well and won’t pull through

- Alternative closures: Toggles, frogs, snaps, and zippers all work well with boiled wool

Common Mistakes to Avoid

- Using too small a needle: This creates skipped stitches and needle damage. Size up for thick boiled wool

- Over-handling edges: While boiled wool doesn’t fray, excessive handling can distort edges. Handle with care during construction

- Pressing too hard: Heavy pressing flattens the fabric’s lovely texture. Use steam and a light touch

- Not testing first: Always test stitch length, needle, and techniques on scraps before working on your garment

How to Sew Boiled Wool Fabric: Step-by-Step

Here’s a basic process for sewing a boiled wool project:

Video tutorial: How to Make a Simple Vest with Boiled Wool

- Pre-treat if necessary: Most boiled wool doesn’t need pre-washing, but steam out any storage wrinkles

- Cut carefully: Use sharp tools and follow pattern grain lines

- Pin or clip pieces: Secure seams ready for stitching

- Set up your machine: Install a size 90-100 needle, use polyester thread, set stitch length to 3.0-3.5mm

- Sew seams: Stitch at a moderate, steady speed. Don’t rush through thick seams

- Press seams open: Use steam and a pressing cloth. Let fabric cool before moving it

- Add topstitching if desired: This adds a professional finish and helps flatten seams

- Leave hems raw or finish traditionally: Your choice based on design

- Add closures: Buttonholes, zippers, or other fastenings

- Final press: Steam the finished garment gently to set everything

Care and Maintenance of Boiled Wool

Boiled wool fabric layers illustrating care and long term maintenance

Proper care keeps boiled wool looking beautiful for decades. The good news is that wool naturally resists dirt and odors, so it needs less frequent cleaning than many other fabrics.

Can Boiled Wool Fabric Be Washed?

Yes, boiled wool can be washed, but it requires gentle care to prevent additional shrinkage or distortion. The fabric has already been through an intense fulling process, so you need to avoid recreating those conditions during cleaning.

Is Boiled Wool Dry Clean Only?

Not necessarily. While many boiled wool garments are labeled “dry clean only” for safety, most can be hand-washed or machine-washed carefully. Dry cleaning is the safest option and recommended for structured garments, items with linings, or pieces you particularly value. However, simple boiled wool items like scarves, hats, or unlined jackets can usually be washed at home.

Regular Maintenance

Between Washes

- Air it out: After wearing, hang your boiled wool garment outside or in a well-ventilated area. Fresh air removes odors naturally – wool’s antimicrobial properties mean it stays fresher longer than synthetic materials

- Spot clean: Address stains immediately by blotting (never rubbing) with a damp cloth. Most stains can be removed without full washing

- Brush regularly: Use a soft brush to remove surface dirt and debris. This simple step extends time between washes

- Let it rest: Give wool 24 hours between wears to allow fibers to relax and recover their shape

Hand Washing Boiled Wool

Hand washing is the safest home cleaning method:

- Fill a basin with cool to lukewarm water (maximum 30°C/86°F)

- Add a small amount of wool-specific detergent (not regular laundry detergent). Products like Eucalan or Woolite work well

- Submerge the garment and gently press water through the fabric. Don’t agitate, rub, or twist – these actions can cause additional felting and shrinkage

- Let it soak for 5-10 minutes

- Drain the water and rinse with clean, cool water until all soap is removed

- Press out excess water gently by squeezing (never wringing)

- Roll in a clean, dry towel and press to absorb more water

- Reshape the garment to its original dimensions while still damp

- Lay flat to dry on a clean, dry towel away from direct heat and sunlight

Machine Washing Boiled Wool

If you must machine wash, follow these strict guidelines:

- Use the wool or delicate cycle only

- Cold or lukewarm water (30°C/86°F maximum)

- Wool-specific detergent

- No fabric softener (it can affect wool’s natural properties)

- Lowest spin speed possible (400 RPM or less)

- Fill the machine with similar items to prevent the garment from being thrown around excessively

- Remove promptly when cycle finishes

- Reshape immediately and lay flat to dry

Never:

- Use hot water – this will cause severe shrinkage and distortion

- Use the regular spin cycle – excessive spinning can felt the fabric further

- Put boiled wool in the dryer – heat and tumbling will ruin it

- Hang wet boiled wool to dry – the weight will stretch it out of shape

- Wring or twist – this distorts the fabric permanently

Drying Boiled Wool

Proper drying is crucial:

- Always lay flat to dry on a clean, dry towel or mesh drying rack

- Reshape while damp to original measurements

- Turn occasionally to ensure even drying

- Keep away from direct heat (radiators, heating vents, direct sunlight)

- Allow plenty of time – boiled wool takes longer to dry than lighter fabrics, often 24-48 hours

- Ensure complete drying before storing to prevent mildew

Stain Removal

Act quickly for best results:

- Liquids: Blot immediately with an absorbent cloth. Don’t rub – this pushes the stain deeper

- Tea or coffee: Mix lemon juice with a spoonful of baking soda, dampen a cloth with this mixture, and gently clean the stain

- Grease: Sprinkle with cornstarch or talcum powder to absorb the oil, let sit for several hours, then brush off. For stubborn grease, use a small amount of gentle dish soap

- Sticky substances (wax, gum): Place absorbent paper over the spot and press with a warm (not hot) iron to transfer the substance to the paper

- Food stains: Gently dab with a solution of cool water and wool detergent

Removing Wrinkles

Boiled wool rarely wrinkles, but if you need to remove creases:

- Steam is your best friend: Hold a steamer a few inches from the fabric and let steam penetrate without touching

- Or hang in a steamy bathroom: The steam from a hot shower can relax wrinkles

- If ironing is necessary: Use the wool setting, place a pressing cloth between iron and fabric, and use steam. Press lightly – don’t slide the iron or press hard

- Never iron dry: Steam or slight moisture is essential to avoid flattening the fabric’s texture

Dealing with Pilling

Boiled wool resists pilling better than regular wool, but if small pills do form:

- Use a fabric shaver or de-pilling comb to gently remove them

- Never pull pills off by hand – this can damage the fabric

- Pills typically appear in high-friction areas like under arms or where bags rest

Storage

Proper storage protects your investment:

- Clean before storing: Moths are attracted to body oils and food stains

- Store in a cool, dry place: Avoid damp basements or hot attics

- Use breathable storage: Cotton garment bags allow air circulation. Avoid plastic bags that trap moisture

- Fold heavy items: Store coats and jackets folded on a shelf rather than hanging, which can cause shoulder distortion

- Light items can hang: Jackets and cardigans can be hung on padded hangers to maintain shape

- Add cedar or lavender: These natural moth deterrents are safer than mothballs

- Check periodically: Air out stored items once or twice during long storage periods

Professional Cleaning

For valuable garments, complex construction, or when you’re unsure, professional cleaning is worth the investment. A good dry cleaner experienced with wool care will:

- Use appropriate solvents that won’t damage the fabric

- Handle shaping and pressing professionally

- Address specific stains with proper techniques

- Ensure zippers, linings, and embellishments are protected

Tell your cleaner the fabric is boiled wool and point out any specific concerns. A quality cleaner will appreciate the information.

Buying Guide: What to Look For

Boiled wool buying guide showing fabric rolls, colors, and texture

Not all boiled wool is created equal. Here’s how to identify quality fabric and make smart purchasing decisions.

Identifying Quality Boiled Wool

Check the Label

- Fiber content: Look for 100% wool or high wool content (at least 70%). Some blends with rayon or viscose are acceptable if disclosed, as they add softness and drape

- Origin: Authentic boiled wool from Alpine regions (Austria, Bavaria, Northern Italy) typically indicates traditional quality production

- Mill information: Reputable sellers can tell you which mill produced the fabric. Traditional mills like Loden Steiner, Gottstein, or others in the Tyrol region are known for excellence

Examine the Fabric

- Uniform thickness: Quality boiled wool has consistent thickness throughout. Thin spots or thick spots indicate poor fulling

- Dense, even texture: The surface should be smooth and even with a slight fuzz. You shouldn’t see obvious knit structure or loose fibers

- Clean edges: When cut, edges should be clean and stable with no fraying or shedding

- Color consistency: Dye should be even throughout with no blotches or fading

Feel the Hand

- Soft but substantial: Quality boiled wool feels soft to touch but has body and weight

- Slight flexibility: Should have a bit of give when stretched gently, then spring back

- No scratchiness: Good boiled wool shouldn’t feel itchy or rough

- Warm to the touch: Natural wool feels warm immediately, unlike synthetics

Understanding Weight and Density

Boiled wool comes in different weights for different applications:

- Lightweight (260 g/m²): Best for cardigans, light jackets, scarves, and garments for warmer weather or layering

- Midweight (350-380 g/m²): Versatile weight suitable for most jackets, coats, and accessories

- Heavyweight (420 g/m² and up): Traditional weight for serious outerwear, especially items meant for very cold weather or extreme durability

Typical Fabric Specifications

- Width: Standard is 142-150cm (56-58 inches)

- Price range: Expect $20-50 per yard for quality boiled wool. Very premium or specialty colors may cost more. Prices under $15/yard may indicate lower quality or blends

- Certifications to look for: GOTS (organic), Oeko-Tex Standard 100 (tested for harmful substances), Responsible Wool Standard

Where to Buy

Online Fabric Retailers

- Mood Fabrics – Wide selection of boiled wool by the yard

- Stone Mountain & Daughter – Curated selection of quality wool fabrics

- Oak Fabrics – Independent retailer with premium selections

- Nature’s Fabrics – Specializes in wool and natural fibers

Direct from Mills

Some traditional Alpine mills sell directly to consumers or through their websites. This guarantees authenticity and often better prices.

Specialty Brands for Ready-Made Items

- Robert W. Stolz – Authentic Alpine outerwear and accessories

- Giesswein – Known for slippers and modern boiled wool fashion

- Disana, Engel, SISKIN – Children’s boiled wool clothing

- Eileen Fisher – High-end fashion pieces featuring boiled wool

Red Flags to Avoid

- Extremely low prices: If it seems too cheap, it probably isn’t true boiled wool

- Can’t identify the mill: Legitimate sellers know their sources

- High synthetic content without disclosure: Some sellers misrepresent synthetic felt as boiled wool

- Obvious uneven felting: Skip fabric with thin spots, thick spots, or incomplete fulling

- Chemical smell: Quality boiled wool should smell like clean wool, not chemicals

Questions to Ask Sellers

- What is the fiber content?

- Where was it produced?

- What is the weight/density in g/m²?

- Can I get a sample before ordering?

- What are the care requirements?

- Does it have any certifications (GOTS, Oeko-Tex, etc.)?

Buying Smart

- Order samples first: For online purchases, order swatches to verify quality, color, and hand before buying yardage

- Calculate yardage carefully: Remember that boiled wool is typically 56-58″ wide. Factor in pattern layout and any directional considerations

- Buy extra for testing: Purchase an extra quarter to half yard for testing sewing techniques and care methods

- Check return policies: Ensure you can return fabric if it doesn’t meet your expectations

- Consider shipping costs: Boiled wool is heavy, so shipping can be expensive for larger orders

Frequently Asked Questions

Conclusion

After this deep look into boiled wool, one thing becomes clear: this isn’t just another fabric. It’s a remarkable material that bridges ancient wisdom with modern needs, traditional craftsmanship with contemporary style, and environmental responsibility with exceptional performance.

What We’ve Learned

Boiled wool starts as knitted wool fabric that’s transformed through fulling – a process involving hot water, agitation, and sometimes natural soap. This treatment causes the fibers to shrink up to 50-66% and mat together, creating a dense, felt-like material that won’t fray, resists water naturally, provides exceptional warmth, and lasts for decades.

The fabric’s roots in the Alpine regions of Austria and Bavaria stretch back to at least the Middle Ages. What began as survival gear for mountain shepherds became fashionable thanks to Archduke Johann’s 19th-century style choice. Today, only a handful of traditional mills maintain the centuries-old production methods that create authentic boiled wool.

The Real-World Benefits

Whether you’re a sewer, a conscious consumer, or someone who simply wants quality clothing that performs, boiled wool delivers:

- For sewers: It’s surprisingly easy to work with, doesn’t fray when cut, needs no edge finishing, and creates professional results even for beginners tackling outerwear. The stable fabric won’t shift or slide as you sew.

- For fashion lovers: Boiled wool creates beautiful, structured garments with timeless style. Its clean lines and sophisticated drape work equally well in traditional Alpine designs and modern minimalist fashion.

- For sustainability advocates: Few materials match boiled wool’s environmental credentials – completely biodegradable, made from renewable resources, produced with minimal chemicals, lasting 20-30 years or more, and releasing no microplastics.

- For practical people: It’s exceptionally warm without weight, naturally water-resistant, breathable even when dense, wrinkle-resistant, low-maintenance, and becomes more beautiful with age.

Making Smart Choices

When buying boiled wool, look for:

- 100% wool or high wool content (at least 70%)

- Authentic Alpine origin when possible

- Appropriate weight for your project (260 g/m² for light garments, 420 g/m² for serious outerwear)

- Certifications like GOTS or RWS for verified sustainability

- Reputable sellers who can identify the mill that produced the fabric

Yes, quality boiled wool costs more initially – typically $20-50 per yard. But when you factor in its decades-long lifespan, the cost per wear drops far below cheaper alternatives that need replacing every few years.

Care That Makes It Last

Boiled wool’s longevity depends on proper care. The good news is that it needs less frequent washing than synthetic materials because wool naturally resists odors and dirt. When cleaning is necessary, use cool water, wool-specific detergent, gentle handling, and always lay flat to dry. Never machine dry or use hot water, which can cause additional shrinkage.

Between washes, simply air out garments and spot clean any stains. Store clean items in breathable bags with natural moth deterrents like cedar or lavender.

The Bottom Line

In our world of fast fashion and disposable clothing, boiled wool stands as proof that better alternatives exist. It’s a fabric that gets better with age rather than falling apart, performs without chemicals, and returns to the earth harmlessly when its long life finally ends.

Whether you’re sewing your first jacket, looking for sustainable outerwear, or simply curious about quality natural materials, boiled wool deserves your consideration. It represents the kind of thoughtful, durable design that our future needs more of – products that work beautifully, last decades, and respect both people and planet.

The Alpine shepherds who developed this fabric centuries ago created something that remains relevant today. In fact, it’s more relevant than ever. As we seek alternatives to petroleum-based synthetics and disposable fashion, boiled wool shows us what’s possible when we work with nature instead of against it.

Key Takeaways

- Boiled wool is knitted wool that’s fulled through hot water and agitation, creating dense, no-fray fabric

- It’s warmer, more water-resistant, and more durable than regular wool

- The fabric is highly sustainable: biodegradable, renewable, long-lasting, and chemical-free

- Perfect for outerwear, accessories, slippers, and structured garments

- Easy to sew with – edges don’t fray, making it beginner-friendly

- Care with cool water washing and lay flat to dry for decades of wear

- Quality boiled wool from Alpine mills offers the best performance and authenticity

- Higher initial cost is offset by 20-30+ year lifespan

Ready to experience boiled wool for yourself? Whether you’re cutting into your first yard or slipping on a finished garment, you’re connecting with a craft tradition that’s stood the test of time. And in today’s world, that’s something special.

For more information on working with luxury wool fabrics and natural fibers, explore our guide to natural vs. synthetic fabrics and our comprehensive wool care guide.